Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

old glue joints

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: old glue joints

Re: old glue joints

roddie wrote:Check out this OLD Jr. Flite Streak wing! Built sometime in the late 60's/early 70's.. probably with Ambroid. I was holding the tip and looking at it's brace layout while it was hanging from the ceiling. To my horror..the tip came "right-off" in my hand. There is no wood damage whatsoever..

Think about that.. when your tempted to fly an old heirloom...

Many models were built without reading the instructions on the glue tube, including mine. After a few failed joints I learned to "double cement", that is, to apply a penetrating layer first, then another layer when actually making the joint.

Good idea to use those plastic tips for better reach. Before Ambroid had the plastic screw-on tips, they used an eye screw that became a pushrod guide for the next model.

I had never thought of brushing on some dope to rejuvenate a glue joint. I'll have to give it a try. I usually just apply a little CA to repair it.

White glue works well. I understand some guys (mostly FF) will apply a penetrating thinned coat then un-thinned for the actual joint...all applied with a brush to create a super light yet strong joint.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: old glue joints

Re: old glue joints

gcb wrote:roddie wrote:Check out this OLD Jr. Flite Streak wing! Built sometime in the late 60's/early 70's.. probably with Ambroid. I was holding the tip and looking at it's brace layout while it was hanging from the ceiling. To my horror..the tip came "right-off" in my hand. There is no wood damage whatsoever..

Think about that.. when your tempted to fly an old heirloom...

Many models were built without reading the instructions on the glue tube, including mine. After a few failed joints I learned to "double cement", that is, to apply a penetrating layer first, then another layer when actually making the joint.

Good idea to use those plastic tips for better reach. Before Ambroid had the plastic screw-on tips, they used an eye screw that became a pushrod guide for the next model.The glue tube itself became a wingtip weight when the tube was empty.

I had never thought of brushing on some dope to rejuvenate a glue joint. I'll have to give it a try. I usually just apply a little CA to repair it.

White glue works well. I understand some guys (mostly FF) will apply a penetrating thinned coat then un-thinned for the actual joint...all applied with a brush to create a super light yet strong joint.

George

Hi George, I don't own any K & B engines. The photo I posted of the "Stallion" was a reference for Rusty, that I found on the web.

I "do" remember the old "lead" glue-tubes being rolled-up and used for tip-weights! I'd never heard of rejuvenating old (celluloid..?) glue-joints using dope either.. and want more specifics on that. I'm not real savvy regarding vintage or currently available modeling solvents. If dope can be used to rejuvenate old glue joints.. I'd assume that it's "vintage" dope that's to be used.. if you can find it. For example; "Ambroid" cement originally used.. and rejuvenating with Pactra "Aero-Gloss" clear dope. Celluloid cement with a Cellulose-based (?) dope.. ?? I guess in theory; the dope will temporarily soften the old cement.. and also cause it to "wick" further into the surrounding structure, more than when originally applied. Does this make sense? It would be a lot lighter than re-gluing every joint in built-up framework.

As far as I know; "Ambroid" cement can still be obtained. I have a full tube that's "old".. but still "seems" ok. I've had a few people tell me to just apply a little Ambroid to joints were Ambroid was used.. and the solvent will melt-in to the old joint. This seems rational to me.. and might be my course of action with the old models that I have. I'm fairly certain that they were all built with Ambroid because of the amber color; still evident at the joints. The "dope-method" might be a better way to go though; seeing that the wood used in these old models generally wasn't of the lightest-weight to start with.

I'll definitely heed the advice I've been given; to pay extra attention to the bellcrank-mounts in these old models. I have plenty of plywood around my shop.. even if it means laminating thin stock, to get the thickness required. I'd actually rather do that.. than go with an old mount that "looks" ok. The plywood that was supplied in many old kits was really sub-standard. Actually much of it was more of a "luan-type" with voids/pockets in it's core. Not too bad for nose-doublers.. but not for a bellcrank-mount. There was generally one die-smashed sheet for all the ply-parts.. including control-horns. Fortunately none of my models were built with plywood control-horns.. but there's many left-over in some old kit-boxes that I have.

Re: old glue joints

Re: old glue joints

Very many of our glues are all variants of solids... man made or organic... thinned with some sort of solvent

The solids were ground or chemically disintegrated and added to the solvents that when exposed to warm air, dried out leaving the solid....some inflexible and some with a little elastic quality

The reason doping over old glues usually works is the solvent in the dope...mostly MEK (Methyl Ethel Keytone)/Toluene/or Xylene.. and many times a mix of each and other VOCs...is very similar to the original solvent in the glue

These will soften the original solid enough to let it re-flow and cross-link some before drying and become a solid again...although not quite as efficiently as the original fully suspended solid in the solvent

Also Dope Is really a glue...in as much as the solvents all dry out and the base solid binds with whatever it is in contact with

I have not tried it but I tend to think a 30+ year old UNCOVERED built up airframe could be Sprayed with a very heavy dose of 80%(thinner)20% Dope and set to dry for a while and be as strong as when first built with very little weight gain

The solids were ground or chemically disintegrated and added to the solvents that when exposed to warm air, dried out leaving the solid....some inflexible and some with a little elastic quality

The reason doping over old glues usually works is the solvent in the dope...mostly MEK (Methyl Ethel Keytone)/Toluene/or Xylene.. and many times a mix of each and other VOCs...is very similar to the original solvent in the glue

These will soften the original solid enough to let it re-flow and cross-link some before drying and become a solid again...although not quite as efficiently as the original fully suspended solid in the solvent

Also Dope Is really a glue...in as much as the solvents all dry out and the base solid binds with whatever it is in contact with

I have not tried it but I tend to think a 30+ year old UNCOVERED built up airframe could be Sprayed with a very heavy dose of 80%(thinner)20% Dope and set to dry for a while and be as strong as when first built with very little weight gain

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: old glue joints

Re: old glue joints

I'll definitely heed the advice I've been given; to pay extra attention to the bellcrank-mounts in these old models. I have plenty of plywood around my shop.. even if it means laminating thin stock, to get the thickness required. I'd actually rather do that.. than go with an old mount that "looks" ok. The plywood that was supplied in many old kits was really sub-standard. Actually much of it was more of a "luan-type" with voids/pockets in it's core. Not too bad for nose-doublers.. but not for a bellcrank-mount. There was generally one die-smashed sheet for all the ply-parts.. including control-horns. Fortunately none of my models were built with plywood control-horns.. but there's many left-over in some old kit-boxes that I have.

Along those lines, the adhesive that holds the plies together on most plywoods does not allow easy gassing of the solvents in Ambroid or any other "cement" type adhesives nor air for drying of white glues. (It takes a loooooong time to dry.) For ply joints Epoxy is much better.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: old glue joints

Re: old glue joints

Fred, that was an excellent explanation!

George

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: old glue joints

Re: old glue joints

Unfortunately, the cement shrinks back so far it's rather useless and must be re glued. No rejuvenating process is going to make the glue joint sound. It must be removed and re glued. Nine out of ten times the entire piece just picks right off. When things are at this stage which is essentially what Roddie's Streak appears to be, the parts can easily be dismantled, sanded a bit and glued up again. This is the safest and most practical way to go about repairing it. I recently spent months restoring a Sterling Skylark with this same problem. Between the tedious silkspan removal and all of the glue joints, I could've built a new one. In the end I still have a POS Sterling kit that's just structurally sound. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: old glue joints

Re: old glue joints

I think Ken is correct, now that I think some more on just doping over a very old glue joint

If The model to be rejuvenated is a heirloom, or has some significance, I would do the process the right way as tedious as it may be

If it was just some old beater plane I had fun with in the 70s... I might give the dope process a shot and Hope the new covering added some of the lost strength and when the whole thing folded I would most likely shake my head and giggle as it re-kitted

If The model to be rejuvenated is a heirloom, or has some significance, I would do the process the right way as tedious as it may be

If it was just some old beater plane I had fun with in the 70s... I might give the dope process a shot and Hope the new covering added some of the lost strength and when the whole thing folded I would most likely shake my head and giggle as it re-kitted

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: old glue joints

Re: old glue joints

Ken Cook wrote:Unfortunately, the cement shrinks back so far it's rather useless and must be re glued. No rejuvenating process is going to make the glue joint sound. It must be removed and re glued. Nine out of ten times the entire piece just picks right off. When things are at this stage which is essentially what Roddie's Streak appears to be, the parts can easily be dismantled, sanded a bit and glued up again. This is the safest and most practical way to go about repairing it. I recently spent months restoring a Sterling Skylark with this same problem. Between the tedious silkspan removal and all of the glue joints, I could've built a new one. In the end I still have a POS Sterling kit that's just structurally sound. Ken

Yikes.. (regarding the Skylark..) Had you built it originally? I'm guessing "no".. unless it wasn't flown much. What did you use when re-gluing.. and what did you re-cover it with?

Is there a current adhesive.. or combination of adhesive/filler that's lightweight, sands as easily as Ambroid does.. which holds up better over the course of time?

I've never used (and don't have any..) "micro-balloons" filler, but wonder if it can be added to certain glues for lighter-weight glue-joints? How about mixing balsa-dust with glue? Are these materials only recommended for "fillets"?

When Ambroid is applied properly to a joint.. (as noted; a penetrating-application to both surfaces, then a second application once dry and prior to assembly) how long approximately.. and under ideal conditions; can it be expected to hold-up before the joint is at risk of failing? Five.. ten, twenty years? Would environmental conditions play a part in this?

I'm just a naturally curious person..

I'm just a naturally curious person..  Re: old glue joints

Re: old glue joints

I recently saw some models built in the 60s using Humbrol Balsa Cement (similar to Ambroid and smells the same!) and Araldite (the original epoxy resin that took 48 hours to completely cure). The air frames were still sound but the coverings - dope and tissue - nylon and dope - had gone brittle. The dope would have been what we knew as Humbrol Nitro Cellulose.

These were, however, stored in a spare bedroom. The chap who had them also had some he built in the 90s using PVA and many of the joints had given way but the old PVA glue was never waterproof.

The aliphatic resins are pretty odourless and easily sanded but I don't know about longevity. I have no really old models - they keep crashing!

I have seen models stored in unheated garages subject to temperature extremes - cold and damp/ hot and humid that have been shot the following season.

The chaps with the models has restored a few but the process of stripping of the covering weakened the glue. He used thinner to soften the dope and painstakingly removed the covering but then he used a large plastic bag - put one of the models in it - sprayed MEK in there - sealed the bag and the next morning he had a kit of parts in a bag! He used heat to remove the epoxy resin.

He only did this treatment once! By the time he had finally cleaned everything up for reassembly - he could have cut out the parts ten times over!

The other models he lived with the less than perfect covering removal.

These were, however, stored in a spare bedroom. The chap who had them also had some he built in the 90s using PVA and many of the joints had given way but the old PVA glue was never waterproof.

The aliphatic resins are pretty odourless and easily sanded but I don't know about longevity. I have no really old models - they keep crashing!

I have seen models stored in unheated garages subject to temperature extremes - cold and damp/ hot and humid that have been shot the following season.

The chaps with the models has restored a few but the process of stripping of the covering weakened the glue. He used thinner to soften the dope and painstakingly removed the covering but then he used a large plastic bag - put one of the models in it - sprayed MEK in there - sealed the bag and the next morning he had a kit of parts in a bag! He used heat to remove the epoxy resin.

He only did this treatment once! By the time he had finally cleaned everything up for reassembly - he could have cut out the parts ten times over!

The other models he lived with the less than perfect covering removal.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: old glue joints

Re: old glue joints

Roddie, the newer Ambroid was very poor compared to the old stuff. If you happen to look at a old Ambroid joint, you will note that it's built up to almost 3/16". You could never do this with the newer stuff. The color of the new stuff was more yellowy and very very thin. The second you opened the tube, it would need the sides squeezed to stop it from flowing out all over the place. Just like everything else that was old and good, formulations changed and certain chemicals that allowed it's superiority were removed. Over the pas 15 years, the models I used Ambroid on haven't seemed to redeem any failing qualities. My models though aren't exposed to heat other than the field which by itself can do some serious damage alone. I have had doped planes blister from the sun.

I haven't been able to source a place for Ambroid in over 4 years. I don't believe it's even in production. In addition, I found Sig-Ment to work equally well and is readily available through Sig. I typically purchase it when I purchase fuel from them. I used Duco cement in the past but I haven't tried it currently. I have noticed that they don't offer large size tubes. I mainly used solvent based cements for sheeting and laminating due to it's sanding qualities.

As for the Skylark, I used what was essentially left of my Ambroid and basically anything on hand. CA doesn't work well on old wood . Ribs, spars, doublers were all glued with carpenter's yellow glue. The less you use, the better it works. I don't get carried away with glue joints . The entire wing and fuse was getting silkspanned and doped which is what really holds things together. I completed the model a few months ago and while it was on top of my to do list, It went to a fellow club member who almost has it completed. In my model trashing and smashing venue recently, it was one of the bigguns that was just taking up too much real estate inside. This particular Skylark was a NATS winning plane in the 70's. It had a beautiful finish on it, it was heavy as all heck and the controls were just plain worn out. I had to do a shotgun blast of the control system. The bearers were also redrilled for a OS FP.40. I removed wood anywhere I could on the model. To my surpise, I had the plane down to 40 oz's with engine, tank wheels no covering.

Micro balloons, I wouldn't use it to thin out any cements other than epoxy. It greatly compromises the strength and it doesn't allow epoxy to retain it's structural integrity. No joint that's being called upon for strength should have micro balloons added to it. While it lightens epoxy, it also accelerates it's kick off time. Epoxy joints are little to no value if the epoxy doesn't soak into the wood. The slower the cure, the stronger the joint. It works great for additional strength as a fillet to a rudder, stab or side of fuse fillet.

Adding baking soda sprinkled over a CA joint can bridge huge gaps. I would tend to believe that micro balloons in CA would do the same. Baking soda kicks CA off instantly. It makes for a very crude bubbly glue joint however. But, if you have that front end that's so busted up that you can't find the wood through the CA, baking soda could be you best friend here when added to thick CA.

One thing I forgot to add when posting was epoxy. When I was repairing the old Skylark which was very oil soaked, I used the last of my K2R spot lifter. This worked quite well for oil soaked balsa. It took an entire can to wick out the oil. So to glue things back after this grueling treatment, I used T-88 epoxy which when applied was immediately heated with a heat gun. It would run down alongside of plywood and balsa firewalls not to mention the engine crutch. T-88 has the ability to stick to oily woods wuch as teak, and ipe. I used it when I felt the glue joint was compromised due to my acetone wash following the K2R.

I haven't been able to source a place for Ambroid in over 4 years. I don't believe it's even in production. In addition, I found Sig-Ment to work equally well and is readily available through Sig. I typically purchase it when I purchase fuel from them. I used Duco cement in the past but I haven't tried it currently. I have noticed that they don't offer large size tubes. I mainly used solvent based cements for sheeting and laminating due to it's sanding qualities.

As for the Skylark, I used what was essentially left of my Ambroid and basically anything on hand. CA doesn't work well on old wood . Ribs, spars, doublers were all glued with carpenter's yellow glue. The less you use, the better it works. I don't get carried away with glue joints . The entire wing and fuse was getting silkspanned and doped which is what really holds things together. I completed the model a few months ago and while it was on top of my to do list, It went to a fellow club member who almost has it completed. In my model trashing and smashing venue recently, it was one of the bigguns that was just taking up too much real estate inside. This particular Skylark was a NATS winning plane in the 70's. It had a beautiful finish on it, it was heavy as all heck and the controls were just plain worn out. I had to do a shotgun blast of the control system. The bearers were also redrilled for a OS FP.40. I removed wood anywhere I could on the model. To my surpise, I had the plane down to 40 oz's with engine, tank wheels no covering.

Micro balloons, I wouldn't use it to thin out any cements other than epoxy. It greatly compromises the strength and it doesn't allow epoxy to retain it's structural integrity. No joint that's being called upon for strength should have micro balloons added to it. While it lightens epoxy, it also accelerates it's kick off time. Epoxy joints are little to no value if the epoxy doesn't soak into the wood. The slower the cure, the stronger the joint. It works great for additional strength as a fillet to a rudder, stab or side of fuse fillet.

Adding baking soda sprinkled over a CA joint can bridge huge gaps. I would tend to believe that micro balloons in CA would do the same. Baking soda kicks CA off instantly. It makes for a very crude bubbly glue joint however. But, if you have that front end that's so busted up that you can't find the wood through the CA, baking soda could be you best friend here when added to thick CA.

One thing I forgot to add when posting was epoxy. When I was repairing the old Skylark which was very oil soaked, I used the last of my K2R spot lifter. This worked quite well for oil soaked balsa. It took an entire can to wick out the oil. So to glue things back after this grueling treatment, I used T-88 epoxy which when applied was immediately heated with a heat gun. It would run down alongside of plywood and balsa firewalls not to mention the engine crutch. T-88 has the ability to stick to oily woods wuch as teak, and ipe. I used it when I felt the glue joint was compromised due to my acetone wash following the K2R.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: old glue joints

Re: old glue joints

Thanks for the valuable advice Ken. My full tube of Ambroid was purchased many years ago.. possibly close to twenty. It's likely the "good ol' formula".. I hope. It says made in Taunton, MA like my other older tubes.

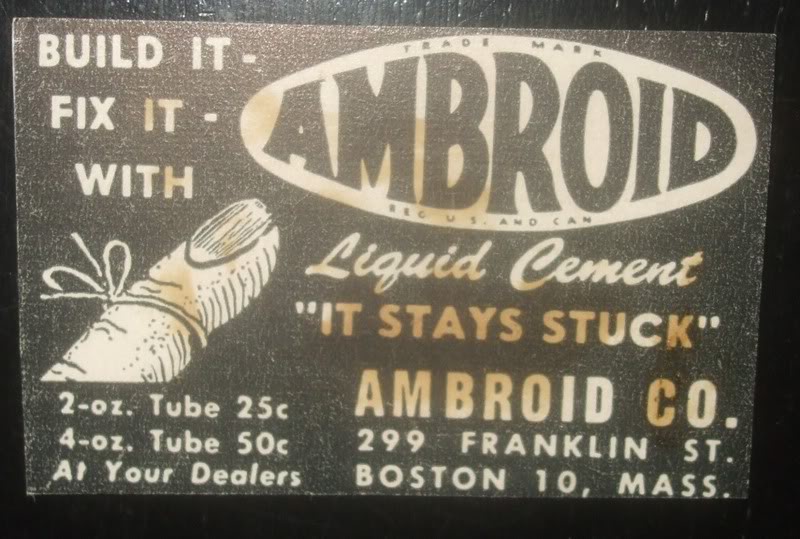

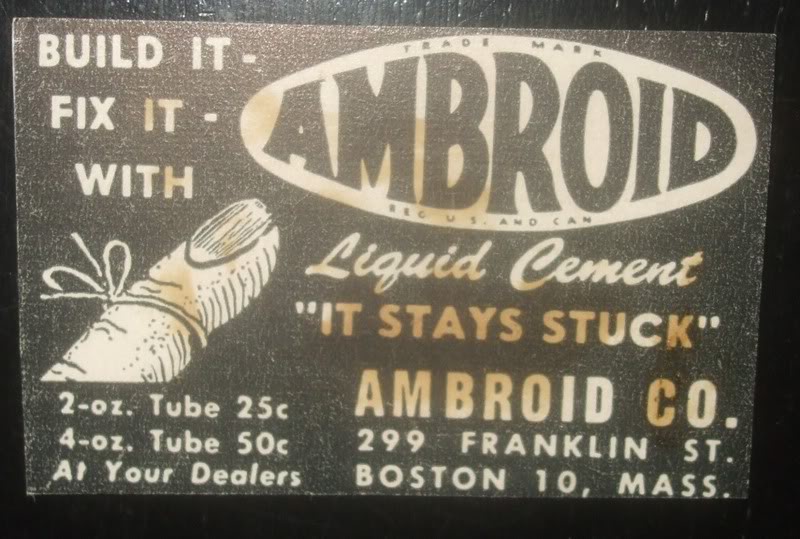

Here's a close-up of an interesting tube of Ambroid that I found at a railroad-salvage outlet (Building 19) back in the early-90's..

As much as I can tell.. the product that was made in Swanzey, NH was the last known source.. and probably the new formula that doesn't work as well.

but it was also made in Lowell, MA... I assume just before the move to NH.

but was "originally made in Boston (proper), MA.. (check out this old ad!)

You'll notice that the tube-graphics are inverted on all the web-images of the tubes made in NH

Here's a close-up of an interesting tube of Ambroid that I found at a railroad-salvage outlet (Building 19) back in the early-90's..

As much as I can tell.. the product that was made in Swanzey, NH was the last known source.. and probably the new formula that doesn't work as well.

but it was also made in Lowell, MA... I assume just before the move to NH.

but was "originally made in Boston (proper), MA.. (check out this old ad!)

You'll notice that the tube-graphics are inverted on all the web-images of the tubes made in NH

Re: old glue joints

Re: old glue joints

Most of the aliphatic resin type glues suffer a similar fate as Ambroid. I like it though and this can really aid in taking a model apart if needed. One yellow glue that seemed to have a quality above the rest for me was Sig-bond. I have used this in both a white and yellow version. Anymore seeing I get it by the gallons is Titebond. While I'm not a fan of Titebond II, I found it to remain real flexible over time instead of drying out. The oldest flying model I have on hand currently was built 5/23/69. It was the first .35 size plane I learned to fly built by my father and we still fly it today and just laugh about it. That was built entirely using Ambroid. The fuse and stab was doped with Aero Gloss silvaire aluminum and the wings were Monokote. It crashed in 1984 due to a line break and my father repaired it changing the entire paint scheme. Surprisingly , it still flies well although heavy.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: old glue joints

Re: old glue joints

Ken Cook wrote: Most of the aliphatic resin type glues suffer a similar fate as Ambroid. I like it though and this can really aid in taking a model apart if needed. One yellow glue that seemed to have a quality above the rest for me was Sig-bond. I have used this in both a white and yellow version. Anymore seeing I get it by the gallons is Titebond. While I'm not a fan of Titebond II, I found it to remain real flexible over time instead of drying out. The oldest flying model I have on hand currently was built 5/23/69. It was the first .35 size plane I learned to fly built by my father and we still fly it today and just laugh about it. That was built entirely using Ambroid. The fuse and stab was doped with Aero Gloss silvaire aluminum and the wings were Monokote. It crashed in 1984 due to a line break and my father repaired it changing the entire paint scheme. Surprisingly , it still flies well although heavy.

Ken, thanks again for sharing your experience. I appreciate your taking the time to write, and I've saved our conversation as a word doc. under "adhesives/glues" in my modeling files.

As to "which" products to use; seems to depend on a lot of variables. It boils down to everything (including ourselves..) having a useful lifespan.. IMHO. With model airplanes that are or were great flyer's.. we want to keep flying them indefinitely.. but there inevitably comes a point to where they need to retire.

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Just couldn’t sleep.

» Ball - Socket Joints

» Sig-ment and Ambroid

» CA Glue, Accelerator, Epoxy and Debonder now available

» New CA glue

» Ball - Socket Joints

» Sig-ment and Ambroid

» CA Glue, Accelerator, Epoxy and Debonder now available

» New CA glue

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules