Log in

Search

Latest topics

» Did you spot the Cox engine in this NASA research video?by balogh Today at 5:08 pm

» Roger Harris revisited

by rsv1cox Today at 3:44 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 2:54 pm

» Happy 77th birthday Andrew!

by Admin Today at 12:34 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

Cox Engine of The Month

spider wire for 1/2A's

Page 1 of 1

spider wire for 1/2A's

spider wire for 1/2A's

For those of you who use a fishing lines as lines to fly our 1/2A's.Would this be a line that one could use?

Thanks guy's.

http://www.ebay.com/itm/Hercules-Fluorescent-Yellow-Green-Spectra-PE-Dyneema-10-100LB-Braid-Fishing-Line-/231774435976?var=&hash=item35f6d53a88:m:mBGV0TyIZUZh6AXqGUB5Wcw

Thanks guy's.

http://www.ebay.com/itm/Hercules-Fluorescent-Yellow-Green-Spectra-PE-Dyneema-10-100LB-Braid-Fishing-Line-/231774435976?var=&hash=item35f6d53a88:m:mBGV0TyIZUZh6AXqGUB5Wcw

oldguy- Gold Member

- Posts : 368

Join date : 2015-12-10

Age : 70

Location : Idaho

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

I do not know the source of the listed post but the local (Academy/Cabellas/ Dick's Sporting, and even my Wally World) fishing supply had the high vis yellow I desired in 10 and 20 pound for pretty cheap as I recall

NOT all spider wire is the same...the China knock off is suspect and a lot has been written in these forums

ON the other hand it is 1/2A you are asking about

so I doubt a knock of china brand at 35~42 feet would been any real problem as long as we are NOT talking a speed 100+MPH plane

NOT all spider wire is the same...the China knock off is suspect and a lot has been written in these forums

ON the other hand it is 1/2A you are asking about

so I doubt a knock of china brand at 35~42 feet would been any real problem as long as we are NOT talking a speed 100+MPH plane

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

fredvon4 wrote:I do not know the source of the listed post but the local (Academy/Cabellas/ Dick's Sporting, and even my Wally World) fishing supply had the high vis yellow I desired in 10 and 20 pound for pretty cheap as I recall

NOT all spider wire is the same...the China knock off is suspect and a lot has been written in these forums

ON the other hand it is 1/2A you are asking about

so I doubt a knock of china brand at 35~42 feet would been any real problem as long as we are NOT talking a speed 100+MPH plane

No we are talking just your run of the mill 1/2A's.Maybe a lil satan or something similar to that.I was at wally world the other day checking out their [bleep] and they only had green.So better off sticking to spider wire I quess. I wonder if the spider wire is made in china.

oldguy- Gold Member

- Posts : 368

Join date : 2015-12-10

Age : 70

Location : Idaho

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

oldguy wrote:fredvon4 wrote:I do not know the source of the listed post but the local (Academy/Cabellas/ Dick's Sporting, and even my Wally World) fishing supply had the high vis yellow I desired in 10 and 20 pound for pretty cheap as I recall

NOT all spider wire is the same...the China knock off is suspect and a lot has been written in these forums

ON the other hand it is 1/2A you are asking about

so I doubt a knock of china brand at 35~42 feet would been any real problem as long as we are NOT talking a speed 100+MPH plane

No we are talking just your run of the mill 1/2A's.Maybe a lil satan or something similar to that.I was at wally world the other day checking out their [bleep] and they only had green.So better off sticking to spider wire I quess. I wonder if the spider wire is made in china.

All of my Walmart stuff, yellow or green, says 'Made in USA'...

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

I go stealth and Berkley's and they are made here , I think I would just stick with the local , we probably sent the stuff over there and they F^ed it up and sent it back . The stuff I got was more expensive !! even if it does say dyneema I would bee leery of the longevities , just my  getback

getback

getback

getback

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

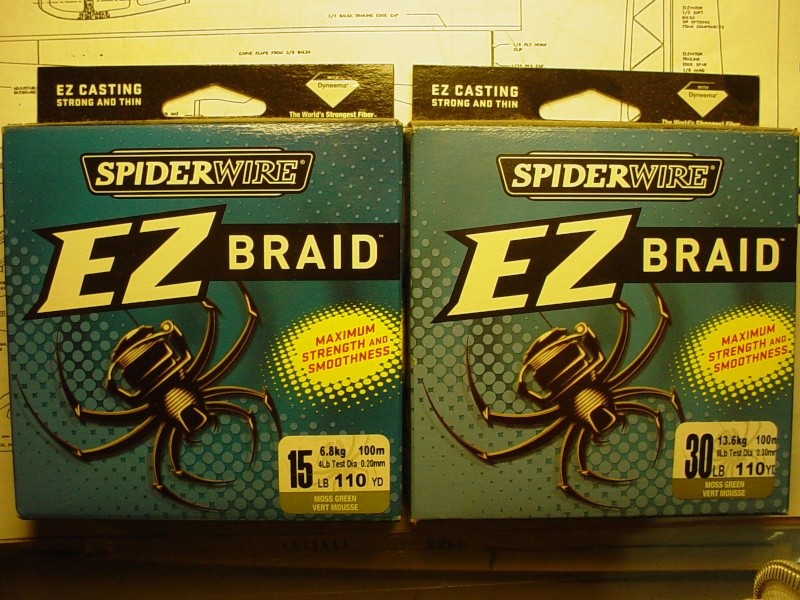

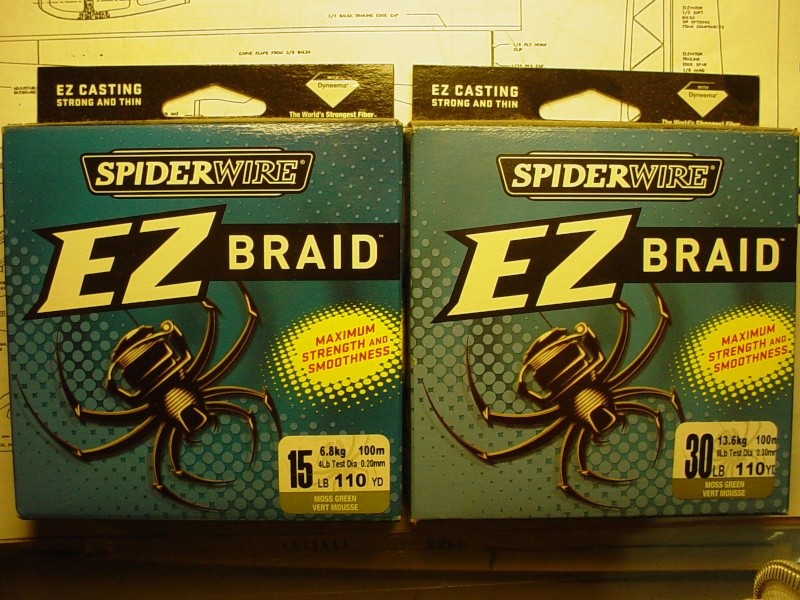

My 15# SpiderWire is made in the USA and has a Dyneema-braid dia. of 0.2mm (.008") I bought mine at Walmart. It's moss-green.. but I'll deal with it.

I made-up a set of 42' lines from the 30# reel when I built my reed-speed model. It was probably overkill.. but the tiny model weighs 7.2oz. I didn't want to risk it.. and haven't... because it hasn't flown yet. oh well.. maybe this year.

oh well.. maybe this year.

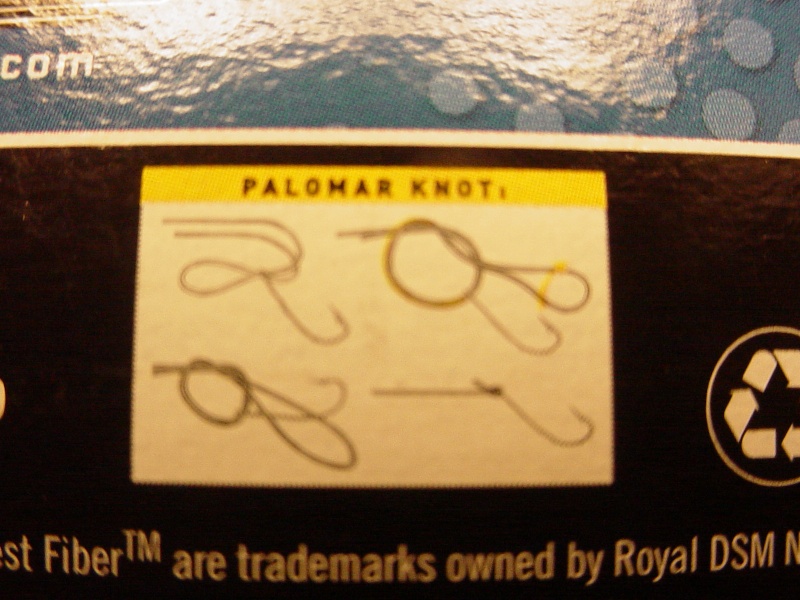

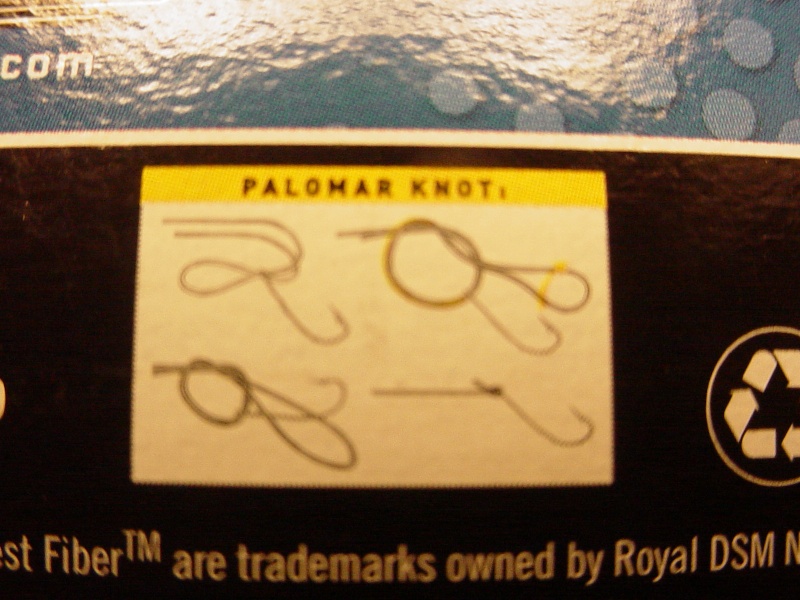

The SpiderWire references a "Palomar" knot to be used.

I'm not an angler.. so I had to learn to tie the knot. The AMA recommends a 5-turn "uni-knot" for this type of line.. so that's the knot I used.

I made-up a set of 42' lines from the 30# reel when I built my reed-speed model. It was probably overkill.. but the tiny model weighs 7.2oz. I didn't want to risk it.. and haven't... because it hasn't flown yet.

The SpiderWire references a "Palomar" knot to be used.

I'm not an angler.. so I had to learn to tie the knot. The AMA recommends a 5-turn "uni-knot" for this type of line.. so that's the knot I used.

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

Oldguy, I thought about mail ordering in bulk, but I decided to just buy the 150 yard rolls locally as they are made in USA. There are a lot of things I don't buy if they are made in China. My basic rules are: Is it something ingested? Nope. Is it something electrical that would be unattended? Nope. Is it a safety related product (like our lines). Definitely nope. Other than that, I usually don't have a problem with Chinese stuff.

Roddie, when you say you use the 5-turn Uni knot, you mean a Double Uni knot, right? That's the AMA specification. Single Uni would probably work for 1/2A, but I've never tried it. I've always gone with the AMA recommendation.

The Safety Gadfly Mark

Roddie, when you say you use the 5-turn Uni knot, you mean a Double Uni knot, right? That's the AMA specification. Single Uni would probably work for 1/2A, but I've never tried it. I've always gone with the AMA recommendation.

The Safety Gadfly Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

Mark I think Roddie is right the Double Uni knot is for joining two lines https://www.google.com/search?q=double+uni+knot&biw=1280&bih=566&tbm=isch&imgil=827OkuEx984qAM%253A%253BDrMHXdjVRzuXAM%253Bhttp%25253A%25252F%25252Fwww.albacorelures.com%25252Fbest-fishing-knots-for-saltwater-anglers-videos%25252F&source=iu&pf=m&fir=827OkuEx984qAM%253A%252CDrMHXdjVRzuXAM%252C_&usg=___UEQiNUV833Oga47YU4cryXBE4E%3D&ved=0ahUKEwiU9NXW1tPLAhULdD4KHVwmDoUQyjcILQ&ei=qOfwVpSAKYvo-QHczLioCA#imgrc=827OkuEx984qAM%3A wow what a knot that is , May be you know something I don't I am not AMA cert. Roddie one of the Scout leaders on here told me about Palomar knot I like it and have had no probs. with it and can get closer to were I want it to end up  Eric

Eric

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

Just to clarify what I meant by other forum discussion of the China knock off of so called Spiderwire

UP front I think it would be OK for light 1/2a use but not for the larger planes

Several guys on SH or SSW pull tested the knock off stuff--- and it always breaks well before the rated load and not consistently

It also has much more stretch compared to the real stuff

Another note; you must wet the knot with water or spit to cinch it tight

ALSO do not use CA or other glues to "fix" the knot...most do not stick to it anyway and the glue can cause a section before the knot that will flex more and weaken that area

UP front I think it would be OK for light 1/2a use but not for the larger planes

Several guys on SH or SSW pull tested the knock off stuff--- and it always breaks well before the rated load and not consistently

It also has much more stretch compared to the real stuff

Another note; you must wet the knot with water or spit to cinch it tight

ALSO do not use CA or other glues to "fix" the knot...most do not stick to it anyway and the glue can cause a section before the knot that will flex more and weaken that area

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

I just wanted to throw in my experience if I may. About three years ago I made up a set of green 80#, 60' Spiderwire lines and not to brag but just to state, I know I must have at least 300 flights, if not more, on them with my myriad .35 and .40 sized planes .... Ringmasters, Sig Twister, Sig Banshee, Novi III, Flite Streak, Voodoo and Armageddon!! And although I give them, the lines, a quick inspection before each days flying, I have yet to detect any flaws or questionable nicks or fraying. I have been very pleased and all of the guys I fly with have helped me check/inspect the lines from time to time. As for the 1/2A's, I made up a set of yellow 32', 15# and 20# Power Pro lines both of which have performed very well, although I have no where as many flights on either set of them. In summary, I believe the Spiderwire lines are sound and acceptable as long as the line terminations are strong and sound and a reasonable effort to inspect them for any signs of failure is part of your checklist.

modelbuilder49- Gold Member

- Posts : 290

Join date : 2013-09-12

Age : 75

Location : Titusville Florida

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

My 2 cents. Spiderwire is not Spectra. Spectra is what AMA approved for use. PowerPro is the only line made from Spectra. If you want to be legal in case of an accident buy PowerPro. Dyneema stretches much more that Spectra. It's like flying a plane on rubberbands. I have been flying GSUMP lines for 5 years and have tried them ALL. PowerPro Spectra is the only way to go. I fly everything from 1/2A to Nelson .36 Fast Combat on PowerPro Spectra. I would not fly Dyneema on anything I own.

londke3- Gold Member

- Posts : 177

Join date : 2011-12-30

Age : 57

Location : nashville TN

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

This vid is a good example of how I tied my Spiderwire braided line. This tutorial is straight-forward. Note that threading the line through the eye "twice" doubles it's strength by spreading the load at the termination.. and saliva lubricates when cinching-up the knot.

https://www.youtube.com/watch?v=ZnHPxP2Ux3w

Here's how it came out using 30# braid (a little fuzzy.. sorry)

The trick is; making two equal-length lines as you tie your final knot.. Allow enough extra line to comfortably handle tying your finish lengths. I did this outdoors by sticking a push-pin through each line's line-connector into a heavy piece of wood to hold one end. Extend the completed-line and the reel (second line) out to the desired length and use another push-pin/wood-block to hold the completed-line taught. If you have limited space you can run the lines around a pole and back; cutting the distance in half.

It's time for another "Roddie" idea.. For 1/2A length lines; obtain a 2" x 6" x 8 foot piece of fir and some finish-nails; small enough to fit through the eye on your smallest line-connector. Install an upright evenly-spaced row of 4 nails at each end. There will probably be 95" inches or less between each end.. so after 5 loops around.. you're close to 40 feet. Use a chalk-line to mark the zigzag path of the line.. and pencil-in assorted measurements. 20, 25, 30, 35.. on up to 42 feet. If you're concerned with a tight-radius.. install larger dowels instead of the nails, for the line to go around. Use a push-pin to cinch-up the first completed-line with it's connector taught. You now have a reference for tying the second line. You only need to measure once when you build it. Install a couple of hooks on each end-side.. and hang it on the wall or from the ceiling for storage.

For 1/2A length lines; obtain a 2" x 6" x 8 foot piece of fir and some finish-nails; small enough to fit through the eye on your smallest line-connector. Install an upright evenly-spaced row of 4 nails at each end. There will probably be 95" inches or less between each end.. so after 5 loops around.. you're close to 40 feet. Use a chalk-line to mark the zigzag path of the line.. and pencil-in assorted measurements. 20, 25, 30, 35.. on up to 42 feet. If you're concerned with a tight-radius.. install larger dowels instead of the nails, for the line to go around. Use a push-pin to cinch-up the first completed-line with it's connector taught. You now have a reference for tying the second line. You only need to measure once when you build it. Install a couple of hooks on each end-side.. and hang it on the wall or from the ceiling for storage.

https://www.youtube.com/watch?v=ZnHPxP2Ux3w

Here's how it came out using 30# braid (a little fuzzy.. sorry)

The trick is; making two equal-length lines as you tie your final knot.. Allow enough extra line to comfortably handle tying your finish lengths. I did this outdoors by sticking a push-pin through each line's line-connector into a heavy piece of wood to hold one end. Extend the completed-line and the reel (second line) out to the desired length and use another push-pin/wood-block to hold the completed-line taught. If you have limited space you can run the lines around a pole and back; cutting the distance in half.

It's time for another "Roddie" idea..

For 1/2A length lines; obtain a 2" x 6" x 8 foot piece of fir and some finish-nails; small enough to fit through the eye on your smallest line-connector. Install an upright evenly-spaced row of 4 nails at each end. There will probably be 95" inches or less between each end.. so after 5 loops around.. you're close to 40 feet. Use a chalk-line to mark the zigzag path of the line.. and pencil-in assorted measurements. 20, 25, 30, 35.. on up to 42 feet. If you're concerned with a tight-radius.. install larger dowels instead of the nails, for the line to go around. Use a push-pin to cinch-up the first completed-line with it's connector taught. You now have a reference for tying the second line. You only need to measure once when you build it. Install a couple of hooks on each end-side.. and hang it on the wall or from the ceiling for storage.

For 1/2A length lines; obtain a 2" x 6" x 8 foot piece of fir and some finish-nails; small enough to fit through the eye on your smallest line-connector. Install an upright evenly-spaced row of 4 nails at each end. There will probably be 95" inches or less between each end.. so after 5 loops around.. you're close to 40 feet. Use a chalk-line to mark the zigzag path of the line.. and pencil-in assorted measurements. 20, 25, 30, 35.. on up to 42 feet. If you're concerned with a tight-radius.. install larger dowels instead of the nails, for the line to go around. Use a push-pin to cinch-up the first completed-line with it's connector taught. You now have a reference for tying the second line. You only need to measure once when you build it. Install a couple of hooks on each end-side.. and hang it on the wall or from the ceiling for storage. Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

Eric, not to be contentious, but the AMA Control Lines General Rules, section 5.3.5.1 on Spectra Lines says, "Terminations shall be constructed using a 5 turn uni-knot, tied on a bight, or two strands of line looped back from the free end. An instruction film of the knot can be found at www.youtube.com/watch?v=cGL2aD9q-cE."

The video here:

Even though the video doesn't show it, Fred is spot on. Make sure you wet the line before you draw the loop to tighten the knot. I just use a dollop of saliva to ease the friction as I pull it.

The Stickler Mark

The video here:

Even though the video doesn't show it, Fred is spot on. Make sure you wet the line before you draw the loop to tighten the knot. I just use a dollop of saliva to ease the friction as I pull it.

The Stickler Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

roddie wrote:

It's time for another "Roddie" idea..For 1/2A length lines; obtain a 2" x 6" x 8 foot piece of fir and some finish-nails; small enough to fit through the eye on your smallest line-connector. Install an upright evenly-spaced row of 4 nails at each end. There will probably be 95" inches or less between each end.. so after 5 loops around.. you're close to 40 feet. Use a chalk-line to mark the zigzag path of the line.. and pencil-in assorted measurements. 20, 25, 30, 35.. on up to 42 feet. If you're concerned with a tight-radius.. install larger dowels instead of the nails, for the line to go around. Use a push-pin to cinch-up the first completed-line with it's connector taught. You now have a reference for tying the second line. You only need to measure once when you build it. Install a couple of hooks on each end-side.. and hang it on the wall or from the ceiling for storage.

Roddie, this is a good idea, but I think it'd work better for me for steel cables than Spectra, as I never get my uni knots to terminate exactly the same length. I'm always about 1/4 to 1/2 inch off on one line. Plus, I'm too lazy. I just measure off the desired length X2 and then run it through a SIG or Cox handle with the slide adjustment.

But, years ago when I was taught to swage control cables on full size aircraft, my mentor had a table set up with pulleys at both ends and a large nail at one end. He'd take the original frayed cable and run it from the nail, snaking across the table on the pulleys, and where the original cable ended, he'd put a nail through the thimble to mark the total length. Then he'd swage one end of the new cable, route it through the pulleys, and then set up the other end thimble on the nail he just drove in. Perfect cables every time.

The Student Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

And, just so Y'all don't have to try and look up the AMA recommended Spectra lines, here's what's in the AMA handbook:

5.3.5.1 Spectra Lines

Lines made of Spectra fiber, made of gel spun ultra-high

molecular weight polyethylene are permitted for sport

flying and demonstration purposes. Spectra lines are not

permitted in competition unless the specific rules for the

event flown expressly permit such use. The use of high

visibility yellow lines is recommended, but not required.

For sport and demonstration flying with two lines, Spectra

lines shall have the following strengths:

Aircraft Engine Watts Rated

Weight Displ. Spectra St.

24 oz. .09 300 20 lbs. .010”

40 oz. .25 450 40 lbs. .013”

64 oz. .40 600 60 lbs. .016”

75 oz. .75 750 100 lbs. .018”

The Reference Mark

5.3.5.1 Spectra Lines

Lines made of Spectra fiber, made of gel spun ultra-high

molecular weight polyethylene are permitted for sport

flying and demonstration purposes. Spectra lines are not

permitted in competition unless the specific rules for the

event flown expressly permit such use. The use of high

visibility yellow lines is recommended, but not required.

For sport and demonstration flying with two lines, Spectra

lines shall have the following strengths:

Aircraft Engine Watts Rated

Weight Displ. Spectra St.

24 oz. .09 300 20 lbs. .010”

40 oz. .25 450 40 lbs. .013”

64 oz. .40 600 60 lbs. .016”

75 oz. .75 750 100 lbs. .018”

The Reference Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: spider wire for 1/2A's

Re: spider wire for 1/2A's

Well I wasn't meaning to ruffle any feathers but it seems that if you don't put the D on the end of double you end up with the pic I posted , I know the Double Uniknot is the preferred one .But its all good as lone as we know  At least did learn some thing about the difft. in the spiderwire and to lube the knot a little before pulling that I was not doing so I should give this some more credit . I didn't realize people were flying with this on much larger aircraft on stronger test line and thanks for the chart Mark. Eric

At least did learn some thing about the difft. in the spiderwire and to lube the knot a little before pulling that I was not doing so I should give this some more credit . I didn't realize people were flying with this on much larger aircraft on stronger test line and thanks for the chart Mark. Eric

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» Possible new and novel use for spider wire.

» Super PT-19 !! IT FLYS !!!!! (or, "How I Test the Tensile Strength of Spider Wire !!)

» Spider case

» [solved]most Efficent Glowhead Clip for Norvel Engine

» Sanwa servo connector conversion

» Super PT-19 !! IT FLYS !!!!! (or, "How I Test the Tensile Strength of Spider Wire !!)

» Spider case

» [solved]most Efficent Glowhead Clip for Norvel Engine

» Sanwa servo connector conversion

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules