Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

My Fancherized Twister build; 3 days til Huntersville

Page 2 of 10

Page 2 of 10 •  1, 2, 3, 4, 5, 6, 7, 8, 9, 10

1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

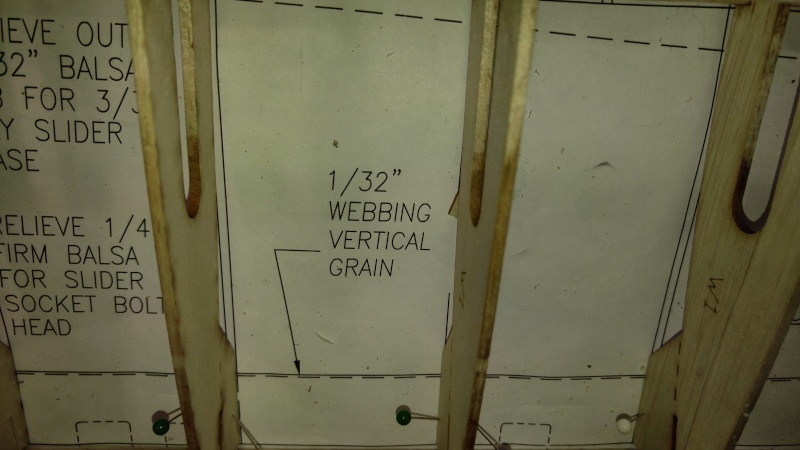

Here are those shear webs with the horizontal grain. What am I missing. did Walter Umland make a mistake?

That one is not installed, just fit in place for illustration.

Rusty

That one is not installed, just fit in place for illustration.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

I'm lost...are you saying the grain is suppose to be vertical? If so i'd think the grain running span wise would be a little stronger?

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Mark, shear webs trapped between the main spars or the TE sheets are supposed to be vertical grain to prevent compressing with load forces on the wing, keeping it from flexing up and down. They're less flexible in that direction. I'm pretty sure the back side of a D tube is the same way. They are most necessary between the first few ribs out from the root, and less so on the outer wing. Here's a good explanation. I refer to this site often.

http://www.airfieldmodels.com/information_source/math_and_science_of_model_aircraft/rc_aircraft_design/shear_webs_in_model_aircraft_wings.htm

http://www.airfieldmodels.com/information_source/math_and_science_of_model_aircraft/rc_aircraft_design/shear_webs_in_model_aircraft_wings.htm

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

ok, i've never built a wing with sheer webs on trailing edge and i guess could see it with compression being vertical grain.

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

The pieces are so narrow in width it makes little difference. Your only trying to prevent compression between the top and bottom sheeting on the trailing edge. I would think that Walter was faithful to the original design as he does a lot or research on his kits prior to cad. Walter is a real pleasure to talk to and I wouldn't hesitate to ask him any questions via e-mail. It certainly is looking good Rusty. It's a very nice kit and I'm glad to see it's going to get some air time. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Like Ken said the TE shear web span of 2.5 inches already laser cut using horizontal grain will do the job and save you a ton of time cutting and fitting vertical grain pieces

I am curious how the plywood jigs with all the pin holes in your first set of photos work..IE how are they used? What is the purpose of the bizzion pin holes? Looks like alignment guides of some sort

I am curious how the plywood jigs with all the pin holes in your first set of photos work..IE how are they used? What is the purpose of the bizzion pin holes? Looks like alignment guides of some sort

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

fredvon4 wrote:Like Ken said the TE shear web span of 2.5 inches already laser cut using horizontal grain will do the job and save you a ton of time cutting and fitting vertical grain pieces

I am curious how the plywood jigs with all the pin holes in your first set of photos work..IE how are they used? What is the purpose of the bizzion pin holes? Looks like alignment guides of some sort

I think I'll send Walter an e-mail. I forgot to mention this was written on the plans:

Fred, the pins are through the pair of jig tabs built onto each rib. the first thing I did was pinned the ribs to the plans with one pin in each of the front and rear tabs. Then I laid the top spar in the slots, and used one of the kit supplied ply right-angles to get the ribs all vertical. After I could take the square and check all the way down the line confirming the ribs were all square, I put a second pin in each tab to secure it and also pinned the rib to the spar. After it's finished, I'll break off the jig tabs.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Thanks Rusty but I am asking bout he Stab Alignment jigs (? hard to read) shown on photo #4 on the first page of this thread

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Oh, gotcha. I haven't quite figured them out yet, Usually when I align a wing's TE hinge line to the stab hinge line. I use a stick with index marks on it, tediously going back and forth ad-nauseum till I'm convinced it's straight. These are a more sophisticated example of that, but with no instructions, I won't know until I start getting close to that part of the project. When I know the answers, I'll make sure you'll know too.fredvon4 wrote:Thanks Rusty but I am asking bout he Stab Alignment jigs (? hard to read) shown on photo #4 on the first page of this thread

Now, then, regarding the TE webs. I just went to look at the box and plans for Walter's contact info, and realized the answer. It's another of my over-thought, too quick to shoot, dumbass questions. Upon closer thinking, the supplied webs are 1/16", twice the thickness of the plan's 1/32" reference. At twice the thickness, they'll be fine, I'm going to use the supplied webs.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

It doesn't look like much difference, but a lot of detailing has gone into it in the past few days. It seems as straight as balsa can be, and tonight I added the 1/4" x 3/8" balsa TE butt strip... or half of it. I was applying Elmer's wood glue and tacking it down with tape and pins, it became too unwieldy for me to handle neatly, so I took the razor saw and chopped half of it off to glue after the first one was set. If I don't go flying.

The forecast has changed to 19 mph winds, and that means well over 20 at the fort, so looking like a shop day Sunday. That's disappointing, I haven't flown since the week before Christmas, and I test ran the Oriental with its new head gaskets today. Next are the half-ribs, bellcrank assy and wingtips and it's done. The bellcrank and leadouts are already bushed and wrapped.

Rusty

Edit: Today, Sunday, I sanded to blend the TE joint. I then deviated from what I said was next and marked the hinge locations and a centerline along the TE and also on the flaps. And I took a tiny paint brush and painted some slightly thinned Elmers wood glue onto most of the joints that were previously CAd. I don't know if it added much, as I figured the hardened CA will prevent absorption, but it looks like it did soak in more than I expected, and filled minor gaps, of which there weren't many. This yellow Elmers seems like very good glue and looks cleaner than Titebond when it dries.

The forecast has changed to 19 mph winds, and that means well over 20 at the fort, so looking like a shop day Sunday. That's disappointing, I haven't flown since the week before Christmas, and I test ran the Oriental with its new head gaskets today. Next are the half-ribs, bellcrank assy and wingtips and it's done. The bellcrank and leadouts are already bushed and wrapped.

Rusty

Edit: Today, Sunday, I sanded to blend the TE joint. I then deviated from what I said was next and marked the hinge locations and a centerline along the TE and also on the flaps. And I took a tiny paint brush and painted some slightly thinned Elmers wood glue onto most of the joints that were previously CAd. I don't know if it added much, as I figured the hardened CA will prevent absorption, but it looks like it did soak in more than I expected, and filled minor gaps, of which there weren't many. This yellow Elmers seems like very good glue and looks cleaner than Titebond when it dries.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Earlier this week I got the weight box installed. Today I glued in the bellcrank. I added one extra 1/2" square to brace it to the lower spar on the inboard side. I'll also add a hardwood block to tie the top of the bolt to the top spar. It needs none of that, but it makes me feel better during pull tests. I also installed the leadout slider and the inboard 1/4" wingtip doubler.

Hanging from the leadouts

Hanging from the leadouts

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Rusty, I have to make a suggestion here. I wouldn't place any faith whatsoever in a single platform bellcrank. While it was the norm back in the day, this is a larger plane and it's going to be powered with more authority then a Fox .35 which it was designed for. I would seriously consider placing another piece of ply up above and use a decent grade allen socket head or a 1/8" music wire axle. I prefer the 1/8" music wire for that application and run it all the way through the sheeting encapsulating it with small discs of ply this way the bellcrank floats. While your platform will work, it's very prone to flexing and that can cause a control jam and a bent center pivot. Additionally, if you do use a single platform, fill in the bottom of the platform to the spar so that more glue area is provided to the bottom and your not relying on the inboard rib to take a side load. I would hate to see such a fine kit become destroyed like a fishbone due to lines getting slacked and a quick jerk. It happens and you've experienced those kind of forces. The wood in this kit is unlike conventional kit wood and while it's nice and light, it doesn't provide the same resistance to stress. I've bent more than my share of common steel bellcrank bolts and I refuse to use them for .35 and up especially the cheap quality crap that's offered today. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Yeoww.

In meager defence, I did use my own stainless steel bolt. And there is enough bolt on top to do as I mentioned, to tie it to the top spar ("I'll also add a hardwood block to tie the top of the bolt to the top spar."). What I had in mind is to use a 1/2" engine beam with a slot cut in it that will slide tightly over the bolt to keep the screw from flexing toward the side and rear. And it will be epoxied to the top spar, spanning the width of the rib bay. The 1/2" square block in pic #3, glued to the spar outside of the inboard side of the platform, is tall enough to brace the platform and epoxied to the bottom spar, so I feel like that's a big relief to the inboard rib. I hope you can picture what I'm describing. I'll post a picture when I've done it.

Rusty

In meager defence, I did use my own stainless steel bolt. And there is enough bolt on top to do as I mentioned, to tie it to the top spar ("I'll also add a hardwood block to tie the top of the bolt to the top spar."). What I had in mind is to use a 1/2" engine beam with a slot cut in it that will slide tightly over the bolt to keep the screw from flexing toward the side and rear. And it will be epoxied to the top spar, spanning the width of the rib bay. The 1/2" square block in pic #3, glued to the spar outside of the inboard side of the platform, is tall enough to brace the platform and epoxied to the bottom spar, so I feel like that's a big relief to the inboard rib. I hope you can picture what I'm describing. I'll post a picture when I've done it.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

I like this type of build! It's amazing how much strength is imparted, even with TE, by adding those shear webs!

ARUP- Gold Member

- Posts : 179

Join date : 2015-09-13

Location : Kentucky

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Yes, the shear webs keep that wing from flexing when the plane needs sudden lift, especially in square corners or those high speed pullouts like the wingover and hourglass.ARUP wrote:I like this type of build! It's amazing how much strength is imparted, even with TE, by adding those shear webs!

Getting back to Ken's concerns about the bellcrank platform strength. I hope what I've done will sufficiently tie the unit to both spars and prevent any trouble in a hard yank. Lets see what my friend and mentor think of this.

So, first I made this hard maple brace to capture the bolt end protruding from the top of the crank. Notice it has a brass tube fit into the cutout at one end. This brass will be JB Welded to both the hardwood bearer and around the protruding 5mm of the bolt tip.

Next the bearer is epoxied to the top spar. The connection to the spar should take on any forces to prevent any bending of the bolt in the event of a hard line yank.

The 1/8" ply platform sits on 1/4" rails that are epoxied to both the two center ribs and also to the bottom spar.

Also note the 1/2" brace outside the center bay. It is aligned with the edge of the platform and center of the pivot bolt. Any pulling force will be taken by that bearer's connection to the bottom spar to which it is epoxied.

Note: This picture was taken before the top brace was installed, but can also be seen in the above picture.

I believe this will work the same as if I had originally built it suspended.

Hope so.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Rusty, that certainly captures the load for the top of the bellcrank. I won't disagree with that. My concern initially was more on the underside of crank where the bolt penetrates the platform and the fact that there was a potential for the platform to roll out. It's always best to epoxy the pivot bolt in and secure it with a nut on the bellcrank side prior to installing the bellcrank. Unfortunately, unless the nut is real thin this can jack the bellcrank up too high. All in all, I think it's going to be very impressive and I hope it works well. ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

You mean like this?Ken Cook wrote: ...It's always best to epoxy the pivot bolt in and secure it with a nut on the bellcrank side prior to installing the bellcrank. Unfortunately, unless the nut is real thin this can jack the bellcrank up too high. All in all, I think it's going to be very impressive and I hope it works well. ken

Last edited by RknRusty on Tue Jan 19, 2016 2:37 pm; edited 1 time in total

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Smart ass... ken and I could not see this in your other pics

That said...grin

I think your solution is very good and should keep a oh crap moment from leaving you with a limp set of lines as the plane heads for down town Fort jackson

That said...grin

I think your solution is very good and should keep a oh crap moment from leaving you with a limp set of lines as the plane heads for down town Fort jackson

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Haha! Fred you made me laugh. I just gotta make sure and pull it in close to my chest if it gets away like that again. The last time it happened it was two months before I could use my damn shoulder again.

Rockin' Rusty

Rockin' Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Rusty I don't have the shoulder problems you do but had a combat plane take a mid air that did not kill it...however she flew directly across the circle and when came up tight pulled me off my feet on onto my chest ....I was so surprised that it took a few for me to get on my back and try to keep flying it....not too successfully cuz I needed to crash it and not decapitate the other fellow in the circle with the steel lines

Hoping you have a great 2016 stunting and occasionally playing with a real airplane (combat)...grin

Hoping you have a great 2016 stunting and occasionally playing with a real airplane (combat)...grin

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Man that was quite a jerk. Mine didn't make me fall, though everybody thought so. I just crumpled after it hit the ground.fredvon4 wrote:Rusty I don't have the shoulder problems you do but had a combat plane take a mid air that did not kill it...however she flew directly across the circle and when came up tight pulled me off my feet on onto my chest ....I was so surprised that it took a few for me to get on my back and try to keep flying it....not too successfully cuz I needed to crash it and not decapitate the other fellow in the circle with the steel lines

Hoping you have a great 2016 stunting and occasionally playing with a real airplane (combat)...grin

I took my little gladiator out to play not too long ago. I was surprised, I kept it in the air for a whole bladder full. All I can do is keep it turning though, I need to narrow my handle width so I can tame it enough to fly it where I want it to go. I haven't tried flying with a streamer, that might make it easier.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

I took a break. It was too cold for work in the shop, but this week I finally decided to button up the wing, and cut the center sheeting. It's done, save for painting the flaps, but that can wait til the plane is almost finished. Waiting for the next pay cycle to get a roll of Jet White Monokote. I test fit the wing in the fuselage and it's better than any one I've ever done. This is such a nice kit, thanks Walter Umland if you're out there reading this Lol. Probably not, but I told him as much on the phone.

I'm switching to rattlecan Duplicolor paint from NAPA for the Twister. They have a large selection. I'm using Duplicolor DC 540 primer from NAPA, since it's been recommended by Wayne and Will, plus many at Stunthangar... and DC Acrylic Lacquer colors( I think... But I'll let y'all know for sure when I buy them... not Acrylic Enamel) I already have the primer. A friend, John Tate of the Norfolk Aeromodelers has used Lustrekote on top of DC with good results until he started buying cans with poor spitty sprayers and quit. The LK I have now doesn't have that problem. The DC clear is not as fuelproof as the Lustrekote, however the colors are as fuel resistant as Rustoleum, so in a pinch, you could skip the clear, as I've done with Rusto.

EDIT: DC acrylic lacquer is NOT fuel resistant. It will need clear for this.

Here's are questions:

The Twister's fuselage is covered with ultra light fiberglass. I can not look at it and see or feel any fabric weave, and I am expecting the primer will ensure that it's filled and smooth. If not, I'll have to sand the primer back off and dope it with talc. Anyone know if talc and Aerogloss clear will work as a filler... and then re-prime and sand over that? Might that blow up the paint? Alternatively I could use Polycrylic and filler but it's a bit heavy, at least before sanding. But you can paint anything on top of it.

Let's just hope the fiberglass stays invisible, so I can simply apply it, sand it, and spray on the colors. Simple as that.

Here's to hoping.

Rattlecan Rusty

I'm switching to rattlecan Duplicolor paint from NAPA for the Twister. They have a large selection. I'm using Duplicolor DC 540 primer from NAPA, since it's been recommended by Wayne and Will, plus many at Stunthangar... and DC Acrylic Lacquer colors( I think... But I'll let y'all know for sure when I buy them... not Acrylic Enamel) I already have the primer. A friend, John Tate of the Norfolk Aeromodelers has used Lustrekote on top of DC with good results until he started buying cans with poor spitty sprayers and quit. The LK I have now doesn't have that problem. The DC clear is not as fuelproof as the Lustrekote, however the colors are as fuel resistant as Rustoleum, so in a pinch, you could skip the clear, as I've done with Rusto.

EDIT: DC acrylic lacquer is NOT fuel resistant. It will need clear for this.

Here's are questions:

The Twister's fuselage is covered with ultra light fiberglass. I can not look at it and see or feel any fabric weave, and I am expecting the primer will ensure that it's filled and smooth. If not, I'll have to sand the primer back off and dope it with talc. Anyone know if talc and Aerogloss clear will work as a filler... and then re-prime and sand over that? Might that blow up the paint? Alternatively I could use Polycrylic and filler but it's a bit heavy, at least before sanding. But you can paint anything on top of it.

Let's just hope the fiberglass stays invisible, so I can simply apply it, sand it, and spray on the colors. Simple as that.

Here's to hoping.

Rattlecan Rusty

Last edited by RknRusty on Wed Jul 13, 2016 10:48 pm; edited 1 time in total

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

My personal feelings would be to take Aerogloss out of the picture entirely. It has too many incompatibility issues associated with using it. I've seen many planes where the fiberglass was set in Polycrylic followed with 1-2 additional coats followed by primer. That's how Allan Brickhouse finished many planes. Apply the primer lightly, scuff sand with a scuff pad between coats. Lightly build up your coats or the stuff will never dry and it will also shrink. Only put enough primer so that when you do wet sand, you take it down to the glass and stop. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

Yeah, that's what I thought, but since I have some Aerogloss, I figured I'd ask. Not much survives exposure to MEK.Ken Cook wrote:My personal feelings would be to take Aerogloss out of the picture entirely. It has too many incompatibility issues associated with using it...

That's actually such a dumb question I wish I could un-write it.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Fancherized Twister build; 3 days til Huntersville

Re: My Fancherized Twister build; 3 days til Huntersville

OK, greenie for making me laugh on that one RustyRknRusty wrote:Yeah, that's what I thought, but since I have some Aerogloss, I figured I'd ask. Not much survives exposure to MEK.Ken Cook wrote:My personal feelings would be to take Aerogloss out of the picture entirely. It has too many incompatibility issues associated with using it...

That's actually such a dumb question I wish I could un-write it.

Rusty

akjgardner- Diamond Member

Posts : 1602

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Page 2 of 10 •  1, 2, 3, 4, 5, 6, 7, 8, 9, 10

1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Similar topics

Similar topics» "Fancherized" Twister build

» Some Days are Diamonds...Some Days are Stone...

» Guillows Cessna 150 build circa 1970 (Build Log)

» Twister on ebay

» Sig Twister, My First Big Bird

» Some Days are Diamonds...Some Days are Stone...

» Guillows Cessna 150 build circa 1970 (Build Log)

» Twister on ebay

» Sig Twister, My First Big Bird

Page 2 of 10

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules