Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Modifiying ''Horseshoe'' backplates

Page 1 of 1

Modifiying ''Horseshoe'' backplates

Modifiying ''Horseshoe'' backplates

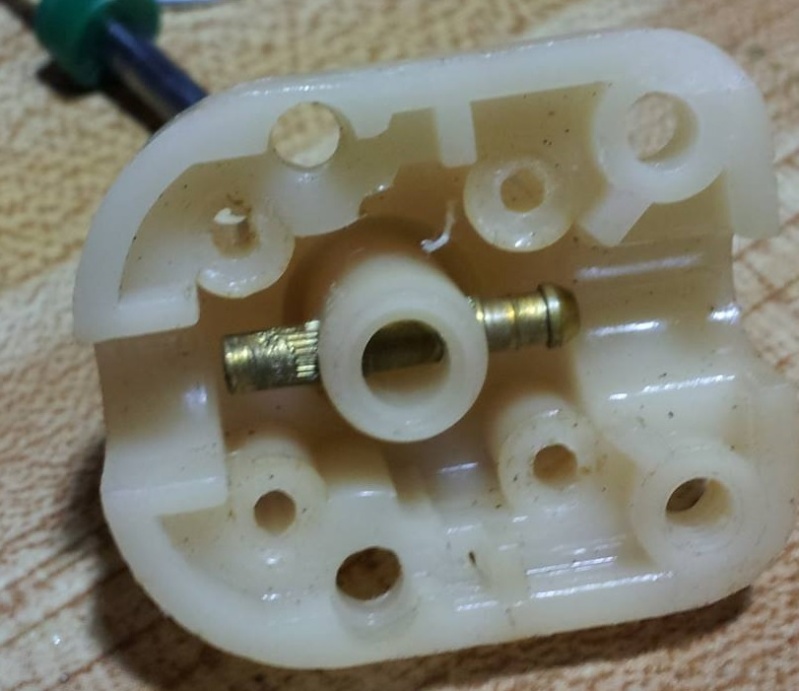

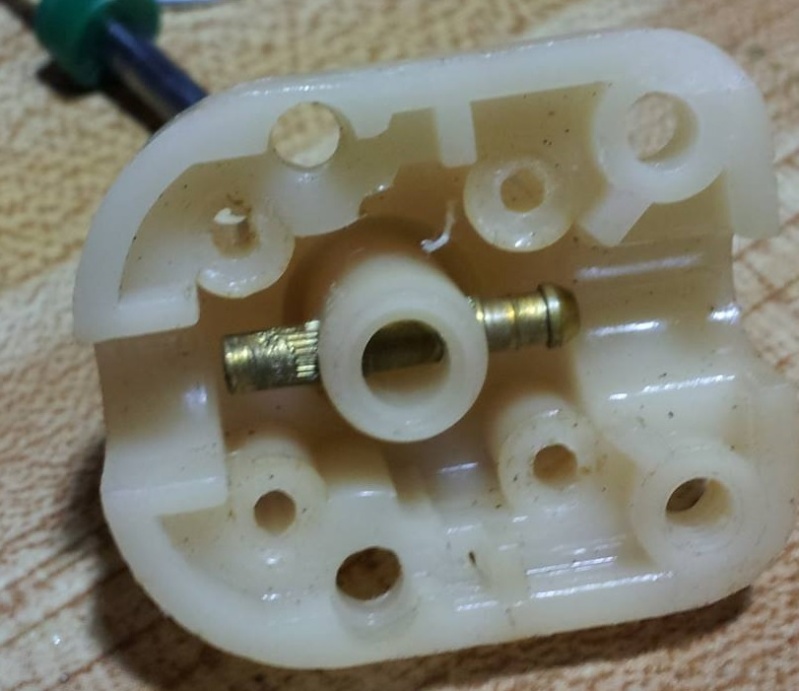

In the early seventies (c. '72) Cox introduced a new plastic backplate we now referred to as the "Horseshoe" for their RTF's. In a cost savings measure (c. '76) the needle was changed from brass to aluminum and in '79, to reduce machine costs changed the threads from 124 to 90 tpi, threads per inch.

These backplates can easily be converted with the older fine thread (124 tpi) brass needle that everybody seems to have laying around from the early "postage stamp" backplate.

Grab a heat gun and carefully get it warm, using a small needle nose pliers, from the fuel line side pull spray bar out.

While backplate is still warm carefully press in 124 tpi spray bar making sure fuel hole is facing engine and is centered. You can mark it with a Sharpie or look down venture as you start to pull it up.

You can also open up intake with a Dremel stone prior to new spray bar, use a piece of fuel line as a spring/retainer.

The only issue with this is if you get plastic too soft you could damage/enlarge hole, as the fine needle spay bar is actually slightly smaller and you may need/want to touch a little JB weld on the top just to make sure the spray bar is locked in.

These backplates can easily be converted with the older fine thread (124 tpi) brass needle that everybody seems to have laying around from the early "postage stamp" backplate.

Grab a heat gun and carefully get it warm, using a small needle nose pliers, from the fuel line side pull spray bar out.

While backplate is still warm carefully press in 124 tpi spray bar making sure fuel hole is facing engine and is centered. You can mark it with a Sharpie or look down venture as you start to pull it up.

You can also open up intake with a Dremel stone prior to new spray bar, use a piece of fuel line as a spring/retainer.

The only issue with this is if you get plastic too soft you could damage/enlarge hole, as the fine needle spay bar is actually slightly smaller and you may need/want to touch a little JB weld on the top just to make sure the spray bar is locked in.

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

That's how I modify them to run on a pressure bladder. Once you put them on pressure you can bore the Venturi all the way through to 13/64 and from the back to just past the spraybar with a 7/32.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

Mark Boesen wrote:In the early seventies (c. '72) Cox introduced a new plastic backplate we now referred to as the "Horseshoe" for their RTF's. In a cost savings measure (c. '76) the needle was changed from brass to aluminum and in '79, to reduce machine costs changed the threads from 124 to 90 tpi, threads per inch.

These backplates can easily be converted with the older fine thread (124 tpi) brass needle that everybody seems to have laying around from the early "postage stamp" backplate.

Grab a heat gun and carefully get it warm, using a small needle nose pliers, from the fuel line side pull spray bar out.

While backplate is still warm carefully press in 124 tpi spray bar making sure fuel hole is facing engine and is centered. You can mark it with a Sharpie or look down venture as you start to pull it up.

You can also open up intake with a Dremel stone prior to new spray bar, use a piece of fuel line as a spring/retainer.

The only issue with this is if you get plastic too soft you could damage/enlarge hole, as the fine needle spay bar is actually slightly smaller and you may need/want to touch a little JB weld on the top just to make sure the spray bar is locked in.

Mark, Thanks for this information. Its very helpful. I have a few questions.

Are all of the old postage stamp backplates using the fine thread needle valves?

From your description, some of the horseshoe backplates have fine threads and some do not, is that correct?

What is the best way to determine if the needle valve and the needle are fine thread?

What is the advantage of the fine thread needle valve?

Were the KK Fine Thread Needle Valves 128 tpi or 124 tpi?

Thanks again, and sorry for all the questions. Andy

anm2- Gold Member

- Posts : 293

Join date : 2013-03-30

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

Hmm...good questions, I didn't catch that till I saw your post. I got the 124tpi from a old ECJ article by Dan Sitter, but I see the Texas Timers web site quotes "128tpi" and I guess I always referred to it as 128, not thinking about 124 tpi as per the article till you mentioned it?

So based on that:

The article is in error and should be 128 (tpi) not 124?

That maybe at some point in recent years it's been changed, it's now 128 and maybe it was 124? All my fine threads are the same, KK or Cox, but I've not bought a 'fine' thread needle in twenty years.

Or maybe 128 is also known as 124 and that they're one and the same?

The Shadow knows...so until we find out more, lets just refer to them as 'fine' threads and 'standard' threads

Here's your questions and answers:

Are all of the old postage stamp backplates using the fine thread needle valves?

Yes, they seem to be...a great source for a fine 'fine' thread needle.

From your description, some of the horseshoe backplates have fine threads and some do not, is that correct?

Yes, the early horseshoes were fine thread spraybar/needle, but I don't think they're as common.

What is the best way to determine if the needle valve and the needle are fine thread?

Try to see if they fit? Look at pics, the KK and Cox look very much the same... 124 or 128 whatever?

What is the advantage of the fine thread needle valve?

They're easier to needle as the air/fuel ratio changes more slowly, especially if your running a higher compression engine, too little to too much, can be tricky?

Were the KK Fine Thread Needle Valves 128 tpi or 124 tpi?

Again, I believe they were 128...and Coxes are 128 and the article I got info from is in error...or that they're 'one-and-the-same'?

Thanks again, and sorry for all the questions. Andy

no problem, your welcome!

So based on that:

The article is in error and should be 128 (tpi) not 124?

That maybe at some point in recent years it's been changed, it's now 128 and maybe it was 124? All my fine threads are the same, KK or Cox, but I've not bought a 'fine' thread needle in twenty years.

Or maybe 128 is also known as 124 and that they're one and the same?

The Shadow knows...so until we find out more, lets just refer to them as 'fine' threads and 'standard' threads

Here's your questions and answers:

Are all of the old postage stamp backplates using the fine thread needle valves?

Yes, they seem to be...a great source for a fine 'fine' thread needle.

From your description, some of the horseshoe backplates have fine threads and some do not, is that correct?

Yes, the early horseshoes were fine thread spraybar/needle, but I don't think they're as common.

What is the best way to determine if the needle valve and the needle are fine thread?

Try to see if they fit? Look at pics, the KK and Cox look very much the same... 124 or 128 whatever?

What is the advantage of the fine thread needle valve?

They're easier to needle as the air/fuel ratio changes more slowly, especially if your running a higher compression engine, too little to too much, can be tricky?

Were the KK Fine Thread Needle Valves 128 tpi or 124 tpi?

Again, I believe they were 128...and Coxes are 128 and the article I got info from is in error...or that they're 'one-and-the-same'?

Thanks again, and sorry for all the questions. Andy

no problem, your welcome!

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

I have 2 different thread pitch "fine" NVA's for my TDs. The one Texas Timers sells, and a different pitch that does not interchange.

So be careful with mix and match.

Phil

So be careful with mix and match.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

hmm...so maybe the new ones are 128 and the old kk's/postage stamps are 124?

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

Mark Boesen wrote:hmm...so maybe the new ones are 128 and the old kk's/postage stamps are 124?

It is possible. I don't have an accurate way to measure pitch that fine, and I have no desire to count threads directly. I am just warning caution with mixing parts that were not already fitted together because they might be different, even though they look very similar.

If two male threads against each other, the grooves will mesh if the pitch is the same. If the pitch is different the threads will not perfectly mesh. With this fine of thread pitches (124 and 128 tpi) one would need to compare at least 1/4 inch of thread, and I am not sure if the naked eye will perceive a difference, although 1 full turn of thread shift should be visible.

I'll look and see if I can find the different NVA (hopefully it is not the one I broke the needle on) and take a pic next to a TT NVA

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

Hi Phil,

You can see in the first two photos, the old 'postage stamp' needle and a KK needle that there the same, my question is are they 128 or 124?

You can see in the first two photos, the old 'postage stamp' needle and a KK needle that there the same, my question is are they 128 or 124?

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

Mark Boesen wrote:Hi Phil,

You can see in the first two photos, the old 'postage stamp' needle and a KK needle that there the same, my question is are they 128 or 124?

I don't know. Short of measuring out and counting I don't know how to determine thread pitch for this size. I suppose using calipers to measure out 1/2 inch and counting 62 or 64 threads in a picture might be easiest. You take very good "macro" pictures.

All I know for sure is one of my NVA's is different from the Texas Timer NVA, and the needles are not interchangeable. I found the broken needle and it appears to be a Texas Timer needle. I need to get the three engines out of the garage and look very, very carefully at the needles to tell which is the different one. Two are Texas Timer and one is something else.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

yep, ain't modern technology nifty, that's the cel phone! I think it takes better pics then a digital camera of ten years ago.

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

Here's the stupid question. What does the postage stamp backplate look like? Is it the red ones with no mounting holes?

duke.johnson- Diamond Member

- Posts : 1734

Join date : 2012-11-05

Age : 53

Location : Rochester, Washington

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

duke.johnson wrote:Here's the stupid question. What does the postage stamp backplate look like? Is it the red ones with no mounting holes?

yep, 'bout the size of a stamp. The ones used on the P-51, Stukas, Corsairs, etc.

Re: Modifiying ''Horseshoe'' backplates

Re: Modifiying ''Horseshoe'' backplates

Mark-

Cool, I'll keep an eye out for those in the future.

PM'ed you

Cool, I'll keep an eye out for those in the future.

PM'ed you

duke.johnson- Diamond Member

- Posts : 1734

Join date : 2012-11-05

Age : 53

Location : Rochester, Washington

Similar topics

Similar topics» WTB Horseshoe backplates with wire reed retainer (not plastic cage)

» Horseshoe Run….

» Horseshoe backplate mounting template

» Mounting screws for horseshoe backplate

» Cox 190, 290, Or Horseshoe Engine Manual

» Horseshoe Run….

» Horseshoe backplate mounting template

» Mounting screws for horseshoe backplate

» Cox 190, 290, Or Horseshoe Engine Manual

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules