Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

tank soldering fixture

Page 1 of 1

tank soldering fixture

tank soldering fixture

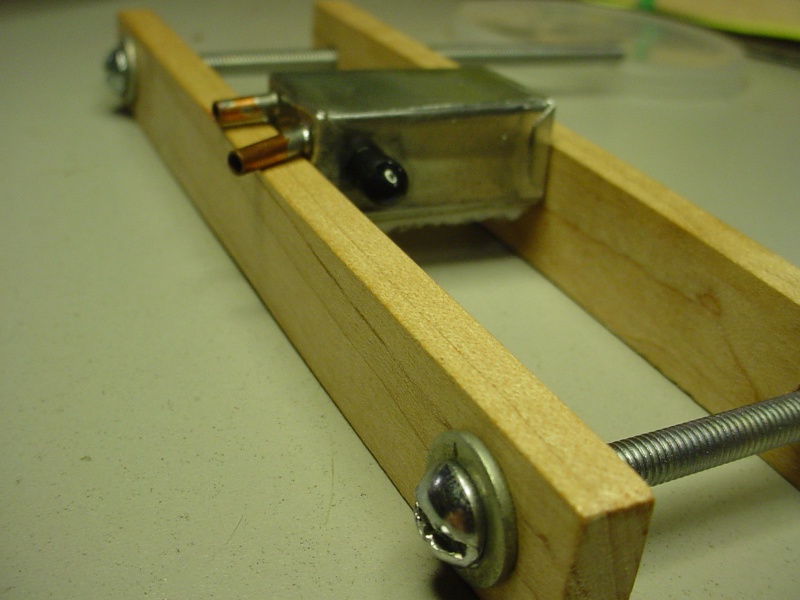

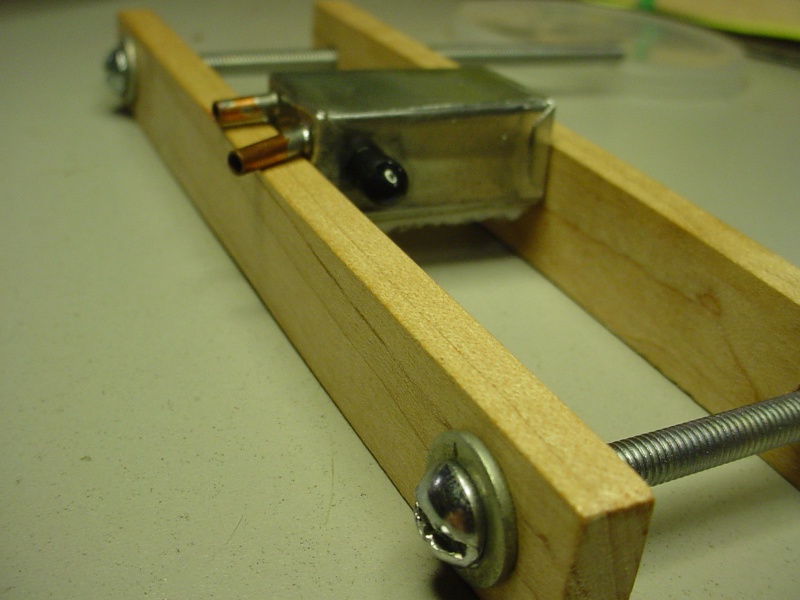

Here's a simple little tool I made last night, as a "third hand" for helping to solder end-caps to a fuel tank body. Metal C-clamps or vise-jaws sink heat away from your work.. and make it difficult; if not impossible to get solder to flow. This fixture was made from a piece of maple; 1/4" thick x 1.5" wide x 6" long.. ripped down the center into 2 pcs. I took two 4" long 10-32 machine screws, two #10 flat washers, two 10-32 T-nuts and 5 minutes of time to make this. Drill one rail about 1/2" in from the ends on-center with clearance-holes for the T-nuts.. and the other rail with clearance-holes for the machine screws. This fixture will accommodate a tank up to over 3-3/4" long. Threaded rod and wing-nuts could be used if you need more clamping length.

Making your own hard-tank can be fun and rewarding. Having the right tools on hand is everything.

Making your own hard-tank can be fun and rewarding. Having the right tools on hand is everything.

Re: tank soldering fixture

Re: tank soldering fixture

I like it!

Good idea Roddie. I would probably use wing nuts though.

Good idea Roddie. I would probably use wing nuts though.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: tank soldering fixture

Re: tank soldering fixture

Cribbs74 wrote:I like it!

Good idea Roddie. I would probably use wing nuts though.

Yes.. if you're using threaded-rod, you'd need to. Keep in mind though; that your parts only need to be "snugged" if they're fitted correctly beforehand. I used a screwdriver on the machine screws; only to initially "set" the T-nuts in the maple rails. Holding the tank, merely requires twisting the screws tight by hand... because the spread of the rails provides "spring" leverage when the tank is centered in the fixture.

Re: tank soldering fixture

Re: tank soldering fixture

That fixture is a neat idea! Thanks for sharing.

I've made a few tanks in the past and a fixture like that would have definitely come in handy.

Shawn

I've made a few tanks in the past and a fixture like that would have definitely come in handy.

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Similar topics

Similar topics» Can it be done? A fixture for testing fuel tank flow under a G-load

» Scientific P-40 Red Tiger

» Butane soldering torches

» New butane soldering torch

» Plastic repair

» Scientific P-40 Red Tiger

» Butane soldering torches

» New butane soldering torch

» Plastic repair

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules