Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

building surfaces

Page 1 of 1

building surfaces

building surfaces

I have been building a Baby Flite Streak for my Tee Dee .051, and I really appreciate all the help I've gotten on the forum and especially from Rusty. I have been building on glass or with magnets for a while, and didn't have the right size jig for the FS, and the wing just isn't as straight as I would be happy with. I hate to stick pins into small pieces of wood...how do you like to build the smaller planes? Do you like pins and if so, what surface material do you pin them on? I would also like to move more of my assembly into the living room instead of the cold/hot garage. Ideas?

Thanks Steve

Thanks Steve

steve thornton- Bronze Member

- Posts : 44

Join date : 2013-10-06

Location : SE Michigan

Re: building surfaces

Re: building surfaces

Something cheap and easy to find would be a piece of sheetrock/wallboard. Keep an eye out for where there's building-construction going on nearby.. and watch for wallboard being delivered. Scrap/cut-offs of the size you'd need could be found in the job-site dumpster.. or around the job-site after hours.

Re: building surfaces

Re: building surfaces

Exactly, it's called "plaster-paper sheet", and it's exactly what it is, easy to get and cheap in home-depot. Dead flat and accepts pins easily.

dirk gently- Gold Member

- Posts : 430

Join date : 2012-02-03

Age : 42

Location : Poznań

Re: building surfaces

Re: building surfaces

Thanks guys I have a friend who is a contractor...

Steve

Steve

steve thornton- Bronze Member

- Posts : 44

Join date : 2013-10-06

Location : SE Michigan

Re: building surfaces

Re: building surfaces

I use a hollow core door for my building surface, the pins go all the way in and are held captive inside the door.

akjgardner- Diamond Member

Posts : 1602

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: building surfaces

Re: building surfaces

Right now its glass with cling wrap for glue spillage  Getback

Getback

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: building surfaces

Re: building surfaces

I use a lot of wax paper when building. A 12" x 36" sheet of wallboard with a sheet of wax paper thumb-tacked to it with push-pins at the corners, makes a nice little building board. You can see through the wax paper, in case you have a building-plan underneath it.

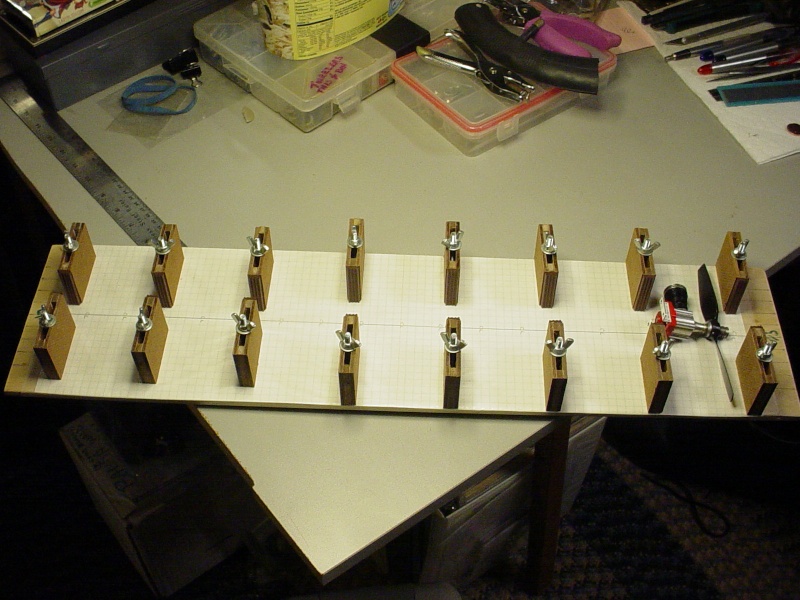

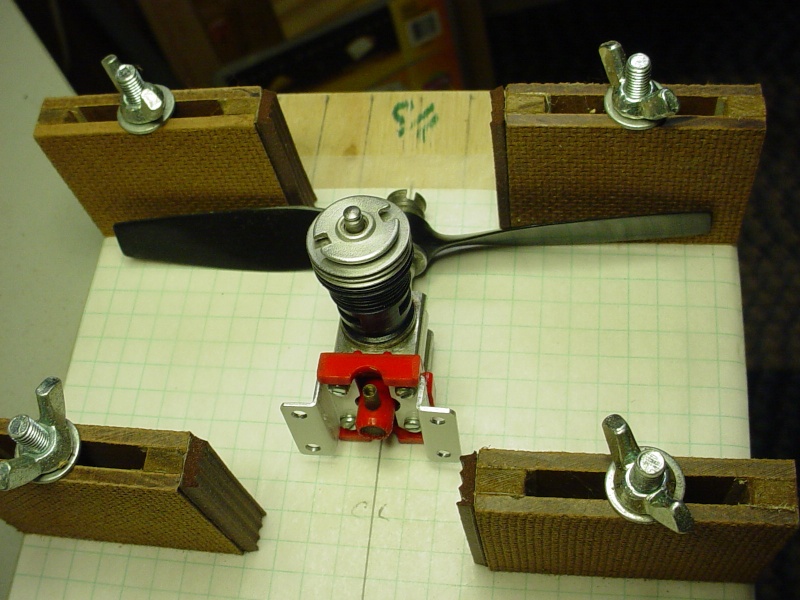

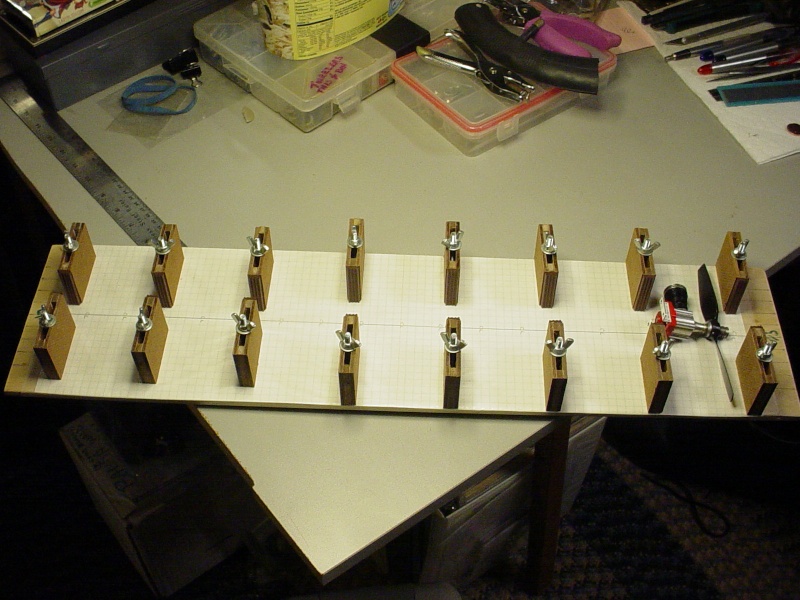

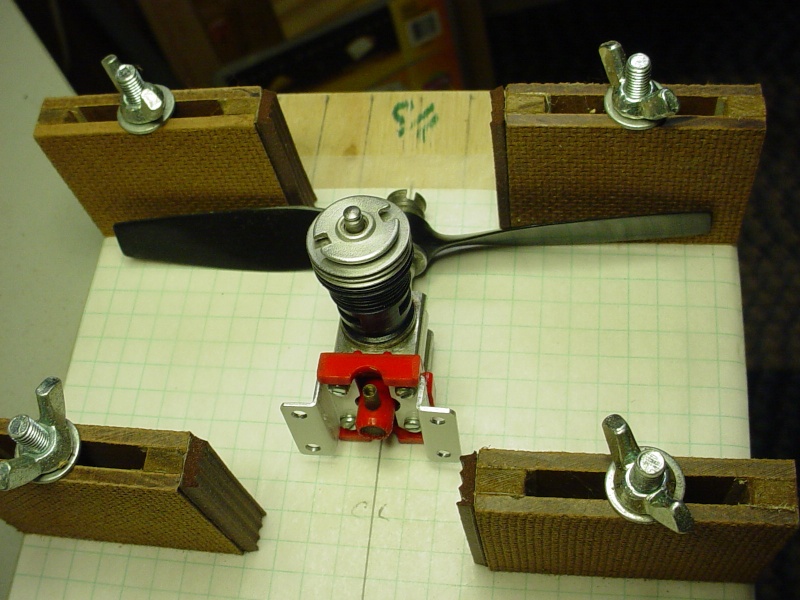

My fuse jigs have graph paper with a wax paper overlay. This 1/2A size fuse-jig measures 6" x 24" and is built similar to the larger RCM type that I built.

The graph paper has a center-line drawn.. which helps to build your fuse nice and straight.

Of course; no "pins" are involved with this building fixture. The clamps slide-in to hold the sides against the bulkheads while the glue sets. I used common 3/8" wide EDPM weather-strip on the faces of the clamps, which provides extra spring-clamping action and also won't mark the soft balsawood fuse sides.

My fuse jigs have graph paper with a wax paper overlay. This 1/2A size fuse-jig measures 6" x 24" and is built similar to the larger RCM type that I built.

The graph paper has a center-line drawn.. which helps to build your fuse nice and straight.

Of course; no "pins" are involved with this building fixture. The clamps slide-in to hold the sides against the bulkheads while the glue sets. I used common 3/8" wide EDPM weather-strip on the faces of the clamps, which provides extra spring-clamping action and also won't mark the soft balsawood fuse sides.

Re: building surfaces

Re: building surfaces

I really like the look of that jig and it looks as if you used "hardboard" with the smooth side inside for the clamps.

I couldn't work out what sheetrock was. It appears to be a trade name adopted as a generic term for what we refer to as plasterboard. (a bit like the word biro or hoover).

There are trade names such as Gyproc but generally we would just ask for plasterboard.

Enough of the vagaries of US english!

How long does the plasterboard last? The stuff here is not what I would call "self healing". The centre is gypsum and would crumble with repeat pin holes. I have to say I would never have thought of using it as a modelling board and yet I have used many sheets for drywalling.

My preference is Sundeala. Sundeala is a unique pin board made from 100% waste paper with a quality sanded surface offering a suede like pre-finish. It holds pins really well, won't last forever, but for a very long time with repeated pinning.

A perfectionist chap I know uses glass on a sheet of steel together with various jigs employing very powerful tiny magnets. Mind you, that set up was expensive - the neodymium magnets weren't cheap! He sends me drawings of the parts he wants with the magnets and I "print" them.

I couldn't work out what sheetrock was. It appears to be a trade name adopted as a generic term for what we refer to as plasterboard. (a bit like the word biro or hoover).

There are trade names such as Gyproc but generally we would just ask for plasterboard.

Enough of the vagaries of US english!

How long does the plasterboard last? The stuff here is not what I would call "self healing". The centre is gypsum and would crumble with repeat pin holes. I have to say I would never have thought of using it as a modelling board and yet I have used many sheets for drywalling.

My preference is Sundeala. Sundeala is a unique pin board made from 100% waste paper with a quality sanded surface offering a suede like pre-finish. It holds pins really well, won't last forever, but for a very long time with repeated pinning.

A perfectionist chap I know uses glass on a sheet of steel together with various jigs employing very powerful tiny magnets. Mind you, that set up was expensive - the neodymium magnets weren't cheap! He sends me drawings of the parts he wants with the magnets and I "print" them.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: building surfaces

Re: building surfaces

ian1954 wrote:I really like the look of that jig and it looks as if you used "hardboard" with the smooth side inside for the clamps.

I couldn't work out what sheetrock was. It appears to be a trade name adopted as a generic term for what we refer to as plasterboard. (a bit like the word biro or hoover).

There are trade names such as Gyproc but generally we would just ask for plasterboard.

Enough of the vagaries of US english!

How long does the plasterboard last? The stuff here is not what I would call "self healing". The centre is gypsum and would crumble with repeat pin holes. I have to say I would never have thought of using it as a modelling board and yet I have used many sheets for drywalling.

My preference is Sundeala. Sundeala is a unique pin board made from 100% waste paper with a quality sanded surface offering a suede like pre-finish. It holds pins really well, won't last forever, but for a very long time with repeated pinning.

A perfectionist chap I know uses glass on a sheet of steel together with various jigs employing very powerful tiny magnets. Mind you, that set up was expensive - the neodymium magnets weren't cheap! He sends me drawings of the parts he wants with the magnets and I "print" them.

Hi Ian, you are correct about the clamp material being hardboard.. and yes; the smooth side faces "in". The most expensive parts to building a jig like this are the carriage-bolts, wing-nuts and flat-washers. The clamps; I actually assembled using thin double-sided "film-tape".

The "Gypsum" board is the same basic thing I was referring to as wall-board or "sheet-rock".. as we call it here. It is a very cheap alternative to a self-healing type mat.. especially where small "cut-off" pieces are thrown away, that are often of a size that would be useful for a building-board.

Re: building surfaces

Re: building surfaces

I laminated cellulose Homasote onto a large piece of 3/4" MDF which is on top of 1/2" glass. This takes pins far superior and holds better than ceiling tiles and drywall. I've found that drywall can quickly dull your X-acto blades and when glue sticks to it, the paper lifts off of the gypsum. Drywall manufacturers are also making a move to a lighter core. I see this growing quickly in popularity, This is USG Ultralight. While the sheets are 1/3 of the weight, the core is very very hard which can make pin placement less than desirable. Homasote is a brand name and can easily be confused for several of the products they manufacturer. The product I'm making reference to is one we use in new elevators for temporary protection. I'm sure temporary protection is not the purpose of this product. It's gray in color in looks like paper mache which is compressed tightly. What I found is that after 10 years of use on my table, if any spills of adhesive epoxy or yellow glues easily pick off of the substrate and I can take a coarse sanding block with 40 grit and go over the table which cleans it giving it a new appearance without dishing it.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Similar topics

Similar topics» Who is Building

» Kit building 55 yrs. later

» A building tip

» My homemade ski-sled

» Building an XA-8

» Kit building 55 yrs. later

» A building tip

» My homemade ski-sled

» Building an XA-8

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules