Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Cox prop question

Page 2 of 4

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: Cox prop question

Re: Cox prop question

AGREED !! I'm in for ten or so...along with my usual order of assorted gaskets and tubing and such !!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Cox prop question

Re: Cox prop question

Just recently picked up an 020. Still looking for a couple more. Since I was planning on picking up some new parts, I would be interested in these props too.

Aero- Silver Member

- Posts : 73

Join date : 2014-08-10

Location : Southern IN

Re: Cox prop question

Re: Cox prop question

Thanks for the Update Bernie. I'm in for a couple.

Shawn

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: Cox prop question

Re: Cox prop question

T minus 10 and counting I did a design build for a CL TD .020 racer and had to settle with a 2p prop the 4D x 2.5P should make this one rip. I have only flown it a handful of times waiting to source something with more pitch to handle more wind!

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox prop question

Re: Cox prop question

By black plastic do you mean flexible as opposed to grey competition?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Cox prop question

Re: Cox prop question

Yes, the classic "double tough" flexible, as opposed to the grey "competition" version.

The grey, nylon-filled, resin needs to be bought in a quantity that is bigger than the planned production run, so we will mould the grey ones next time we do a production run of another prop size in grey. If the black ones sell that is ...

The grey, nylon-filled, resin needs to be bought in a quantity that is bigger than the planned production run, so we will mould the grey ones next time we do a production run of another prop size in grey. If the black ones sell that is ...

Re: Cox prop question

Re: Cox prop question

Here's some pics on a few various engines with double tuf blacks. Bernie good idea with competition grey should work great for the reed .049's. and strong enough for the TD's 10% nitro.

If used with the throttle sleeve should get fast crisp throttle response.

If used with the throttle sleeve should get fast crisp throttle response.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox prop question

Re: Cox prop question

It would be helpful if the pictures showed the actual product?

To me the images of the "grey" 4.5x4 are identical to the black 5x4 props...?

To me the images of the "grey" 4.5x4 are identical to the black 5x4 props...?

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox prop question

Re: Cox prop question

All our pictures are of the actual product.

However, the "grey" compound that the moulder used is identical to the one Cox used but the manufacturer now uses a darker dye. Yes, they are almost black but the difference becomes visible when held beside a black prop.

If we list them as "grey" they are guaranteed the stiff competition version.

Speaking of, we have a small quantity of OEM grey 6x3 props for sale here:

http://coxengines.ca/cox-.049-propeller-grey-6-x-3.html

However, the "grey" compound that the moulder used is identical to the one Cox used but the manufacturer now uses a darker dye. Yes, they are almost black but the difference becomes visible when held beside a black prop.

If we list them as "grey" they are guaranteed the stiff competition version.

Speaking of, we have a small quantity of OEM grey 6x3 props for sale here:

http://coxengines.ca/cox-.049-propeller-grey-6-x-3.html

Re: Cox prop question

Re: Cox prop question

Nice Bernie,

I didn't know the 4.5 x 4 was in grey either

I have 6 of the yellow plastic one's great prop and the big brother of the 4 x 2.5 in general shape.

I didn't know the 4.5 x 4 was in grey either

I have 6 of the yellow plastic one's great prop and the big brother of the 4 x 2.5 in general shape.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox prop question

Re: Cox prop question

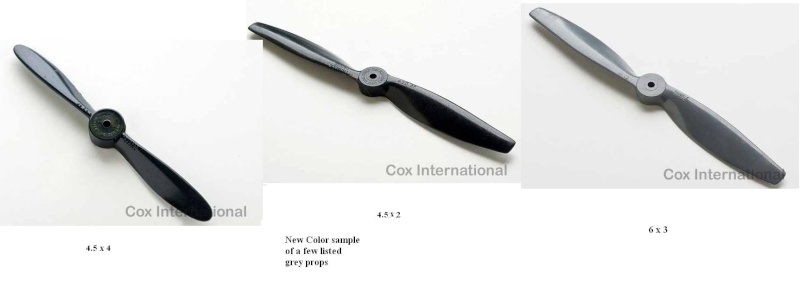

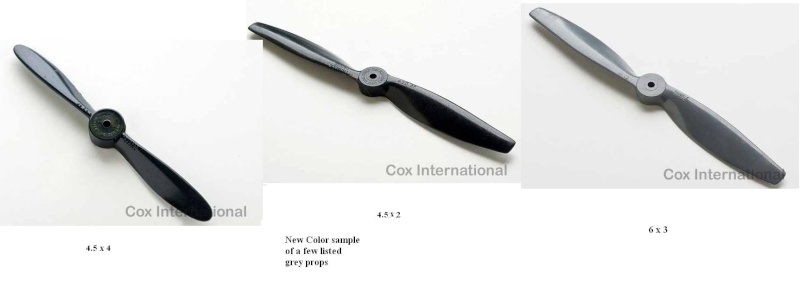

To help us all see the differences here are 3 samples of the listed grey competition props as displayed at this time

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox prop question

Re: Cox prop question

Not too much difference but it's also they way we edit the raw picture files.

By the same token, colour does not matter; it's the material that the props are moulded with

By the same token, colour does not matter; it's the material that the props are moulded with

Re: Cox prop question

Re: Cox prop question

Well here is what I see, I can't tell any difference....?

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox prop question

Re: Cox prop question

Pictures are now corrected:

http://coxengines.ca/cox-.049-propeller-grey-4.5-x-4.html

Surfer_kris,

My apologies for not listening to you when you first posted this. On your next order with us please mention this and we shall include 3 of those little beasts for you at no charge

and we shall include 3 of those little beasts for you at no charge

http://coxengines.ca/cox-.049-propeller-grey-4.5-x-4.html

Surfer_kris,

My apologies for not listening to you when you first posted this. On your next order with us please mention this

and we shall include 3 of those little beasts for you at no charge

and we shall include 3 of those little beasts for you at no charge

Re: Cox prop question

Re: Cox prop question

Oh, that explains why they looked so similar then...

Thank you for the offer, I will include that in the next order.

Another question, do you have any recommended rpm limits for these props?

Thank you for the offer, I will include that in the next order.

Another question, do you have any recommended rpm limits for these props?

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox prop question

Re: Cox prop question

Probably around 40,000 RPM with the compound we used.

Don't let the message on the hub scare you. Back in time they were made with a weaker compound.

Don't let the message on the hub scare you. Back in time they were made with a weaker compound.

Re: Cox prop question

Re: Cox prop question

Bernie, you said you noted the .049 reed engine does 20k + with the 4.5x4

Out of the teflon, copper, crystal clear plastic, stainless steel and mylar reeds which reed material has been shown to helps provide the highest rpm?

Thank you, also let us know when the 4x2.5 props are ready for sale.

Out of the teflon, copper, crystal clear plastic, stainless steel and mylar reeds which reed material has been shown to helps provide the highest rpm?

Thank you, also let us know when the 4x2.5 props are ready for sale.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

4D x 2P .049 Combat Prop

4D x 2P .049 Combat Prop

Hey guys cox made some CL dog fighters meant to be combat with streamers here is the triplane with a reed .049 note the prop size 4.0D x 2P written on the other blade of this RH prop is the word COX

The prop dia is suits the plane as the wee lil plane is small like a Lil Stinker.

The cylinder has the twin slits I would imagine to help protect the plastic. Very interesting prop choice and without question the least amount of prop pitch in relation to diameter ever mass produced for a cox .049 reed engine. This engine has to pull a streamer and must screaaam with this prop - have not ran it as of yet I would guess 25k ish. unloaded. If anyone has flown the biplane or the triplane let me know I would like to hear how well it did. I would imagine this prop would work very well with the Pee Wee engine too.

The prop dia is suits the plane as the wee lil plane is small like a Lil Stinker.

The cylinder has the twin slits I would imagine to help protect the plastic. Very interesting prop choice and without question the least amount of prop pitch in relation to diameter ever mass produced for a cox .049 reed engine. This engine has to pull a streamer and must screaaam with this prop - have not ran it as of yet I would guess 25k ish. unloaded. If anyone has flown the biplane or the triplane let me know I would like to hear how well it did. I would imagine this prop would work very well with the Pee Wee engine too.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox prop question

Re: Cox prop question

1/2A Nut wrote:Bernie, you said you noted the .049 reed engine does 20k + with the 4.5x4

Out of the teflon, copper, crystal clear plastic, stainless steel and mylar reeds which reed material has been shown to helps provide the highest rpm?

Thank you, also let us know when the 4x2.5 props are ready for sale.

The Beryllium Copper ones are the least suited as they are prone to "float" and likely the reason that Cox discontinued them. Steel, Mylar and the crystal ones (still not sure what they are made of) would all work. The preference out there seems to be the Mylar version but, if you ask 3 Cox engines users, may get 3 different answers.

Of course we will post when we get the props

Re: Cox prop question

Re: Cox prop question

Among Cox reedy enthusiasts, I have heard significantly more people that think mylar runs fastest, however will become bowed over a fairly short time. For a speed contest, after trying steel(also bows), solid teflon, woven teflon, copper, and mylar, but not crystal, I am 100% in the mylar camp.

The bow does not appear to me to affect it for sport use, and I can't say whether it hurts or helps RPMs. It seems to continue to seal just fine after short and long term bowing.

Rusty

The bow does not appear to me to affect it for sport use, and I can't say whether it hurts or helps RPMs. It seems to continue to seal just fine after short and long term bowing.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Cox prop question

Re: Cox prop question

I got curious about the thickness of the different reeds. About 5 years ago, I stocked-up on new Mylar, Teflon and Steel reeds.. and measured the thickness using a vernier caliper. I also had the older "star-shaped" reeds of Copper and Mylar. The "thickest" reed was the "Teflon" @ .010".. Both of the Mylar (star and oval) are .005".. The Steel reed is .002".. and the Copper is .001". How would the "much thicker" Teflon reed function with a tighter circlip clearance/fit? I've heard it mentioned, that the reed should not bind once the circlip is installed. The .009" difference in thickness between the Teflon and the Copper is quite a bit. Maybe that's why the Copper reed tends to "float" as Bernie mentioned? The Steel @ .002" is probably much more rigid than the Copper.. yet it's .003" thinner than the Mylar.

The "flex" between the different materials is probably a big factor.. but the circlips are all the same size wire diameter. I would think that the reed is meant to be held "stationary" by the circlip.. because of these wide variations in reed thicknesses. Pressure-differential valves "in general" don't float "radially" during their operation. The "disc" comes off the "seat" and reseals on a "linear" path.. without any radial movement happening.

The circlip-style reed-holder design has a "tang" in the center. Depending on which way you hold it; you will see that it protrudes one way or the other.. in relation to the "outer-circle" part of the clip, which seats in a groove around the seat. The circlip should be installed; so that this "tang" protrudes "away" from the reed/seat.. allowing the reed to flex away from the seat when there is a vacuum in the crankcase (piston moves "up" in the cylinder..) After installing a reed and a circlip-style retainer.. I hold the assembly up to my mouth.. and gently "blow" against the reed with my lips tightly sealed around the valve. If I don't feel any resistance.. this indicates that the reed is not seating properly.. (sometimes it "whistles") Oftentimes; removing and re-installing the reed/circlip will establish a reliable seal. Repeat the process as many times as it takes (swap-out a different reed/circlip) to achieve a good seal.. before you continue assembling the engine. This (along with cleanliness...) is the single most important thing to get right.. for a "reliable-running" Cox reed-valve engine.

The "flex" between the different materials is probably a big factor.. but the circlips are all the same size wire diameter. I would think that the reed is meant to be held "stationary" by the circlip.. because of these wide variations in reed thicknesses. Pressure-differential valves "in general" don't float "radially" during their operation. The "disc" comes off the "seat" and reseals on a "linear" path.. without any radial movement happening.

The circlip-style reed-holder design has a "tang" in the center. Depending on which way you hold it; you will see that it protrudes one way or the other.. in relation to the "outer-circle" part of the clip, which seats in a groove around the seat. The circlip should be installed; so that this "tang" protrudes "away" from the reed/seat.. allowing the reed to flex away from the seat when there is a vacuum in the crankcase (piston moves "up" in the cylinder..) After installing a reed and a circlip-style retainer.. I hold the assembly up to my mouth.. and gently "blow" against the reed with my lips tightly sealed around the valve. If I don't feel any resistance.. this indicates that the reed is not seating properly.. (sometimes it "whistles") Oftentimes; removing and re-installing the reed/circlip will establish a reliable seal. Repeat the process as many times as it takes (swap-out a different reed/circlip) to achieve a good seal.. before you continue assembling the engine. This (along with cleanliness...) is the single most important thing to get right.. for a "reliable-running" Cox reed-valve engine.

Last edited by roddie on Sun Aug 31, 2014 10:25 pm; edited 2 times in total

Re: Cox prop question

Re: Cox prop question

Steel or Mylar,

I prefer steel, only because it seems more robust. It does hold a shape like the Mylar as Rusty mentioned. They both do a fine job though.

I prefer steel, only because it seems more robust. It does hold a shape like the Mylar as Rusty mentioned. They both do a fine job though.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» CEF speed contest Design Discussions

» Cox Prop Rod

» Question Cox .020 prop screw size

» Performance Question - Prop Pitch/Length

» [The Traveling Prop] Who wants to be the one to send the prop overseas?

» Cox Prop Rod

» Question Cox .020 prop screw size

» Performance Question - Prop Pitch/Length

» [The Traveling Prop] Who wants to be the one to send the prop overseas?

Page 2 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules