Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Cox integral tanks-not enough run time?

Page 1 of 1

Cox integral tanks-not enough run time?

Cox integral tanks-not enough run time?

Ken Cook mentioned in a recent thread; running a Bee engine's fuel pick-up, out through a hole drilled through the tank wall.. and running an external tank. I've done this several times on at least two conversions under bench-run conditions. Fuel-draw is a non-issue. Tank-placement is a non-issue. That's just one of the reed-valve engine's features that I appreciate the most. I once dropped a 12+ in. silicone fuel-line extension from an engine so equipped; into a small glass of fuel below it. A short blip of an electric-starter nearly primed the line.

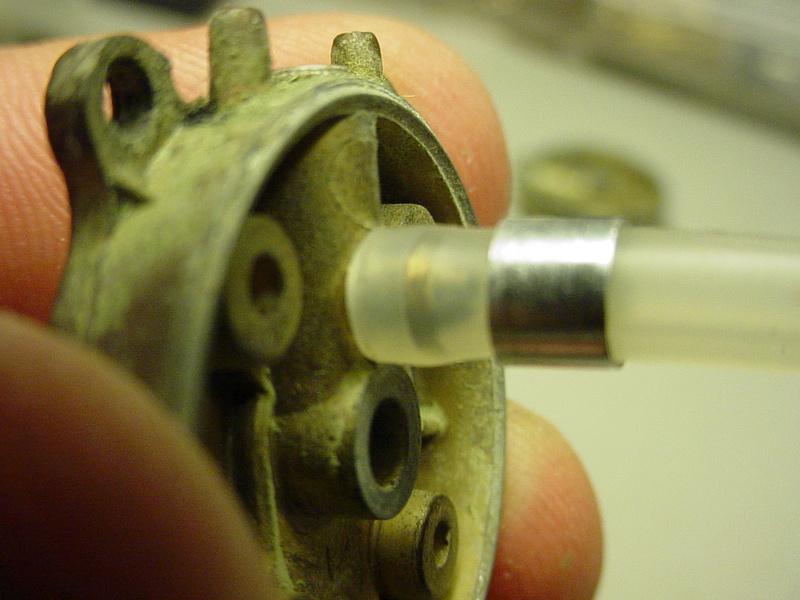

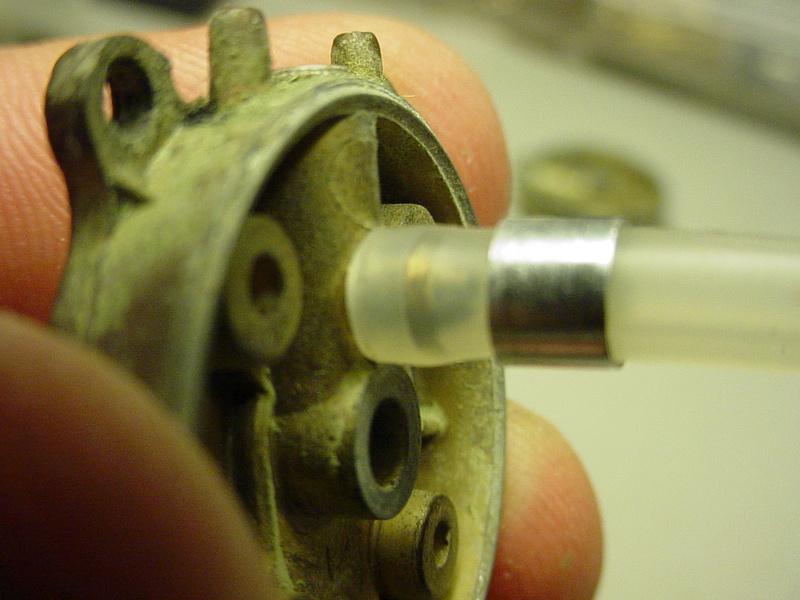

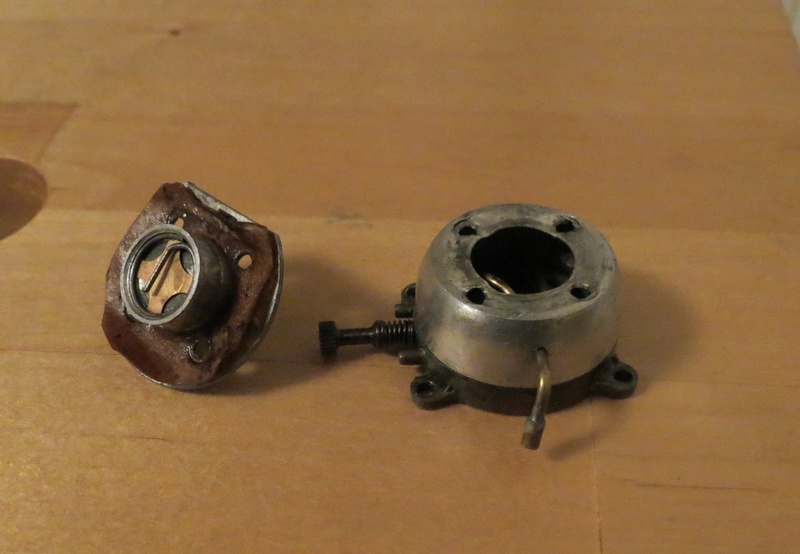

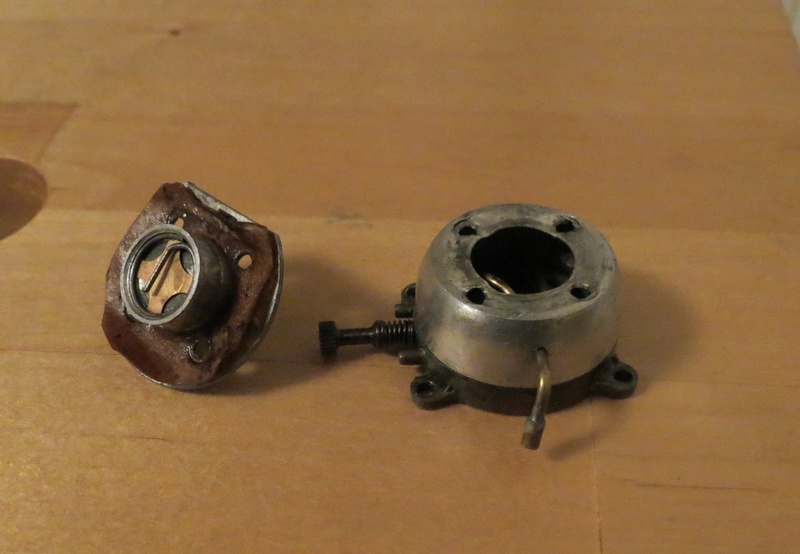

As shown below; a short-length/hard-tube sleeve will compress silicone tubing for a more secure fit on the *backplate-nipple. Apply a lubricant to slide the sleeve into place. It's extra insurance against the feed-line being inadvertently pulled-off during assembly and after. (*applies to original Mazak/cast backplates.. having a shouldered-nipple)

Then comes drilling a hole through the tank-wall. I like to size it to accept a rubber grommet to lessen abrasion to the fuel-line.. plus; it's a cleaner look.

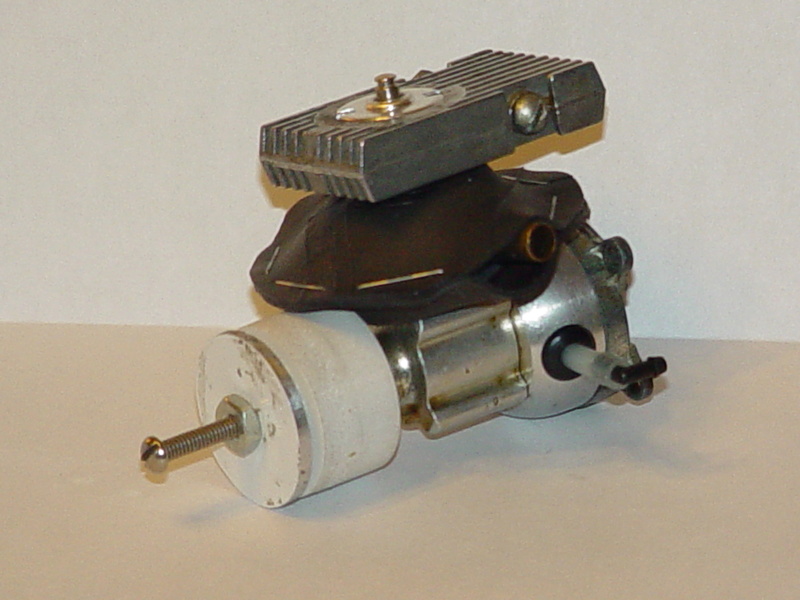

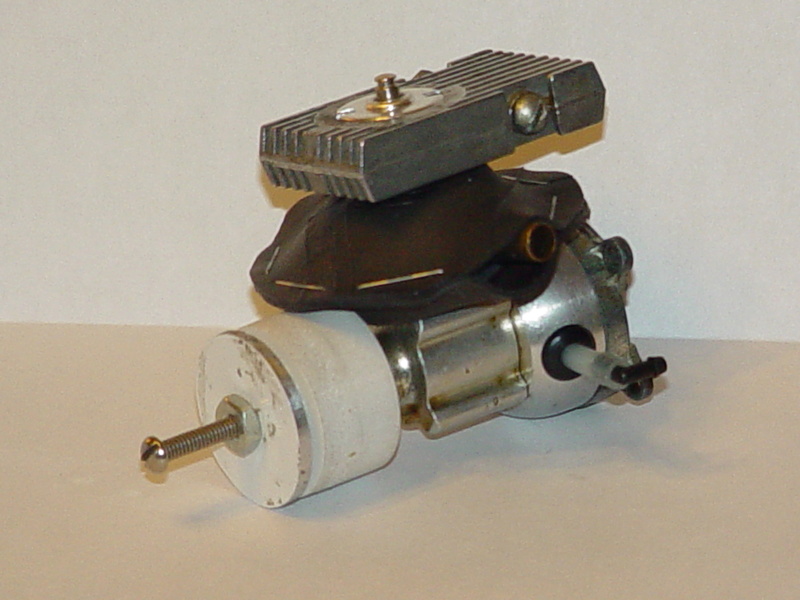

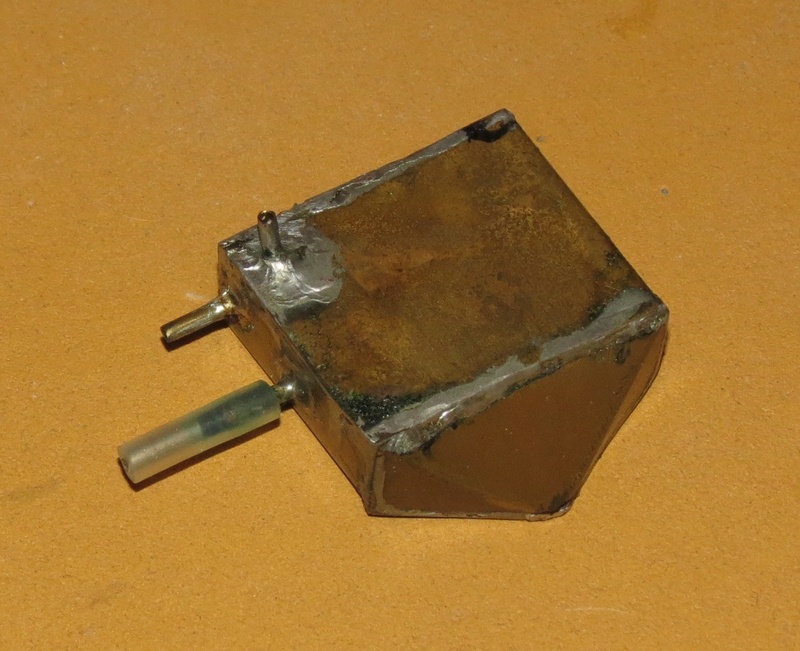

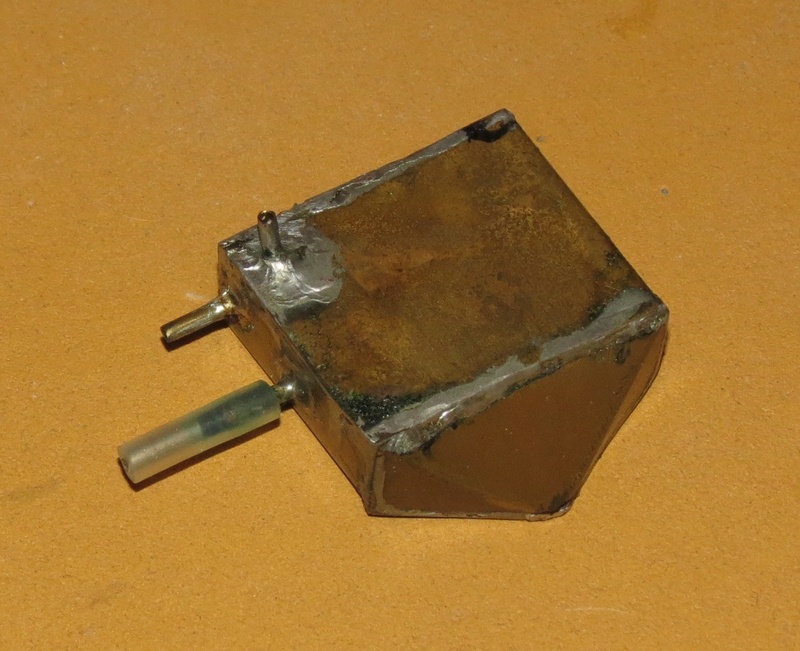

Below is an example (img) of one of my Babe Bees (marine) utilizing an external fuel-line. There's one in use on my Ace-throttle-video too.

https://www.youtube.com/watch?v=Sy9o2WDzLqc

There are big benefits involved. You bypass the integral tank's notorious air-leaks.. and gain tank capacity/configuration options. Provide a good seal at the needle-valve.. and you've eliminated a variety of fuel-related troubleshooting variables.

Another way to look at this.. is if you have an airplane that finishes-out a bit nose-heavy. Fuel-weight can be transferred-back toward/over the CG.. so that becomes less of a factor throughout the flight.

Then there's "surface" models. Tether-cars/boats, RC or free-running models.. Having fuel-tank choices is always a good thing.

As shown below; a short-length/hard-tube sleeve will compress silicone tubing for a more secure fit on the *backplate-nipple. Apply a lubricant to slide the sleeve into place. It's extra insurance against the feed-line being inadvertently pulled-off during assembly and after. (*applies to original Mazak/cast backplates.. having a shouldered-nipple)

Then comes drilling a hole through the tank-wall. I like to size it to accept a rubber grommet to lessen abrasion to the fuel-line.. plus; it's a cleaner look.

Below is an example (img) of one of my Babe Bees (marine) utilizing an external fuel-line. There's one in use on my Ace-throttle-video too.

https://www.youtube.com/watch?v=Sy9o2WDzLqc

There are big benefits involved. You bypass the integral tank's notorious air-leaks.. and gain tank capacity/configuration options. Provide a good seal at the needle-valve.. and you've eliminated a variety of fuel-related troubleshooting variables.

Another way to look at this.. is if you have an airplane that finishes-out a bit nose-heavy. Fuel-weight can be transferred-back toward/over the CG.. so that becomes less of a factor throughout the flight.

Then there's "surface" models. Tether-cars/boats, RC or free-running models.. Having fuel-tank choices is always a good thing.

Re: Cox integral tanks-not enough run time?

Re: Cox integral tanks-not enough run time?

That's right, Roddimus, it's a great way to enhance the operation of your frequently maddening tanked Bees. But comparing a bench run with a flight run is not really telling, especially in control line applications. Tank position including, but not only, height and distance in relation to the engine is critical on a plane pulling g-forces on the fuel and plumbing. I'm not intending to undermine your good tips, but there are some additional considerations for going in circles, loops, etc.

You cannot mount an external tank too high or low, or too far away from the engine and expect it to run well, regardless of what it did on the bench. Also the kickout angle shimming the rear end of the tank outward is cruicial to drawing out the last drop of fuel without a bunch of laps of burping. That rear shimming keeps the tank's pickup tube wet when the plane's yaw would otherwise cause the last drops to be out of position to enter the feed tube.

Rusty

You cannot mount an external tank too high or low, or too far away from the engine and expect it to run well, regardless of what it did on the bench. Also the kickout angle shimming the rear end of the tank outward is cruicial to drawing out the last drop of fuel without a bunch of laps of burping. That rear shimming keeps the tank's pickup tube wet when the plane's yaw would otherwise cause the last drops to be out of position to enter the feed tube.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cox integral tanks-not enough run time?

Re: Cox integral tanks-not enough run time?

In the early 80-ties I used a thin brass tube that was a tight fit inside the nipple of the backplate. That removed the risk of having a silicon tube fall of the nipple or get damaged against the sharp edge of the tank. Engine runs (in non-acrobatic RC) were very consistent with a DIY metal tank mounted behind the battery, about level with the leading edge of the wing. One could easily double the runtime and have better constancy than it ever had with the stock tank. The stock tank was also made paper thin (!) in the front, I've never seen that machining error in any other of my engines...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox integral tanks-not enough run time?

Re: Cox integral tanks-not enough run time?

RknRusty wrote:That's right, Roddimus, it's a great way to enhance the operation of your frequently maddening tanked Bees. But comparing a bench run with a flight run is not really telling, especially in control line applications. Tank position including, but not only, height and distance in relation to the engine is critical on a plane pulling g-forces on the fuel and plumbing. I'm not intending to undermine your good tips, but there are some additional considerations for going in circles, loops, etc.

You cannot mount an external tank too high or low, or too far away from the engine and expect it to run well, regardless of what it did on the bench. Also the kickout angle shimming the rear end of the tank outward is cruicial to drawing out the last drop of fuel without a bunch of laps of burping. That rear shimming keeps the tank's pickup tube wet when the plane's yaw would otherwise cause the last drops to be out of position to enter the feed tube.

Rusty

Yea Rusty.. I know. I basically wanted to show how the mod could be done, for those wanting to try it. My experience was running stock (.062") venturi Babe Bee-configured engines. Even when using the Ace-style throttle, my engine continued to draw fuel effectively down below 3K rpm.

I totally agree with proper tank-placement for control-line. No sense in creating more variables there..

My only experience thus far "flying", is with Cox .049 reed-valve engines. I've heard that the rotary-valve engines are sensitive to fuel-tank placement.. especially the Tee Dee. The Medallion to a lesser-extent.

The reed-valve product-engine backplates (horseshoe, postage-stamp) have large venturis when compared to the integrally-tanked-engines. The std. horseshoe.. mounted horizontally and using a wedge-tank, had been my standard set-up.. and was pretty reliable. I had lots of wedges that I'd purchased from a hobby-shop on Cape Cod in the early 90's. and also another fellow who's shop had closed. All Perfect/NOS wedges between 1/8 oz./1oz. So.. I ordered a few HS backplate-assembly's direct from Cox. More than a few Bee's were stripped of their back-ends.. and their tanks/backplates/screws saved in parts-boxes. I replaced them with wedges in the 8/10cc range generally. Since then I've assembled some engines back to Babe Bee configuration.. mainly for bench-testing the Ace throttle.

Re: Cox integral tanks-not enough run time?

Re: Cox integral tanks-not enough run time?

I read an interesting explanation about the Tee Dee fuel draw, and it makes sense. The 3 hole sprinkler venturi tends to draw unevenly through the 3 holes, and one becomes dominant while the other two cavitate, thus wasting useful vacuum. That's why Tee Dees need some sort of pressure to run reliably. That's what I read, and it sounds like a good story. I have no idea if it's true or total B.S.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cox integral tanks-not enough run time?

Re: Cox integral tanks-not enough run time?

RknRusty wrote:I read an interesting explanation about the Tee Dee fuel draw, and it makes sense. The 3 hole sprinkler venturi tends to draw unevenly through the 3 holes, and one becomes dominant while the other two cavitate, thus wasting useful vacuum. That's why Tee Dees need some sort of pressure to run reliably. That's what I read, and it sounds like a good story. I have no idea if it's true or total B.S.

Rusty

I gotta' wonder if the KK NVA's overcame those issues.

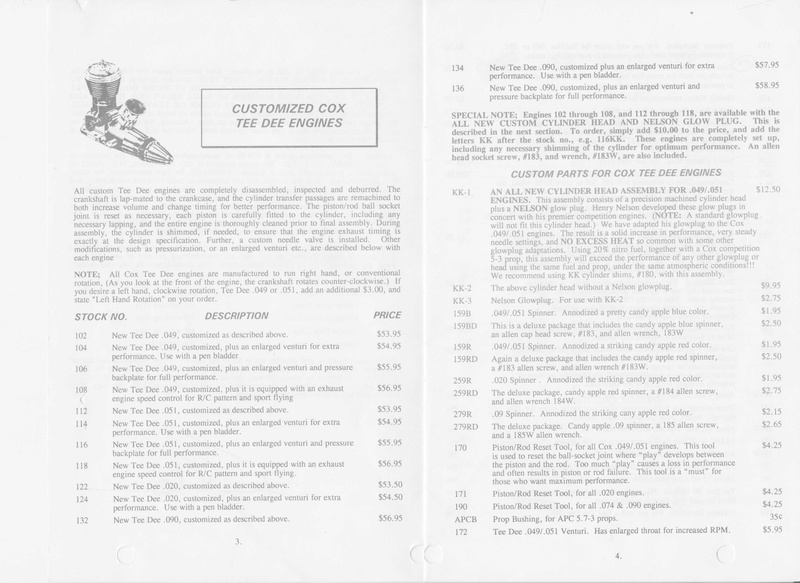

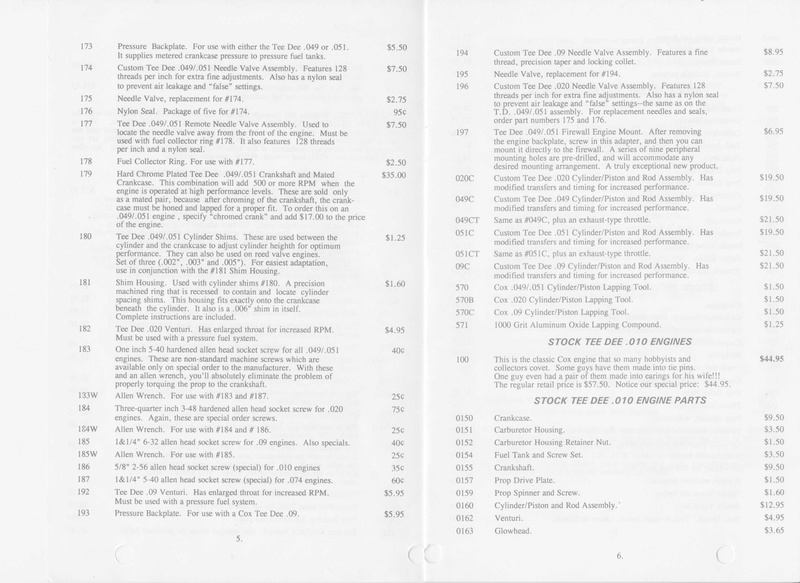

I posted my entire catalog-scans a while back. COOL STUFF! Let me know if you want all pages.

Re: Cox integral tanks-not enough run time?

Re: Cox integral tanks-not enough run time?

Not alone, but they sure helped by allowing the engines to be run with pressure-fed fuel. Alone, the 128 tpi needle allows leak-free and finer fuel/air mixture adjustments, but it's more precision than necessary for suction fed engines. I wonder why Cox made fine needles for some product engines and not others. If they had made them for all of their engines, we might not have as much need for sleeving the needles with fuel tube to prevent air leaks, although sleeving does prevent wear on the threads by damping vibrations.roddie wrote:RknRusty wrote:I read an interesting explanation about the Tee Dee fuel draw, and it makes sense. The 3 hole sprinkler venturi tends to draw unevenly through the 3 holes, and one becomes dominant while the other two cavitate, thus wasting useful vacuum. That's why Tee Dees need some sort of pressure to run reliably. That's what I read, and it sounds like a good story. I have no idea if it's true or total B.S.

Rusty

I gotta' wonder if the KK NVA's overcame those issues.

When pressure is introduced into the fuel feed, the KK and other fine needle valves make it possible to reliably tune the F/A mixture because finer adjustments are necessary, plus it prevents fuel from being pushed back out past the threads. That's where the Tee Dee comes into its full potential, because the gutter around the venturi base is feeding all three sprinkler holes equally. It makes a world of difference in ease of cranking and feeds the engine every bit as much fuel as it can burn. It can be further improved by widening the venturi up to .140" allowing the full capacity of the combustion chamber to be used.

If you've put a bladder on a TD and not bored the venturi, try it, you're in for a treat. Also Our esteemed member bandit tells me the Redcap caulking tube condoms make good bladders with low enough pressure to use without a fine thread NV. He gave me one to try, and it worked great. My caulking tube stayed useable for months Lol.

http://www.littleredcap.com/

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Similar topics

Similar topics» High performance Integral tanks for Cox engines

» WHO NEEDS TANKS!!!?? Perfect Brand Tanks For Sale

» Flew yesterday, first time in a LONG time....

» Triva Time II (an easy one this time)

» Metal Fuel Tanks

» WHO NEEDS TANKS!!!?? Perfect Brand Tanks For Sale

» Flew yesterday, first time in a LONG time....

» Triva Time II (an easy one this time)

» Metal Fuel Tanks

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules