Log in

Search

Latest topics

» Retail price mark-up.. how much is enough?by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Shimming Cox Cylinder for Transfer and Exhaust Timing

Page 1 of 1

Shimming Cox Cylinder for Transfer and Exhaust Timing

Shimming Cox Cylinder for Transfer and Exhaust Timing

Shimming Cox Engines --- Port / Timing Guide

by M. McIntyre

Because of an accumulation of tolerances of production tolerances, the crown of the piston can, and often does, extend above the inside shoulder of the cylinder when the piston is at top dead center (ATDC). Optimum, design, transfer and exhaust porting occurs when the crown of the piston is exactly level with the shoulder ATDC. One way to check this is with a depth micrometer. However, since most modelers do not have such micrometers, here is another way.

Take a piece of thin (.010” or 0.25mm) brass shim stock, and cut a full moon circle (disc), that will fit into the top of the cylinder head – the approximation diameter of a copper glow head gasket. Cut (drill or punch), an air bleed hole in the center of the disc, and be sur there are no burrs anywhere on the disc. Now, take an old, burnt out glow head, and remove the center stem (glow wire, etc.). The objective is to convert it into a screw-in hold-down insert that will not be pressure tight. Or you can purchase a glow head adapter to do the same? See fig. #1

With the engine assembled, place the bass disc on the cylinder shoulder, and screw in the insert (or glow head adapter). See fig. #2 – alias glow head. Thus, when you gently rotate the crankshaft, you’ll feel the piston “bump” and stop against the disc, if it were to try to pass the shoulder ATDC. See fig. #3 Now, loosen the cylinder from the crankcase until you cannot feel a “bump” or obstruction ATDC. With a set of feller gages insert a shim between the cylinder head and crank case (at the threads location). This will give you an idea of the proper shim required.

I purchased a punch and die set to make my own shims. Also purchased was a step less reamer. See fig. #4 and #5. You will also need brass shim stock (.002” / .003” / .005”). The first hole in the shim stock will be ½” diameter (see fig. #6), but the is not big enough to slip over threads on the cylinder (after the threads it is). That is where the step less reamer is used to enlarge the hole, (See fig. #7) just large enough to engage the threads on the cylinder. See fig. #8 and #9.

Next, insert the shim stock to the ¾” hole on the punch, and try to center it the best you can to the ½” hole on the shim stock. See fig. #10 Now punch out you shim at the ¾” hole with the die See fig. #11 and fig. #12

Screw the shim onto the cylinder head, then screw the cylinder head to the crankcase. The cylinder head should have been raised enough to just clear the brass disc which is still screwed into the top of the cylinder head (on the shoulder – See fig. #13 and #3) with no “bump” feeling. Then you’ll know that the proper shimming has been ascertained.

Next step, using an Exacto knife, score the brass shim a around the cylinder head. See fig. #14 Remove the cylinder head and shim from the crankcase. Remove the shim from the cylinder head. You should be able to see a scored circle on your brass shim. See fig. #15 Using a good heavy pair of sharp scissors start cutting the shim stock to the scored circle on the brass shim. See fig. #16 Cut off all the extra shim stock to the scored circle until none is left. See fig. #17

Install the shim back onto the cylinder head, then the cylinder head back on to the crankcase, making sure when the cylinder head contacts the crankcase the shim is centered under the cylinder head. See fig. #18 and #19 and tighten the head to the crankcase. Check ATDC one more time for correct shim height. After that is done, remove the (glow) head insert and brass disc, and install a copper head gasket and functional glow head.

Your engine now has the correct designed transfer and exhaust timing. Note, however that the optimum performance my vary from this position. In particular, be sure that you still have about .012” (0.30mm) sub-piston induction (SPI) when the piston is ATDC.

Years ago, Kustom Kraftsmanship (owner: Joe Klause) sold shim kits, stock #181 which had four different shim sizes and a shim housing. The shim housing fits neatly over the crankcase shoulder and the shims slipped into the shim housing (so the shims were not bent when the cylinder was screwed on). Kustom Kraftsmanship is no longer in business --- it’s a shame. You could get good custom parts for any Cox engines.

If you purchase your own punch and die set, here is a tip before you start using it. First, clean any oil or rust preventative off the punches and die. Next, turn over your die (steel plate with holes in it), so the plexiglass is on the bottom. Grab one of your punches and insert it through the metal side of the die (as if you are going to punch a hole.) Now knock it all the way through. What this does is to shave the plexiglass so it will be exactly lined up to the metal plate below. If you don’t do this, the first time you use it, it will either crack the plexiglass, or damage the cutting edge on the punch. Do this until the punch fall through, then move onto the next punch hole until all are done. When you do use your punch and die set make sure that you punches do not drop onto the floor or any hard surface to where it damages the cutting edge of the punch (nick or burr).

Fig. #1

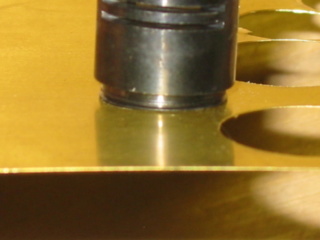

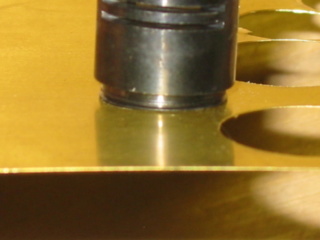

Fig. #2

Fig. #3

Fig. #4

Fig. #5

Fig. #6

Fig. #7

Fig. #8

Fig. #9

Fig. #10

Fig. #11

Fig. #12

Fig. #13

Fig. #14

Fig. #15

Fig. #16

Fig. #17

Fig. #18

Fig. #19

by M. McIntyre

Because of an accumulation of tolerances of production tolerances, the crown of the piston can, and often does, extend above the inside shoulder of the cylinder when the piston is at top dead center (ATDC). Optimum, design, transfer and exhaust porting occurs when the crown of the piston is exactly level with the shoulder ATDC. One way to check this is with a depth micrometer. However, since most modelers do not have such micrometers, here is another way.

Take a piece of thin (.010” or 0.25mm) brass shim stock, and cut a full moon circle (disc), that will fit into the top of the cylinder head – the approximation diameter of a copper glow head gasket. Cut (drill or punch), an air bleed hole in the center of the disc, and be sur there are no burrs anywhere on the disc. Now, take an old, burnt out glow head, and remove the center stem (glow wire, etc.). The objective is to convert it into a screw-in hold-down insert that will not be pressure tight. Or you can purchase a glow head adapter to do the same? See fig. #1

With the engine assembled, place the bass disc on the cylinder shoulder, and screw in the insert (or glow head adapter). See fig. #2 – alias glow head. Thus, when you gently rotate the crankshaft, you’ll feel the piston “bump” and stop against the disc, if it were to try to pass the shoulder ATDC. See fig. #3 Now, loosen the cylinder from the crankcase until you cannot feel a “bump” or obstruction ATDC. With a set of feller gages insert a shim between the cylinder head and crank case (at the threads location). This will give you an idea of the proper shim required.

I purchased a punch and die set to make my own shims. Also purchased was a step less reamer. See fig. #4 and #5. You will also need brass shim stock (.002” / .003” / .005”). The first hole in the shim stock will be ½” diameter (see fig. #6), but the is not big enough to slip over threads on the cylinder (after the threads it is). That is where the step less reamer is used to enlarge the hole, (See fig. #7) just large enough to engage the threads on the cylinder. See fig. #8 and #9.

Next, insert the shim stock to the ¾” hole on the punch, and try to center it the best you can to the ½” hole on the shim stock. See fig. #10 Now punch out you shim at the ¾” hole with the die See fig. #11 and fig. #12

Screw the shim onto the cylinder head, then screw the cylinder head to the crankcase. The cylinder head should have been raised enough to just clear the brass disc which is still screwed into the top of the cylinder head (on the shoulder – See fig. #13 and #3) with no “bump” feeling. Then you’ll know that the proper shimming has been ascertained.

Next step, using an Exacto knife, score the brass shim a around the cylinder head. See fig. #14 Remove the cylinder head and shim from the crankcase. Remove the shim from the cylinder head. You should be able to see a scored circle on your brass shim. See fig. #15 Using a good heavy pair of sharp scissors start cutting the shim stock to the scored circle on the brass shim. See fig. #16 Cut off all the extra shim stock to the scored circle until none is left. See fig. #17

Install the shim back onto the cylinder head, then the cylinder head back on to the crankcase, making sure when the cylinder head contacts the crankcase the shim is centered under the cylinder head. See fig. #18 and #19 and tighten the head to the crankcase. Check ATDC one more time for correct shim height. After that is done, remove the (glow) head insert and brass disc, and install a copper head gasket and functional glow head.

Your engine now has the correct designed transfer and exhaust timing. Note, however that the optimum performance my vary from this position. In particular, be sure that you still have about .012” (0.30mm) sub-piston induction (SPI) when the piston is ATDC.

Years ago, Kustom Kraftsmanship (owner: Joe Klause) sold shim kits, stock #181 which had four different shim sizes and a shim housing. The shim housing fits neatly over the crankcase shoulder and the shims slipped into the shim housing (so the shims were not bent when the cylinder was screwed on). Kustom Kraftsmanship is no longer in business --- it’s a shame. You could get good custom parts for any Cox engines.

If you purchase your own punch and die set, here is a tip before you start using it. First, clean any oil or rust preventative off the punches and die. Next, turn over your die (steel plate with holes in it), so the plexiglass is on the bottom. Grab one of your punches and insert it through the metal side of the die (as if you are going to punch a hole.) Now knock it all the way through. What this does is to shave the plexiglass so it will be exactly lined up to the metal plate below. If you don’t do this, the first time you use it, it will either crack the plexiglass, or damage the cutting edge on the punch. Do this until the punch fall through, then move onto the next punch hole until all are done. When you do use your punch and die set make sure that you punches do not drop onto the floor or any hard surface to where it damages the cutting edge of the punch (nick or burr).

Fig. #1

Fig. #2

Fig. #3

Fig. #4

Fig. #5

Fig. #6

Fig. #7

Fig. #8

Fig. #9

Fig. #10

Fig. #11

Fig. #12

Fig. #13

Fig. #14

Fig. #15

Fig. #16

Fig. #17

Fig. #18

Fig. #19

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Similar topics

Similar topics» Shimming Cox Cylinder for Transfer and Exhaust Timing

» New Uploads: KK Shimming / Timing guide and Cox Parts Price Lists from 1995 and 1996

» Cylinder Performance Figures

» Cylinder shimming

» Cylinder Timing

» New Uploads: KK Shimming / Timing guide and Cox Parts Price Lists from 1995 and 1996

» Cylinder Performance Figures

» Cylinder shimming

» Cylinder Timing

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules