Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:17 pm

» New Model Build

by bsadonkill Today at 11:31 am

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 10:49 am

» Octura engines?

by UncleLumpy Today at 8:16 am

» Tatone EM-7

by sosam117 Today at 7:50 am

» Honoring All Who Served

by roddie Yesterday at 8:59 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Yesterday at 3:30 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 1:41 pm

» Cox 020 PeeWee rebuild questions

by balogh Yesterday at 1:36 pm

» K&B .09 Torpedo Engine

by LooseSpinner99 Yesterday at 12:01 pm

» 3D printing of parts?

by UncleLumpy Yesterday at 9:08 am

» L4 Grasshopper

by bottomgun Yesterday at 7:58 am

Cox Engine of The Month

WEN-MAC STORY

Page 1 of 2

Page 1 of 2 • 1, 2

WEN-MAC STORY

WEN-MAC STORY

WEN-MAC STORY

from American Modeler, September-October, 1964

In the custom moldings business producing plastic parts for others for some time, the McRoskey brothers, Len and Jack figured it might be less hectic if they did some of it for themselves. Pre-fabbed all-aluminum model airplanes that sold for $75 caught their eye. They felt a comparable affair could be done better and cheaper in plastic. Some molds were made and sales of the planes were good from the start. At first they used only 100 engines a week, but soon got up to 1000 per day; by this time they were obtaining power-plants from three different makers, but still couldn't get enough.

Only answer was to make their own. Bill Atwood designed an .049 for them, and with production and quality control in their own hands, things went lots better. Then they decided that starting any small engine was the biggest hurdle for the purchaser. A pull-cord starter was developed, which worked fine. But there was still a problem-the cord was designed for a 4" pull and when some users yanked it a foot or more, the starter was out of business. So the present Roto-Matic starter has no cord but depends upon self-contained spring action to flip the engine. This first came out in '57, has been used ever since.

By this time Wen-Mac had accumulated quite a few firsts in the hobby field. They had made the first ready-to-fly all-plastic model planes, introduced window packaging to better display them, marketed the first complete model plane outfit which included fuel, starting battery and all other accessories needed to fly and maintain the model. Since then still more firsts include bomb dropping, parachute ejection in flight, and rocket firing.

Perhaps we'd better explain how the company name originated. The Mac part is obvious; the "Wen" came from Adolph Wenland, an early partner in the model manufacturing. Though Wenland left the organization many years ago, it was felt the name was too well known in the field then to change it.

Six thousand .040's are turned out per day by Wen-Mac. Some 15% of these, picked at random from production are test run; if any trouble shows up in this sampling, the production line is stopped to find out what's wrong. Line stoppages have ranged from 1/2 hour to several days (but there have been no serious hold-ups). There are 6 test stations in the engine testing building, and there are usually several engines being run 8 hours per day, for as much as 30 days or more, as a check on overall endurance.

During our trip through the plant, parts were picked at random from bins and when enough had been accumulated, two complete engines were assembled as we waited. These were taken to the test stands and both were started on the first flip. The gal who did the running handled the engines with all the aplomb of a top grade Team Racing mechanic. Engines are normally tested only for easy starting end peak RPM; they are run for just long enough to peak them out.

For the volume of engines they turn out, Quality Control has to be tops at Wen-Mac. Pistons are held to tolerances of 15 millionths of an inch for size, roundness and taper. Each machine operator spot checks a certain percentage of the parts she produces (women do most of the engine manufacture), there are several further checks before engine parts and assemblies leave the department, and an overall factory check on top of this. Such care is one reason Wen-Mac can give a 3 year guarantee on their engines. Company salesmen offer to take a Wen-Mac engine from a hobby shop shelf, promise to have it running in 15 seconds after it's mounted and fuelled, or they will close their order books and leave.

Successful high volume production requires close control over every manufacturing process, by doing every job themselves Wen-Mac has such control. They grind 5000 engine parts per hour (on grinders normally used for precision gage making). They do their own heat treating. They make their own glow plugs; one operator sitting at a rotary table turns these out at tremendous speed. The last step is an electrical and high pressure air test. The concern mixes and cans all its own premium grade fuel. Ingredients cost more, but this makes Wen-Mac engines run better and last longer.

That first plane at the start of the business was called Aeromite—remains a good seller (100,000 per year). Only change has been substitution of trike landing gear for the original 2-wheeler. All planes in the line come fully assembled and ready to fly. There are some 10 basic designs, but various modifications and different color schemes more than double this. Most of the planes are scale-with such favorites as the Cessna 175, Airacobra and Corsair.

For such an extensive line of plastic planes, you expect a large moulding department. Largest are three 48 oz. "spiral feed" machines. There are many smaller machines of various types. Both vacuum forming and injection moulding are handled in this department, and in three main materials. High impact polystyrene which is employed for most parts comes in many bright colors. For parts that must be clear such as canopies butyrate is favoured. And for toughness and wearing qualities (props, bearing surfaces) nylon is used.

Metalizing, a specialty process in its own right) is handled in one of the five Wen-Mac buildings. This process which consists of vaporizing aluminium foil in large vacuum chambers is most spectacular to watch. For proper adherence and protection, plastic parts to be metalized are sprayed with special lacquers before and after the vapour has been deposited. Needless to say, the last coat must be both tough and fuel proof. The aluminium skin is about 2 ten thousandths of an inch thick. The entire building where this work is accomplished is slightly pressurized so any dust in the air is blown outward at doors and crevices.

For the sort of high volume production Wen-Mac does the most modern handling methods must be used. We saw many overhead conveyor lines supplying parts to the assembly area while moving belts carried along models as more and more pieces were added to their assembly. Packaging and sealing is done automatically. Employment at the five buildings (all within a few hundred feet of each other) varies from 180 to 450; peak employment is in mid-summer, while low tide comes around New Years—all typical of this rather seasonal business.

Wen-Mac turns out premiums for various outfits. Many readers will recall seeing sleek marine oil tankers at just about every Texaco gas station in the country a few years ago. Well, all those tankers-to the tune of some 9,000 per day and over a million a year-came from Wen-Mac. Wen-Mac fire engines, later premiums for Texaco, were over a foot long, mostly of metal, and went out of the plant at the rate of 10,000 per day.

Practically all models, toys and other items produced in the plant are designed and engineered right there. One exception was the Wen-Mac R/C package, which consists of a super-het receiver and a compact but potent hand-held tone transmitter—both all-transistor. The transmitter was certainly the first in our field, the superhet one of the very first. These units, designed to strict Wen-Mac specs by Packard-Bell, sold in very large volume.

A line of Space-Age action toys are large units easily assembled without nuts, bolts, screws, rivets, cement or other adhesive by youngsters aged 4-9. All have moving parts powered by an electric motor.

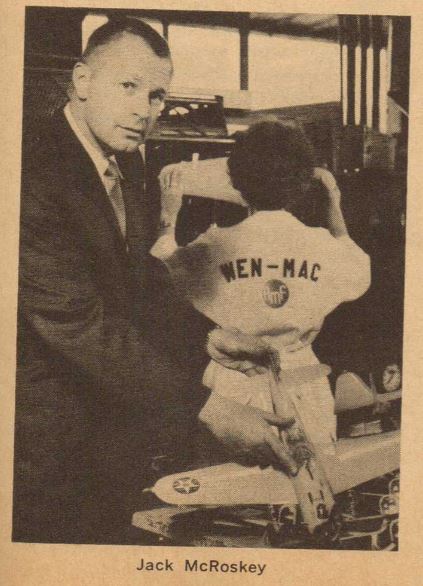

It comes as no surprise to learn that Jack and Len McRoskey were avid model builders as youngsters. Both seem to be getting more and more active in this line now. Jack quite often rounds up a group of plant associates, heads out in the country for a day of model flying...

Jack McRoskey is President of Wen-Mac, Len is Chairman of the Board. The titles appear only a formality, since both can and do handle administration, sales, finance, manufacturing design and other problems in a very flexible arrangement. The concern is a division of American Machine & foundry Co., a complex covering such diverse fields as the well-known AMF bowling pin spotters, automatic cigar and cigarette making equipment, nuclear reactors, golf clubs, precision tools and meters, bicycles, oil field drilling equipment.

And what about future products? Here we drew a complete blank. In the large volume hobby and toy business, competition is extremely keen. So a strict security setup is one of the facts of life. Under these conditions of operation, you can be sure Jack McRoskey wasn't about to discuss with us his future. products!

(Here's an email i'd saved from a gentleman years ago, if anything it confirms the date for Testors and that Jack was the head engineer)

I joined Wen-Mac in 1956 as Marketing Manager. The company was founded a couple of

years before that. The founders were Leonard H. McRoskey, Deceased. And Jack McRoskey

who lives in Rancho Santa Fe. Jack was the engineer who designed everything and was in

charge of production.. Leonard dealt with the office, finances and major chain store sales.

From 1956-1958 the company was family owned. Then in 1959 it was purchased by American Machine

& Foundry Co. (AMF--the bowling alley people). I then was Vice-President, marketing until 1966. I left

when Testor bought Wen-Mac and hired all new executives...that knew nothing about the hobby business).

I then became a marketing consultant for other companies.

Bob

from American Modeler, September-October, 1964

In the custom moldings business producing plastic parts for others for some time, the McRoskey brothers, Len and Jack figured it might be less hectic if they did some of it for themselves. Pre-fabbed all-aluminum model airplanes that sold for $75 caught their eye. They felt a comparable affair could be done better and cheaper in plastic. Some molds were made and sales of the planes were good from the start. At first they used only 100 engines a week, but soon got up to 1000 per day; by this time they were obtaining power-plants from three different makers, but still couldn't get enough.

Only answer was to make their own. Bill Atwood designed an .049 for them, and with production and quality control in their own hands, things went lots better. Then they decided that starting any small engine was the biggest hurdle for the purchaser. A pull-cord starter was developed, which worked fine. But there was still a problem-the cord was designed for a 4" pull and when some users yanked it a foot or more, the starter was out of business. So the present Roto-Matic starter has no cord but depends upon self-contained spring action to flip the engine. This first came out in '57, has been used ever since.

By this time Wen-Mac had accumulated quite a few firsts in the hobby field. They had made the first ready-to-fly all-plastic model planes, introduced window packaging to better display them, marketed the first complete model plane outfit which included fuel, starting battery and all other accessories needed to fly and maintain the model. Since then still more firsts include bomb dropping, parachute ejection in flight, and rocket firing.

Perhaps we'd better explain how the company name originated. The Mac part is obvious; the "Wen" came from Adolph Wenland, an early partner in the model manufacturing. Though Wenland left the organization many years ago, it was felt the name was too well known in the field then to change it.

Six thousand .040's are turned out per day by Wen-Mac. Some 15% of these, picked at random from production are test run; if any trouble shows up in this sampling, the production line is stopped to find out what's wrong. Line stoppages have ranged from 1/2 hour to several days (but there have been no serious hold-ups). There are 6 test stations in the engine testing building, and there are usually several engines being run 8 hours per day, for as much as 30 days or more, as a check on overall endurance.

During our trip through the plant, parts were picked at random from bins and when enough had been accumulated, two complete engines were assembled as we waited. These were taken to the test stands and both were started on the first flip. The gal who did the running handled the engines with all the aplomb of a top grade Team Racing mechanic. Engines are normally tested only for easy starting end peak RPM; they are run for just long enough to peak them out.

For the volume of engines they turn out, Quality Control has to be tops at Wen-Mac. Pistons are held to tolerances of 15 millionths of an inch for size, roundness and taper. Each machine operator spot checks a certain percentage of the parts she produces (women do most of the engine manufacture), there are several further checks before engine parts and assemblies leave the department, and an overall factory check on top of this. Such care is one reason Wen-Mac can give a 3 year guarantee on their engines. Company salesmen offer to take a Wen-Mac engine from a hobby shop shelf, promise to have it running in 15 seconds after it's mounted and fuelled, or they will close their order books and leave.

Successful high volume production requires close control over every manufacturing process, by doing every job themselves Wen-Mac has such control. They grind 5000 engine parts per hour (on grinders normally used for precision gage making). They do their own heat treating. They make their own glow plugs; one operator sitting at a rotary table turns these out at tremendous speed. The last step is an electrical and high pressure air test. The concern mixes and cans all its own premium grade fuel. Ingredients cost more, but this makes Wen-Mac engines run better and last longer.

That first plane at the start of the business was called Aeromite—remains a good seller (100,000 per year). Only change has been substitution of trike landing gear for the original 2-wheeler. All planes in the line come fully assembled and ready to fly. There are some 10 basic designs, but various modifications and different color schemes more than double this. Most of the planes are scale-with such favorites as the Cessna 175, Airacobra and Corsair.

For such an extensive line of plastic planes, you expect a large moulding department. Largest are three 48 oz. "spiral feed" machines. There are many smaller machines of various types. Both vacuum forming and injection moulding are handled in this department, and in three main materials. High impact polystyrene which is employed for most parts comes in many bright colors. For parts that must be clear such as canopies butyrate is favoured. And for toughness and wearing qualities (props, bearing surfaces) nylon is used.

Metalizing, a specialty process in its own right) is handled in one of the five Wen-Mac buildings. This process which consists of vaporizing aluminium foil in large vacuum chambers is most spectacular to watch. For proper adherence and protection, plastic parts to be metalized are sprayed with special lacquers before and after the vapour has been deposited. Needless to say, the last coat must be both tough and fuel proof. The aluminium skin is about 2 ten thousandths of an inch thick. The entire building where this work is accomplished is slightly pressurized so any dust in the air is blown outward at doors and crevices.

For the sort of high volume production Wen-Mac does the most modern handling methods must be used. We saw many overhead conveyor lines supplying parts to the assembly area while moving belts carried along models as more and more pieces were added to their assembly. Packaging and sealing is done automatically. Employment at the five buildings (all within a few hundred feet of each other) varies from 180 to 450; peak employment is in mid-summer, while low tide comes around New Years—all typical of this rather seasonal business.

Wen-Mac turns out premiums for various outfits. Many readers will recall seeing sleek marine oil tankers at just about every Texaco gas station in the country a few years ago. Well, all those tankers-to the tune of some 9,000 per day and over a million a year-came from Wen-Mac. Wen-Mac fire engines, later premiums for Texaco, were over a foot long, mostly of metal, and went out of the plant at the rate of 10,000 per day.

Practically all models, toys and other items produced in the plant are designed and engineered right there. One exception was the Wen-Mac R/C package, which consists of a super-het receiver and a compact but potent hand-held tone transmitter—both all-transistor. The transmitter was certainly the first in our field, the superhet one of the very first. These units, designed to strict Wen-Mac specs by Packard-Bell, sold in very large volume.

A line of Space-Age action toys are large units easily assembled without nuts, bolts, screws, rivets, cement or other adhesive by youngsters aged 4-9. All have moving parts powered by an electric motor.

It comes as no surprise to learn that Jack and Len McRoskey were avid model builders as youngsters. Both seem to be getting more and more active in this line now. Jack quite often rounds up a group of plant associates, heads out in the country for a day of model flying...

Jack McRoskey is President of Wen-Mac, Len is Chairman of the Board. The titles appear only a formality, since both can and do handle administration, sales, finance, manufacturing design and other problems in a very flexible arrangement. The concern is a division of American Machine & foundry Co., a complex covering such diverse fields as the well-known AMF bowling pin spotters, automatic cigar and cigarette making equipment, nuclear reactors, golf clubs, precision tools and meters, bicycles, oil field drilling equipment.

And what about future products? Here we drew a complete blank. In the large volume hobby and toy business, competition is extremely keen. So a strict security setup is one of the facts of life. Under these conditions of operation, you can be sure Jack McRoskey wasn't about to discuss with us his future. products!

(Here's an email i'd saved from a gentleman years ago, if anything it confirms the date for Testors and that Jack was the head engineer)

I joined Wen-Mac in 1956 as Marketing Manager. The company was founded a couple of

years before that. The founders were Leonard H. McRoskey, Deceased. And Jack McRoskey

who lives in Rancho Santa Fe. Jack was the engineer who designed everything and was in

charge of production.. Leonard dealt with the office, finances and major chain store sales.

From 1956-1958 the company was family owned. Then in 1959 it was purchased by American Machine

& Foundry Co. (AMF--the bowling alley people). I then was Vice-President, marketing until 1966. I left

when Testor bought Wen-Mac and hired all new executives...that knew nothing about the hobby business).

I then became a marketing consultant for other companies.

Bob

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Good little read, and interesting. Thanks.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Really interesting. Thanks for posting.

watertrucker- Bronze Member

- Posts : 45

Join date : 2016-08-15

Age : 64

Location : Imperial Valley Ca.

Re: WEN-MAC STORY

Re: WEN-MAC STORY

First flip starting? 15 second start from mount to fuel? I once cranked on one of the little darlings for a half hour becoming so frustrated that I almost did a Wen hurl even before I knew of a Fox hurl.

Seriously, immediately thereafter I found a Cox Babe Bee which thankfully started right off renewing my faith in glow engines.

Bob

Seriously, immediately thereafter I found a Cox Babe Bee which thankfully started right off renewing my faith in glow engines.

Bob

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: WEN-MAC STORY

Re: WEN-MAC STORY

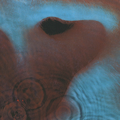

Hope Mark doesn't mind...figured I'd add these grainy, but somewhat cool photos from the article:

Kim- Top Poster

Posts : 8624

Join date : 2011-09-06

Location : South East Missouri

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Thanks for the history lesson. I don't recall WenMac models as much as I do Cox. Did not realize they had such a large production and model selection. Seems like I would have wanted a Aeromite Circus as a replacement for my Cox TD-3 flying circus if I'd known one was available.

WEN-MAC, I always thought it was a shorten version of Wendel MacDonald

The little known but playfull brother of Ronald.

WEN-MAC, I always thought it was a shorten version of Wendel MacDonald

The little known but playfull brother of Ronald.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Thank Kim, i had those pics, but couldn't find them.

Yep, the plastic RTF toy market was pretty packed in the fifties into the early sixties, Comet, Cox & Wen-Mac were the big three, Aurora made some really nice stuff but only for about 5 years, Anderson made some Balsa RTF and ARF, likewise there where overseas companies making them as well.

Yep, the plastic RTF toy market was pretty packed in the fifties into the early sixties, Comet, Cox & Wen-Mac were the big three, Aurora made some really nice stuff but only for about 5 years, Anderson made some Balsa RTF and ARF, likewise there where overseas companies making them as well.

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Very impressive story and description of a certainly professional hobby business venture..I may see this from a far distance in Central Europe but COX seems to have retained a much wider visibility by today than Wen Mac...is it just because Wen Mac lost its independence to Testors much earlier i.e some 50 years ago while COX remained standing up longer i.e until acquired by ESTES 20 years ago, and COX Int'l in Canada and Ex-Model Engines in the US take good care of the continuation of the COX engine history today?

While the 2 companies operated in their heyday in parallel, I still see a distinct difference between the appearance and quality/survival of their genuine products, in the obvious favor of COX.

While the 2 companies operated in their heyday in parallel, I still see a distinct difference between the appearance and quality/survival of their genuine products, in the obvious favor of COX.

balogh- Top Poster

Posts : 4951

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: WEN-MAC STORY

Re: WEN-MAC STORY

I think clearly it was the Babe Bee, it just plainly kicked everybodys butt! The machined case was the key as it was vastly cheaper and quicker to make than the traditional cast case, that along with Thimble-Dromes precision manufacturing aka 'Temp-Trol' and by the early sixties about everybody except Wen-Mac/AMF/Testors was gone!

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Very cool, thanks for sharing...

SteveM- Bronze Member

- Posts : 48

Join date : 2018-11-27

Age : 60

Location : Palatine, Illinois

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Thanks for sharing, Mark. Seems when companies weren't large conglomerates they produced better products. Even Cox seemed to suffer, the quality of RTF's seemed to drop after the 1980's. I guess this is when Leroy Cox was not as prominently involved as before. I saw colored printed glossy paper stickers for windows and markings, the quality decals and paint used before were gone. Stuff just looked cheap compared with a decade and half ago.

Comment about Testors buying the company in 1966 and not know how to run a hobby manufacturing business was of interest. Seems when a company is smaller, then it is easier to handle quality than when it becomes a large conglomerate. Also, I gather that there was much more personalization in know people, the Wen Mac upper management were intimately involved with details and got with people.

Nowadays seems corporate magnates are so high up that they are not in touch with their people. Also, the salary spread is tremendously wider, cutting technical people's salary yet expanding their own.

I saw that at McDonnell Douglas in the latter 1980's. A change in presidents, they laid off the one who saved the company during recession, said they were people oriented, but did away with the company store, which also allowed you to buy tickets to sporting events and shows in the LA and other areas. Old timers weren't happy when McDonnell took over Douglas in the mid 1960's. First thing they did was sell of the recreational park in Santa Monica that was used for the company's annual picnic. Before I left, they removed all engineers except managers with access to their mainframe E-mail system, we went back to 3 part hand written speed memos. (Pink copy you kept, other side filled out reply section, kept white copy and sent you back the yellow copy.)

Several years later, the 55,000 employees at Douglas dropped to less than 12,000, company was sold to Boeing. Anyway, enough of past history.

Regarding ease of starting a Wen Mac, one my brother had in 1966 on his all chrome F4U Corsair was definitely easy starting. I suppose like in everything, if an engine is difficult to start or continue running probably boils down to a few things, may be a glow head or plug that has gone south. I had a hard starting NOS OS Max .10R/C (1964 version) back in the late 1970's. Found it was the new Fox idle bar short plug I bought for it. Changed it out with a Swanson Fireball Hot non-idle bar, it fired up and ran as reliably as a Cox reedy.

Last Cox engine I bought until the past decade was the R/C Bee in the late 1970's. It was a quality engine, ran very well, always was happy with it, even though historically it was discontinued not long after, replaced by the Dragonfly. Last new engines I bought were from the Estes Cox surplus store in 2008 were 2 Sure Starts. Since I have a acquired more Cox, but most these are used engines. The Medallion .09 R/C I got this summer for under $30 was lo and behold, a new never run probably late 1970's vintage engine. (It was mislabled as a Tee Dee with not many bidding on it.)

Anyway, enough of my rambling.

Comment about Testors buying the company in 1966 and not know how to run a hobby manufacturing business was of interest. Seems when a company is smaller, then it is easier to handle quality than when it becomes a large conglomerate. Also, I gather that there was much more personalization in know people, the Wen Mac upper management were intimately involved with details and got with people.

Nowadays seems corporate magnates are so high up that they are not in touch with their people. Also, the salary spread is tremendously wider, cutting technical people's salary yet expanding their own.

I saw that at McDonnell Douglas in the latter 1980's. A change in presidents, they laid off the one who saved the company during recession, said they were people oriented, but did away with the company store, which also allowed you to buy tickets to sporting events and shows in the LA and other areas. Old timers weren't happy when McDonnell took over Douglas in the mid 1960's. First thing they did was sell of the recreational park in Santa Monica that was used for the company's annual picnic. Before I left, they removed all engineers except managers with access to their mainframe E-mail system, we went back to 3 part hand written speed memos. (Pink copy you kept, other side filled out reply section, kept white copy and sent you back the yellow copy.)

Several years later, the 55,000 employees at Douglas dropped to less than 12,000, company was sold to Boeing. Anyway, enough of past history.

Regarding ease of starting a Wen Mac, one my brother had in 1966 on his all chrome F4U Corsair was definitely easy starting. I suppose like in everything, if an engine is difficult to start or continue running probably boils down to a few things, may be a glow head or plug that has gone south. I had a hard starting NOS OS Max .10R/C (1964 version) back in the late 1970's. Found it was the new Fox idle bar short plug I bought for it. Changed it out with a Swanson Fireball Hot non-idle bar, it fired up and ran as reliably as a Cox reedy.

Last Cox engine I bought until the past decade was the R/C Bee in the late 1970's. It was a quality engine, ran very well, always was happy with it, even though historically it was discontinued not long after, replaced by the Dragonfly. Last new engines I bought were from the Estes Cox surplus store in 2008 were 2 Sure Starts. Since I have a acquired more Cox, but most these are used engines. The Medallion .09 R/C I got this summer for under $30 was lo and behold, a new never run probably late 1970's vintage engine. (It was mislabled as a Tee Dee with not many bidding on it.)

Anyway, enough of my rambling.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Despite my anti Wen Mac comment above made in 2016 I have since developed a friendly relationship with Wen engines. I actually got several of them to run and start easily.

Last week I found this Wen Mac Airacobra on ebay BIN. I had never seen a camouflage version before so before buying it I had the good sense to run it by Mark Boesen to determine if it was legitimate or a kid playing with paint cans.

Mark found an ad that showed it along with other Wen Mac models so I bought it. Arrived yesterday well packed. No box or accessories, but it is as new, never fueled or ran. I have about seven of these, white, olive drab, chrome but no camo until now.

I will do a picture post of the group someday.

Bob

Last week I found this Wen Mac Airacobra on ebay BIN. I had never seen a camouflage version before so before buying it I had the good sense to run it by Mark Boesen to determine if it was legitimate or a kid playing with paint cans.

Mark found an ad that showed it along with other Wen Mac models so I bought it. Arrived yesterday well packed. No box or accessories, but it is as new, never fueled or ran. I have about seven of these, white, olive drab, chrome but no camo until now.

I will do a picture post of the group someday.

Bob

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: WEN-MAC STORY

Re: WEN-MAC STORY

I believe that your Airacobra is a Testors version. Check for molded engraving on bottom of plane. It may even have a "McCoy" engine or it could have a Wen-Mac engine. There was a post acquisition transition stage when parts inventories were mixed.

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: WEN-MAC STORY

Re: WEN-MAC STORY

ticomareado wrote:I believe that your Airacobra is a Testors version. Check for molded engraving on bottom of plane. It may even have a "McCoy" engine or it could have a Wen-Mac engine. There was a post acquisition transition stage when parts inventories were mixed.

I think your right Victor. The camo version has a Wen Mac engine, but a Testor paddle propeller. It doesn't have any identifying script on the bottom that says Testor either, just Made in USA and control line configuration.

It also has a break away front landing gear unlike the break your plane gear of the earlier Wen Version which has Wen Mac embossed on the nose while the Testor version doesn't.

I will compare these more in a different thread.

Bob

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: WEN-MAC STORY

Re: WEN-MAC STORY

rsv1cox wrote:Despite my anti Wen Mac comment above made in 2016 I have since developed a friendly relationship with Wen engines. I actually got several of them to run and start easily.

Last week I found this Wen Mac Airacobra on ebay BIN. I had never seen a camouflage version before so before buying it I had the good sense to run it by Mark Boesen to determine if it was legitimate or a kid playing with paint cans.

The grey matter is getting weaker. Thinking back some 40+ years ago, think I remember seeing those in early 1970's? Beige camo offsetting the black would make it more appealing physically. Call it the night version P-39 / P-63? May be the Testor's Corp got a big low cost buy on black durable styrene plastic? Perhaps this was the same plastic they were moulding their retail product .049 tanks from? Or needed to get rid of the unused black plastic?

Anyway, Bob, you certainly got a rare one there, looks good. There's something about the Airacobra's tricycle gear that makes it a desirable warbird CL to model. Wen Mac did a decent job on replicating it.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Bob. As you may recall, I got myself a White Wen Mac version of the P-39 quite a while back. I'd like to try to fly it, but it's missing a canopy, which may make its marginal flight characteristics even worse. Have you ever tried moulding plastic canopies? Any chance you could make me a copy of one of your originals? I've seen plastic soda bottles used. I'm not after collectable type authenticity, just something to streamline and neaten it up.

Rod.

Rod.

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: WEN-MAC STORY

Re: WEN-MAC STORY

I have them in clear and blue tint Rod.

I made one from balsa for this crashed Airacobra that was missing the canopy. Casting one from an original would be difficult due to the pivot extensions at the rear that are quite thin and prone to breakage. But Jim is the authority here for heat shrinking them.

I just filled in the slots with putty on the balsa canopy.

Bob

I made one from balsa for this crashed Airacobra that was missing the canopy. Casting one from an original would be difficult due to the pivot extensions at the rear that are quite thin and prone to breakage. But Jim is the authority here for heat shrinking them.

I just filled in the slots with putty on the balsa canopy.

Bob

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: WEN-MAC STORY

Re: WEN-MAC STORY

I had a Wen Mac hovercraft back in the mid 1960s. Never did get it to run.

I guess it got tossed out, along with my PT-19, Riviera, and Spitfire, after I moved out of the house.

I guess it got tossed out, along with my PT-19, Riviera, and Spitfire, after I moved out of the house.

TLAnderson- Gold Member

- Posts : 243

Join date : 2016-07-21

Location : Northern Wisconsin

Re: WEN-MAC STORY

Re: WEN-MAC STORY

TLAnderson wrote:I had a Wen Mac hovercraft back in the mid 1960s. Never did get it to run.

I guess it got tossed out, along with my PT-19, Riviera, and Spitfire, after I moved out of the house.

Don't feel so bad. When I left the house 40+ some years ago, all the engines and wheels on about a dozen CL planes and props and wheels on my stick and tissue rubber powered planes were removed, planes trashed along with my plans when I left the house. I all got those in a single box.

GallopingGhostler- Top Poster

Posts : 5700

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: WEN-MAC STORY

Re: WEN-MAC STORY

I got to thinking, maybe one could be 3D printed out of clear plastic. Or perhaps one could be drawn over an existing original canopy without the pivots, then just fill in the planes slots. But your risking the original canopy being damaged by the heat so probably a form would have to be made.

rsv1cox- Top Poster

Posts : 11214

Join date : 2014-08-18

Location : West Virginia

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Mark Boesen wrote:(bump) wen-mac story

Where?

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: WEN-MAC STORY

Re: WEN-MAC STORY

Whoops  . No problems. Had to go back to the start of the thread.

. No problems. Had to go back to the start of the thread.

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Previous thread on my recent Ebay power head buy for Wen-Mac hovercraft

Previous thread on my recent Ebay power head buy for Wen-Mac hovercraft

Further forensic examination indicates that it was never fueled, just subject to less than optimum storage conditions over the years. I guess the dog chewed up the plastic airframe or maybe a long time in an attic just heat rotted it away.

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Page 1 of 2 • 1, 2

Similar topics

Similar topics» sad story...

» A P51 story

» Jim Walkers Firebabies with a story.

» Revisited childhood moments

» A Christmas Story

» A P51 story

» Jim Walkers Firebabies with a story.

» Revisited childhood moments

» A Christmas Story

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules