Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 5:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 5:18 am

» My N-1R build log

by roddie Today at 1:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 1:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 10:43 pm

» Landing-gear tips

by roddie Yesterday at 7:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 3:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 2:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 2:37 pm

» My latest doodle...

by roddie Yesterday at 11:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 2:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 10:24 am

Cox Engine of The Month

Broken nose, all fixed... Final Installment(s)

Page 3 of 5

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

I think , The little Miss me Not .... I hope you can get some more fun out of it Rusty but if it were me I would be preparing some thing else for the event just my 2$ and ever body has got one. If you get it going in time I am seeing some trimming in the future and you may run out of time before you can Get R Done . No since in putting pressure on your self if you don't have too  Eric

Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Words of wisdom, Eric. I'm becoming aware of that too slowly. It all looks so simple until I get into the details and minimal shop time. I'm down to bolting a 25fp on my Shoestring as a backup plane. You may not even know that one, since it's been so long. It was my first Beginner contest plane.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Mark your calendars, Folks. This may be the only time you hear this from me...

"Sorry Rusty, I got nothing."

The Unhelpful Mark

"Sorry Rusty, I got nothing."

The Unhelpful Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

That's okay, Mark. Just knowing you're watching helps. I love an audience, Lol.batjac wrote:Mark your calendars, Folks. This may be the only time you hear this from me...

"Sorry Rusty, I got nothing."

The Unhelpful Mark

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Don't panic, your going to get it in the air.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

RknRusty wrote:Roddie, your first idea is a good one, Lol. If... the plane wasn't on its last crash, I would put a 1/2oz smaller BH-560 tank in it and get a smaller venturi and go through the engine trimming routine. But this combo is already tuned, and the plane has one wheel in the slag heap, so, you get my drift. I also have no idea if I'll fly it better than the Nobler by Sunday, Oct. 25 at 9:45am. However my fabulous friend Ken is offering to bail me out, so I'm going to take advantage of his generosity... again.

As for your second idea, a Roddimus Prime Classic for sure. But, nnnnnI think I'll just go wit wut I got. Dude, I'd brainstorm with you any time, just don't expect me to keep up.

Rusty

Ha Ha! Yes.. I often think way too far outside the box with crazy s#*t... but that's my job here..

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

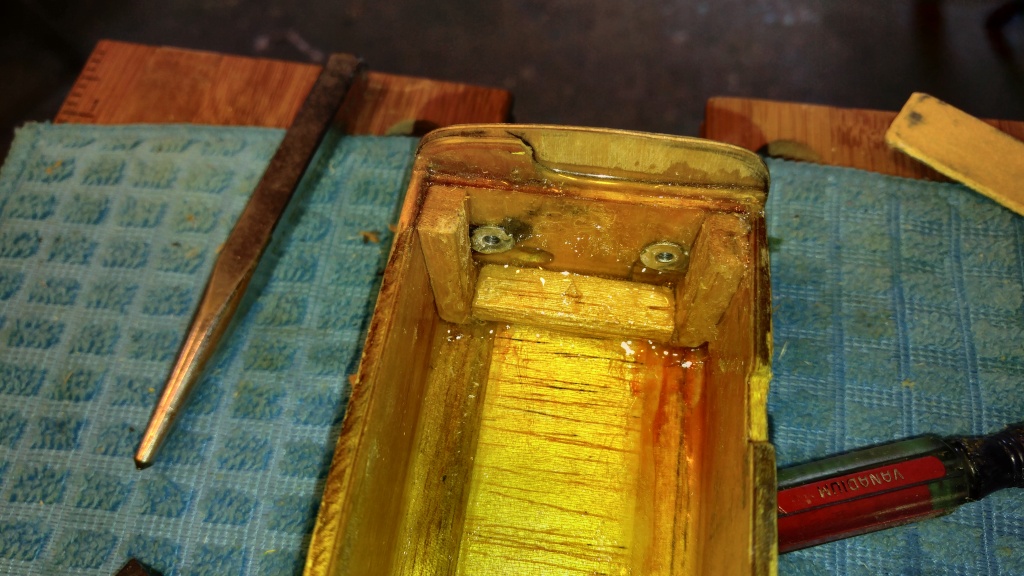

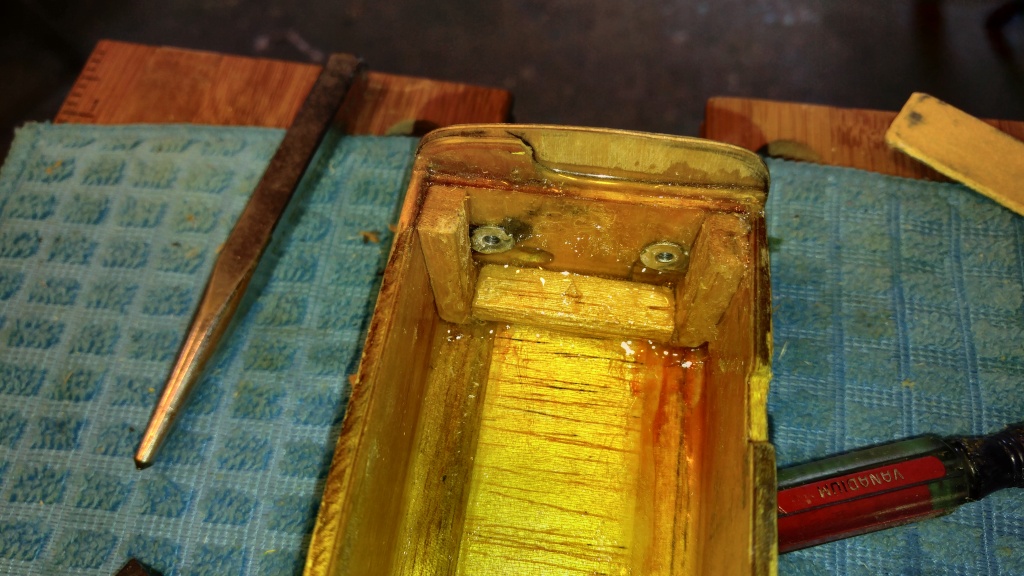

Rusty, I did some searching and found this. Indeed a 5 oz. uniflow. This has the overflow exiting just outside the fuse. This indeed would require a simple notch in the fuse followed by small rat tail to give it a nice round finish. This will fit the Oriental perfectly. However, based on our conversation, the fill pipe needs to be bent over 45 deg. I took a few pics. It's yours. I can bend the tubing as required. Remember to send me your address. Ken

Here's Dennis's Oriental I mentioned. I may just fly this in Huntersville. I haven't flown it with this engine in it yet. I personally and still may, move the tank forward and shorten the pickup line as short as possible. I don't like the long pickup line, but I flew it with other engines in it and it worked fine. This Oriental has had about 6 different powerplants.

The one pic is blurry but you get the idea. Put a jump up in the uniflow tubing or a loop in it to prevent siphoning.

Here's Dennis's Oriental I mentioned. I may just fly this in Huntersville. I haven't flown it with this engine in it yet. I personally and still may, move the tank forward and shorten the pickup line as short as possible. I don't like the long pickup line, but I flew it with other engines in it and it worked fine. This Oriental has had about 6 different powerplants.

The one pic is blurry but you get the idea. Put a jump up in the uniflow tubing or a loop in it to prevent siphoning.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Ken, Dude! If you were any prettier I'd kiss you!... well, maybe not, but thanks, I just came in from the shop. My Weller 325/400 was not covering enough area, and my big torch was too much. I was going to hit Lowes in the morning and get one of the soldering torches, as my old one finally got leaky. I did get the backplate off and it looks nice and clean inside, but I stopped there for now. It will be a more leisure project now. And now I have time to fix the stressed out LG on the Nobler before Sunday AM when we go out to fly.

I'll start putting the Monokote on it while I wait on the US Post Office.

Boy, I feel better now. PM on the way.

Rusty

I'll start putting the Monokote on it while I wait on the US Post Office.

Boy, I feel better now. PM on the way.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

You could always fly one of your bladder fed 1/2a Flite Streaks as a 3rd plan. They can do the pattern, they can carry enough fuel, all you need is a wheel for take off and landing.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Hey, there's an idea. I'd have to do 4 laps between stunts to give the judges time to score me. And last Christmas, Ken set me up with a bladder kit for the Shoestring's Thunder Tiger, I could blaze the circle with that too, Lol.pkrankow wrote:You could always fly one of your bladder fed 1/2a Flite Streaks as a 3rd plan. They can do the pattern, they can carry enough fuel, all you need is a wheel for take off and landing.

Phil

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

I took the tank apart, as usual I'm not satisfied with what I see. I removed the fuel pick up tube. The uniflow is soldered and is integrated onto the pickup. This is where things become tricky. I use a propane torch to open the tank backs and to unsolder. This is tricky at best for several reasons. This tank still had residual fuel in it. It does catch fire and the problem with doing so is the internal gasses expand so rapidly, it pops the tank back off usually splattering you with solder and fuel. I can't stress enough to wear safety glasses and gloves. You just can't get it all out. So when one suggests for you to do this on a stove top, your going to make a mess and your wife is going to say words to you that you never thought she knew. I annealed the first 1" of the tubing where it exits and enters the tank. This allows the bend into a 45 deg angle with minimal effort. This tank is a Brodak tank, to my surprise however it does indeed have a locked and rolled seam. This is not typical to a new tank you would buy today. This is a tank I purchased from John more than 15 years ago. The overflow pipe is not to the top of the tank ceiling. It's short about 1/8". This means that while the tank has a 5 oz. capacity, your not using the entire tank due to a airspace. I tried to bend it, but the way things are soldered internally it left for little movement, but I was able to achieve some. To unsolder this joint would more than likely demand taking the entire tank apart due to the amount of solder used and the heat required to separate. This would cause a leak in the locked seam without a doubt. So the tank is now currently taken apart, the internals need to be cleaned and free of any residual solder balls left from the heating process and all existing solder joints need to be cleaned and tinned prior to assembly. I will get back to assembling this evening. I believe this is what were looking for. Ken

The burnishing you see on the tank is from a wire wheel. These tanks and many of the new ones you receive are coated in clear lacquer. The only reasoning for this is rust prevention and to make anyone who solders it extremely hot headed. This is a real pain to get off. Once heated it will contaminate the solder joint usually resulting in a leak. It's more troublesome to remove it then it is to fix the tank itself. When wire wheeling it, it moves around rather than come off. I re solder every joint on the tank. In addition, I cut back the clear coat much further than the joint to prevent any contamination when resoldering. It's as if it just melts and I feel my description of burnishing better describes what happens to it when it is wire wheeled. Rusty, I will get this out to you ASAP when I get it boxed up. Just some FYI the exiting pickup is dead soft now so if more of a bend is requires it could be done with little finger pressure. Ken

The burnishing you see on the tank is from a wire wheel. These tanks and many of the new ones you receive are coated in clear lacquer. The only reasoning for this is rust prevention and to make anyone who solders it extremely hot headed. This is a real pain to get off. Once heated it will contaminate the solder joint usually resulting in a leak. It's more troublesome to remove it then it is to fix the tank itself. When wire wheeling it, it moves around rather than come off. I re solder every joint on the tank. In addition, I cut back the clear coat much further than the joint to prevent any contamination when resoldering. It's as if it just melts and I feel my description of burnishing better describes what happens to it when it is wire wheeled. Rusty, I will get this out to you ASAP when I get it boxed up. Just some FYI the exiting pickup is dead soft now so if more of a bend is requires it could be done with little finger pressure. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

That looks great, Ke. When I took the back off of mine, the vent is a big 8th inch from the top too, so I woun't even notice a difference.

Thanks very much for your help. I'll be Monokoting and finishing all the other details.

Rusty

Thanks very much for your help. I'll be Monokoting and finishing all the other details.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

It's good to see that it's coming back together man looks great! I wish I could help ya too it's just metal hard tanks are not my forte at least not yet anyway. I can set one up but taking one apart I haven't done yet. That is coming though since I have a brand new Brodak 4 oz that failed the pressure test and has slag rattling around inside so it's got to come apart. It's for my twister which I will be starting on soon after I get my dad's ringmaster done. (Bandit)RknRusty wrote:That looks great, Ke. When I took the back off of mine, the vent is a big 8th inch from the top too, so I woun't even notice a difference.

Thanks very much for your help. I'll be Monokoting and finishing all the other details.

Rusty

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

TDbandit wrote:It's good to see that it's coming back together man looks great! I wish I could help ya too it's just metal hard tanks are not my forte at least not yet anyway. I can set one up but taking one apart I haven't done yet. That is coming though since I have a brand new Brodak 4 oz that failed the pressure test and has slag rattling around inside so it's got to come apart. It's for my twister which I will be starting on soon after I get my dad's ringmaster done. (Bandit)RknRusty wrote:That looks great, Ke. When I took the back off of mine, the vent is a big 8th inch from the top too, so I woun't even notice a difference.

Thanks very much for your help. I'll be Monokoting and finishing all the other details.

Rusty

Yea.. it takes patience to solder. Preparation is everything. One thing I learned (through my limited experience) is to make sure that any holding-fixtures/clamps/wedges etc.. won't "sink" heat away from the work. I learned this when trying to tack the feed and uni-flow tubes to the inside lower-rear corner of my 1st tiny speed tank. I had tried to use an alligator-clip to hold the tubes in position.. bad idea. I thought something was wrong with my iron. The paste-flux was sizzling and flowing.. but the solder wasn't melting. A small wooden wedge/plug to hold the tubes in position, made a night and day difference. I was only using a small (sub 30W) pencil iron.. but it worked fine once I figured that out. I since made a little wooden jig/clamp.. but haven't tried it yet.

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Aside from gaining experience taking the tank apart and fixing it, a quick phone call to John might be helpful. He typically makes good on any products your dissatisfied with. Personally. I like to know exactly what is going on inside the tank and I take them all apart. If your suggesting that your hearing stuff inside, it could be cold solder slag or corrosion. Regardless, both are not good . It also suggests to me that all of the joints should be inspected for either cold or failed joints. GRW currently makes the best commercially purchased tanks. I felt when Glen Wells owned GRW tanks the quality was much higher. I've been heading more and more to plastic tanks. I find them rarely to leak, I also find them to be most problematic when trying to adjust them. However, you can see exactly what's going on inside of them.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

I had to remount the LG on The nobler last night. It fell off on my last launch last Sunday, a good laugher at the time. Better than on landing, it just dropped to its belly and stalled. I took the time to tidy up some other things. Pressure tap on the muffler, opening the cooling vents more, re-padding the tank. No room to angle it out for Yaw compensation, but I figure the clunk is all the way in the corner anyway, so not as critical. I can only get a slight angle on the tank in the Oriental too. It seems to empty itself and cut off clean every time though.

I'm going out this morning to try and correct the handle monkey motion I saw in my "Inside the Circle" video from last Sunday. Flight report to follow.

Gotta go pack, stayed in the shop way too late last night... this morning.

Rusty

I'm going out this morning to try and correct the handle monkey motion I saw in my "Inside the Circle" video from last Sunday. Flight report to follow.

Gotta go pack, stayed in the shop way too late last night... this morning.

Rusty

Last edited by RknRusty on Thu Sep 17, 2015 10:52 pm; edited 1 time in total

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Busted nose, New tank... perfectomundo!... and a side of flying

Busted nose, New tank... perfectomundo!... and a side of flying

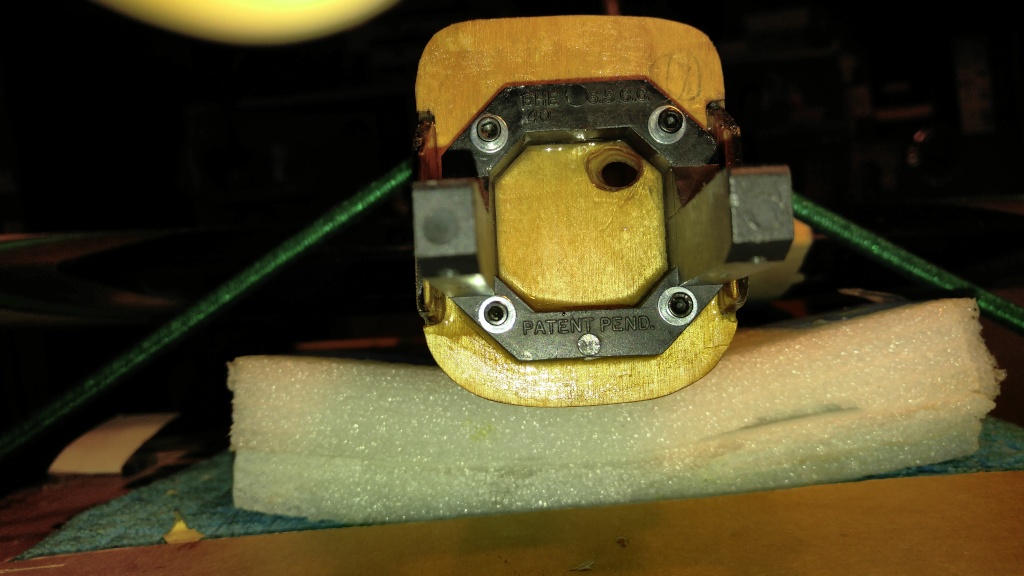

The tank Ken modified for me came in the mail today. Who says the USPS ain't on the ball! Mailed on Tuesday, test fit on Thursday. Looks great, I'll bore a hole and shoot a line through the firewall at that exact same angle. I wish I was going to have time this weekend to put the pedal to the metal and finish this thing.

And there will be room to add some hardwood triangle stock, bracing against vibration. Considering the engine is only secondarily connected to the beams now, I think that's a good idea.

Today was a great day for flying, steady, though firm breeze, partly cloudy and mid 80s. Rich and Bob came up from the Low Country, Wayne and me from the Midlands all converged on the Fort this morning. They play with carefree abandon while all that's on my mind is Huntersville. I brought them a gallon bag of boiled peanuts to keep them from talking so much, Lol.

I've been practicing landings and staying on the bottom 5' limit for level flight and maneuver bottoms. I have finally started consistently rolling out one touch landings. All I had to do is... nothing, basically. Just let the damn plane land itself, with only corrections for up and down wind. I made a couple of nice ones with the Nobler. Boy, 5' is low though. I learned today, in trying to make perfect bottoms, that when you dive straight at the ground, like in an outside square, you better start pulling out early because an 8mph wind accelerates the plane so much it takes more room than I had previously(in my high-bottom flying) noticed. I uh... er.. learned the hard way. On the aforementioned outside square. I cracked a beam. It looked like nothing was wrong, but I took the cowl off and checked. Yep, I have busted more wood. I suppose that's what happens when an Intermediate pilot is pushing himself hard. I hope so. Sounds good anyway.

In any case, that means the Oriental is my only full grown stunter now. I have another Nobler ARF fuse and wing, but I am not going to fix it until this winter. I continued flying the Ukey and actually flew it very well. hitting good bottoms and making all one touch rollouts after landing. I'll get back in the shop next week.

Rusty

And there will be room to add some hardwood triangle stock, bracing against vibration. Considering the engine is only secondarily connected to the beams now, I think that's a good idea.

Today was a great day for flying, steady, though firm breeze, partly cloudy and mid 80s. Rich and Bob came up from the Low Country, Wayne and me from the Midlands all converged on the Fort this morning. They play with carefree abandon while all that's on my mind is Huntersville. I brought them a gallon bag of boiled peanuts to keep them from talking so much, Lol.

I've been practicing landings and staying on the bottom 5' limit for level flight and maneuver bottoms. I have finally started consistently rolling out one touch landings. All I had to do is... nothing, basically. Just let the damn plane land itself, with only corrections for up and down wind. I made a couple of nice ones with the Nobler. Boy, 5' is low though. I learned today, in trying to make perfect bottoms, that when you dive straight at the ground, like in an outside square, you better start pulling out early because an 8mph wind accelerates the plane so much it takes more room than I had previously(in my high-bottom flying) noticed. I uh... er.. learned the hard way. On the aforementioned outside square. I cracked a beam. It looked like nothing was wrong, but I took the cowl off and checked. Yep, I have busted more wood. I suppose that's what happens when an Intermediate pilot is pushing himself hard. I hope so. Sounds good anyway.

In any case, that means the Oriental is my only full grown stunter now. I have another Nobler ARF fuse and wing, but I am not going to fix it until this winter. I continued flying the Ukey and actually flew it very well. hitting good bottoms and making all one touch rollouts after landing. I'll get back in the shop next week.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Rusty, I meant to make a note of which is the uniflow and which is the overflow. I have now forgotten myself. You will know when you fill it. It's going to half tank if you fill through the overflow. If your not currently doing so, run a fuel filter on this for a few flights just so that any residual debris gets trapped in the filter media. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

It's usually the top one, which enters the tank closest to the rear, when the plane is on its wheels, but I can figure it out.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Rusty, I should've sent you the extra Oriental fuse. Mine is in good shape aside from the typical covering issues. If things are broken up on the fuse, another option is to put a coat of Polycrilic and lay some 1/2oz. glass cloth over the entire fuse and Polycrilic it on. When dried, auto primer wet sanding it all off until the mesh is filled on the glass and shoot some Rustoleum. I'm not a fan of Rustoleum and it never works for me, but I have a plane here that seems to be standing up to the job. I'm well aware of how much of a headache trying to put covering on a full fuse plane is when it's entirely assembled. One thing I found that worked well for me was using microballoon fillets. By cutting the covering oversize, this allowed me to use a single edge razor and apply enough pressure to cut around intersections without fear of cutting into wood or sacrificing oil creepage to unwanted areas. Seeing that you have the covering off currently, I can't say enough about glassing a strip over the belly pan joints at least do it around the belly pan to mid wing root front and back. Seeing the plane took a shot on the nose, the weakest point of the fuse is the cutout on the leading edge side. This is due to the landing gear being mounted to the bottom of the fuse directly at that point. The kit version has it's gear J bolted to the F-3 firewall in a central location which takes the shock far superior. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

I had an old spar left over from the Sterling Yak-9, 3/8"x1/4". I thought it was Spruce, because it was a very stiff stick, and hard to press a fingernail into. But in the pictures I just took, the grain looks just like balsa. In any case, it's soaked with epoxy and bracing the corners behind the firewall. I could drill a pinhole in the end grain of the vertical sticks and soak them with super thin CA.

Tonight, I'll cover the front face of the firewall with epoxy and bolt the mount to it. So it'll be glued and screwed. There is room for Nylock nuts inside too. There's a little broken piece of ply you can see on the edge of the firewall. It's been missing since July, and I cut a piece of 16th ply to fill that in so I have a place for the locking dowel on the tank compartment door. I will wrap a strip of glass around the firewall joint on the outside of the fuse. I think I'm short on the medium glass, so I hope 1/2 oz. glass is strong enough.

So, after tonight, all that's left is the Monokote job. I decided against paint.

But I am considering urethane and tissue on the nose the nose just for added stiffness, and Monokote over that. I'll defer to advice on that. Question: Would it be okay to lay the tissue on with Solvent based urethane rather than Polycrylic? I have both. Or just Kote straight to the wood? I'm only talking about the front end, forward of the canopy for this step.

Rusty

P.S. Long ago, I glassed the rear belly-pan joint. That should be in the instructions, as it's a very weak point. So, there's no reason I can't do the front joint too. Inside the tank compartment is all glassed in front of that same bulkhead.

Tonight, I'll cover the front face of the firewall with epoxy and bolt the mount to it. So it'll be glued and screwed. There is room for Nylock nuts inside too. There's a little broken piece of ply you can see on the edge of the firewall. It's been missing since July, and I cut a piece of 16th ply to fill that in so I have a place for the locking dowel on the tank compartment door. I will wrap a strip of glass around the firewall joint on the outside of the fuse. I think I'm short on the medium glass, so I hope 1/2 oz. glass is strong enough.

So, after tonight, all that's left is the Monokote job. I decided against paint.

But I am considering urethane and tissue on the nose the nose just for added stiffness, and Monokote over that. I'll defer to advice on that. Question: Would it be okay to lay the tissue on with Solvent based urethane rather than Polycrylic? I have both. Or just Kote straight to the wood? I'm only talking about the front end, forward of the canopy for this step.

Rusty

P.S. Long ago, I glassed the rear belly-pan joint. That should be in the instructions, as it's a very weak point. So, there's no reason I can't do the front joint too. Inside the tank compartment is all glassed in front of that same bulkhead.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

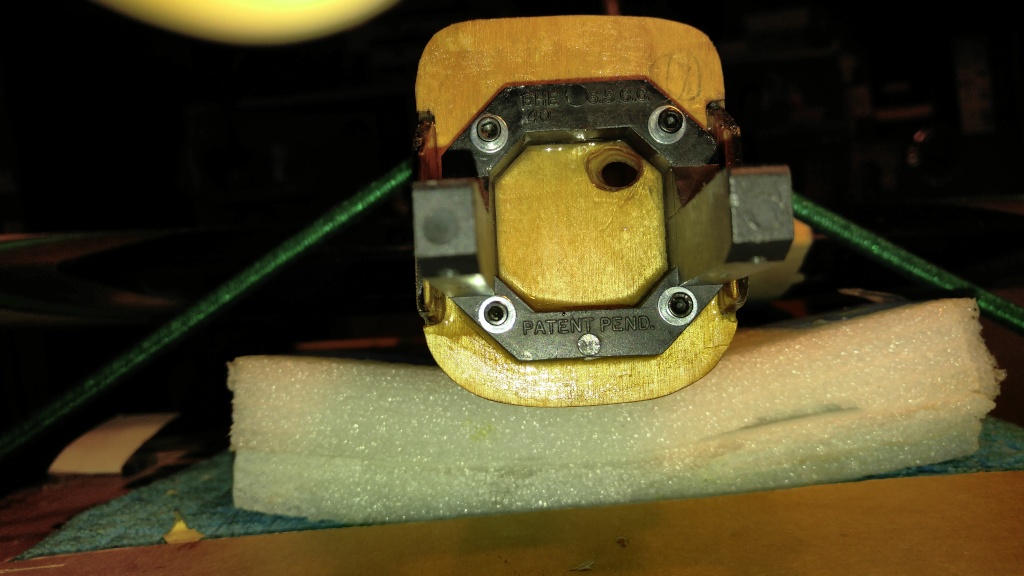

I like it.

The engine is farther forward, maybe just 5/16" or so, eyeballing the ruler. I need to build an extension for the cowl to fit over. I may fly it before I get around to that. It'll probably run better without it, but I'd like for it to look good.

Not much room for padding the sides of the tank. I can't keep it from touching the sides of the compartment at two corners. I use Son of a Gun in my fuel and it works wonders to suppress foaming. Barely any outboard angle in the rear. A degree or less.

The engine is farther forward, maybe just 5/16" or so, eyeballing the ruler. I need to build an extension for the cowl to fit over. I may fly it before I get around to that. It'll probably run better without it, but I'd like for it to look good.

Not much room for padding the sides of the tank. I can't keep it from touching the sides of the compartment at two corners. I use Son of a Gun in my fuel and it works wonders to suppress foaming. Barely any outboard angle in the rear. A degree or less.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Looking good man. Btw on the hold down screws for the engine I like to use socket head cap screws so I can get a better bite on the screws to make sure the engine is secured well. Looking forward to seeing it fly again!RknRusty wrote:I like it.

The engine is farther forward, maybe just 5/16" or so, eyeballing the ruler. I need to build an extension for the cowl to fit over. I may fly it before I get around to that. It'll probably run better without it, but I'd like for it to look good.

Not much room for padding the sides of the tank. I can't keep it from touching the sides of the compartment at two corners. I use Son of a Gun in my fuel and it works wonders to suppress foaming. Barely any outboard angle in the rear. A degree or less.

(Bandit)

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

Rusty, absolutely make certain that the cowling screws don't protrude into the tank compartment. If the tip of the screw even protrudes it can cut a hole in the tank. As far as canting the tank, you won't know until you fly it. If it does become an issue, sweep the leadouts forward 1/16"-1/8" until you get a clean shut off. Just keep a reference of where there at currently so if an issue occurs, you can return it back. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Broken nose, all fixed... Final Installment(s)

Re: Broken nose, all fixed... Final Installment(s)

If I can find socket screws with the same threads as the philips I have, I will.

I might make the extension part of the cowl out of a tin strip, and the screws will go into the existing cowl screw holes that are beside the engine compartment. I'll cover the tin strip with yellow Monokote trim.

Rusty

I might make the extension part of the cowl out of a tin strip, and the screws will go into the existing cowl screw holes that are beside the engine compartment. I'll cover the tin strip with yellow Monokote trim.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» Narrow neck nose / Enlarged neck nose

» Cape Girardeau's Christmas Holiday Float...The Baby Snowbird's Last Installment!!!!!

» Tee Dee .09 rebuild.. and run!

» well its fixed !

» Cox Stocker 0.49 / Indy Car / Nissan GTP

» Cape Girardeau's Christmas Holiday Float...The Baby Snowbird's Last Installment!!!!!

» Tee Dee .09 rebuild.. and run!

» well its fixed !

» Cox Stocker 0.49 / Indy Car / Nissan GTP

Page 3 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules