Log in

Search

Latest topics

» Cox 020 PeeWee rebuild questions by LooseSpinner99 Today at 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Today at 5:08 pm

» Roger Harris revisited

by rsv1cox Today at 3:44 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 2:54 pm

» Happy 77th birthday Andrew!

by Admin Today at 12:34 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

Cox Engine of The Month

Tee Dee Performance Crank

Page 3 of 13

Page 3 of 13 •  1, 2, 3, 4 ... 11, 12, 13

1, 2, 3, 4 ... 11, 12, 13

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

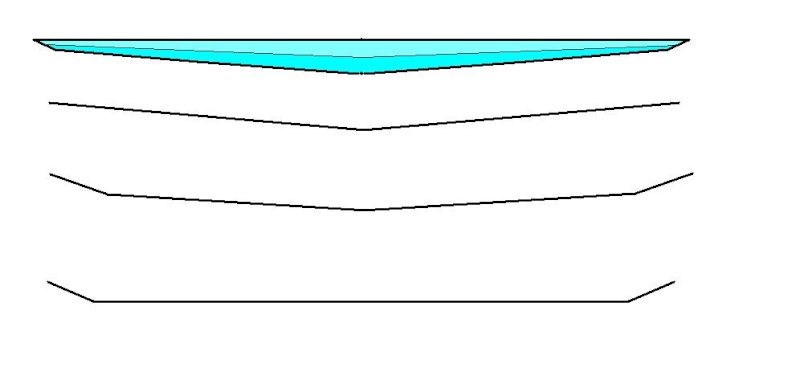

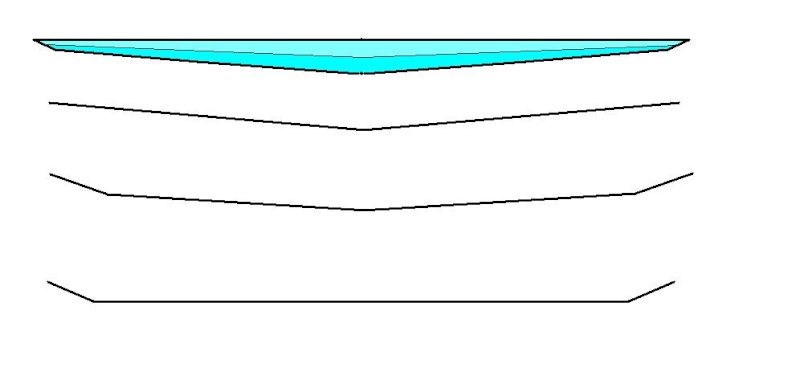

The design concept is to have a very strong, rigid, slim fuselage providing minimal drag for speed.

Here is a size comparison of the 1/2A Skorch to the TD .020 Lil Speedy.

Here is a size comparison of the 1/2A Skorch to the TD .020 Lil Speedy.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Thanks a lot for the build thread!!!

Here is where my project stands as of tonight:

I omitted the fuselage doubler but glued in a couple longitudinal balsa stiffeners to save weight. I will also omit the landing gear because the field where I am flying is a deep grass and the landing gear would only bend on each landing.

I am thinking of soaking the leading edge in light CA glue to let it resist when I mow grass on landing. Or maybe a narrow strip of plywood sunk like a blade into the leading edge is better? Or a carbon tube to replace the leading edge where it intersects the fuse? I am afraid the leading edge may crack when I push the plywood in...I am good at destroying delicate parts..

I am still puzzled how you fix the wing to the fuse as I can only see the rubber bands but no dowel to hook them on. Or do you have the dowels mounted on the wing?

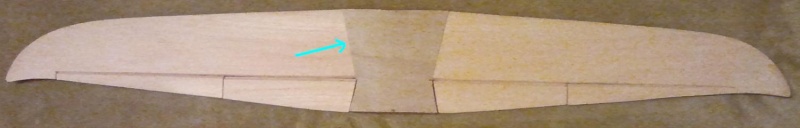

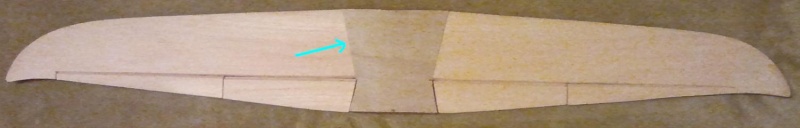

I will have a sheet wing with flat bottom, the top of the airfoil sanded

Here is where my project stands as of tonight:

I omitted the fuselage doubler but glued in a couple longitudinal balsa stiffeners to save weight. I will also omit the landing gear because the field where I am flying is a deep grass and the landing gear would only bend on each landing.

I am thinking of soaking the leading edge in light CA glue to let it resist when I mow grass on landing. Or maybe a narrow strip of plywood sunk like a blade into the leading edge is better? Or a carbon tube to replace the leading edge where it intersects the fuse? I am afraid the leading edge may crack when I push the plywood in...I am good at destroying delicate parts..

I am still puzzled how you fix the wing to the fuse as I can only see the rubber bands but no dowel to hook them on. Or do you have the dowels mounted on the wing?

I will have a sheet wing with flat bottom, the top of the airfoil sanded

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

I use 1/64th top and bottom in the center of the wing to protect the balsa from the fuselage.

I use a 3mm carbon tube for a dowel. and steel piano wire in the back for dowel to clear the pushrods.

I use a 3mm carbon tube for a dowel. and steel piano wire in the back for dowel to clear the pushrods.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

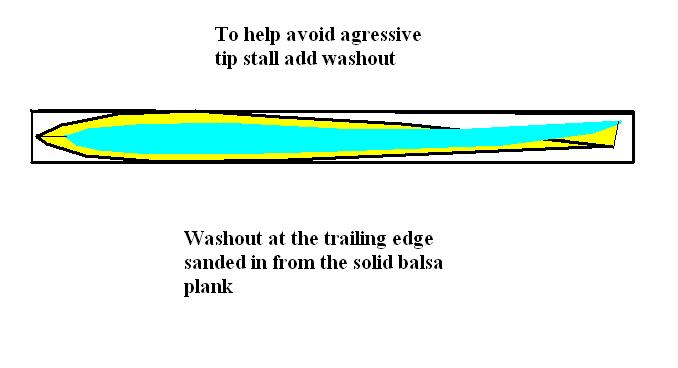

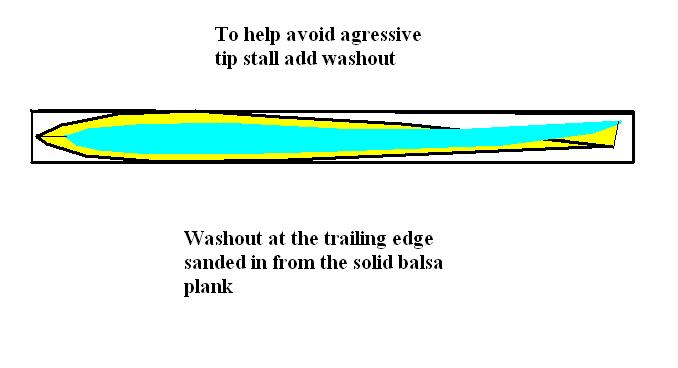

Leading edge tricks are good and trailing to help protect the soft balsa you have to go out far enough as the rubber bands will slide out far during a crash and can crush the balsa ( I know) happend to my Lil Speedy had to do a fix. So when I made the Skorch I went with a wide section of thin ply. I see you didn't tapper the tail of the fuselage as much is that rear former glued in? The flat bottom wing will turn better if you only have rudder, should sand in some washout at the wing tips and really need (some) dihedral.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Just use your gut feelings, best and past experience to solve design aspects as you go along and you should have a nice flying plane. Everything I did with the plane was carefully thought out for best overall performance of each part, for looks and for flying.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

With the washout did you mean thinning/tapering the wingtips from below so as to add some dehydral? Will this not weaken the tips for a tough landing in deep grass? Maybe patching up the tip with thin plywood?

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

You can wick in thin CA into the balsa grains to add strength prior to monokote or some sort of covering can fuel proof with paint if desired.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Tapperd tail to reduce drag / weight

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Looking at Freds numbers and knowing the max recommended rpm I wonder if Cox meant 24000 rpm in the air unloaded or 24k static??

Here is the prop I used a 3g Tornado 6x2 wood but note the other prop:

Carbon / plastic prop 4 x 4.5 pitch

- If static 24,000rpm 102.3 mph

- unloaded 26,00rpm 111 mph

Here is the prop I used a 3g Tornado 6x2 wood but note the other prop:

Carbon / plastic prop 4 x 4.5 pitch

- If static 24,000rpm 102.3 mph

- unloaded 26,00rpm 111 mph

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

1/2A Nut wrote:Tapperd tail to reduce drag / weight

The tapering of my tail is less than yours because of a simple reason: in Hungary the snooker is more popular than baseball thus it was a snooker pole with less tapering that I had for a template instead of a baseball bat...this will be Skorch Eastern European Dragster...

At the firewall the diameter of the domed part is 37mm and it tapers down to 26mm at the tail.

[quote="1/2A Nut"]Looking at Freds numbers and knowing the max recommended rpm I wonder if Cox meant 24000 rpm in the air unloaded or 24k static??

I tached my old-stock 051 in mid-air with my accoustic rpm gauge app on my Samsung phone yesterday, and.... holy shot....it measured 26,5k while slightly diving. The prop is a 5x4 black nylon. When I hold the plane in my hand the static mesures 22,5k. This app seems to be accurate, I once gauged it to a Hobbyco Digital Mini Tach and the two critters showed the same numbers.

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

1/2A Nut wrote:Leading edge tricks are good and trailing to help protect the soft balsa you have to go out far enough as the rubber bands will slide out far during a crash and can crush the balsa ( I know) happend to my Lil Speedy had to do a fix. So when I made the Skorch I went with a wide section of thin ply. I see you didn't tapper the tail of the fuselage as much is that rear former glued in? The flat bottom wing will turn better if you only have rudder, should sand in some washout at the wing tips and really need (some) dihedral.

Really need some dehydral....how do you do that with a solid balsa sheet wing? Cut a deep transverse notch at the wing middle and bend then glue the notch edges? Or by sanding? That willl take Michelangelo-kind of sculpturing skills that I miss...mine is those of an Australopitecus making flintstone utensils..

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

LOL yes would be a major feat to do that type of sanding!

You could go with 3 ply dihedral braces, cut the wing in half and sand a tad angle in both halfs for when you butt joint them together. Notch for the two main braces rear one is just to help with the rubber bands more so than anything. Could use a strip of fiberglass or cloth and wick in some CA across the butt joint.

You could go with 3 ply dihedral braces, cut the wing in half and sand a tad angle in both halfs for when you butt joint them together. Notch for the two main braces rear one is just to help with the rubber bands more so than anything. Could use a strip of fiberglass or cloth and wick in some CA across the butt joint.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

5x4 black nylon should lose a tad pitch loaded in the air say 5x3.7 or more -if with the cox black flexible prop.

- 26,5k while slightly diving. 93 mph / 3.7P

- static measures 22,5k. - 74.6 mph / 3.5P

- 26,5k while slightly diving. 93 mph / 3.7P

- static measures 22,5k. - 74.6 mph / 3.5P

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Source for the 4Dx 4.5P carbon plastic prop you are using?

I think it was Paul Gibeault who noted that much above 26K RPM the Piston to rod joint had a short life and the tendency to bust crank shafts increased. I have twisted a Tee Dee .051 up to 27,800 RPM on the bench with 45% Nitro and too small a propeller. As soon as I noticed the RPM with the tach I pinched off the fuel just knowing I probably hurt the engine. Still one of my best .051 today but I prop it larger and keep the Nitro at 35% or 25%. For sport flying especially RC like you guys are describing I doubt the occasion diving scream up over 26K RPM will hurt the engine. Paul is a racer so his engines are at the ragged edge for many refuels and sustained duration at high RPMs

I think it was Paul Gibeault who noted that much above 26K RPM the Piston to rod joint had a short life and the tendency to bust crank shafts increased. I have twisted a Tee Dee .051 up to 27,800 RPM on the bench with 45% Nitro and too small a propeller. As soon as I noticed the RPM with the tach I pinched off the fuel just knowing I probably hurt the engine. Still one of my best .051 today but I prop it larger and keep the Nitro at 35% or 25%. For sport flying especially RC like you guys are describing I doubt the occasion diving scream up over 26K RPM will hurt the engine. Paul is a racer so his engines are at the ragged edge for many refuels and sustained duration at high RPMs

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Here are three in 1/2A range I have them all.

I took the 4.5 x 4.5 and reshaped the tips down a 1/8th each.

The 4.75 x 4.75 I plan to take to 3.8 x 4.75 if at 26k /117mph

I have their 6 x 5 (not shown) same hub size and blade width if 3.8 x 5 at 26K /123mph

Stiff blades wont lose their pitch.

http://www.ebay.com/itm/4-75X4-75-E-4-75X4-75E-Propeller-Prop-airplane-park-fly-/140386536469#ht_2257wt_1018

http://www.ebay.com/itm/4-5X4-5-E-4-5X4-5E-Propeller-Prop-for-airplane-park-fly-/130390633710#ht_2291wt_927

http://www.ebay.com/itm/3PCS-RC-Propeller-EMP-4-1x4-1E-Prop-Motor-Shaft-Adaptation-for-RC-Aircraft-plane-/140897059386#ht_2310wt_1018

RC Propeller EMP

I took the 4.5 x 4.5 and reshaped the tips down a 1/8th each.

The 4.75 x 4.75 I plan to take to 3.8 x 4.75 if at 26k /117mph

I have their 6 x 5 (not shown) same hub size and blade width if 3.8 x 5 at 26K /123mph

Stiff blades wont lose their pitch.

http://www.ebay.com/itm/4-75X4-75-E-4-75X4-75E-Propeller-Prop-airplane-park-fly-/140386536469#ht_2257wt_1018

http://www.ebay.com/itm/4-5X4-5-E-4-5X4-5E-Propeller-Prop-for-airplane-park-fly-/130390633710#ht_2291wt_927

http://www.ebay.com/itm/3PCS-RC-Propeller-EMP-4-1x4-1E-Prop-Motor-Shaft-Adaptation-for-RC-Aircraft-plane-/140897059386#ht_2310wt_1018

RC Propeller EMP

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Something to consider the blade material is great reshaping, I have concidered taking the

4.7 5 x 4.75 to a 4 x 4.75 with reduced trailing edge to have a 4in dia prop.

All can have a thinner cord to keep dia. up.

4.7 5 x 4.75 to a 4 x 4.75 with reduced trailing edge to have a 4in dia prop.

All can have a thinner cord to keep dia. up.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Darn, too bad, they looked promising.

Please be very careful to not be in the path of those if or when they explode. I have seen more than one electric propeller on a IC engine shed a blade on start up.

I hasten to add that my observation was in the 7",8", and 9" sized electric propellers and I have no personal experience with the 1/2A versions.

Can't remember but I think either the APC site or Master Airscrew site has a blurb on why. Generally speaking propeller makers state the max RPM like "165,000 RPM/prop diameter" and usually slow fly props are "65,000 RPM/prop diameter"

Example a Glow sport prop from APC at 10" diameter has a max of 16,500 RPM the same prop, but slow fly version, can only spin 6500 RPM or less

I bet there is no way to find the props you are using specifications.

And considering the insane RPMs I have seen with some RC high speed planes they may be just fine in the 26K RPM range

Please be very careful to not be in the path of those if or when they explode. I have seen more than one electric propeller on a IC engine shed a blade on start up.

I hasten to add that my observation was in the 7",8", and 9" sized electric propellers and I have no personal experience with the 1/2A versions.

Can't remember but I think either the APC site or Master Airscrew site has a blurb on why. Generally speaking propeller makers state the max RPM like "165,000 RPM/prop diameter" and usually slow fly props are "65,000 RPM/prop diameter"

Example a Glow sport prop from APC at 10" diameter has a max of 16,500 RPM the same prop, but slow fly version, can only spin 6500 RPM or less

I bet there is no way to find the props you are using specifications.

And considering the insane RPMs I have seen with some RC high speed planes they may be just fine in the 26K RPM range

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Yes, I wouldn't trust those props either. They don't state the material (other than composits which could mean anything) and they don't give any rpm rating either....

Even the cox 5x3 props can have problems around 20krpm. I haven't had that problem myself but there was a bad batch or something, where the blades were easily broken off right at the hub if/when they were bent.

Even the cox 5x3 props can have problems around 20krpm. I haven't had that problem myself but there was a bad batch or something, where the blades were easily broken off right at the hub if/when they were bent.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

The electric props are not suitable for IC engines. It is not the revs but the vibration.

They are also extemely sharp and a little brittle Not kind to fingers!

They are also extemely sharp and a little brittle Not kind to fingers!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

For me I just remain behind the prop at all times after I have started an engine.

I have tested the 4.1 x 4.1 prop to 31.4k with a 140w 11.2v brushless motor. The blade is thicker at the hub / more robust compared to other electric props of this size, a stock uncut 4.5 x 4.5 did just fine on the bench with a throttled TD.

Soon I will flight test with throttle. For my own past testing efforts the best and safe way to induce and force the possibility of shearing a blade: while in flight power down during a vertical climb till the plane is on the edge of falling off then bang full throttle inducing maximum loading at the hub testing the materials limits. Do that a few times and then if no failure land and check for stresses at the hub if no stress then press on and enjoy the attributes of the prop design. Thus far these EMP props are the best molded electric props I have seen / used other than APC and some German Speed props.

I own a 7000 watt 9.4hp outrunner with a 32x15 prop the material appears to be same type. The first time I applied 60v my heart beat out of my chest impressive amount of thrust even the sound of the prop 2ft away was shocking. Two geared motors to a 48in 3 bladed prop could lift a man straight up. I plan to buy 3 more and make a quad copter to fly around. I have calculated for 15-18 min flights 3/4 throttle with Li poly cells. 36 x 8 props 34 lbs of batteries. 4 150A esc's.

I have tested the 4.1 x 4.1 prop to 31.4k with a 140w 11.2v brushless motor. The blade is thicker at the hub / more robust compared to other electric props of this size, a stock uncut 4.5 x 4.5 did just fine on the bench with a throttled TD.

Soon I will flight test with throttle. For my own past testing efforts the best and safe way to induce and force the possibility of shearing a blade: while in flight power down during a vertical climb till the plane is on the edge of falling off then bang full throttle inducing maximum loading at the hub testing the materials limits. Do that a few times and then if no failure land and check for stresses at the hub if no stress then press on and enjoy the attributes of the prop design. Thus far these EMP props are the best molded electric props I have seen / used other than APC and some German Speed props.

I own a 7000 watt 9.4hp outrunner with a 32x15 prop the material appears to be same type. The first time I applied 60v my heart beat out of my chest impressive amount of thrust even the sound of the prop 2ft away was shocking. Two geared motors to a 48in 3 bladed prop could lift a man straight up. I plan to buy 3 more and make a quad copter to fly around. I have calculated for 15-18 min flights 3/4 throttle with Li poly cells. 36 x 8 props 34 lbs of batteries. 4 150A esc's.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

My understanding is IC props have no problem in a electric application other than shape and weight (They try to make electric blades have less mass to keep amp draw down)

BUT the harmonics and vibration from the IC engine can significantly impact a electric designed blade

Again...I won't be ordering any although they look promising

And since I have seen the small electric blades PUSHING a Parkjet at near 200 MPH and what sounded like well over 30,000 RPM....they probably will be oK but I don't need to screw up and have one crap out around my grandson

http://www.hobbyking.com/hobbyking/store/__36677__Parkjet_2_High_Speed_Wing_with_3_axis_Flight_Stabilizer_EPO_550mm_Mode_2_RTF_.html

BUT the harmonics and vibration from the IC engine can significantly impact a electric designed blade

Again...I won't be ordering any although they look promising

And since I have seen the small electric blades PUSHING a Parkjet at near 200 MPH and what sounded like well over 30,000 RPM....they probably will be oK but I don't need to screw up and have one crap out around my grandson

http://www.hobbyking.com/hobbyking/store/__36677__Parkjet_2_High_Speed_Wing_with_3_axis_Flight_Stabilizer_EPO_550mm_Mode_2_RTF_.html

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

I don't start engines or fly unless spectators are well behind me and when running boats the ducks, turtles have the right away.

The quad copter market is starting to make all carbon props, I have been keeping an eye on potential props for anything from .010 to .061 thus far only one suitable found for a .020... there is hope.

That foam delta looks good and all the foam planes have opened up some additional small IC fun. I have balsa planked a foamy with sorghums and covered with monokote made for a very strong lightweight plane.

Some of the scale planes have been calling my name.

This balsa / ply delta comes with a fuel proof finish and RTF less gear for $50.56 to $66

http://www.hobbyking.com/hobbyking/store/__56286__delta_rocket_high_speed_wing_red_640mm_arf_.html

USA warehouse:

http://www.hobbyking.com/hobbyking/store/__68858__delta_rocket_high_speed_wing_red_640mm_arf_us_warehouse_.html

Made to run up to 200 watts so TD.09 to TD .15 should make a nice screamer.

The quad copter market is starting to make all carbon props, I have been keeping an eye on potential props for anything from .010 to .061 thus far only one suitable found for a .020... there is hope.

That foam delta looks good and all the foam planes have opened up some additional small IC fun. I have balsa planked a foamy with sorghums and covered with monokote made for a very strong lightweight plane.

Some of the scale planes have been calling my name.

This balsa / ply delta comes with a fuel proof finish and RTF less gear for $50.56 to $66

http://www.hobbyking.com/hobbyking/store/__56286__delta_rocket_high_speed_wing_red_640mm_arf_.html

USA warehouse:

http://www.hobbyking.com/hobbyking/store/__68858__delta_rocket_high_speed_wing_red_640mm_arf_us_warehouse_.html

Made to run up to 200 watts so TD.09 to TD .15 should make a nice screamer.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

1/2A Nut wrote:The flat bottom wing will turn better if you only have rudder, should sand in some washout at the wing tips and really need (some) dihedral.

How much dihedral would you estimate is needed? I have a mid-wing R/C plane with 34" winspan, flat wing bottom, that flies and maneuvers excellently without ailerons and has a dehidral angle of 14 degree (between each wing-half and the horizontal plane).

I know the lower the wing/higher the CG point, more dihedral angle might be needed.

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

If 14 deg has worked for you 14 to 16 degree should be enough. If this plane flies faster than the mid wing it will respond better in the turns in theory.

Could go with a flat top and only dihedral where it counts.

Could go with a flat top and only dihedral where it counts.

1/2A Nut- Top Poster

- Posts : 3539

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee Performance Crank

Re: Tee Dee Performance Crank

Thanks a lot. I will go with a flat bottom, sanded airfoil top, and dihedral of 14 degree by sanding the wind root edges for the halves to meet in this degree.

I appreciate your help. This one SHOULD fly this weekend more than the small speeedy I made for the TD010..still cannot understand the reasons why its rpm remains below 27k that it used to have...

I appreciate your help. This one SHOULD fly this weekend more than the small speeedy I made for the TD010..still cannot understand the reasons why its rpm remains below 27k that it used to have...

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Page 3 of 13 •  1, 2, 3, 4 ... 11, 12, 13

1, 2, 3, 4 ... 11, 12, 13

Similar topics

Similar topics» Wanted: Tee Dee .049 crank case and crank

» TD 049 crank mod

» My crank said No!

» 049 crank vs. 051 crank

» Finished cleaning the chopper engine (baby bee)

» TD 049 crank mod

» My crank said No!

» 049 crank vs. 051 crank

» Finished cleaning the chopper engine (baby bee)

Page 3 of 13

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules