Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Happy Cox Day Today

Page 1 of 2

Page 1 of 2 • 1, 2

Happy Cox Day Today

Happy Cox Day Today

Ok. Well it may not be a national holiday, but today my Franken-Cox took its first breath. Well after its first breath and a huge smile on my face, I allowed it to take a few more breaths, or tanks I should say. Long story short. Had a Cox Baby Bee engine that was very dirty and ugly looking. Never even tried to start it. So, I took it apart, cleaned it up the best I could and was still not happy with the look. So, I taped over all major areas I thought of, then put it in the sandblaster. It looked good now. Replaced the fuel line, glow plug was shot. So, off to the drill press it went. Drilled it and tapped it for a standard short plug. Piston and cylinder were tight so I put a drop of the finest polishing compound I had in the cylinder and kept rotating it. Smooth and shiny now! Replaced the venture gasket with a new one made from tiny fuel line. I then made a copper thrust washer and installed it behind the drive plate. I then assembled it. No to very little compression. I looked and the copper head gasket was missing. So I made one. Out of the side of a pop can. Had a bit of compression, but not enough. So I made and installed 2 more. Now it had a bit of compression. And today since my electric starter was not yet completed, I robbed the starter spring from my other engine. Mounted it and adjusted the needle valve 3 turns out. First flip, brrrrap. Second flip nothing. Third try, it kept going. I was so happy I filled it and ran it for about 5 or 6 tanks. They only ran about 1 minute each though. I did however see a bit of leakage from between the crankcase and tank. The gasket was new. As well, I saw a bit of bubbling coming up from beside the standard glow head on top. So I got to figure out how to stop this. Anyways, I am just happy and wanted to share my day and story.

[img] [/img]

[/img]

[img] [/img]

[/img]

[img]

[/img]

[/img][img]

[/img]

[/img]

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Happy to hear that you got the engine to run! "Sealing".. especially in these reed-valve engines is EVERYTHING. Even sometimes under the heads of the four 2-56 Fillister-head tank-to-case screws you can experience a leak. I always tighten mine gradually in a criss-cross sequence. Don't try to tighten them one at a time. Try loosening them back up and re-tightening them in this way. Also; the gasket sealing surface on the "crankcase side" may be irregular. You can fix this by removing the tank and placing the rear of the case over a piece of super-fine (600 grit) sandpaper placed preferably on a platen of glass.. and without too much pressure; move the case in a circular motion while holding the paper from sliding. As soon as you see some "grey" on the paper, STOP.. and reassemble the engine with it's new gasket and give it another try.

Try to locate a standard "Cox" glowhead and it's proper Copper gasket. This will ensure a proper sealing of the top-end.. as well as proper compression.. assuming your piston/cylinder fit is good. I have not had good luck with the conversion heads for standard 1/4-32 threaded plugs. Did you thread the Cox head that you drilled out with a 1/4"-32 tap? If it was a different size.. that would surely cause trouble.

EDIT: one more thing... I see that there is a needle-valve extension. I would eliminate that. It looks like a nail.. and will vibrate causing your needle setting to drift while running. It could also break your needle off in the back-plate if something knocks into it.

Try to locate a standard "Cox" glowhead and it's proper Copper gasket. This will ensure a proper sealing of the top-end.. as well as proper compression.. assuming your piston/cylinder fit is good. I have not had good luck with the conversion heads for standard 1/4-32 threaded plugs. Did you thread the Cox head that you drilled out with a 1/4"-32 tap? If it was a different size.. that would surely cause trouble.

EDIT: one more thing... I see that there is a needle-valve extension. I would eliminate that. It looks like a nail.. and will vibrate causing your needle setting to drift while running. It could also break your needle off in the back-plate if something knocks into it.

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Thank you for your help. For the glow head, I have 1 spare one here, it is just that I wanted to try a conversion. I did buy and use the correct glow plug tap from my LHS on the head. I will definitely try the sandpaper thing when I disassemble it this week. And as for the needle, I will then remove the top piece. It was already installed when I got the motor and never thought of any adverse effects on the rest of the needle, so I will heed your advice and remove. Thank you. I also just got back inside again and wow, the garage smells nice. I am not sure what the other half will say when she gets home, but who cares, I had fun. It has actually been an honest 2 -3 years since I had run anything nitro.  I now remember what I was missing.

I now remember what I was missing.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Sounds like you had a great day

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Happy Cox Day Today

Re: Happy Cox Day Today

I like to pressure test my engines when assembled. This can reveal many leaks. The four tank backplate screws can leak very bad. This can be a result of poorly fitting screws or even cracks in the boss of the backplate itself. This can result in a very short and problematic run not to mention fuel seepage into your firewall. I tried many things to prevent this. My first solution to this is to use Bernie's stainless steel screws. A new set usually solves the problem. Sometimes however the fix isn't always simple. Silicone is very problematic if the incorrect type is used. Silicone caulks like GE that you find in the home centers is the WORST choice for applications on metal. This type of sealer/caulk unlike automotive RTV gives off acetic acid which is extremely corrosive to metal especially zinc plating found on most screws. I found a very simple cure to sealing the screws. I take a Q-tip and pull the swab from the stick. I then shred it into 3-4 equal pieces by tearing it directly down the center. I roll one of the sections between my fingers and wrap it around the underside of the screw head. Most important is to wrap it in the direction that the screw turns during tightening. I've found this to work almost every time and more importantly, this solution is service removable without having to dig out silicone. Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Happy Cox Day Today

Re: Happy Cox Day Today

NEW222 wrote:Thank you for your help. For the glow head, I have 1 spare one here, it is just that I wanted to try a conversion. I did buy and use the correct glow plug tap from my LHS on the head. I will definitely try the sandpaper thing when I disassemble it this week. And as for the needle, I will then remove the top piece. It was already installed when I got the motor and never thought of any adverse effects on the rest of the needle, so I will heed your advice and remove. Thank you. I also just got back inside again and wow, the garage smells nice. I am not sure what the other half will say when she gets home, but who cares, I had fun. It has actually been an honest 2 -3 years since I had run anything nitro.I now remember what I was missing.

That's great! Everybody needs to have fun once in a while. I think that burnt glow-fuel may be an aphrodisiac! I like to experiment too.. so I can understand your trying a head conversion. A few members here have tried these with standard plugs.. and while they "do" work; they just don't perform as well. I think it has to do mostly with the "shape" of the combustion chamber at the top; around where the coil element is.

Your needle.. I would remove from the back-plate and slip an inch or so of fuel line over the threads so you can grip it with your fingers and use a dremel cut-off wheel to remove the extension. (wear safety glasses)

A "Sig-Skyray" would make a nice little control-line model for that engine!

Shown here, with a Cox Golden Bee engine that has a slightly larger 8cc tank which is vented for stunt flying. It has a 23-3/4" wingspan.

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Thanks again. I guess that the pictures do not show it, but thanks to this forum, I have installed a piece of fuel tubing to the needle valve prior to trying it as it had nothing on, needle or tubing before. As for the removal, it does appear to be soldered on, so I will try the simple removal first. As for the Skyray, I have built them in the past, still have the original and a second one that was my balloon bust plane (although it bust up after a steep dive at a balloon), and I even have a Baby Ringmaster built that just needs covering, and an engine..... Wonder where I can get one?  Anyways, thanks all again for the comments. After disassembly, I will also put a couple of threads of q-tip on the screws.

Anyways, thanks all again for the comments. After disassembly, I will also put a couple of threads of q-tip on the screws.

Anyways, thanks all again for the comments. After disassembly, I will also put a couple of threads of q-tip on the screws.

Anyways, thanks all again for the comments. After disassembly, I will also put a couple of threads of q-tip on the screws.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Congrats on assembling your "Franken-Cox" and getting it to run. Fun is what it's all about.

Great suggestions too by roddie etc. Your probably familar with the proper tightening sequence of those fuel tank screws, like roddie says cris/cross. I like to leave all four loose, snug them down then slowily tightening them a bit at a time per old cris. How tight is tight, we all know when.

Welcome back to the hobby. My absence was a bit longer, in the order of about 35 years.....But fair warning, one engine leads to two, one airplane leads to several. But you already know that. I never bought a plastic model before I signed on here, now I have lost track.

Great suggestions too by roddie etc. Your probably familar with the proper tightening sequence of those fuel tank screws, like roddie says cris/cross. I like to leave all four loose, snug them down then slowily tightening them a bit at a time per old cris. How tight is tight, we all know when.

Welcome back to the hobby. My absence was a bit longer, in the order of about 35 years.....But fair warning, one engine leads to two, one airplane leads to several. But you already know that. I never bought a plastic model before I signed on here, now I have lost track.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Happy Cox Day Today

Re: Happy Cox Day Today

NEW222 wrote:I have installed a piece of fuel tubing to the needle valve prior to trying it as it had nothing on, needle or tubing before. As for the removal, it does appear to be soldered on, so I will try the simple removal first.

I should have been more explicit about cutting off the needle extension. Yes.. the short piece of fuel tubing that you installed is great for helping to seal air-leaks.. so you'll want to keep that on there.

When you remove the needle to remove the extension.. whether you use a dremel's cut-off wheel, a soldering iron or a torch (you mentioned that it is soldered on.. right?) the needle will get HOT. Slipping a larger diameter piece of fuel-line; covering the needle's threads (from the pointed end) will keep your fingers from getting burned while your holding it. I would remove the short (sealing-piece) first.. then put it back on after the needle cools down. It's also helpful to find a small flat-washer just larger than the OD of the threads on the needle, and install it first.. for it to bear on the sealing-tubing.

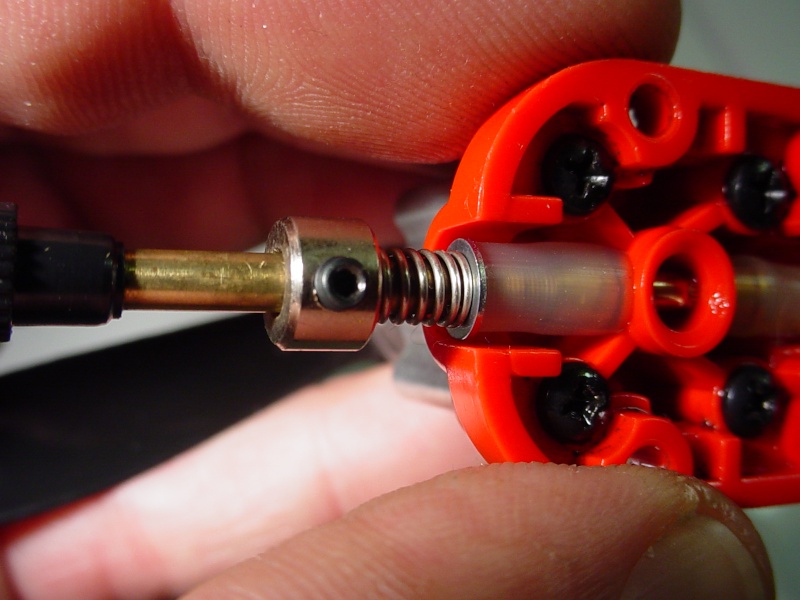

This is a different back-plate/needle.. but you can see how the steel flat-washer that I installed, bears on the piece of silicone sealing-tubing.

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Good work, New, you're now self initiated into the forum engine nut's club!

One more thing about the leaks. Sometimes the holes in the crankcase will not be threaded deeply enough so the screw will feel like it's tight, but not actually compressing the tank to the crankcase. You can shorten the screw, but I prefer to use a 2-56 bottoming tap to add threads deeper into the hole. They're always bored deep enough, but sometimes not tapped all the way.

Rusty

One more thing about the leaks. Sometimes the holes in the crankcase will not be threaded deeply enough so the screw will feel like it's tight, but not actually compressing the tank to the crankcase. You can shorten the screw, but I prefer to use a 2-56 bottoming tap to add threads deeper into the hole. They're always bored deep enough, but sometimes not tapped all the way.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Glad to hear you have it going. A really good very fine grinding paste is good ol' toothpaste. I often use it on a piece of plate glass I inherited from my Dad. Does a fine job of lapping metal to metal.NEW222 wrote:No to very little compression. I looked and the copper head gasket was missing. So I made one. Out of the side of a pop can. Had a bit of compression, but not enough. So I made and installed 2 more. Now it had a bit of compression.

However, I'm surely at a loss as to how you increased your compression by adding head gaskets. Exactly the opposite is what you should have observed. I suspect that you had other leaks causing the lack of compression. I'd try a little meticulous cleaning, checking and assembly and then go back to 1 gasket and see what happens. If it doesn't work better with 1 than with 3 head gaskets then methinks you have other problems.

dinsdale- Account Deactivated by Owner

- Posts : 317

Join date : 2012-02-22

Re: Happy Cox Day Today

Re: Happy Cox Day Today

dinsdale wrote:Glad to hear you have it going. A really good very fine grinding paste is good ol' toothpaste. I often use it on a piece of plate glass I inherited from my Dad. Does a fine job of lapping metal to metal.NEW222 wrote:No to very little compression. I looked and the copper head gasket was missing. So I made one. Out of the side of a pop can. Had a bit of compression, but not enough. So I made and installed 2 more. Now it had a bit of compression.

However, I'm surely at a loss as to how you increased your compression by adding head gaskets. Exactly the opposite is what you should have observed. I suspect that you had other leaks causing the lack of compression. I'd try a little meticulous cleaning, checking and assembly and then go back to 1 gasket and see what happens. If it doesn't work better with 1 than with 3 head gaskets then methinks you have other problems.

My thought exactly. I believe that his "pop can gasket" just wasn't sealing properly until he added more gaining a proper seal as he went.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Happy Cox Day Today

Re: Happy Cox Day Today

That's some complicated needle roddie. So you have a collet, a spring, and a flat washer all on top of tubing. I gather the spring compresses over a range of rpm's as you adjust for best performance?

Bob

Bob

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Having a slight flu and therefore not being particularly keen on standing in the windy field with my transmitter in my shivering hands, I thought I will have my own Tach-race in my garage instead...I wanted to reproduce the 24+ rpm numbers the Tach-race participants reached in the TeeDee 049 class recently.

Pretty cold though, I could squeeze out some 23,5k from my veteran 051 with the smaller 4,54x4 prop, while the 4,82x4 (supposed to be 5x4, this is Bernies brand new stuff) turned 20,5k.

I used 20% nitro..I guess with 25% and a bit warmer ambient my 051 could have revved the 4,54x4 beyond 24k too. I wonder what props you guys finally used on the Tach race for the TeeDee049 class?

Pretty cold though, I could squeeze out some 23,5k from my veteran 051 with the smaller 4,54x4 prop, while the 4,82x4 (supposed to be 5x4, this is Bernies brand new stuff) turned 20,5k.

I used 20% nitro..I guess with 25% and a bit warmer ambient my 051 could have revved the 4,54x4 beyond 24k too. I wonder what props you guys finally used on the Tach race for the TeeDee049 class?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Happy Cox Day Today

Re: Happy Cox Day Today

rsv1cox wrote:That's some complicated needle roddie. So you have a collet, a spring, and a flat washer all on top of tubing. I gather the spring compresses over a range of rpm's as you adjust for best performance?

Bob

I "do" tend to over-complicate things..

Below is a better example for the OP.. (photo courtesy of Paul Gibeault) of various "Bee"-style back-plates incorporating different needle configurations.

Note the "center" example uses a stock-type needle with no spring at all.. but has the silicone tube-seal with a steel flat-washer above it. No doubt that Paul cut his tubing to a length that would work within the needle's operating range for his engine.. and still seal; with enough tension from the tubing to "act" as a spring.. and hold the needle-setting from wandering while running his engine.

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Thanks again all for the help and replies.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Ok. Needle extension removed, check. Crankcase and fuel tank separated, then crankcase bottom sanded with 400 than 800 on a piece of glass on my modeling table(I did not have 600), check. Crankcase gasket checked ok. Reassembled and tightened screws in a cross type pattern, check. Now just to take two gaskets out from under the Cox glowhead, and check the standard plug for leaks again, then off to the bench again.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

What are you using for fuel? It's very important to use fuel that has enough castor oil in it, ESPECIALLY with Cox engines. If in doubt.. it's better to wait until you can get some. A good fuel to use is "Sig" 1/2A Champion "25" which you can obtain in one pint bottles directly from Sig Manufacturing Co. "Hobbico" just recently reformulated the "Cox Super Fuel" with the proper oil mixture. It was tested here by several forum members and found to meet or exceed the Cox engine's requirements. This is reflected on the new product packaging.. and should be available through Hobbico/Tower Hobbies soon.. if not already.

A fuel having 100% synthetic oil and zero castor can ruin the Cox engine in as little as one tankful.

A fuel having 100% synthetic oil and zero castor can ruin the Cox engine in as little as one tankful.

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Hi there again. The following Sig fuel is what I am using:

CHAMPION "25"

25% Nitromethane

20% Lubricating Oils

(1/2 Castor, 1/2 Klotz)

For high performance 2-stroke engines. The next step up from CHAMPION "15", this high performance fuel provides more horsepower for specialized contest use. Also excellent for use in very small .010-.049 glow engines, which require a hotter fuel to start and run properly.

Thank you.

CHAMPION "25"

25% Nitromethane

20% Lubricating Oils

(1/2 Castor, 1/2 Klotz)

For high performance 2-stroke engines. The next step up from CHAMPION "15", this high performance fuel provides more horsepower for specialized contest use. Also excellent for use in very small .010-.049 glow engines, which require a hotter fuel to start and run properly.

Thank you.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Update

Update

I would just like to give a little update on my engine.

Ok, despite it being cold here again, and getting colder, I tried it out once again. Well, it ran and started rather good still, but I still had a fuel leak at the tank and crankcase area again. This was even after the sanding on glass. So, I am again at a loss. I am thinking of disassembling again and using a sealant, or making a gasket out of something a bit thicker that might have a bit of compression, like a playing card? There was no noticeable leak at the glow plug today. I even sanded that copper washer too. And after fuelling it up and quickly starting it, I had timed it at approximately 1 minute 10 seconds run time. Anyways, I am not sure of a proper run time of a Baby Bee engine, but I was actually hoping for 2 minutes.

Ok, despite it being cold here again, and getting colder, I tried it out once again. Well, it ran and started rather good still, but I still had a fuel leak at the tank and crankcase area again. This was even after the sanding on glass. So, I am again at a loss. I am thinking of disassembling again and using a sealant, or making a gasket out of something a bit thicker that might have a bit of compression, like a playing card? There was no noticeable leak at the glow plug today. I even sanded that copper washer too. And after fuelling it up and quickly starting it, I had timed it at approximately 1 minute 10 seconds run time. Anyways, I am not sure of a proper run time of a Baby Bee engine, but I was actually hoping for 2 minutes.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Well back in from the last rebuild. I cut out a new gasket from 0.008 heavy paper similar to postal wrapping paper that I had laying around. Before tracing out the used gasket, I was drying it out between two pieces of paper towel and saw that it has a crack around the main ring which I suspect caused my problems. So tonight I saw it and just wanted to test it for leaks. I filled it up, completely wiped it off and sat it down for a couple of minutes. Picked it up and saw no evidence of leaks. As I was now done, I thought how am I going to drain this? So, back inside and grabbed my starting equipment. Started and ran great. 3 runs total and times were 1 minute 40 seconds, 1 minute 50 seconds, and lastly 2 minutes 5 seconds. This was all using a 5.5 x 4.5 prop as pictured above. Needless to say I am happy with this now, and think that my run times are ok for what I got, unless someone has anything else I need to know about running this beast. Anyways, just happy here and wanted to share.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

new222 I think run time is 3-4 min. on a 5cc tank, but you may not get that on a test stand if the pick up hose is set to the right side for flight  Bee sure to clean and put the spring in the hose if you replace the hose . Eric

Bee sure to clean and put the spring in the hose if you replace the hose . Eric

Bee sure to clean and put the spring in the hose if you replace the hose . Eric

Bee sure to clean and put the spring in the hose if you replace the hose . Eric

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Yes, Eric (getback) makes a good point. When the engine is stationary it won't use all the fuel in the tank. In a control-line model flying conventionally (ccw) around the circle; the fuel will hug the outside wall of the tank where the fuel pick-up is located because of centrifugal force.

A fraction of a turn with the needle may have caused your varying times on the test stand. Naturally; if you have a slightly leaner setting, you'll have a longer run than a rich setting.

The Sig Champion "25" is a great fuel. If you plan on flying, get yourself a few more props in the 5" to 6" diameter range.. and pitches between 2 and 4 inches. Depending on the airplane model you choose, you will see differences in performance.. even with different brand props having the same size. Look for balsawood models having a profile fuselage and a wingspan between 18-24" specifying a "radial" engine mounting. I mentioned the Sig Skyray.. but the Goldberg "Swordsman" (18") and the "Stuntman" (23") are good flying little models too.. and easy to build. You would need to source "plans" for the Goldberg models though.. as they are no longer produced.

Kudos on making a new gasket!

A fraction of a turn with the needle may have caused your varying times on the test stand. Naturally; if you have a slightly leaner setting, you'll have a longer run than a rich setting.

The Sig Champion "25" is a great fuel. If you plan on flying, get yourself a few more props in the 5" to 6" diameter range.. and pitches between 2 and 4 inches. Depending on the airplane model you choose, you will see differences in performance.. even with different brand props having the same size. Look for balsawood models having a profile fuselage and a wingspan between 18-24" specifying a "radial" engine mounting. I mentioned the Sig Skyray.. but the Goldberg "Swordsman" (18") and the "Stuntman" (23") are good flying little models too.. and easy to build. You would need to source "plans" for the Goldberg models though.. as they are no longer produced.

Kudos on making a new gasket!

Re: Happy Cox Day Today

Re: Happy Cox Day Today

Thank you. I now feel really stupid yet again. Back apart one more time!  The fuel line is on the bottom, this I do know from my old control line days, BUT I set it this way when rebuilding it and now thanks to you all mentioning it, I have to take the backplate off yet again to position it to the outside as it will be for use on my Baby Ringmaster and Man-Win trainer! Oh well, lesson learned again. I was just happy to get an engine together and running I forgot the obvious, the type of flying it will be doing, and heck, I was even building the planes while rebuilding the motor.

The fuel line is on the bottom, this I do know from my old control line days, BUT I set it this way when rebuilding it and now thanks to you all mentioning it, I have to take the backplate off yet again to position it to the outside as it will be for use on my Baby Ringmaster and Man-Win trainer! Oh well, lesson learned again. I was just happy to get an engine together and running I forgot the obvious, the type of flying it will be doing, and heck, I was even building the planes while rebuilding the motor.

I am a bit shocked too at the recommended run times suggested, as I think I was only getting approximately 2 1/2 minutes on my Black Widow (bought new in 1999 or 2000) and has never been apart! So I thought the 2 minutes I was getting were good. Thanks again for the help and advice.

I am a bit shocked too at the recommended run times suggested, as I think I was only getting approximately 2 1/2 minutes on my Black Widow (bought new in 1999 or 2000) and has never been apart! So I thought the 2 minutes I was getting were good. Thanks again for the help and advice.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Happy Cox Day Today

Re: Happy Cox Day Today

New222 you have just begun on this forum if you read you learn just pick what or ask a question it all in fun man , glad you got her going  Getback

Getback

Getback

Getback

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 1 of 2 • 1, 2

Similar topics

Similar topics» happy birthday happy dad

» Cox Venom Piston Rod Reset Question

» Where I was today

» A real strange looking Cox .049 Ebay buy now listing

» ACE GLH II MODS?SUGESTIONS

» Cox Venom Piston Rod Reset Question

» Where I was today

» A real strange looking Cox .049 Ebay buy now listing

» ACE GLH II MODS?SUGESTIONS

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules