Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Shimming: How do you know compression is right?

Page 1 of 2

Page 1 of 2 • 1, 2

Shimming: How do you know compression is right?

Shimming: How do you know compression is right?

Okay, I'm showing my igrnorance here. But beyond "no compression, no fire," I have zero understanding of how to determine if compression is right. What are indications and risks from incorrect compression?

flyjsh- Gold Member

- Posts : 129

Join date : 2013-03-12

Location : Houston, Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

The general rule (if I am not mistaken) is one head shim per 10% nitro. So for 30% you should install 3 shims.

That will probably work fine for sport use. However if you are looking for max them you need to play around a little.

Say you have 25% nitro, well you can't add half a shim(gasket) so this is when it helps to have a tach. You can add 2 shims and see what your RPM is and then add or subtract as necessary to see if you can bring the RPM's up.

Piston fit, head type, prop and atmosphere all play into this equation.

To simplify: not enough compression, and performance is hampered, too much and performance is hampered.

Grab yourself a tach and a bunch of shims and play around. Once you achieve the best performance for the combo you have chosen, if you change anything then start again

Ron

That will probably work fine for sport use. However if you are looking for max them you need to play around a little.

Say you have 25% nitro, well you can't add half a shim(gasket) so this is when it helps to have a tach. You can add 2 shims and see what your RPM is and then add or subtract as necessary to see if you can bring the RPM's up.

Piston fit, head type, prop and atmosphere all play into this equation.

To simplify: not enough compression, and performance is hampered, too much and performance is hampered.

Grab yourself a tach and a bunch of shims and play around. Once you achieve the best performance for the combo you have chosen, if you change anything then start again

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

The compression is ideal when the engine produces maximum power. In theory it means the ignition occurs just right before the piston reaches its top dead center, and heat input to the cycle occurs thus at the highest average temperature. (This comes from the Carnot cycle theory and laws of thermodynamics)

To early explosion caused by excessive compression means part of the combustion energy will work against the piston moving upwards. Too late ignition i.e. on the top DC or slightly afterwards will not result in the highets possible mean pressure in the cylinder, because part of the fuel will burn with the piston already near to opening the exhaust opening and the burning mix will leave the engine before spending its useful energy to drive it.

I guess setting the ideal compression is more or less an empyrical stuff and exact, one-fit-for all answer cannot be given. You must exercise by starting up the engine, peak it by setting the carb, take rev readings on a tachometer, stop the engine and change the number of shims. Obviously the compression is ideal when the peak rpm of the engine is the highest with a given prop and fuel blend.

The more shims under the head, the lower the compression.

As a rule of thumb, this is my experience:

Normal glow heads require one or two shims under the head. This is true up to 20% nitro (I do not use higher than 20% nitro)

High compression heads need 3-5 shims. Too high compression typically becomes manifest in very hot engine temperature and premature firing of the engine. (When you flip the propeller by hand the engine will backfire much before you turn the prop over the top dead center of the piston.)

Higher nitro content (say, above 20%) causes higher engine temperature that triggers premature ignition, the prevention of which will certainly call for more shims.

Sorry if it was not quite an exact methodology.

To early explosion caused by excessive compression means part of the combustion energy will work against the piston moving upwards. Too late ignition i.e. on the top DC or slightly afterwards will not result in the highets possible mean pressure in the cylinder, because part of the fuel will burn with the piston already near to opening the exhaust opening and the burning mix will leave the engine before spending its useful energy to drive it.

I guess setting the ideal compression is more or less an empyrical stuff and exact, one-fit-for all answer cannot be given. You must exercise by starting up the engine, peak it by setting the carb, take rev readings on a tachometer, stop the engine and change the number of shims. Obviously the compression is ideal when the peak rpm of the engine is the highest with a given prop and fuel blend.

The more shims under the head, the lower the compression.

As a rule of thumb, this is my experience:

Normal glow heads require one or two shims under the head. This is true up to 20% nitro (I do not use higher than 20% nitro)

High compression heads need 3-5 shims. Too high compression typically becomes manifest in very hot engine temperature and premature firing of the engine. (When you flip the propeller by hand the engine will backfire much before you turn the prop over the top dead center of the piston.)

Higher nitro content (say, above 20%) causes higher engine temperature that triggers premature ignition, the prevention of which will certainly call for more shims.

Sorry if it was not quite an exact methodology.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

This is somewhat confusing to me too. Until recently (since joining CEF) I wasn't aware that high-compression Cox glowheads existed. From what I have come to understand.. they would only be useful when using a fuel with a lower nitro content. Am I correct here? If you need to add copper gaskets when increasing to a high-nitro fuel.. you're effectively reducing compression.. so; wouldn't "switching" to a standard head accomplish the same thing?

Here's a question.. ... does the difference in compression between the two heads work out to be less than.. or possibly "half of" a single copper gasket's difference? If so; then I could understand how using the high-compression head allows for more fine-tuning possibilities.

... does the difference in compression between the two heads work out to be less than.. or possibly "half of" a single copper gasket's difference? If so; then I could understand how using the high-compression head allows for more fine-tuning possibilities.

Here's a question..

... does the difference in compression between the two heads work out to be less than.. or possibly "half of" a single copper gasket's difference? If so; then I could understand how using the high-compression head allows for more fine-tuning possibilities.

... does the difference in compression between the two heads work out to be less than.. or possibly "half of" a single copper gasket's difference? If so; then I could understand how using the high-compression head allows for more fine-tuning possibilities. Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

The high compression head can be as effective on a Babe Bee as a TD. The outcome won't be the same because the designs are different. However a bump in compression is always a bump in power no matter what fuel you use. To a point...

Anyway to answer your question there is a significant difference in compression between a standard head and a TD head. And way more than a gasket.

Ron

Anyway to answer your question there is a significant difference in compression between a standard head and a TD head. And way more than a gasket.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

You can lap a head (grind or sand against a plate) too. This can increase compression to a middle value.

Think about compression as a timing adjustment. Higher compression advances timing (earlier than top dead center or tdc) for a given fuel and glow plug. Similarly a hotter glow plug will advance timing.

Don't forget the plethora of drop in heads available.

Phil

Think about compression as a timing adjustment. Higher compression advances timing (earlier than top dead center or tdc) for a given fuel and glow plug. Similarly a hotter glow plug will advance timing.

Don't forget the plethora of drop in heads available.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

I have found with a smaller prop you can get away with higher compression as the engine doesn't lag lugging the load and thus nirvana can be had baring the mechanical limits of the engine. So if you have no spare gaskets in the field you can always prop down for the day if with just 1 shim and a HC head. Higher nitro can cool an engine  You can cut down the fins to make up the difference to improve head temps when exceeding 60 mph + with no cowl / reduces nose weight and drag.

You can cut down the fins to make up the difference to improve head temps when exceeding 60 mph + with no cowl / reduces nose weight and drag.

Here is an example of one of my own engines:

Engine weight and prop as shown 39.4g.

HC Plug

SPI TD cylinder

APC 4.2 x 4

45% nitro / 25% castor on 2 shims.

22,180 rpm / 84 mph theoretical with the 4p.

You can cut down the fins to make up the difference to improve head temps when exceeding 60 mph + with no cowl / reduces nose weight and drag.

You can cut down the fins to make up the difference to improve head temps when exceeding 60 mph + with no cowl / reduces nose weight and drag. Here is an example of one of my own engines:

Engine weight and prop as shown 39.4g.

HC Plug

SPI TD cylinder

APC 4.2 x 4

45% nitro / 25% castor on 2 shims.

22,180 rpm / 84 mph theoretical with the 4p.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

I'll probably get myself slammed here, but the way I see it, Cox R&D & QC people surely would have ensured that all Cox engines came from the factory in a state that would be as efficient as possible. As far as I know, all Cox engines came from the factory with one head gasket and with the expectation that they would be run on (at least) the standard 25% nitro Cox fuel. Otherwise, the instructions would state that the engine should be run on 10% maximum. Tee Dees had much higher compression than babe Bees but came out with the ssme head gasket, and only one. Was there any official documentation from Cox that stated that more gaskets should be used? Why would any Cox engine using a standard head ever need more than one gasket, when it's quite feasible to install a Tee Dee head and get more power? The QZ was an example. It was basically a non-SPI Babe Bee with a Tee Dee head installed to up the power to compensate for the muffler. I'd be interested to see if the QZ instructions state the need to run more than one gasket, or any Cox engine instructions for that matter.

Clearly, many of you have disproved my thoughts by experimenting and getting more power from your engines, but I feel that any shift from original design in anything mechanical can comprimise efficiency. In my job I refuse to perform modifications to people's engines for that very reason. Can of worms!!

Rod.

(What have I done?? )

)

Clearly, many of you have disproved my thoughts by experimenting and getting more power from your engines, but I feel that any shift from original design in anything mechanical can comprimise efficiency. In my job I refuse to perform modifications to people's engines for that very reason. Can of worms!!

Rod.

(What have I done??

)

)

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Rod, that was something I was thinking too. Or, if not set up for peak power, maybe for ease of operation.

I don't think as kids we ever used more than one shim, and with a chemist father who whipped us up everything from 0-50% nitro, it sounds like we should have.

I don't think as kids we ever used more than one shim, and with a chemist father who whipped us up everything from 0-50% nitro, it sounds like we should have.

flyjsh- Gold Member

- Posts : 129

Join date : 2013-03-12

Location : Houston, Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Yes, I suppose it was set up to run out of the box from the factory. Maybe I mistakenly misunderstood the intent of the post and I answered as pertaining to performance.

Anyway, if you just want to have a hands free engine out of the box then run it as is. If you want a little more then play around.

A little story, I was having a very hard time starting an engine a couple weeks ago. I was told the engine was a consistent runner. I also noticed that it was doing the prop wobble which is a sign of over compression. I added a gasket and we were in business next flip.

What changed? I don't know for sure, have a few theories, but I say all that because it helps to understand what's going on and how things work. It could have made for a crummy day if I hadn't taken the time to learn a few things beforehand.

Just a thought.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Rod has a good point. Maybe we've been telling each other this stuff for so long that we believe it to be gospel. I never was one to read documentation so if the instructions ever mentioned extra head gaskets I wouldn't have known. But the blue Cox can I always used was 15% nitro and the rule of thumb I now refer to is one gasket up to 20% nitro and add one for every 10% after that. However the red Cox racing fuel can was 30% nitro but I didn't use it until the last days of Cox. I do know that I never blew a plug with the one gasket I ran until I was back into it and using 25% post Cox internet fuel. Then started popping them in the air and learned of this new-to-me rule of thumb and quit blowing them again.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Yes Rod is ok with his stock rule of thumb in general use all will be golden.

As noted in my last post I am only using 2 shims with a high compression head on 45% nitro - mind you I'm all castor at 25%

As noted in my last post I am only using 2 shims with a high compression head on 45% nitro - mind you I'm all castor at 25%

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Oldenginerod wrote:I'll probably get myself slammed here, but the way I see it, Cox R&D & QC people surely would have ensured that all Cox engines came from the factory in a state that would be as efficient as possible. As far as I know, all Cox engines came from the factory with one head gasket and with the expectation that they would be run on (at least) the standard 25% nitro Cox fuel. Otherwise, the instructions would state that the engine should be run on 10% maximum. Tee Dees had much higher compression than babe Bees but came out with the ssme head gasket, and only one. Was there any official documentation from Cox that stated that more gaskets should be used? Why would any Cox engine using a standard head ever need more than one gasket, when it's quite feasible to install a Tee Dee head and get more power? The QZ was an example. It was basically a non-SPI Babe Bee with a Tee Dee head installed to up the power to compensate for the muffler. I'd be interested to see if the QZ instructions state the need to run more than one gasket, or any Cox engine instructions for that matter.

Clearly, many of you have disproved my thoughts by experimenting and getting more power from your engines, but I feel that any shift from original design in anything mechanical can comprimise efficiency. In my job I refuse to perform modifications to people's engines for that very reason. Can of worms!!

Rod.

(What have I done??)

Rod,

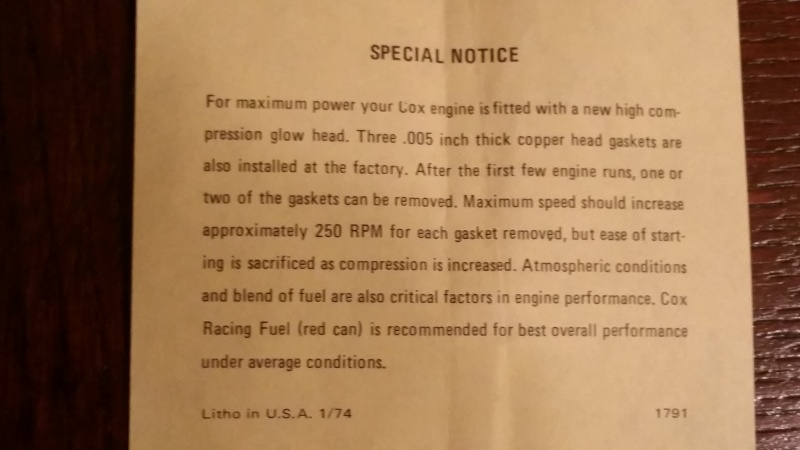

TeeDee049 and 051 engines came with the below instruction, stating 3 factory installed shims were under the head.

I believe the number of shims must be set by the engine user empyrically because quite a number of factors may cause ignition timing to be different between 2, otherwise identical stock engines:

1. The dome geometry inside the head (I saw many different high-compression head domes)

2. The balljoint "play" and wear of the ball top that may result in a lowered piston crown thus lowered compression

3. Thickness of the castor varnish burnt on the top of the cylinder

4. The piston/cylinder fit...even though my experience is this is very precise and lasting compression is maintained in COX engines even after many tens of hours of running (except one has leaned out the engine many times or run it with dirt in the cylinder)

5. Elevation above see level (the higher you live the thinner the air..)

5. Last but not at least, fuel blend/nitro content

In such small engines the variance of the above conditions/geometry will significantly impact the ignition timing thus a one-fit-for all solution i.e. number of shims cannot be expected..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Hey now thats helpful wtg!

Hey now thats helpful wtg!Yes says you can remove 1 or 2 of the shims after a (few) runs to get 250 rpm increases per shim. So in lieu of that 1 shim can / may based on preference to starting qualities / be enough.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Cribbs74 wrote:

A little story, I was having a very hard time starting an engine a couple weeks ago. I was told the engine was a consistent runner. I also noticed that it was doing the prop wobble which is a sign of over compression. I added a gasket and we were in business next flip.

What changed? I don't know for sure, have a few theories, but I say all that because it helps to understand what's going on and how things work. It could have made for a crummy day if I hadn't taken the time to learn a few things beforehand.

Just a thought.

Prop wobble? Is that when the engine fires but cannot get past TDC, then cranks backwards to fire again but again cannot get past TDC? If so, I think you may have just saved one of my hanger queens

flyjsh- Gold Member

- Posts : 129

Join date : 2013-03-12

Location : Houston, Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Yep, that's exactly what it looks like.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

flyjsh wrote:Cribbs74 wrote:

A little story, I was having a very hard time starting an engine a couple weeks ago. I was told the engine was a consistent runner. I also noticed that it was doing the prop wobble which is a sign of over compression. I added a gasket and we were in business next flip.

What changed? I don't know for sure, have a few theories, but I say all that because it helps to understand what's going on and how things work. It could have made for a crummy day if I hadn't taken the time to learn a few things beforehand.

Just a thought.

Prop wobble? Is that when the engine fires but cannot get past TDC, then cranks backwards to fire again but again cannot get past TDC? If so, I think you may have just saved one of my hanger queens

A year ago I thought that was one of the most infuriating things on the planet! Half my engines did this!

Yes, a gasket or two will save your hanger queen and possibly make it a favorite runner.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

What do you call a hanger queen?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

I think I have found out...planes with defunct engines hanging on the wall of your shop?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Yep, you got it.

flyjsh- Gold Member

- Posts : 129

Join date : 2013-03-12

Location : Houston, Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

HAZAAA! Okay, I finally put down the balsa on my current build and took the PT-19 out for a spin. Fiddled with shims and was able to go from mid 13s to high 14s/low 15s (according to my crappy phone app tach)! Quite pleased with the first attempt. Now I guess I need to buy a good tach.

flyjsh- Gold Member

- Posts : 129

Join date : 2013-03-12

Location : Houston, Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Nah, not really. Just set it for 2 blades and point it at a fluorescent lamp. Count any amount over or under 3600 RPM as your offset to add or subtract from your actual engine readings. It should be consistent.flyjsh wrote: Now I guess I need to buy a good tach.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

The phone tach is acoustically driven. Set for 1 cylinder 2cycle it bounces from 15k to 30 k, so I think it sometimes doubles the revs. I bounces around a bunch. I figure it is+/- 500 at any time.

flyjsh- Gold Member

- Posts : 129

Join date : 2013-03-12

Location : Houston, Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

I set the phone tach to RC and if I know rough numbers I will set min and max rpm setting close to where it should be the resolution is 80 rpm when check with photocell tachs its actually very close this only works if the engine rpm is not bouncing around. You can check tach vids on youtube to confirm it's readings.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Shimming: How do you know compression is right?

Re: Shimming: How do you know compression is right?

Yeah, I see what you mean.flyjsh wrote:The phone tach is acoustically driven. Set for 1 cylinder 2cycle it bounces from 15k to 30 k, so I think it sometimes doubles the revs. I bounces around a bunch. I figure it is+/- 500 at any time.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Cylinder shimming

» Shimming Cox Cylinder for Transfer and Exhaust Timing

» Shimming Cox Cylinder for Transfer and Exhaust Timing

» New Uploads: KK Shimming / Timing guide and Cox Parts Price Lists from 1995 and 1996

» Restoring a rusty engine

» Shimming Cox Cylinder for Transfer and Exhaust Timing

» Shimming Cox Cylinder for Transfer and Exhaust Timing

» New Uploads: KK Shimming / Timing guide and Cox Parts Price Lists from 1995 and 1996

» Restoring a rusty engine

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules