Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Super Super Bee

Page 1 of 1

Super Super Bee

Super Super Bee

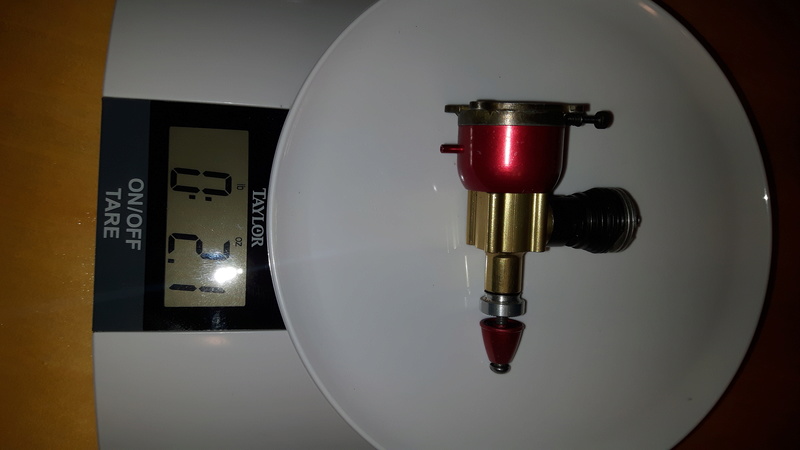

My Super Super Bee. Killer Bee power head. Tank extender copied from a Kavan kit. The engine runs about 9 minutes on a 6X3.

Controlliner- Bronze Member

- Posts : 34

Join date : 2016-08-24

Location : Canada

Re: Super Super Bee

Re: Super Super Bee

Nice one! That engine is as long as John Kerrys face! How did you make the extention?

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: Super Super Bee

Re: Super Super Bee

took a super bee tank and turned it down with the same grove and tongue fit as the original tank and back plate set. the venturi extension is from 6061 t6 bar stock. Intake ID is drilled a #43 drill.

Controlliner- Bronze Member

- Posts : 34

Join date : 2016-08-24

Location : Canada

Re: Super Super Bee

Re: Super Super Bee

Looks like a contender for the next Cox Engine of the Month

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Super Super Bee

Re: Super Super Bee

Nice extension , you did a heck of a job . You machinist are something // what is the weight on the engine now ?"

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Super Super Bee

Re: Super Super Bee

I want to submit for next month contest. Yes, I am a machinist. I want to take a car engine crank case and make an oil lite bushing to fit and use a killer bee crank shaft. I know there won't be any gains, but is would be cool to have a bushed crank case.

Last edited by Controlliner on Sun Oct 16, 2016 9:03 am; edited 1 time in total

Controlliner- Bronze Member

- Posts : 34

Join date : 2016-08-24

Location : Canada

Re: Super Super Bee

Re: Super Super Bee

I will weigh and post.getback wrote:Nice extension , you did a heck of a job . You machinist are something // what is the weight on the engine now ?"

Controlliner- Bronze Member

- Posts : 34

Join date : 2016-08-24

Location : Canada

Re: Super Super Bee

Re: Super Super Bee

Not bad for the almost 2 times the run time , would certainly bee nice for a RC lite weight Skylane or so  i just happen to have one new in the box from way back then

i just happen to have one new in the box from way back then  Just seems the faster i go the less i get done

Just seems the faster i go the less i get done  You have any plans for that extra run time controlliner ?

You have any plans for that extra run time controlliner ?

i just happen to have one new in the box from way back then

i just happen to have one new in the box from way back then  Just seems the faster i go the less i get done

Just seems the faster i go the less i get done

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Super Super Bee

Re: Super Super Bee

I've used it in an Ace Grasshopper. Sweet run times and you should hear it in a dive when it unloads. I would love to get that kit again.

Controlliner- Bronze Member

- Posts : 34

Join date : 2016-08-24

Location : Canada

Re: Super Super Bee

Re: Super Super Bee

Controlliner wrote:took a super bee tank and turned it down with the same grove and tongue fit as the original tank and back plate set. the venturi extension is from 6061 t6 bar stock. Intake ID is drilled a #43 drill.

That is quite nice work there! I'm familiar with that Kavan tank-extender. Given an existing 8cc tank..

how were you able to obtain 2-56 case-screws that were long enough? Did you use couplers with threaded-rod? That method would likely make the screws captive to the backplate. Not a bad thing. Are the screw-heads the stock slotted-Fillister.. or did you opt for a different head-config./mat'l.?

how were you able to obtain 2-56 case-screws that were long enough? Did you use couplers with threaded-rod? That method would likely make the screws captive to the backplate. Not a bad thing. Are the screw-heads the stock slotted-Fillister.. or did you opt for a different head-config./mat'l.? I would guess the venturi-extension only .. to be drilled to an .089" ID.?? Is there a gasket used at the juncture of the tubes? Maybe I'm seeing it all wrong.. sorry if so. Is there a taper or relief-radius where the two tubes would connect? I'm unsure as to your engines' venturi-size prior to re-work, but I'd say it was at maximum; .082". Any larger than that.. and fuel-feed issues can arise if using a standard suction-feed.. or so I've read. Your engine obviously doesn't suffer from those issues; yielding such long runs! Kudos to you.. for making everything airtight... Heck.. maybe you can run a larger ID venturi tube in a Bee.. if the tube is lengthened? That might make physical-sense.

Easy experiment; the Bee's Air-intake is on-center with all mount-holes in the backplate. Make a test plywood-firewall/bench-mount.. and mark/drill holes to mount the backplate.. plus a "center hole" for your air-tube. Face the firewall with 1/8" thick closed-cell foam padding.. and locate/pierce all the holes with an awl. Install your "extended venturi-tube through the firewall/foam.. then mount the engine. The foam-pad will fill/obstruct the "V-shape" stock air-intake passage in the backplate-casting.. the air-tube will self-center.. and the engine will suck-air through the tube-dia./length that you provide. The little screen can be popped-out with a sewing-needle for when you drill-out the backlplates' air-hole. This could make for some interesting tests.. and also be non-destructive to stock-operation; utilizing a short-length/stock-size air-intake. Document it with your engine-running files.. same as you would for a given propeller; cylinder #/porting, shims, SPI/non-SPI, plug-type/compression-shims, head or insert.. heat-range.. reed-type/retainer, fuel feed-line size/orientation-position... and whatever-else you figure can vary. Weather..

I love this stuff..! I'm a big fan of "make it your own".

In closing.. I'd like to bring-up the CEF Tach-race. I need to read the rules concerning Bee-class engines.. and see if there's a modified-class. The hop-up mentioned above would require mailing the entry-engine mounted to a firewall containing the air-tube.

One last query; ...............

I'm sorry.. I have a bad habit or thinking too-far "outside the box"... but putting my foot in my mouth even further; there's a Cox .049 endurance/duration thread lurking recently. If C/L flying a Cox .049 for 9-10 minutes doesn't phase you.. you might like the conversation!

Here's the thread..

https://www.coxengineforum.com/t10172-cox-049-endurance-record

Re: Super Super Bee

Re: Super Super Bee

The 2X56 tank screws are from a piece of CC130 Avionics, they were just the right length. The screws are slotted.

The venturi is drilled all the way through with a #43 drill. The venturi extension is machined male on one end and female on the other end with the exact dimensions as the tank and tank back respectively. I use two OEM "O" rings to seal each end as you would expect. The tank extension is between the original Super Bee tank and the backplate. The joints are sealed with epoxy as this is impervious to any nitro content in glow fuel. This alleviates any leaks in the usual areas. The Reed is the .001 beryllium OEM reed. The fuel pickup is on the bottom for R/C use. I could use this for Ukie but the nose moment will be pretty long and balance is pretty hard to achieve.

The venturi is drilled all the way through with a #43 drill. The venturi extension is machined male on one end and female on the other end with the exact dimensions as the tank and tank back respectively. I use two OEM "O" rings to seal each end as you would expect. The tank extension is between the original Super Bee tank and the backplate. The joints are sealed with epoxy as this is impervious to any nitro content in glow fuel. This alleviates any leaks in the usual areas. The Reed is the .001 beryllium OEM reed. The fuel pickup is on the bottom for R/C use. I could use this for Ukie but the nose moment will be pretty long and balance is pretty hard to achieve.

Controlliner- Bronze Member

- Posts : 34

Join date : 2016-08-24

Location : Canada

Re: Super Super Bee

Re: Super Super Bee

Thanks for the info.! So.. the "extension-tube" is removable with the backplate, for changing the inner O-ring if needed? That's pretty cool.

Re: Super Super Bee

Re: Super Super Bee

roddie wrote:Thanks for the info.! So.. the "extension-tube" is removable with the backplate, for changing the inner O-ring if needed? That's pretty cool.

I took the liberty of borrowing Overlord's picture of a Kavan tank extension kit. The Kavan kit also came with an extra O-ring and longer tank screws (which by the way are just a bit longer than "ordinary" Cox 8cc tank screws so beware). Anyway, this pic may clarify the idea.

[/quote]

[/quote]

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Super Super Bee

Re: Super Super Bee

I recently acquired a new aluminium tank extension. I suppose it was also made by Kavan as it has the same length as the plastic extensions, but I'm not sure. Unfortunately, I got only 2 bolts with it.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Super Super Bee

Re: Super Super Bee

I wasn't even aware that such a kit existed in aluminum. Anyway, Lieven, many of my Babe Bees have come with a tank extension, so if you want some extra screws, I can send you a set. Just pm me your address and give me a few days

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Super Super Bee

Re: Super Super Bee

Me neither. I knew there were black and red ones but not aluminum. Mine is about .125 longer than the Kavan one. I like the way the extensions are plastic and they seal well but I never liked the way they would bulge, always afraid they would crack.

Controlliner- Bronze Member

- Posts : 34

Join date : 2016-08-24

Location : Canada

Re: Super Super Bee

Re: Super Super Bee

The early versions from Kavan were aluminum. I tried them and was never satisfied with using them. I found it very difficult to keep the screws tight as they needed constant attention. The engine would rotate, leak, etc. I found it much easier to provide a external tank via production backplate or drilling a hole in the side of a tank.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Super Super Bee

Re: Super Super Bee

Curious if you happened to gage the length of the extension-tank to those 2-56 screws from the avionics unit? The stock Bee case-screws have a "Fillister" head. That type screw-head might help to torque-seal the Mazak backplate. I'd like to find Allen-head screws to fit. They may protrude.. but one could always shim between the firewall/backplate.. plus providing for more air into the engine. With your .089" venturi-diameter, you might need more air than the slot in the backplate can ultimately provide. Then there's the question (running flush to the firewall) of whether you're taking full-advantage of enlarging the venturi. More air-flow from the firewall could necessitate a pressure-feed. Another non-SWAG on my part  is that you're possibly seeing an increase in flow-velocity by using a longer tube; albeit of a larger diameter.

is that you're possibly seeing an increase in flow-velocity by using a longer tube; albeit of a larger diameter.

I tried making a simple bench-dyno.. using a digital luggage-scale and floating engine-mount for a small 1 gal. water-tub. It allowed for a baseline static-measurement of power... once the engine was in "tractor-mode"..

These vids are purely for entertainment purposes only..

https://www.youtube.com/watch?v=Fb-j6yjqfXk

https://www.youtube.com/watch?v=Gcj3yjUSdr4

Below is page "two" of a thread I started for building engine-dynos. It Segues from a "beam-style" to the buoyant-design.

https://www.coxengineforum.com/t6212p25-dynomometer-build-for-air-screws?highlight=a+dynomometer

The stock engine averaged 12.5K on that prop and pulled 5oz. dead-weight. I haven't tested any other combinations yet.. but I made alternate-mounts for radial vs. beam mounting. All are a straight/level pull on the scale.

It was a cheap and interesting project.. but was met with a good degree of criticism.

I tried making a simple bench-dyno.. using a digital luggage-scale and floating engine-mount for a small 1 gal. water-tub. It allowed for a baseline static-measurement of power... once the engine was in "tractor-mode"..

These vids are purely for entertainment purposes only..

https://www.youtube.com/watch?v=Fb-j6yjqfXk

https://www.youtube.com/watch?v=Gcj3yjUSdr4

Below is page "two" of a thread I started for building engine-dynos. It Segues from a "beam-style" to the buoyant-design.

https://www.coxengineforum.com/t6212p25-dynomometer-build-for-air-screws?highlight=a+dynomometer

The stock engine averaged 12.5K on that prop and pulled 5oz. dead-weight. I haven't tested any other combinations yet.. but I made alternate-mounts for radial vs. beam mounting. All are a straight/level pull on the scale.

It was a cheap and interesting project.. but was met with a good degree of criticism.

Similar topics

Similar topics» Super Cub 150

» Old Bee from Super Cub 105

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (October 2016)

» *Cox Engine of The Month* Submit your pictures! -November 2016-

» Super Bee 049

» Old Bee from Super Cub 105

» **VOTE-ON-THE-NEXT-COX-ENGINE-OF-THE-MONTH** (October 2016)

» *Cox Engine of The Month* Submit your pictures! -November 2016-

» Super Bee 049

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules