Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Differences between Sure Start And Product Engine With Horseshoe Backplate

Page 1 of 3

Page 1 of 3 • 1, 2, 3

Differences between Sure Start And Product Engine With Horseshoe Backplate

Differences between Sure Start And Product Engine With Horseshoe Backplate

Hi there. This may very well be a stupid question, but I have to ask. What is the differences, if any, between the Cox Sure Start and the Cox product engine with horseshoe backplate. I have each, but after looking at them, I was just wondering if the choke tube and fine thread needle are the only differences? Thank you.

Last edited by NEW222 on Fri Jan 30, 2015 9:24 pm; edited 1 time in total

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

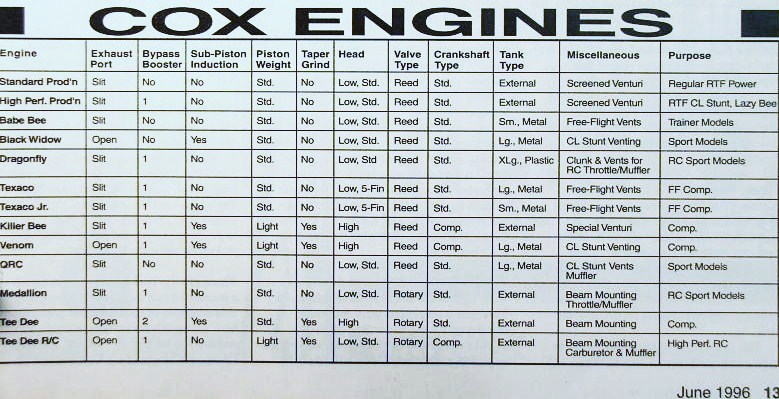

Well one of the differences is the surestart cylinder which is a duel port with a single boost port on each side but as far as I know thats the only difference. Some of the other guys here could probably tell ya more than myself though. (Bandit)

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

In addition, most product engines had SPI cylinders while Sure Starts are non-SPI.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Great, thank you. This is what I was looking for. The little things. But as per the replies, it would appear the differences are internal.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

The Surestarts came only with the slit exhaust ports while early and pre-Estes product engines typically had open exhaust ports. This is , as you term it, an external difference.

In my eyes an old genuine product engine, though, is usually superior to a Surestart. These latter often came with metal particles left in the engine after manufacturing, and the overall quality of pre-Estes engines is said to be higher than that of the Surestarts. I have a couple of the latter too, they look nice, and had some of them in service as well, but they somehow tend to wear off quicker than the old-stock COX stuff.

In my eyes an old genuine product engine, though, is usually superior to a Surestart. These latter often came with metal particles left in the engine after manufacturing, and the overall quality of pre-Estes engines is said to be higher than that of the Surestarts. I have a couple of the latter too, they look nice, and had some of them in service as well, but they somehow tend to wear off quicker than the old-stock COX stuff.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Which one has the fine thread needle?

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

As the COX productline went along a cost cutting program over the years, I would assume the product engines more often had fine-thread (more expensive to make) needle valves than the later Surestarts.

The manual of the latter says you need to open the NV 4 full turns to start the engine...an older manual of a product engine says you open 5 turns, meaning the thread is finer of the product engine NV..

The manual of the latter says you need to open the NV 4 full turns to start the engine...an older manual of a product engine says you open 5 turns, meaning the thread is finer of the product engine NV..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

It is my understanding that Cox made several styles of "Product Engines". These engines were the ones that came installed in their "Ready to Run/Fly" models.. and could be ordered separately as replacement engines for those models. The Babe Bee could actually be called a "Product Engine" because it did come installed in some models in the early days.. IIRC.

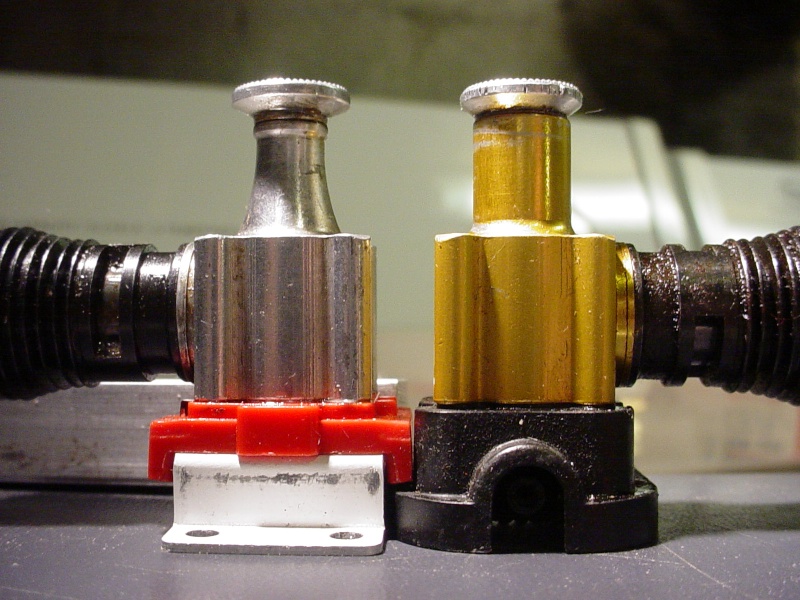

Cox then started to design their models with separate (external) fuel tanks.. and designed a "modular" small plastic back-plate for the engine, that would fit into molded slots in all of their model's mainframes/fuselages. These back-plates are referred to as the "Postage-Stamp" because of their shape and had a fine-thread (128 TPI) needle valve. The engines having this style back-plate had no other mounting provisions for a conventional firewall-mount in a balsa kit type model. There were "aftermarket" mounts designed by other companies which would allow the engines to be used conventionally.. because otherwise; after the Cox model crashed or broke, the engine became useless.. even though it usually survived and still ran fine.

Cox later re-designed their plastic back-plate to still be "modular".. but also had a flange molded-in with four small holes for screw-attachment as an option. It was also flat/flush on the backside allowing it to be conventionally (radially) mounted to the firewall in a balsa kit-model. These back-plates are referred to as the "Horseshoe" because of their shape and had an 80 TPI needle-valve. I don't believe that these back-plates were ever made with the fine-thread needle.

These two styles of back-plates are interchangeable between most Cox .049 reed-valve engines.. so if the older (Postage-Stamp) style is found on an engine, it can be swapped out for the easier to mount "Horseshoe" style which is still available separately as a kit. (back-plate/needle/reed/reed-retainer/gasket/case-screws).

I hope that this was useful information.. although it refers more to the back-ends of the Product Engines than the types of cylinders that the engines came with. I'm still learning about all these elements myself.

Cox then started to design their models with separate (external) fuel tanks.. and designed a "modular" small plastic back-plate for the engine, that would fit into molded slots in all of their model's mainframes/fuselages. These back-plates are referred to as the "Postage-Stamp" because of their shape and had a fine-thread (128 TPI) needle valve. The engines having this style back-plate had no other mounting provisions for a conventional firewall-mount in a balsa kit type model. There were "aftermarket" mounts designed by other companies which would allow the engines to be used conventionally.. because otherwise; after the Cox model crashed or broke, the engine became useless.. even though it usually survived and still ran fine.

Cox later re-designed their plastic back-plate to still be "modular".. but also had a flange molded-in with four small holes for screw-attachment as an option. It was also flat/flush on the backside allowing it to be conventionally (radially) mounted to the firewall in a balsa kit-model. These back-plates are referred to as the "Horseshoe" because of their shape and had an 80 TPI needle-valve. I don't believe that these back-plates were ever made with the fine-thread needle.

These two styles of back-plates are interchangeable between most Cox .049 reed-valve engines.. so if the older (Postage-Stamp) style is found on an engine, it can be swapped out for the easier to mount "Horseshoe" style which is still available separately as a kit. (back-plate/needle/reed/reed-retainer/gasket/case-screws).

I hope that this was useful information.. although it refers more to the back-ends of the Product Engines than the types of cylinders that the engines came with. I'm still learning about all these elements myself.

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

In summary, because Surestarts have a horse-shoe backplate, they come with the 80 thread-per-inch needle valve, while the postage-stamp backplates of the older product engines have 128 tpi design.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Piston/cylinder fit was not good as well. I had one that on the third break-in run, it started loosing compression. I pulled it apart and started fitting pistons, found one that fit better and installed it and never had another problem. (Bandit)balogh wrote:The Surestarts came only with the slit exhaust ports while early and pre-Estes product engines typically had open exhaust ports. This is , as you term it, an external difference.

In my eyes an old genuine product engine, though, is usually superior to a Surestart. These latter often came with metal particles left in the engine after manufacturing, and the overall quality of pre-Estes engines is said to be higher than that of the Surestarts. I have a couple of the latter too, they look nice, and had some of them in service as well, but they somehow tend to wear off quicker than the old-stock COX stuff.

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Thanks guys. Has anyone tried to swap needle assemblies from postage stamp to horseshoe? Reason I am asking is that I have one postage stamp backplate that has maybe overheated and it seems useless. It is discolored and the needle assembly practically fell off. Maybe I could transplant it to a horseshoe? Any glue needed and/or recommended?

This whole fine thread thing has made me seriously think about fabricating "Roddie-style" brackets for my narrow-neck, thin-cylinder Two-Ninety (see my current avatar ). First I thought I'll just throw the red backplate away and mount it to a Silver Bee tank but somehow I just can't bring myself to modify this survivor, even though it is "just" a Two-Ninety

). First I thought I'll just throw the red backplate away and mount it to a Silver Bee tank but somehow I just can't bring myself to modify this survivor, even though it is "just" a Two-Ninety

This whole fine thread thing has made me seriously think about fabricating "Roddie-style" brackets for my narrow-neck, thin-cylinder Two-Ninety (see my current avatar

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

KariFS wrote:Thanks guys. Has anyone tried to swap needle assemblies from postage stamp to horseshoe? Reason I am asking is that I have one postage stamp backplate that has maybe overheated and it seems useless. It is discolored and the needle assembly practically fell off. Maybe I could transplant it to a horseshoe? Any glue needed and/or recommended?

This whole fine thread thing has made me seriously think about fabricating "Roddie-style" brackets for my narrow-neck, thin-cylinder Two-Ninety (see my current avatar). First I thought I'll just throw the red backplate away and mount it to a Silver Bee tank but somehow I just can't bring myself to modify this survivor, even though it is "just" a Two-Ninety

Yes, I have swapped the postage stamp needle valve to the horseshoe needle valve. It works very well. You will need to gently heat the postage stamp backplate until you can remove the needle valve. Same with removing the horseshoe needle valve. I believe I just pushed the new needle valve into position without re-heating the backplate. The older red and beige horseshoe backplates already come with Fine thread needle-valves. Hope this helps.

Andy

anm2- Gold Member

- Posts : 293

Join date : 2013-03-30

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

KariFS wrote:

This whole fine thread thing has made me seriously think about fabricating "Roddie-style" brackets for my narrow-neck, thin-cylinder Two-Ninety (see my current avatar). First I thought I'll just throw the red backplate away and mount it to a Silver Bee tank but somehow I just can't bring myself to modify this survivor, even though it is "just" a Two-Ninety

I'm an advocate for resurrecting the old postage-stamp back-plate.. as you know. Mounts are easy to make. The four-screw mount pattern on the Cox .049 reedie's crankcase is 17/32" (13.49mm) on center. Locate some sheet-steel approx. .031" (0.8mm) thickness and cut two strips 3/4" (19.0mm) wide by approx. 1" (25mm) long. Drill clearance holes for your 2-56 crankcase screws approx. 1/8" (3mm) in from the edge of the short side of the strip. You may need to form a slight radius/relief to clear the protruding venturi housing/stack.

Then you have a choice in how to proceed in the mount-configuration. Using a bench-vise, you can form a two-bend 90 degree "Z" in each mount, for a radial/firewall.. or you can form a single "L"-bend in each mount, for straddling the top/bottom of a custom hardwood nose-block.. as described in the "290 Special" airplane plan.

The above sectional of the "290 Special" plan recommends trimming the postage-stamp back-plate "square". This is not necessary.. and leaving it "stock" will orient the NVA horizontally when the mounts are installed, which is favorable on a profile fuselage for tank/bladder lines to be a short straight-shot to the spray-bar nipple. Your mount's bend location on the engine-side should be approx. 5/16" (8.0mm) from the edge of the mounts.. and if you choose the "L" type mount; the angle will depend on your nose-block design. The "Z" bent mounts require a radial firewall size of approx. 1.375" (35mm) by 3/4" (19mm).. so airplane kits designed for Cox "Bee" engines may need a "taller" plywood plate to attach the engine.

Here are some aluminum "Z" mounts that I made (shown below with a "horseshoe" back-plate for comparisson).

Aluminum may not be the best material though. I sent a set of these to Eric Greeson (getback) and one of the mounts developed a stress-fracture along one of it's bends after he flew it on his hotrod speed model. It could have been a "fluke".. but needs mentioning.

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

roddie wrote:It is my understanding that Cox made several styles of "Product Engines". These engines were the ones that came installed in their "Ready to Run/Fly" models.. and could be ordered separately as replacement engines for those models. The Babe Bee could actually be called a "Product Engine" because it did come installed in some models in the early days.. IIRC.

Cox then started to design their models with separate (external) fuel tanks.. and designed a "modular" small plastic back-plate for the engine, that would fit into molded slots in all of their model's mainframes/fuselages. These back-plates are referred to as the "Postage-Stamp" because of their shape and had a fine-thread (128 TPI) needle valve. The engines having this style back-plate had no other mounting provisions for a conventional firewall-mount in a balsa kit type model. There were "aftermarket" mounts designed by other companies which would allow the engines to be used conventionally.. because otherwise; after the Cox model crashed or broke, the engine became useless.. even though it usually survived and still ran fine.

Cox later re-designed their plastic back-plate to still be "modular".. but also had a flange molded-in with four small holes for screw-attachment as an option. It was also flat/flush on the backside allowing it to be conventionally (radially) mounted to the firewall in a balsa kit-model. These back-plates are referred to as the "Horseshoe" because of their shape and had an 80 TPI needle-valve. I don't believe that these back-plates were ever made with the fine-thread needle.

These two styles of back-plates are interchangeable between most Cox .049 reed-valve engines.. so if the older (Postage-Stamp) style is found on an engine, it can be swapped out for the easier to mount "Horseshoe" style which is still available separately as a kit. (back-plate/needle/reed/reed-retainer/gasket/case-screws).

I hope that this was useful information.. although it refers more to the back-ends of the Product Engines than the types of cylinders that the engines came with. I'm still learning about all these elements myself.

Thank you for this. I was actually going to ask the question that you have answered above regarding the Baby Bee as a product engine. As I was going through MH Aerotools, I saw what looked like a Baby Bee engine that they call Super Bee. It has a description of the transfer ports, which I will look at. Also you mention that you did not recall that Cox made a 'Horseshoe' backplate, then I thought that all horseshoe backplates were created equal as the same as on my Sure Start. So I then go look at my horseshoe backplate engine and lo and behold, a fine thread needle! Who would have thunk? In case it makes a difference, it is a red horseshoe backplate.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Ok, again, I must not be all here today. As I re-read anm2's post, he lays it out in his post: 'The older red and beige horseshoe backplates already come with Fine thread needle-valves.' Right there in front of my closed eyes....

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

NEW222 wrote:Ok, again, I must not be all here today. As I re-read anm2's post, he lays it out in his post: 'The older red and beige horseshoe backplates already come with Fine thread needle-valves.' Right there in front of my closed eyes....

Don't feel bad! There isn't a member here who hasn't been surprised at the numerous different combinations that Cox produced over the course of time!!!!

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Postage stamp Cox 290's had SPI, were considered powerful enough for an entry level 1/2-A speed event AFAIK, (proto?). I've got two of those.TDbandit wrote:Well one of the differences is the surestart cylinder which is a duel port with a single boost port on each side but as far as I know thats the only difference. Some of the other guys here could probably tell ya more than myself though. (Bandit)

Engines I posted about that I recently received from a friend were of the newer 290's with horse shoe back, one from a 2 channel Sportavia RC RTF the other from a Corsair CL RTF. Both have slit exhausts, very large single port on each side, no extra porting for a total of two and no SPI. Pulled the jug off my Sure Start, cylinder certain appears to be the same. Both engines use the same needle thead as the Sure Starts.

The Sportavia engine uses a brass reed valve and wire retainer whereas the Corsair engine is plastic with teflon or nylon reed valve like the Sure Starts.

Except for the choke tube, they certainly seem identical to me. May be I'm wrong.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Here's a pic of the cylinder off my Sure Start it's not the best but if you look carefully to the left of the port, you can see the extra milling and raised edge on the top left corner indicating the boost port it however does not have SPI as previously said. (Bandit)GallopingGhostler wrote:Postage stamp Cox 290's had SPI, were considered powerful enough for an entry level 1/2-A speed event AFAIK, (proto?). I've got two of those.TDbandit wrote:Well one of the differences is the surestart cylinder which is a duel port with a single boost port on each side but as far as I know thats the only difference. Some of the other guys here could probably tell ya more than myself though. (Bandit)

Engines I posted about that I recently received from a friend were of the newer 290's with horse shoe back, one from a 2 channel Sportavia RC RTF the other from a Corsair CL RTF. Both have slit exhausts, very large single port on each side, no extra porting for a total of two and no SPI. Pulled the jug off my Sure Start, cylinder certain appears to be the same. Both engines use the same needle thead as the Sure Starts.

The Sportavia engine uses a brass reed valve and wire retainer whereas the Corsair engine is plastic with teflon or nylon reed valve like the Sure Starts.

Except for the choke tube, they certainly seem identical to me. May be I'm wrong.

Sorry for the pic quality.

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

NEW222 wrote:As I was going through MH Aerotools, I saw what looked like a Baby Bee engine that they call Super Bee. It has a description of the transfer ports, which I will look at.

The Super Bee looked the same as a typical Babe Bee of the era except that it had 2 bypass ports to the Babe Bee's 1, which was identified by number 1. It has SPI as do the early single port Babe Bees and the cylinder was marked "P-40" as the engine was specifically built to install in the Cox P-40 model. It was a heavy plane so the second bypass was introduced to increase power. The P-40 could also be considered a "product engine".

Have a look at "Cylinder Identification" under "Info" on the left of this page.

Rod.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

TDbandit wrote:Photo quality is fine, Bandit. Out of curiosity I pulled the heads off both the Estes Sure Start and Cox 290 Corsai engine.GallopingGhostler wrote:Here's a pic of the cylinder off my Sure Start it's not the best but if you look carefully to the left of the port, you can see the extra milling and raised edge on the top left corner indicating the boost port it however does not have SPI as previously said. (Bandit)

Sorry for the pic quality.

Sure enough there is a second milling, which wasn't evident upon intial inspection, showed up in the photo. in this case, the extra milling's boost must be so subtle as it is hardly noticeable, hence why I didn't see it the first time. Looking especially at the gaps between slit and port milling, width of both appears about the same. Neither have SPI. Seems to me both have about the same volume. Both engines probably have about the same performance. About the only way to know for sure is to tach them, except I don't have a tach.

Both place on sport models, I'd probably never notice the difference.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

In stock form theres not really much of a difference infact the 290 may edge it out a little. This is due to to the poor fit of the estes sure starts. Now if you rework em a little (IE) refit the piston, clean up the reed, check the case excreta it will wake up a little bit. I bet estes used this same cylinder on their version of the killer bee. (Bandit)GallopingGhostler wrote:TDbandit wrote:Photo quality is fine, Bandit. Out of curiosity I pulled the heads off both the Estes Sure Start and Cox 290 Corsai engine.GallopingGhostler wrote:Here's a pic of the cylinder off my Sure Start it's not the best but if you look carefully to the left of the port, you can see the extra milling and raised edge on the top left corner indicating the boost port it however does not have SPI as previously said. (Bandit)

Sorry for the pic quality.

Sure enough there is a second milling, which wasn't evident upon intial inspection, showed up in the photo. in this case, the extra milling's boost must be so subtle as it is hardly noticeable, hence why I didn't see it the first time. Looking especially at the gaps between slit and port milling, width of both appears about the same. Neither have SPI. Seems to me both have about the same volume. Both engines probably have about the same performance. About the only way to know for sure is to tach them, except I don't have a tach.

Both place on sport models, I'd probably never notice the difference.

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Bandit, your advice is spot one. One thing I noticed is that the 290 has a round venturi shaft with no restriction flats whereas the Sure Start does. I put drops of light machine oil in the Sure Start and now it has compression. 290 uses a brass reed, I could replace with a teflon one.TDbandit wrote:In stock form theres not really much of a difference infact the 290 may edge it out a little. This is due to to the poor fit of the estes sure starts. Now if you rework em a little (IE) refit the piston, clean up the reed, check the case excreta it will wake up a little bit. I bet estes used this same cylinder on their version of the killer bee. (Bandit)

Yes, I heard that Estes apparently had folk who didn't know what they were doing, not recognizing the difference between performance and standard parts. Their so-called Killer Bee had the power of a Babe Bee. Estes is now a company of Hobbico. I don't know if they are still in Penrose, CO or moved. Difference now is Cox International and EX Cox with a few others are doing a much better job in matching pistons and cylinders, or so I gather. One is assured to get a quality product.

Nonetheless, since a friend gave me these 290 engines and I want to make a good showing of them, am now consider plane candidates. For the Sportavia 290 I'm thinking of a 30" span poster foamboard Simple Delta with elevons. The Corsair 290 deserves a suitable CL plane.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Sig 1/2A stagger wing! I would look good in it.GallopingGhostler wrote:Bandit, your advice is spot one. One thing I noticed is that the 290 has a round venturi shaft with no restriction flats whereas the Sure Start does. I put drops of light machine oil in the Sure Start and now it has compression. 290 uses a brass reed, I could replace with a teflon one.TDbandit wrote:In stock form theres not really much of a difference infact the 290 may edge it out a little. This is due to to the poor fit of the estes sure starts. Now if you rework em a little (IE) refit the piston, clean up the reed, check the case excreta it will wake up a little bit. I bet estes used this same cylinder on their version of the killer bee. (Bandit)

Yes, I heard that Estes apparently had folk who didn't know what they were doing, not recognizing the difference between performance and standard parts. Their so-called Killer Bee had the power of a Babe Bee. Estes is now a company of Hobbico. I don't know if they are still in Penrose, CO or moved. Difference now is Cox International and EX Cox with a few others are doing a much better job in matching pistons and cylinders, or so I gather. One is assured to get a quality product.

Nonetheless, since a friend gave me these 290 engines and I want to make a good showing of them, am now consider plane candidates. For the Sportavia 290 I'm thinking of a 30" span poster foamboard Simple Delta with elevons. The Corsair 290 deserves a suitable CL plane.

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

Re: Differences between Sure Start And Product Engine With Horseshoe Backplate

That Sig 1/2-A is still a classic, love the looks. A counterpart would be Walt Musiciano's hollow log Scientific Waco cabin bipe. You could take a photo of you with your headset on, color print it to scale and paste it over the painted windows. Could have your face facing looking out with your hand giving the thumbs up.TDbandit wrote:Sig 1/2A stagger wing! I would look good in it.I'm fixing to build one once I'm done with my wildcat. and as far as the Sure Start back plate is concerned, I took the restrictor out of mine and drilled the snorkel which woke it up a good bit. (Bandit)

I had a Dumas 1/2-A Ercoupe at one time, it was a profile with solid wings and Cox 049 Babe Bee. Too bad I don't have plans of it, but wouldn't be hard to make another from an Ercoupe 3-view.

Got a Scientific Piper Super Cruiser hollow log kit (original), not sure what engine to put in it yet. May just template and preserve the kit. Have Walt's Building and Flying Scale Model Aircraft book with his 1/2-A P-61 twin Mustang and 1/2-A Aeronca Sedan hollow log. Those 2 are classics, too.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Page 1 of 3 • 1, 2, 3

Similar topics

Similar topics» COX 049 PT 19 product engine and Sure Start testing

» COX Postage Stamp engine -Babe Bee & Horseshoe Backplate adapters

» CEF .020 Horseshoe Backplate

» Horseshoe backplate spraybar removal

» Mounting screws for horseshoe backplate

» COX Postage Stamp engine -Babe Bee & Horseshoe Backplate adapters

» CEF .020 Horseshoe Backplate

» Horseshoe backplate spraybar removal

» Mounting screws for horseshoe backplate

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules