Log in

Search

Latest topics

» Chocolate chip cookie dough.........by roddie Today at 8:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 6:32 pm

» Tee Dee .020 combat model

by rsv1cox Today at 5:07 pm

» Free Flight Radio Assist

by rdw777 Today at 4:24 pm

» My latest doodle...

by batjac Today at 4:47 am

» My N-1R build log

by roddie Today at 3:50 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 10:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 3:17 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Wed Nov 20, 2024 1:35 am

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 7:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 1:08 pm

» My current avatar photo

by roddie Tue Nov 19, 2024 4:05 am

Cox Engine of The Month

Turbo plug heads

Page 1 of 2

Page 1 of 2 • 1, 2

Turbo plug heads

Turbo plug heads

I have made a few turbo plug heads in the past for other engines with "button" style heads, but haven't made any for the cox engines before. One could make a "button" style head and use the Norvel or Merlin claps, but it turns out that it is very easy to just use an old worn out head too. I know others have done this before, but I just wanted to share my results.

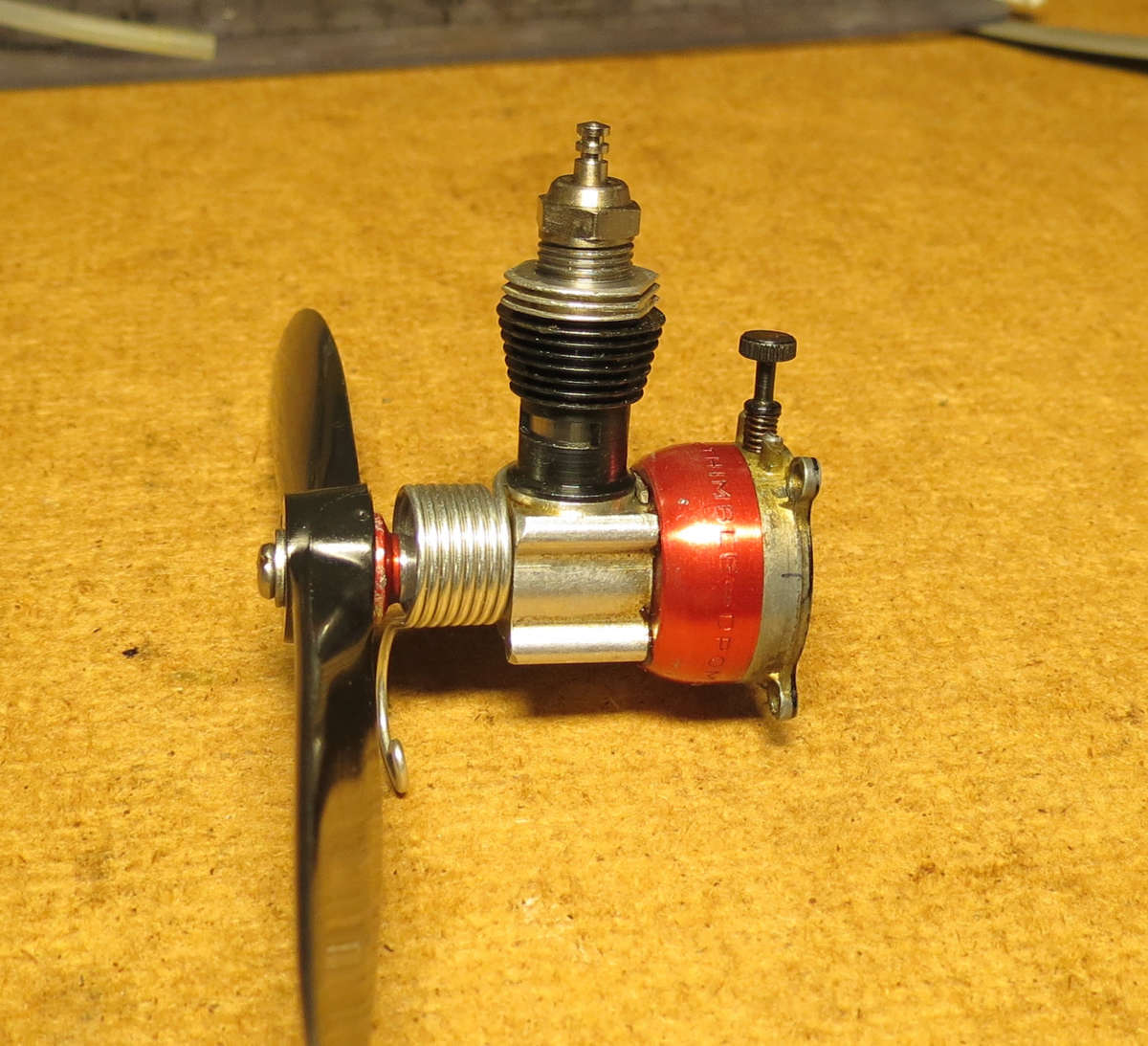

So here is what it looks like after the modification, shown here with a Merlin "Glow Bee" style turbo plug. This gives a very smooth head shape compared to the regular glow plug adapters (on the far right);

So here is what it looks like after the modification, shown here with a Merlin "Glow Bee" style turbo plug. This gives a very smooth head shape compared to the regular glow plug adapters (on the far right);

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

Here is peak inside after the plug has been tightened down and checked for leaks with soap water (it seems to seal well enough). One can see a small band were the plug seal against the aluminium, so the chamfer seems to work well. I would like to fire up an engine with it but the temperature outside is now around -14° C (about 0° F ?). Brrr...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

Kris, is that a "one step" drill and tap all in one, or do you have to have a machine shop, drill, tap and taper ? Could I do this myself with a home shop drill press?

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-29

Age : 72

Location : Grand Rapids, MI

Re: Turbo plug heads

Re: Turbo plug heads

An easy way to check the seal on the chamfer is to colour the chamfer on the head with a Sharpie before fitting the plug, tighten the plug - undo it and then look for high spots. Freshly machined aluminium can be deceiving especially with light reflecting off it.

I always used engineers blue until I discovered Sharpies on this site. They are ideal for making metal - especially, the red, blue and black. I now reserve the special marking fluids and engineers blue for more special jobs. Engineers blue stains fingers, clothes, skin, hair, metal ....... a treat and doesn't wash off!

I always used engineers blue until I discovered Sharpies on this site. They are ideal for making metal - especially, the red, blue and black. I now reserve the special marking fluids and engineers blue for more special jobs. Engineers blue stains fingers, clothes, skin, hair, metal ....... a treat and doesn't wash off!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Turbo plug heads

Re: Turbo plug heads

Surfer_kris wrote:Here is peak inside after the plug has been tightened down and checked for leaks with soap water (it seems to seal well enough). One can see a small band were the plug seal against the aluminium, so the chamfer seems to work well. I would like to fire up an engine with it but the temperature outside is now around -14° C (about 0° F ?). Brrr...

I would really like to see how the turbo plug works with the chamfer, holding it back from protruding into the combustion space. I have always seen sharp output reduction when using the plugs instead of the original stock COX glowheads, no matter how many shims I had under the head or under the plug to prevent it from protruding into the combustion chamber.

The performance loss is less with the TD09 engines, though, where the heat emitted by the plug has a lower impact on the Carnot efficiency - that peaks if the heat input to the cycle occurs in the shortest possible time and at the highest temperature i.e. near the TDC - than with 049 engines.

(The constantly glowing plug radiates heat into the cylinder before and after the piston hits TDC both, and the higher the radiation heat related to the combustion heat from the fuel, the less the efficiency of the Carnot cycle...with the same plug size this radiation heat interference with the combustion heat is more with the smaller 049 than with the larger 090 that burns more fuel in one cycle)

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Turbo plug heads

Re: Turbo plug heads

I forgot to say that this head conversion is a very neat job and is a worthwhile machining exercise as it produces a usable result.

There is always going to be some sort of performance issue as a tiny cavity with a tiny wiggly wire is being replaced by the much larger cavity of the glow plug. A lot depends on the glow plug selected and the fuel being used. However, I have seen remarkable results using turbo plugs and retaining the the shape inside the cylinder head.

Glow plug conversions were always popular in the UK as the Cox heads were expensive. A straight plug conversion is easy but a tapered socket requires much more care. I have made a special reamer for this but I know of chaps who have merely used a Philips head screwdriver bit!

This chap wasn't too successful

http://www.rcuniverse.com/forum/1-2-1-8-airplanes-70/4533758-turbo-plugs-how.html#post4533758

a turbo plug conversion require very careful measurement or meticulous trial and error.

Kim also posted his conversion

https://www.coxengineforum.com/t742-home-made-glowplug-conversion-standard-cox-glowhead

and this You Tube video extols the virtue of using the plug to vary compression.

It is always easy to give up at the first attempt but if you have a stock of duff heads - persevere and you will find an acceptable combination.

Many, many years ago - I quite a few conversions the other way - to fit a Cox 15 glow head to a Super Tiger 15 - just to achieve 500 rpm.

There is always going to be some sort of performance issue as a tiny cavity with a tiny wiggly wire is being replaced by the much larger cavity of the glow plug. A lot depends on the glow plug selected and the fuel being used. However, I have seen remarkable results using turbo plugs and retaining the the shape inside the cylinder head.

Glow plug conversions were always popular in the UK as the Cox heads were expensive. A straight plug conversion is easy but a tapered socket requires much more care. I have made a special reamer for this but I know of chaps who have merely used a Philips head screwdriver bit!

This chap wasn't too successful

http://www.rcuniverse.com/forum/1-2-1-8-airplanes-70/4533758-turbo-plugs-how.html#post4533758

a turbo plug conversion require very careful measurement or meticulous trial and error.

Kim also posted his conversion

https://www.coxengineforum.com/t742-home-made-glowplug-conversion-standard-cox-glowhead

and this You Tube video extols the virtue of using the plug to vary compression.

It is always easy to give up at the first attempt but if you have a stock of duff heads - persevere and you will find an acceptable combination.

Many, many years ago - I quite a few conversions the other way - to fit a Cox 15 glow head to a Super Tiger 15 - just to achieve 500 rpm.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Turbo plug heads

Re: Turbo plug heads

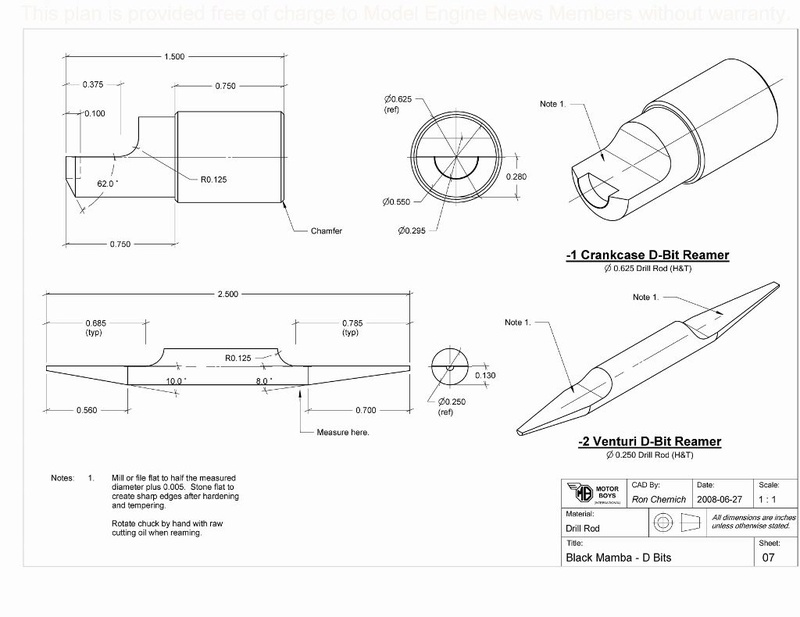

Below are my "tools", I'm using the drillbit trick that AndyW showed in that RCU thread linked to above. Once you get the drill bit sharpened the right way it always works for me. I using a lathe (a very simpel hobby lathe) for all the steps and don't remove the head in-between the different steps. It should work in a drill press too I think, if one doesn't remove the head at the different steps.

My most successful heads, so far, have been heads for the TT GP 07 and the VA .049 MkII. These were done from scratch though and require a lot more work as one has to make the whole chamber shape etc. Compared to those jobs the Cox head is really simple.

It is on the small engines that the combustion head shape seems the most important, together with the interference of the threads of the regular plugs. The threads are actually a "part" of the combustion chamber when you think about it (since the seal is at the gasket). Some people use different sealants in the threads on the regular plugs but I haven't tried that myself.

Here is a head I've made for the VA .049, it spins an APC 5.7x3 prop at around 19500rpm on 10% nitro (!);

The TT 07GP really "woke up" with a turbo head and a few other mods, it went from average .049 power to almost matching the Norvel .074 engine (!). Here is a short video I did while I was working on that engine (almost 9 years ago...), it spins an APC 7x3 at around 16700rpm (on 10% nitro);

My most successful heads, so far, have been heads for the TT GP 07 and the VA .049 MkII. These were done from scratch though and require a lot more work as one has to make the whole chamber shape etc. Compared to those jobs the Cox head is really simple.

It is on the small engines that the combustion head shape seems the most important, together with the interference of the threads of the regular plugs. The threads are actually a "part" of the combustion chamber when you think about it (since the seal is at the gasket). Some people use different sealants in the threads on the regular plugs but I haven't tried that myself.

Here is a head I've made for the VA .049, it spins an APC 5.7x3 prop at around 19500rpm on 10% nitro (!);

The TT 07GP really "woke up" with a turbo head and a few other mods, it went from average .049 power to almost matching the Norvel .074 engine (!). Here is a short video I did while I was working on that engine (almost 9 years ago...), it spins an APC 7x3 at around 16700rpm (on 10% nitro);

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

I felt I had to try out it in engine, at least for quick run inside as it is too cold for me outside, and it runs (!).

The Merlin plug fired right up on a port prime, but it will need a few extra head shims it feels like. Compression is definitely higher with the glow-bee style filament, but it started easy so it might be worth tinkering with.

Next up was an OS plug, I like the P4 (medium heat range) while P7 also has worked in "hotter" engines. The thread on these are a little shorter though so I had make a small relief at the top. The P7 was a little too cold while the P4 seems spot on, at 10% nitro in the fuel.

The Merlin plug fired right up on a port prime, but it will need a few extra head shims it feels like. Compression is definitely higher with the glow-bee style filament, but it started easy so it might be worth tinkering with.

Next up was an OS plug, I like the P4 (medium heat range) while P7 also has worked in "hotter" engines. The thread on these are a little shorter though so I had make a small relief at the top. The P7 was a little too cold while the P4 seems spot on, at 10% nitro in the fuel.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

Here is a look at the inside with the OS P4 plug in the head. Pretty smooth transition between head and plug, and probably as close as one can get to the original shape of the head. The plug might actually give a little lower volume though, so I'll try an extra head shim the next time.

The was also a thread on RCU about measuring head volumes by using oil (counting number of drops), that could be an interesting exercise to do too.

The was also a thread on RCU about measuring head volumes by using oil (counting number of drops), that could be an interesting exercise to do too.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

I took an old battered .15 head today and turned that into a turbo-plug head too. It seems I stopped a just a little bit too early with the machining, should have gone just another 0.1mm or so further. Appart from that, the plug seals very well, so I will leave it like this I think.

With a turbo plug there is now the heat range that one can tune on, should come handy in RC applications and when using lower nitro levels. Plus the fact that the original heads are hard to come by for the .15 engines. I'm down to only two spare heads now I think...

Here are some picture before and after the mod;

With a turbo plug there is now the heat range that one can tune on, should come handy in RC applications and when using lower nitro levels. Plus the fact that the original heads are hard to come by for the .15 engines. I'm down to only two spare heads now I think...

Here are some picture before and after the mod;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

Hi, I have seen this thread and sincerely it is very interesting all the work that you are doing, I have to modify the head of a Cox .15, (we have already talked about it) so I already asked the male to thread and once he does the Work I will share with you / you, to see my results.

When does the Cox .15 start up? Would be interesting also a video!

Greetings, Mauricio.-

When does the Cox .15 start up? Would be interesting also a video!

Greetings, Mauricio.-

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-17

Age : 53

Location : ARG

Re: Turbo plug heads

Re: Turbo plug heads

I misplaced my 1/4"-32 tap quite some time ago. It bugs me.. because I know I'll find it someday, in a place where it never should have been left.

Not sure if this was discussed, but wouldn't it make sense to convert a Cox high-comp glow-head, to somewhat offset the larger cavity inside a standard plug?

It would be interesting to try a standard head-conversion using a 1/4"-32 internally-threaded insert.. and externally-threaded to screw-into a larger hole in the glow-head. Maybe machine a slot across the top for installing/adjusting with a coin or flat-blade screwdriver. A large-dia. insert (3/8"-24??) could have its bottom counter-bored with a ball-mill to re-establish the concavity of the combustion-chamber like the clamp-ring plugs have.. except compression would be adjustable by screwing the insert in/out.. like the contra-piston on a diesel head. Maybe I've had a little too much coffee..

Not sure if this was discussed, but wouldn't it make sense to convert a Cox high-comp glow-head, to somewhat offset the larger cavity inside a standard plug?

It would be interesting to try a standard head-conversion using a 1/4"-32 internally-threaded insert.. and externally-threaded to screw-into a larger hole in the glow-head. Maybe machine a slot across the top for installing/adjusting with a coin or flat-blade screwdriver. A large-dia. insert (3/8"-24??) could have its bottom counter-bored with a ball-mill to re-establish the concavity of the combustion-chamber like the clamp-ring plugs have.. except compression would be adjustable by screwing the insert in/out.. like the contra-piston on a diesel head. Maybe I've had a little too much coffee..

Re: Turbo plug heads

Re: Turbo plug heads

roddie wrote:I misplaced my 1/4"-32 tap quite some time ago. It bugs me.. because I know I'll find it someday, in a place where it never should have been left.

Not sure if this was discussed, but wouldn't it make sense to convert a Cox high-comp glow-head, to somewhat offset the larger cavity inside a standard plug?

There is an old thread on RCU about that too. If the heads are made to have the same total volume, you still have to seal the threads with something like permatex or silicon. Only then can you get close to the stock head performance. With the Turbo, and Nelson, plugs the seal is automatically in the right place by design, and these will then give about the same or even better performance than the stock heads.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

roddie wrote:

It would be interesting to try a standard head-conversion using a 1/4"-32 internally-threaded insert.. and externally-threaded to screw-into a larger hole in the glow-head. Maybe machine a slot across the top for installing/adjusting with a coin or flat-blade screwdriver. A large-dia. insert (3/8"-24??) could have its bottom counter-bored with a ball-mill to re-establish the concavity of the combustion-chamber like the clamp-ring plugs have.. except compression would be adjustable by screwing the insert in/out.. like the contra-piston on a diesel head. Maybe I've had a little too much coffee..

AndyW, among others, have already tried that too...

Here is one of his videos of a Norvel .15 with on-the-fly adjustment of the compression ratio;

I think the consensus was that while very useful one doesn't have to change the compression ratio as long as one doesn't change fuel or propsize. So one can very well do the optimisation using head-gaskets, as we all should do (right?) and keep the same setting for the same fuel and prop. If either of these are changed, one should go back and fiddle with shims again....

Last edited by Surfer_kris on Sun Jan 08, 2017 8:14 pm; edited 1 time in total

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

MauricioB wrote:Hi, I have seen this thread and sincerely it is very interesting all the work that you are doing, I have to modify the head of a Cox .15, (we have already talked about it) so I already asked the male to thread and once he does the Work I will share with you / you, to see my results.

When does the Cox .15 start up? Would be interesting also a video!

Greetings, Mauricio.-

I didn't make a full run today, due to the cold weather, but it fired right up on the first flip inside the workshop!

The thread for the Turbo plug is M8 X 0.75, and you'll need a 7.2mm drill for the hole. The chamfer part is made with a sharpened philips #3 bit. This bit has the correct angle at its end and almost the correct outer-diameter too (helps with the centering). You need to sharpen the four parts of the Philips bit to an edge, without changing the chamfer. The edges doesn't have to be very sharp, it will only be used for a final very small grinding action at the very end, just before making the threads.

When I first started making my own heads I followed the guidelines here by AndyW; http://www.rcuniverse.com/forum/1-2-1-8-airplanes-70/4533758-turbo-plugs-how.html#post4533758

If you want, you could possibly send me a used .15 head and I can try to make the conversion for you.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

In order to make the conversions "complete" I felt had to try one for the .020 also...

There isn't really enough meat in the stock head though, and from the outside it looks kind of weird. The plug hangs on by a "thread" literally (!) or almost a thread and a half actually. The inside looks good though, I think, and it seals up well.

There isn't really enough meat in the stock head though, and from the outside it looks kind of weird. The plug hangs on by a "thread" literally (!) or almost a thread and a half actually. The inside looks good though, I think, and it seals up well.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

Kris the inside does look real good wtg!

Too bad Cox never made Texaco heads for the .020!!!

Look forward to the test results

Too bad Cox never made Texaco heads for the .020!!!

Look forward to the test results

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Turbo plug heads

Re: Turbo plug heads

Thanks for the Good advice , every thing looks like a winner other than the .020 looks like its wearing a hat  or

or  But they do look professionally done what every that is . I have thrown many a bad .049 heads away and have a few on reserve also the inserts but you can't run an A3 plug in it . speaking of do you see a lot of difference in the ones you are making over the TD Hi Comp. heads or just manly has to do with the R/C part of throttling ?

But they do look professionally done what every that is . I have thrown many a bad .049 heads away and have a few on reserve also the inserts but you can't run an A3 plug in it . speaking of do you see a lot of difference in the ones you are making over the TD Hi Comp. heads or just manly has to do with the R/C part of throttling ?

But they do look professionally done what every that is . I have thrown many a bad .049 heads away and have a few on reserve also the inserts but you can't run an A3 plug in it . speaking of do you see a lot of difference in the ones you are making over the TD Hi Comp. heads or just manly has to do with the R/C part of throttling ?

But they do look professionally done what every that is . I have thrown many a bad .049 heads away and have a few on reserve also the inserts but you can't run an A3 plug in it . speaking of do you see a lot of difference in the ones you are making over the TD Hi Comp. heads or just manly has to do with the R/C part of throttling ?

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Turbo plug heads

Re: Turbo plug heads

Nice work Kris! I wonder if forming a sm. "cone" of fine sandpaper or crocus-cloth in conjunction with the Phillips bit might help with dressing the chamfer's final-depth down to exactly where you want it, leaving just enough of a gap for the gasket to seal while helping to optimize compression by decreasing the area of the combustion-chamber. Does that make any sense? Maybe a few less thousandths of an inch in the chamfer-gap could make the difference between good compression and great compression.

I like the .020 conversion! My thought (above) might help you gain a little more thread on the plug.. with less risk of tearing through the web in the head-body.

I like the .020 conversion! My thought (above) might help you gain a little more thread on the plug.. with less risk of tearing through the web in the head-body.

Re: Turbo plug heads

Re: Turbo plug heads

roddie wrote:Nice work Kris! I wonder if forming a sm. "cone" of fine sandpaper or crocus-cloth in conjunction with the Phillips bit might help with dressing the chamfer's final-depth down to exactly where you want it, leaving just enough of a gap for the gasket to seal while helping to optimize compression by decreasing the area of the combustion-chamber.

It is not so much a problem of accuracy, in the lathe I can easily get down to about .05mm accuracy, the problem is more that I'm just doing a trial and error fit. For the .049 I got it just right straight away, by luck, while for the and the for the .020 head I machined it twice. Thus easing up to just the right dimension.

If one took the time to make a proper drawing, I'm pretty sure that one would able to get it right in just one step. The most important is actually the drilling for the tap, this has to stop in the right place. The chamfer is just a shaving of about 0.5-0.6mm feed in the lathe. Of one makes more there can be a problem with the thread depth, and the plug will not reach the cone enough.

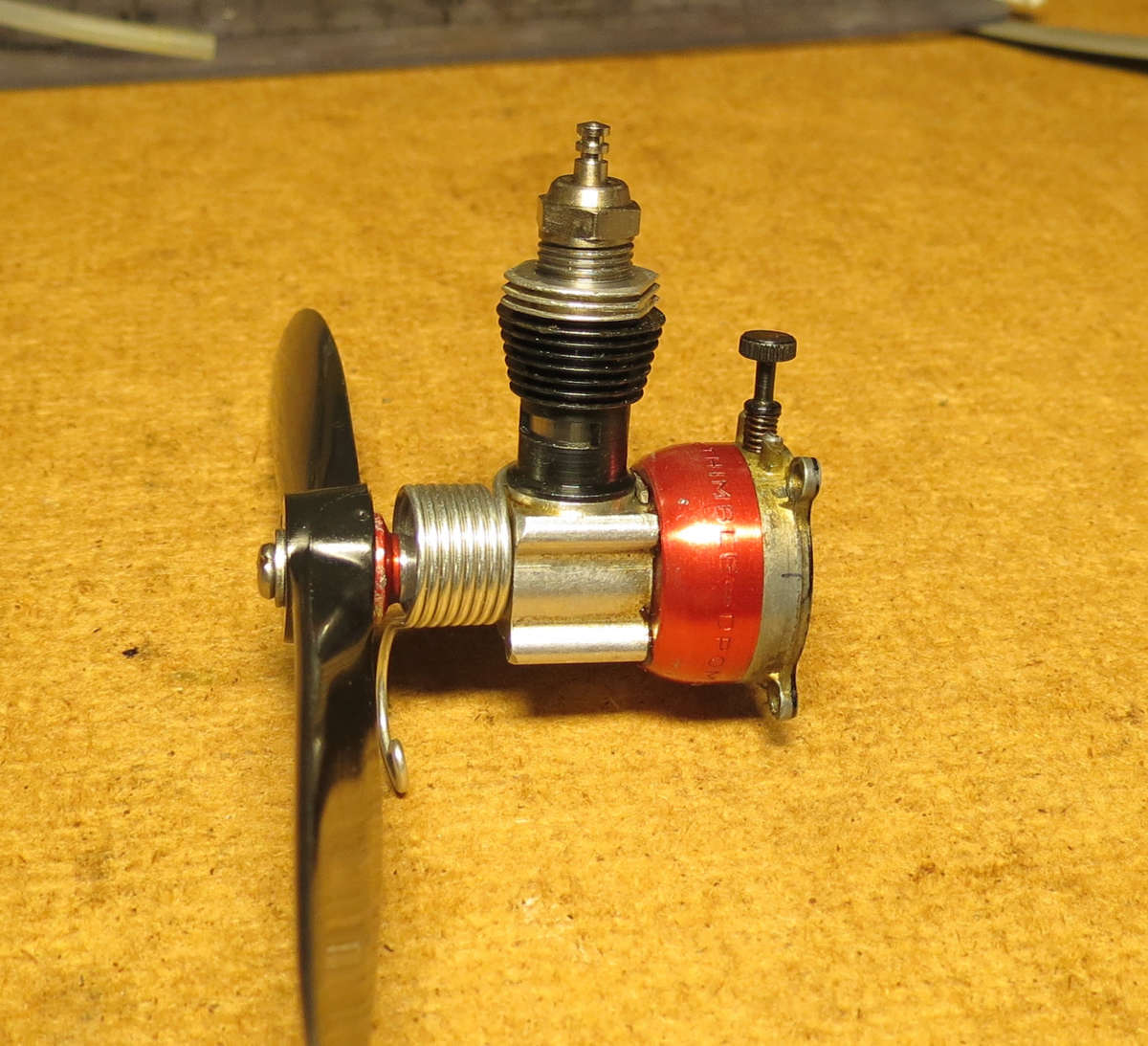

I haven't tried to measure the cone angle of the turbo plugs but the philips bit is just right (for a total of 53° according to specs, see below), while a 60° center-drill will not have the correct angle. That was part of the problem discussed in the RCU thread linked to earlier.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

1/2A Nut wrote:Kris the inside does look real good wtg!

Too bad Cox never made Texaco heads for the .020!!!

Look forward to the test results

The proof will indeed be in the running...

It is not the right season for long engine testing outdoors, but I gave it a little run in works-shop today. It fires right up to a nice song on 10% nitro fuel, never needed the spring starter, and it looks very promising.

The hotter plugs help with the starting and the ability to run with less nitro, I don't think there will be advantages in terms of maximum power.

Edit; In all the excitement I seem to have a grabbed the colder P7 plug (!)

Didn't see it until I zoomed in on the image...

(that seems promising for the hotter plugs)

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

I should perhaps say a few words about the reasons for making these conversion heads. I don't think that they will beat co heads in terms of outright power but they can certainly match them. Unlike the conversions to regular glow plugs (with the copper gasket at the very top. There the power loss is easily in the range of 1000-1500rpm.

With the Turbo plug one has the added advantage of heat ranges and the easy access in most hobby shops. The price will be similar to the Cox heads though while these are still available...

I haven't done any real scientific testing, but below are some of mine notes on the Cox .05RC when I tested different heads on it. This was with the Graupner 6x3 prop and 10% nitro, so a fairly heavy load and low nitro, but that is what I would like to use if I can;

"Cox low compression head: 16900-17000rpm this feels a little undercompressed and doesn't quite sing the way it should, but no signs of overheating.

Cox TD high compression head: about 17200rpm but very touchy needle and at least 1/4 of a turn out on the needle compared to the low compression head. Compression was too high and engine overheats.

Turbo conversion head (Valentine) and OS P3 (hot) plug: a very steady 17200 rpm and a nice broad needle setting. Best combo so far. Needle can actually go further in than on the low compression head."

Here is also a little comparison, or "line-up", of different heads. Starting from the left we have the stock Cox (low compression), Mecoa for a regular glow plug (Enya #4 is in there now), Cox head converted to Turbo, Valentine dedicated Turbo head and finally the Galbreath Nelson plug head;

With the Turbo plug one has the added advantage of heat ranges and the easy access in most hobby shops. The price will be similar to the Cox heads though while these are still available...

I haven't done any real scientific testing, but below are some of mine notes on the Cox .05RC when I tested different heads on it. This was with the Graupner 6x3 prop and 10% nitro, so a fairly heavy load and low nitro, but that is what I would like to use if I can;

"Cox low compression head: 16900-17000rpm this feels a little undercompressed and doesn't quite sing the way it should, but no signs of overheating.

Cox TD high compression head: about 17200rpm but very touchy needle and at least 1/4 of a turn out on the needle compared to the low compression head. Compression was too high and engine overheats.

Turbo conversion head (Valentine) and OS P3 (hot) plug: a very steady 17200 rpm and a nice broad needle setting. Best combo so far. Needle can actually go further in than on the low compression head."

Here is also a little comparison, or "line-up", of different heads. Starting from the left we have the stock Cox (low compression), Mecoa for a regular glow plug (Enya #4 is in there now), Cox head converted to Turbo, Valentine dedicated Turbo head and finally the Galbreath Nelson plug head;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turbo plug heads

Re: Turbo plug heads

I admire your tenacity and patience. If you had a more robust lathe that could turn steel, you would find it easy to make a tool to simplify the operation, make it easily repeatable and practice on scrap material before committing a head.

Aluminium is not the easiest material to machine - you can get away with small pieces and not using coolant, peck drilling and a slower speed - but it is even easier for a drill to wander and aluminium to "stick" to any cutting tool.

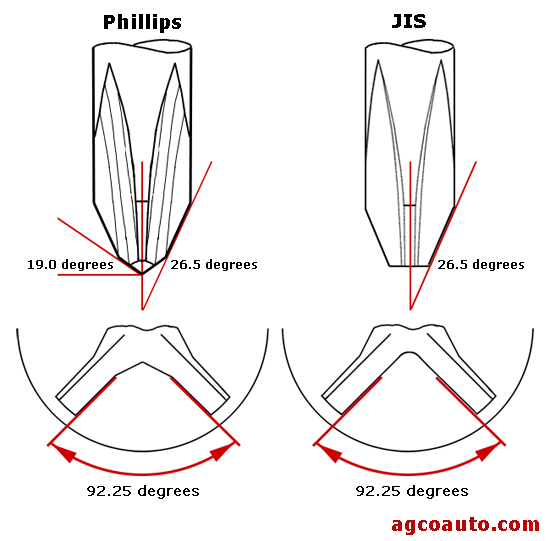

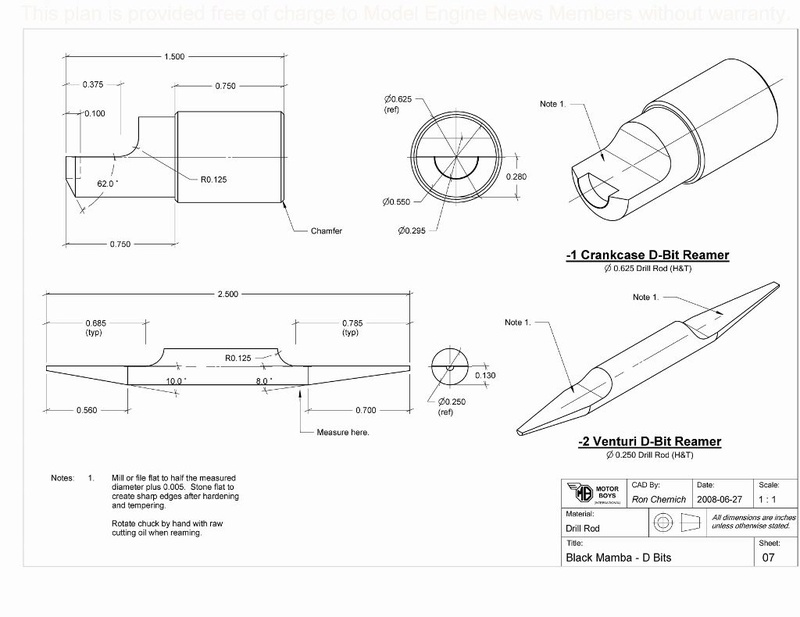

I bore castings (and people!) using "D" bits following a drilled hole. I make the "D" bits and tooling from silver steel and then heat treat the steel to temper it.

I have many of these bits lying around and using them to create angled and flat bottom holes to specific dimensions. The most common use I find is for fitting crankshafts to crankcase castings.

This the tooling for a Cox Bee crankshaft and venturi

Aluminium is not the easiest material to machine - you can get away with small pieces and not using coolant, peck drilling and a slower speed - but it is even easier for a drill to wander and aluminium to "stick" to any cutting tool.

I bore castings (and people!) using "D" bits following a drilled hole. I make the "D" bits and tooling from silver steel and then heat treat the steel to temper it.

I have many of these bits lying around and using them to create angled and flat bottom holes to specific dimensions. The most common use I find is for fitting crankshafts to crankcase castings.

This the tooling for a Cox Bee crankshaft and venturi

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Turbo plug heads

Re: Turbo plug heads

Yes, certainly if one would produce these heads in any larger quantity one would make a tool for the working, so that the machining is done in one step followed by the threading. But for making a few different heads for ones personal use, I don't think that it would be worth be effort.

It bugs me a little that cox-international didn't go for the proper turbo-plug heads. It couldn't have been that much more work when they were remaking the heads, and presumably the tooling, from scratch anyway...

What do you use the D-bit in the drawing for, I don't see much of a cutting edge? Are you using it for reaming only?

Another thing worth doing would be to have the full set-up for making bronze bushing for the crankcases. Especially the casted ones seem to wear out rather quickly...

It bugs me a little that cox-international didn't go for the proper turbo-plug heads. It couldn't have been that much more work when they were remaking the heads, and presumably the tooling, from scratch anyway...

What do you use the D-bit in the drawing for, I don't see much of a cutting edge? Are you using it for reaming only?

Another thing worth doing would be to have the full set-up for making bronze bushing for the crankcases. Especially the casted ones seem to wear out rather quickly...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules