Log in

Search

Latest topics

» TEE DEE Having issuesby balogh Today at 8:42 am

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 8:36 am

» Cox films/videos...

by Coxfledgling Today at 5:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 5:18 am

» My N-1R build log

by roddie Today at 1:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 1:27 am

» Landing-gear tips

by roddie Yesterday at 7:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 3:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 2:41 pm

» My latest doodle...

by roddie Yesterday at 11:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 2:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 10:24 am

Cox Engine of The Month

30, 15, 5 Epoxy

Page 1 of 1

30, 15, 5 Epoxy

30, 15, 5 Epoxy

More like 60, 30, 10!

I wish things would work as advertized. It really slows me down, probably not a bad thing.

That is my experience with epoxy anyway.

Ron

I wish things would work as advertized. It really slows me down, probably not a bad thing.

That is my experience with epoxy anyway.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

Just like when CA glue never sets, come back 10 minutes later to find its still wet (probably time to throw it out). Age of the glue, temperature its stored at (especially in the garage in the winter where it could crystallize), temperature and humidity its used at, how well its mixed and proper ratios... All could affect the time it takes to set and strength after set.

I usually get good results using Harbor Freight epoxy. I have also used 12 year old 15min epoxy from the hobby shop, still worked fine.

I usually get good results using Harbor Freight epoxy. I have also used 12 year old 15min epoxy from the hobby shop, still worked fine.

Last edited by Admin on Wed Jul 09, 2014 12:18 am; edited 2 times in total (Reason for editing : grammar)

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

I always thought he numbers are for working time. That's how I use them anyway. Lately with all of them I've had to use about 5% more hardener to get it to completely harden without being rubbery. I'keep a test puddle after every job and like for it to be able to snap under extreme bending, but never expect that before 24 hours with any of it. I'm satisfied if my 6 min is just hard and bendable. My 30 better be rock hard as well as my 60. Stores don't stock 60 around here any more.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

Hmmm,

Good point Jacob, my Epoxies are over a year old now and have seen all extremes due to my traveling. Perhaps I should buy some new stuff.

Rusty, working time is probably more correct. I always add a little more hardener in hopes it will set faster.

Good point Jacob, my Epoxies are over a year old now and have seen all extremes due to my traveling. Perhaps I should buy some new stuff.

Rusty, working time is probably more correct. I always add a little more hardener in hopes it will set faster.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

I have found that the "times" are usually defined as workable times after which they take on a rubbery texture.

I have 90 second, 5 minute, 30 minute, 60 minute and three hour epoxy.

Only buy from a store that has a high turnover - there is a "shelf" life to epoxy glues.

I have also found that the longer setting times produce a much stronger joint but obviously require clamping.

I also believe that if you increase the amount of hardener to speed up the set - the resulting set will not be as strong as the standard 50/50 mix.

I use the three hour stuff for undercarriage mounts - where the piano wire is bound to the former with twine. It can be corrected as it flows, spread thinly and worked into and through the binding holes. It settles and sets smooth. I then leave it overnight.

Nearly all epoxy takes 12 to 24 hours to reach full strength no matter what the workable time.

I found some 5 minute stuff that I had left in the garage the other day. It must have been "years" old. Mixed it up and after 3 days it still hadn't set. Messy job removing it with alcohol and acetone. If you have old stuff - throw it away!

Now here is a rub - some epoxies set faster if placed in a warm place. (I am not defining warm!) - after a certain temperature - epoxy softens! I have sometimes applied a heat gun to correct a joint (when it has gone off square!)

Now back to do as I say not do as I do.

DON'T DO THIS .....

On the fast setting stuff, after applying it and the remnants I have mixed have gone rubbery. I roll some into a ball (or near) - pick it up and roll it between my thumb and forefinger - if it is sticky then you didn't mix it properly!

I have 90 second, 5 minute, 30 minute, 60 minute and three hour epoxy.

Only buy from a store that has a high turnover - there is a "shelf" life to epoxy glues.

I have also found that the longer setting times produce a much stronger joint but obviously require clamping.

I also believe that if you increase the amount of hardener to speed up the set - the resulting set will not be as strong as the standard 50/50 mix.

I use the three hour stuff for undercarriage mounts - where the piano wire is bound to the former with twine. It can be corrected as it flows, spread thinly and worked into and through the binding holes. It settles and sets smooth. I then leave it overnight.

Nearly all epoxy takes 12 to 24 hours to reach full strength no matter what the workable time.

I found some 5 minute stuff that I had left in the garage the other day. It must have been "years" old. Mixed it up and after 3 days it still hadn't set. Messy job removing it with alcohol and acetone. If you have old stuff - throw it away!

Now here is a rub - some epoxies set faster if placed in a warm place. (I am not defining warm!) - after a certain temperature - epoxy softens! I have sometimes applied a heat gun to correct a joint (when it has gone off square!)

Now back to do as I say not do as I do.

DON'T DO THIS .....

On the fast setting stuff, after applying it and the remnants I have mixed have gone rubbery. I roll some into a ball (or near) - pick it up and roll it between my thumb and forefinger - if it is sticky then you didn't mix it properly!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

I wouldn't recommend using more hardener than specified. This indeed makes the resin cure faster, but also makes it more brittle.

In general, curing time is heavily affected by ambient temperature. Below say, 15-18 degrees (celsius) you may not get a good bind after any curing time.

In general, curing time is heavily affected by ambient temperature. Below say, 15-18 degrees (celsius) you may not get a good bind after any curing time.

dirk gently- Gold Member

- Posts : 430

Join date : 2012-02-03

Age : 42

Location : Poznań

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

I bought some 5-minute Epoxy from Hobby Lobby. It was two of the larger bottles (resin and hardner) at a good price, half that in hobby stores. However, it was more like a 2-minute Epoxy (set up very quick).

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

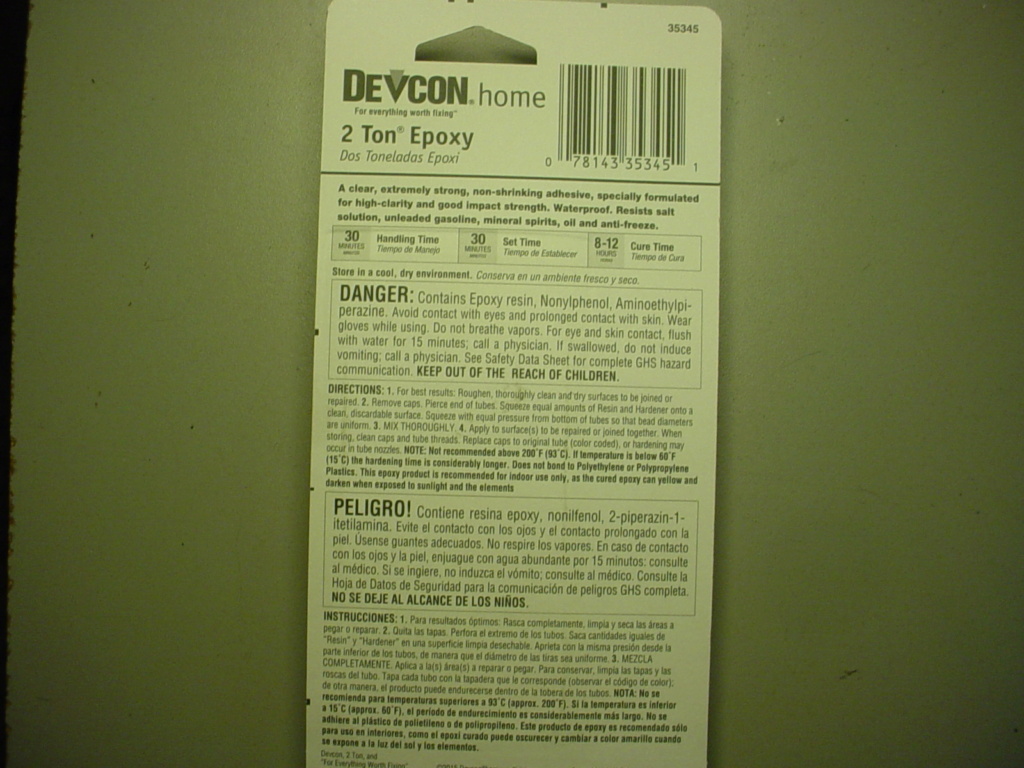

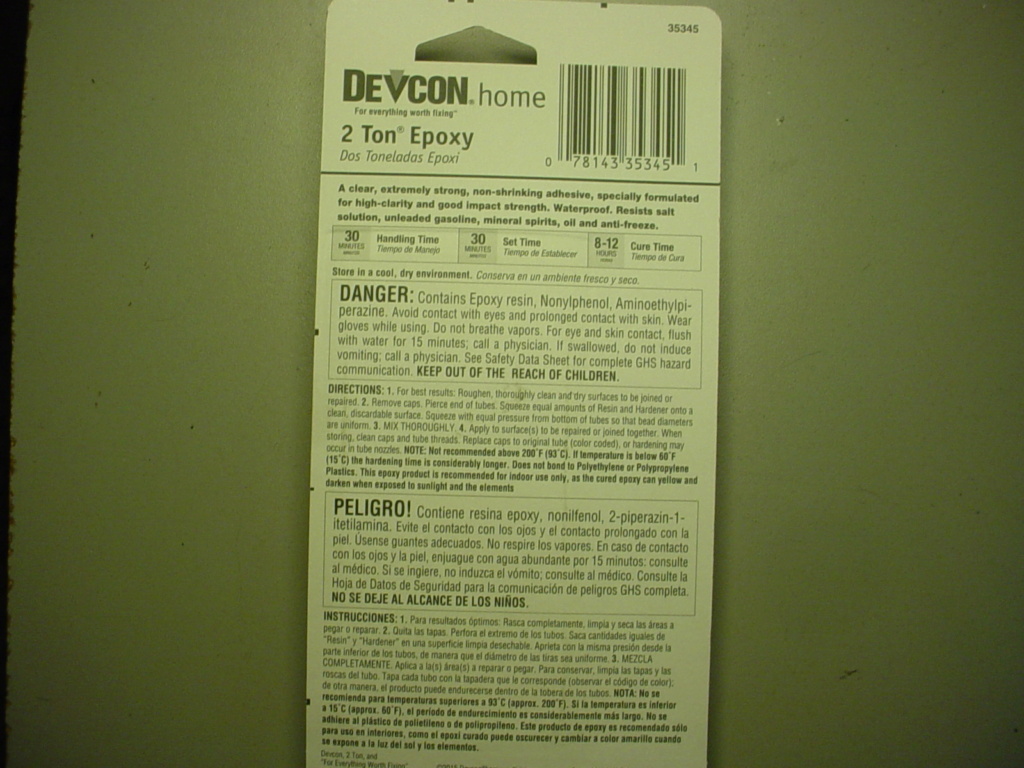

Some of the serious builders over at Stunthangar have discussed epoxy. They say the two part glue casual hobbyists like me buy off the shelf is pretty poor compared to the professional stuff. If I understand correctly, there is so much filler added to the hardener to make it an easy 50/50 mix that the glue is contaminated by design. The pro stuff mixes at more like 1:17 or some such ratio.

But for me, the dumbed down version is plenty strong. I know I may weaken it by adding an extra drop of hardener but it's apparently well within my modeling needs. And I only do it to prevent it from under-setting and being soft. Some of my batches seem to need it and others don't. Whenever I get a new batch I make a 50/50 test puddle to check how hard it sets. I even reheat old crystallized looking containers in a pot of hot water to reconstitute it and it seems to work just like a new batch. It's still some seriously strong glue. I'm a bit of an epoxy freak, though I use it sparingly on any particular job, not globbing it on. Like Ian mentioned, I have reheated joints to reposition minor parts like a rudder or something that's not too critical.

Rusty

But for me, the dumbed down version is plenty strong. I know I may weaken it by adding an extra drop of hardener but it's apparently well within my modeling needs. And I only do it to prevent it from under-setting and being soft. Some of my batches seem to need it and others don't. Whenever I get a new batch I make a 50/50 test puddle to check how hard it sets. I even reheat old crystallized looking containers in a pot of hot water to reconstitute it and it seems to work just like a new batch. It's still some seriously strong glue. I'm a bit of an epoxy freak, though I use it sparingly on any particular job, not globbing it on. Like Ian mentioned, I have reheated joints to reposition minor parts like a rudder or something that's not too critical.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

RknRusty wrote:there is so much filler added to the hardener to make it an easy 50/50 mix that the glue is contaminated by design. The pro stuff mixes at more like 1:17 or some such ratio.

That may well be the case for some brands for which this is true, but it's not that hard to find excellent 50:50 epoxy. I use one particular brand (probably only available in Poland, so no use in sharing the name) that dries hard as a rock, but doesn't become brittle. I also found some unusable specimens. So I would say, the quality of home-depot-grade glues varies from great to downright abysmal.

If in doubt, for any critical joint it is better to use actual epoxy resin and hardener, rather than 50:50 epoxy glue. The resin is used for example in boat construction (not models, actual yachts), where no compromise can be made as to the quality of the joints.

dirk gently- Gold Member

- Posts : 430

Join date : 2012-02-03

Age : 42

Location : Poznań

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

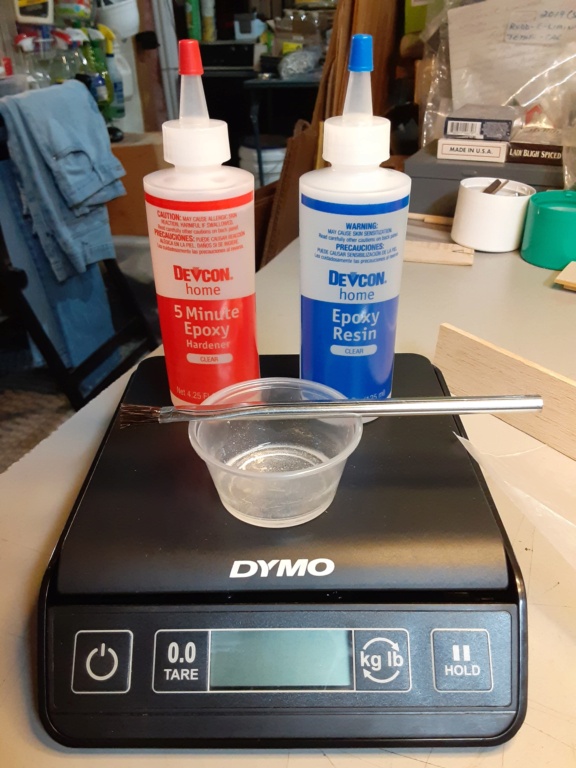

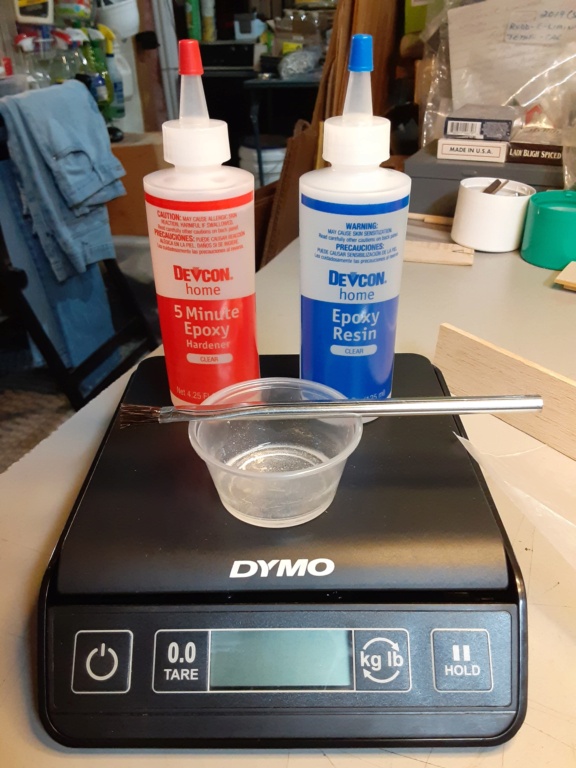

I haven't used epoxy extensively in my builds. If I needed a "weld-like" bond.. is where I might use it. That said; I'm currently using a 5 min. Devcon product in 4.25 oz. plastic bottles with capped spouts.

I've started inverting the bottles to clear air-bubbles, a few minutes before their use. I used pharmaceutical pill-containers to hold the bottles inverted.

I'll be laminating those little plywood panels to face the firewall for that model in the background. A Cox .049 reed-valve engine's mount will bear on it.

I've started inverting the bottles to clear air-bubbles, a few minutes before their use. I used pharmaceutical pill-containers to hold the bottles inverted.

I'll be laminating those little plywood panels to face the firewall for that model in the background. A Cox .049 reed-valve engine's mount will bear on it.

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

I love the 30 minute one!...it's wonderfully perfect! :-)

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

Hi All, good thread,

I am allergic to Epoxy, after decades using the stuff...

Here is some things I learned:

-the two parts mixed together, create heat on a moleculue level, that bonds the resins together.

-They cure best, when everything is within temperature range.

-5 minute stuff, is like, oops, cannot get resins to together fast enough...

-15min, 30min,24hr stuff is way better, molecules get to combine.

Also,

If you can get epoxy,

Between balsa and a Cox.049,

You can wear out,

Any other paint jobs...

Take care,

My Friends,

Dave

I am allergic to Epoxy, after decades using the stuff...

Here is some things I learned:

-the two parts mixed together, create heat on a moleculue level, that bonds the resins together.

-They cure best, when everything is within temperature range.

-5 minute stuff, is like, oops, cannot get resins to together fast enough...

-15min, 30min,24hr stuff is way better, molecules get to combine.

Also,

If you can get epoxy,

Between balsa and a Cox.049,

You can wear out,

Any other paint jobs...

Take care,

My Friends,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

cheapscate tip

cheapscate tip

If you really insist on using old crystalized epoxy then use a microwave.

Had some z-poxy that was well over a decade old and did not want to trow it out.

So placed it in my microwave (oven) with the little cap removed and blasted it at 800w for about 10 sec.

Both the resin and hardner became hot, clear and thin.

Working time while still hot was short but the resulting joints are holding up so far.

After cooling it returned to its normal state (no crystals)

Had some z-poxy that was well over a decade old and did not want to trow it out.

So placed it in my microwave (oven) with the little cap removed and blasted it at 800w for about 10 sec.

Both the resin and hardner became hot, clear and thin.

Working time while still hot was short but the resulting joints are holding up so far.

After cooling it returned to its normal state (no crystals)

cmulder- Gold Member

- Posts : 279

Join date : 2022-02-10

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

cmulder wrote:...............

So placed it in my microwave (oven) with the little cap removed and blasted it at 800w for about 10 sec.

Both the resin and hardner became hot, clear and thin.

...............

After cooling it returned to its normal state (no crystals)

I've done this many time before, but, I'm not sure what effect this has on the overall strength of the joint. Usually, I will try a test joint before using it on a plane -- it always seems to set up just fine. I suspect if the joint breaks from a crash, a weaken epoxy joint will be the least of your problems.

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

Instead of the microwave oven, I warm the parts in a glass of hot water. I call the process done when the epoxy runs fairly loosely to the tip of the inverted bottle. I also mix in small plastic "Dixie cup" lots on a digital scale...just so I know I'm getting repeatable results. 50/50 by weight works for me (so far).

What do you epoxy users think of thinning epoxy? How much is too much "thinner?"

I thinned some 5-min epoxy (Walmart-grade sky blue stuff, probably same brand as Roddie) with straight methanol to make it flow/brush in an engine area for fuel proofing only. This was on my BHM Mossie. The epoxy thinned/brushed into place as expected. It was pliable even after cooking off. It DID remain fuel-proof. It developed a waxy feel. Even after sanding and wiping down with lacquer thinner, dope never stuck to it very well. I blame the make/type of the epoxy for the flexibility and difficulty with dope. I will say this stuff would be good for wrapped terminations in lead-outs and control lines.

Thinning Smith epoxy worked better, as I got a stiffer finish despite significant thinning. Dope does stick to it better. I did note that too much methanol, or even lacquer thinner will cause bubbles that I suspect is the "solvent" evaporating while encapsulated in the epoxy. It almost looked like "solidified" Sprite or soda water with the entrapped bubbles.

My lesson learned was "don't use cheap/blue 5 minute epoxy" so dope sticks, and don't expect to thin epoxy for anything more that engine/tank areas. I don't know how it could be thinned and sprayed without significant build-up, weight and/or ruined air brushes.

I will continue to use epoxy for engine/tank mounts and fuel-proofing "wet areas" subject to raw fuel and exhaust. But I won't use it in enclosed work spaces (my hobby closet) to prevent respiratory distress.

What do you epoxy users think of thinning epoxy? How much is too much "thinner?"

I thinned some 5-min epoxy (Walmart-grade sky blue stuff, probably same brand as Roddie) with straight methanol to make it flow/brush in an engine area for fuel proofing only. This was on my BHM Mossie. The epoxy thinned/brushed into place as expected. It was pliable even after cooking off. It DID remain fuel-proof. It developed a waxy feel. Even after sanding and wiping down with lacquer thinner, dope never stuck to it very well. I blame the make/type of the epoxy for the flexibility and difficulty with dope. I will say this stuff would be good for wrapped terminations in lead-outs and control lines.

Thinning Smith epoxy worked better, as I got a stiffer finish despite significant thinning. Dope does stick to it better. I did note that too much methanol, or even lacquer thinner will cause bubbles that I suspect is the "solvent" evaporating while encapsulated in the epoxy. It almost looked like "solidified" Sprite or soda water with the entrapped bubbles.

My lesson learned was "don't use cheap/blue 5 minute epoxy" so dope sticks, and don't expect to thin epoxy for anything more that engine/tank areas. I don't know how it could be thinned and sprayed without significant build-up, weight and/or ruined air brushes.

I will continue to use epoxy for engine/tank mounts and fuel-proofing "wet areas" subject to raw fuel and exhaust. But I won't use it in enclosed work spaces (my hobby closet) to prevent respiratory distress.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

Hi cmulder,

I have only warmed up old epoxy with hot water... to thin the two parts, to mix them together...

Works good,

Be very careful with your microwave method !

Epoxy resins need the catalitic reaction, And even temperature, to cure.

-5 minute epoxies do not get a chance to get a bond, to anything.

-10-30minute+ stuff is way better.

- if you can, it is all the way, to go.

-I get the epoxy, between my Cox.049s and firewalls/balsa, every chance I get,

Your results,

May vary,

Dave,

P.S. Jim here, is way faster on the internet, than me.

I have only warmed up old epoxy with hot water... to thin the two parts, to mix them together...

Works good,

Be very careful with your microwave method !

Epoxy resins need the catalitic reaction, And even temperature, to cure.

-5 minute epoxies do not get a chance to get a bond, to anything.

-10-30minute+ stuff is way better.

- if you can, it is all the way, to go.

-I get the epoxy, between my Cox.049s and firewalls/balsa, every chance I get,

Your results,

May vary,

Dave,

P.S. Jim here, is way faster on the internet, than me.

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

944_Jim wrote:Instead of the microwave oven, I warm the parts in a glass of hot water. I call the process done when the epoxy runs fairly loosely to the tip of the inverted bottle.....

I've done it both ways -- if using the microwave, I keep a close eye on the bottle and remove and mix the contents thoroughly as it becomes slightly warm. I don't want to develop any "hotspots" in the container.

944_Jim wrote: What do you epoxy users think of thinning epoxy? How much is too much "thinner?"......

I've never thinned my epoxy chemically. I think if I did, it would be only with 30 minute or more epoxy. Whatever thinner you use must be able to evaporate from the mix before it starts to set up, otherwise, you will trap the thinner in the epoxy.

944_Jim wrote: I did note that too much methanol, or even lacquer thinner will cause bubbles that I suspect is the "solvent" evaporating while encapsulated in the epoxy. It almost looked like "solidified" Sprite or soda water with the entrapped bubbles.

Precisely...

944_Jim wrote:

I will continue to use epoxy for engine/tank mounts and fuel-proofing "wet areas" subject to raw fuel and exhaust.....

Other than "high stress" joints, that's how I normally use epoxy. I have had good luck applying unthinned epoxy to these areas, then using a heat gun (monokote gun) to warm it so it soaks into the underlying balsa wood, plywood and joints. As it thins from heat, you can see it being absorbed. Since it does soak into the wood, it is not necessary to have an solid epoxy coating -- just a good coverage.

The marine vendors have a high penetrating epoxy (I suspect it is a standard formulation with a thinner added) that can be painted over wood that has softened, but I'm satisfied with the warming method to get it to absorb.

a--

I barey use epoxy anymore these days

I barey use epoxy anymore these days

Epoxy while relative fast is used less and less.

The most common use i have is to glue polystyrene foam models since some other glues disolve it and pva needs to be able to evaporate.

Years ago i was introduced to a polyurethane "resin" / varnish that is marketed to water proof concrete.

On the mainland to seal basements, in the uk to seal garden ponds.

Its called "G4"

It is "almost anything proof" including glow fuel, petrol and water.

Most of my engine powered planes are varnished with it on the inside.

It also reinforces glue joints.

So for example if there is a leaking fuel tank the fuel does not soak into the wood.

And a few years ago a model (seagull 40 low wing) ended up in a lake floating for a few minutes bevore being recovered.

Water never got into the wood so there was no damage at all.

Also used to glass a balsa sheeted foam core delta.

Its borderline bulit proof but a real pain to sand smooth.

Last year the guys next door trew out there old beaten up kitchen table.

Took it, sanded it down, did some repairs and coated it with it too so now have a durable work bench that also acts as kitchen table.

If you don't mind the smell while aplying and that any brush is single use then its a good alternative for epoxy in some aplications.

The oldest model i usd it on is now about 30 years ago (the varnish, the model is much older) and the wood is still in good shape.

The most common use i have is to glue polystyrene foam models since some other glues disolve it and pva needs to be able to evaporate.

Years ago i was introduced to a polyurethane "resin" / varnish that is marketed to water proof concrete.

On the mainland to seal basements, in the uk to seal garden ponds.

Its called "G4"

It is "almost anything proof" including glow fuel, petrol and water.

Most of my engine powered planes are varnished with it on the inside.

It also reinforces glue joints.

So for example if there is a leaking fuel tank the fuel does not soak into the wood.

And a few years ago a model (seagull 40 low wing) ended up in a lake floating for a few minutes bevore being recovered.

Water never got into the wood so there was no damage at all.

Also used to glass a balsa sheeted foam core delta.

Its borderline bulit proof but a real pain to sand smooth.

Last year the guys next door trew out there old beaten up kitchen table.

Took it, sanded it down, did some repairs and coated it with it too so now have a durable work bench that also acts as kitchen table.

If you don't mind the smell while aplying and that any brush is single use then its a good alternative for epoxy in some aplications.

The oldest model i usd it on is now about 30 years ago (the varnish, the model is much older) and the wood is still in good shape.

cmulder- Gold Member

- Posts : 279

Join date : 2022-02-10

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

I'm using both; "Devcon brand" 5-min. and 30 min. varieties on my current build. This was my first experience using a 5 min. cure epoxy.. and I knew that I needed to act fast with the mixing.. and also with applying the mixed product. I had pre-fit my parts.. and clamps were ready on standby.

I save/recycle/re-use the plastic lids from containers to serve as a palette for mixing epoxies.

I have WAY more than I could ever use.. because once the job is done and the glue has cured.. it doesn't stick to these lids.. and peels off easily. I've been using a wooden toothpick to mix the 5 minute/2-part adhesive.. which seems to work well. There's a minimum of surface-area to the toothpick.. and "twirling it" while mixing helps to achieve a uniform-mix.. which is essential.

I used the 5-min Devcon-brand to attach the 1/64" 3-ply nose-doublers to the profile fuse of my current TBD1 build.

I actually applied a method mentioned previously in this thread by CEF member 944_Jim and utilized a digital scale for a more accurate 50/50 mixing of the product.

The 30 min. Devcon product was used to permanently set the wing/stab joint-junctions; where they had only been previously tacked in place.

.. after the application of the 30 min. product, I dampened a rag/paper-towel with 91% rubbing alcohol.. and wiped-down the model of any drips/blobs.. to minimize sanding them off later.

I save/recycle/re-use the plastic lids from containers to serve as a palette for mixing epoxies.

I have WAY more than I could ever use.. because once the job is done and the glue has cured.. it doesn't stick to these lids.. and peels off easily. I've been using a wooden toothpick to mix the 5 minute/2-part adhesive.. which seems to work well. There's a minimum of surface-area to the toothpick.. and "twirling it" while mixing helps to achieve a uniform-mix.. which is essential.

I used the 5-min Devcon-brand to attach the 1/64" 3-ply nose-doublers to the profile fuse of my current TBD1 build.

I actually applied a method mentioned previously in this thread by CEF member 944_Jim and utilized a digital scale for a more accurate 50/50 mixing of the product.

The 30 min. Devcon product was used to permanently set the wing/stab joint-junctions; where they had only been previously tacked in place.

.. after the application of the 30 min. product, I dampened a rag/paper-towel with 91% rubbing alcohol.. and wiped-down the model of any drips/blobs.. to minimize sanding them off later.

Re: 30, 15, 5 Epoxy

Re: 30, 15, 5 Epoxy

Hi jim and andrew,

I agree with you, mostly.

I learned epoxy/wood from Victor Carpenter. (google him) The West brothers were kids and learned from him.

Vic, called his system, Early And Superior Technique (EAST)

What an amazing person. On a good good day, there might be a chance to talk with him.

Rolled up to the shop, in his big beat up V8 station wagon. Skidding to a stop. His pet Crow flying along...

He claimed he just added oil to it...and had the original tires...

Hazel, his wife, did the books, and brushed on all the varnish. She did not like anyone watching. I remember wet sanding all day.

Next morning, wow !

Anyways,

I learned to use epoxy.

If there was any way to thin it down, Vic would have done it.

Basicly, you have between mixing and gel time with epoxy.

If you cannot clean your brush with acetone, you are slow.

All the hobby store stuff I have used is OK.

The 'real' good epoxy is like milk. The rest is all filler.

As long as the two parts get together, it will cure.

Try mixing a puddle of 5min, and same of 30min, let it cure.

It is all about the time the resin gets to bond together.

Oh no !

I am bonding with you !

Take care,

Have fun,

Dave

I agree with you, mostly.

I learned epoxy/wood from Victor Carpenter. (google him) The West brothers were kids and learned from him.

Vic, called his system, Early And Superior Technique (EAST)

What an amazing person. On a good good day, there might be a chance to talk with him.

Rolled up to the shop, in his big beat up V8 station wagon. Skidding to a stop. His pet Crow flying along...

He claimed he just added oil to it...and had the original tires...

Hazel, his wife, did the books, and brushed on all the varnish. She did not like anyone watching. I remember wet sanding all day.

Next morning, wow !

Anyways,

I learned to use epoxy.

If there was any way to thin it down, Vic would have done it.

Basicly, you have between mixing and gel time with epoxy.

If you cannot clean your brush with acetone, you are slow.

All the hobby store stuff I have used is OK.

The 'real' good epoxy is like milk. The rest is all filler.

As long as the two parts get together, it will cure.

Try mixing a puddle of 5min, and same of 30min, let it cure.

It is all about the time the resin gets to bond together.

Oh no !

I am bonding with you !

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Similar topics

Similar topics» umx a6m5 zero to cox .049 nitro

» Can anyone identify this wood? Hoping it's good stock for beams.

» 2 part epoxy

» Baby Flite Streak build thread

» Quick or slow set epoxy

» Can anyone identify this wood? Hoping it's good stock for beams.

» 2 part epoxy

» Baby Flite Streak build thread

» Quick or slow set epoxy

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules