Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

What is this engine?

Page 1 of 1

What is this engine?

What is this engine?

Hi all,

I'm looking for this engine's history / detail info . It has a cast iron throttle ring. Anyone please?

http://www.ebay.com/itm/Cox-049-Radio-Control-Model-Airplane-Engine-/171078929870?nma=true&si=TxZJBNHBkRvLyTwfZ8iK%252Bm3lNus%253D&orig_cvip=true&rt=nc&_trksid=p2047675.l2557

Ew

I'm looking for this engine's history / detail info . It has a cast iron throttle ring. Anyone please?

http://www.ebay.com/itm/Cox-049-Radio-Control-Model-Airplane-Engine-/171078929870?nma=true&si=TxZJBNHBkRvLyTwfZ8iK%252Bm3lNus%253D&orig_cvip=true&rt=nc&_trksid=p2047675.l2557

Ew

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

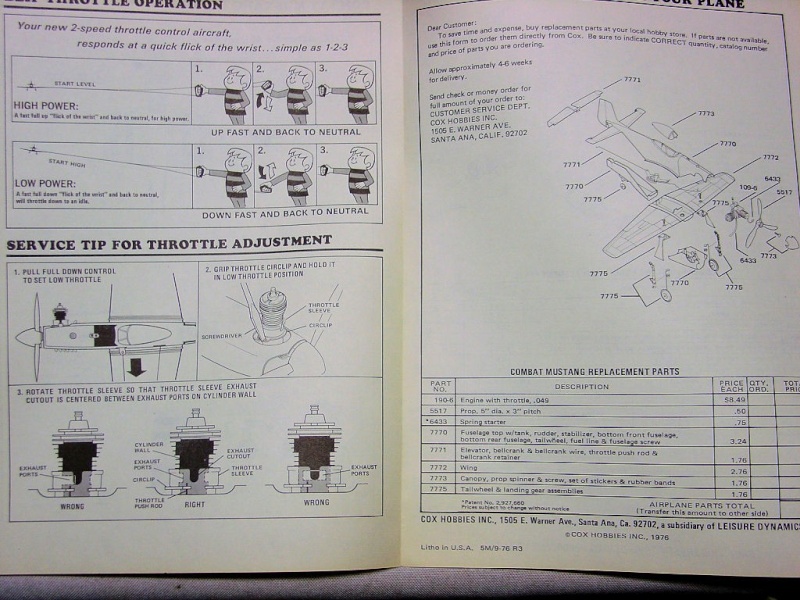

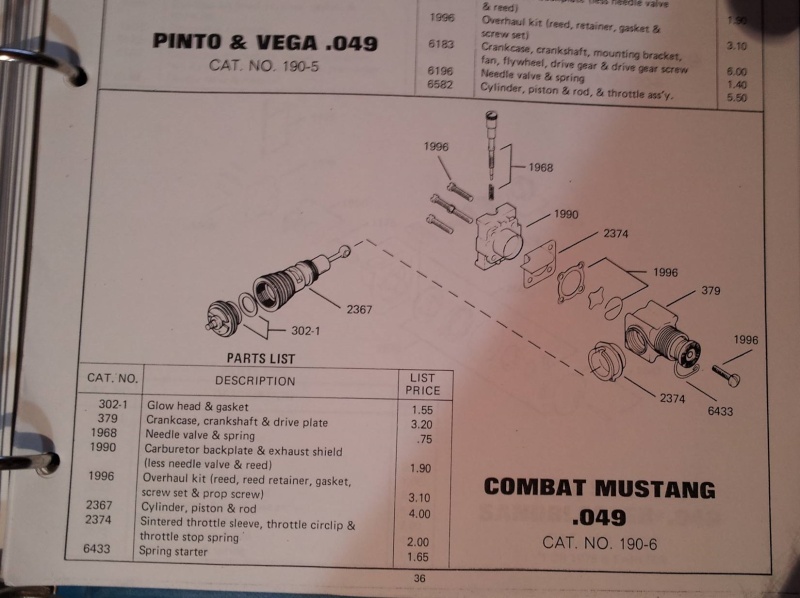

Its a mid 70s product engine for one of their RTF planes. I don't seem to have many notes on this engine. The cox handbook shows this engine with a postage stamp backplate instead of the horseshoe backpate like the one on eBay. In the handbook, the postage stamp one was said to have been used in the Combat Mustang and Skyraider planes.

Re: What is this engine?

Re: What is this engine?

Hi ,

Thanks for info, maybe ebay seller swapped the backplate . I purchased one and it looks new, has #1 cylinder with SPI , a strange combination with SPI cylinder + Throttle ring.

Ew

Thanks for info, maybe ebay seller swapped the backplate . I purchased one and it looks new, has #1 cylinder with SPI , a strange combination with SPI cylinder + Throttle ring.

Ew

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

I think that's Dan Sitter eBay listing, you might want to ask him what it is?

Re: What is this engine?

Re: What is this engine?

Hi,

Yes, that was Dan Sitter's listing, I believe. A very nice guy to deal with.

I like the engine very much. I ask about history of this engine just because of its special throttle sleeve, which I never seen before. Jacob says it's mid 70's product engine for one of Cox's RTF plane. Cox did experiment with quite a lot of die cast parts at that time.

Yes, that was Dan Sitter's listing, I believe. A very nice guy to deal with.

I like the engine very much. I ask about history of this engine just because of its special throttle sleeve, which I never seen before. Jacob says it's mid 70's product engine for one of Cox's RTF plane. Cox did experiment with quite a lot of die cast parts at that time.

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

It's not a cast case, its an extruded or machined case, I just don't know why you'd have a three step throttle on a airplane engine? I would ask him what model this was off of?

Re: What is this engine?

Re: What is this engine?

Hi Mark,

What I mean is the throttle sleeve, it's not machined from steel, it's made of cast iron.

Yes , I'm interested to know what model it's from. Please ask Dan if you meet him . Thanks !

I plan to remove the 3 step stopper and use it as normal throttle.

I'm building Dart Kitten II designed by David Larkin. Which is actually a low wing Texaco RC plane. I wish to use this little engine to power it with APC 7 X 3 prop.

Bench tested yesterday, its powerful, turns APC 7x3 at 12,000rpm max. Thrust measured 420g. But throttle down to only 9000 rpm. Need more head shim I think.

Ew

What I mean is the throttle sleeve, it's not machined from steel, it's made of cast iron.

Yes , I'm interested to know what model it's from. Please ask Dan if you meet him . Thanks !

I plan to remove the 3 step stopper and use it as normal throttle.

I'm building Dart Kitten II designed by David Larkin. Which is actually a low wing Texaco RC plane. I wish to use this little engine to power it with APC 7 X 3 prop.

Bench tested yesterday, its powerful, turns APC 7x3 at 12,000rpm max. Thrust measured 420g. But throttle down to only 9000 rpm. Need more head shim I think.

Ew

Last edited by tru168 on Sat Jan 04, 2014 9:07 pm; edited 1 time in total

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

yep, the throttle rind does appear to be cast, I took the liberty of emailing Dan asking him what model the engine is out of, as I've also become curious?

Last edited by Mark Boesen on Sat Jan 04, 2014 3:41 pm; edited 1 time in total

Re: What is this engine?

Re: What is this engine?

I had one just like it and in this configuration. I even asked about it on here. I may have sold it to mitchg95, cant't remember. I'll see if I can locate the old thread.

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: What is this engine?

Re: What is this engine?

I found the thread, but it was before I knew how to add pictures. The Ebay link doesn't show the picture.

https://www.coxengineforum.com/t704-i-won-it-now-what-is-it

Apparently it had a postage stamp backplate and Mud said it was out of a combat Mustang.

My guess is that's what that engine is and the horseshoe backplate was added to make it more appealing to buyers.

Ron

https://www.coxengineforum.com/t704-i-won-it-now-what-is-it

Apparently it had a postage stamp backplate and Mud said it was out of a combat Mustang.

My guess is that's what that engine is and the horseshoe backplate was added to make it more appealing to buyers.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: What is this engine?

Re: What is this engine?

Yes Ron, I agree that horseshoe backplate was added to make it more appealing to buyers . Thanks Mark for helping me to email Dan.

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

Hi Mark,

Thanks for the info ! good to know where its from .

Ew

Thanks for the info ! good to know where its from .

Ew

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

The Combat Mustang was only around for a couple years ('75-'78) they show up on eBay fairly often, but don't seem to bring big money.

I also tend to agree, if in fact this is a Combat Mustang the backplate is wrong, but the seller states 'original' so its possible Cox switched backplates as they did switch needles and started using the 'horse collar' backplate about this time, but unsure if that applied to the Mustang, I tend to think it didn't? The parts catalog ('77) shows postage stamp, but that could of been changed the following year?

I also tend to agree, if in fact this is a Combat Mustang the backplate is wrong, but the seller states 'original' so its possible Cox switched backplates as they did switch needles and started using the 'horse collar' backplate about this time, but unsure if that applied to the Mustang, I tend to think it didn't? The parts catalog ('77) shows postage stamp, but that could of been changed the following year?

Last edited by Mark Boesen on Sun Jan 05, 2014 7:43 pm; edited 2 times in total

Re: What is this engine?

Re: What is this engine?

We all have to remember that this is Dan Sitter's engine, for all we know he could have gotten engines straight Cox that were made to be in a model that just never happened to be built and released. Cox would probably rather sell the pre-built engines "as-is" instead of have more employees sit down and disassemble them.

Re: What is this engine?

Re: What is this engine?

You got the point there, Jacob. Unless Dan Sitter reveal the truth, thats just my wild guess .

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

Mark's cataloge picture indicates a Sintered throttle sleeve. I wonder what it is made out of and why they would use that process. You still have to machine it to fit and the weight break is not that great compared to blank machining of lighter weight materials. It went into production,,so there must have been some benefit at the time. Someones hand in the Cox money bucket to prove there point maybe?

http://en.wikipedia.org/wiki/Sintering

http://en.wikipedia.org/wiki/Sintering

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: What is this engine?

Re: What is this engine?

Yes it written in the booklet "sintered throttle sleeve " but why ? or just experimental ?

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: What is this engine?

Re: What is this engine?

Pure supposition on my part about Cox sintering

... FWIIW wiki is often wrong, out dated, or opinion and not fact..it is my LAST resource for information

In this case I disagree with the wiki pros and cons, specifically "By sintering one cannot create uniform sizes" as a disadvantage. I say this as a retired Army Test officer that did a test once upon a time on a aircraft part out of a sintered alloy used in a high stress area of UH-1H Bell Huey helicopter. To do the test I had to get smart on the process, tolerances under heat and load, and the quality control procedures. OK a long winded way to say manufacturing cost, tolerances and repeat ability where the driving force to make this part via sintering a specific powdered alloy

I might imagine that Cox was always looking for a inexpensive process. They might have had their engineers working on some other (non model airplane engine) project. On that project, they ordered a lot of the powder to get a price point break. They might have used the excess to do this simple non critical part. The in house tooling to heat and press these exhaust sleeves most likely required no post production machining...simply add the cir-clip and put in the assembly pile

Depending on the alloy....expansion rates can be controlled fairly precisely

From the photos I have seen of the Cox production facilities; they had the heat and presses and "in house" tool makers to do this relatively quickly (I briefly worked for Oil States Industries as a production control technician. They make low production rate rubber parts for the oil industry)

40 ton press with electric or steam heated platens

Pre heater for the powder

Top and bottom mold of 18"x 18" could easily do 50 of these at a time

Time to clean mold, spray release agent, dump fill the hot powder, slide into press, run up (or down) the platen, dwell time to "cook", open the platen, slide mold to lift table, open mold and dump parts then start a new cycle, was probably under 5 minuets per batch....reject rate could be controlled to under 2% (rejects most likely would be incomplete fill unless they used a vibration table)

Bottom line is to get same production rate with traditional machining is labor and equipment expensive

Sorry this is long...boring cold Sunday here waiting for my new Fox 36X Mark VI and 1 liter ultrasonic cleaner from e-bay to get on their way to me

... FWIIW wiki is often wrong, out dated, or opinion and not fact..it is my LAST resource for information

In this case I disagree with the wiki pros and cons, specifically "By sintering one cannot create uniform sizes" as a disadvantage. I say this as a retired Army Test officer that did a test once upon a time on a aircraft part out of a sintered alloy used in a high stress area of UH-1H Bell Huey helicopter. To do the test I had to get smart on the process, tolerances under heat and load, and the quality control procedures. OK a long winded way to say manufacturing cost, tolerances and repeat ability where the driving force to make this part via sintering a specific powdered alloy

I might imagine that Cox was always looking for a inexpensive process. They might have had their engineers working on some other (non model airplane engine) project. On that project, they ordered a lot of the powder to get a price point break. They might have used the excess to do this simple non critical part. The in house tooling to heat and press these exhaust sleeves most likely required no post production machining...simply add the cir-clip and put in the assembly pile

Depending on the alloy....expansion rates can be controlled fairly precisely

From the photos I have seen of the Cox production facilities; they had the heat and presses and "in house" tool makers to do this relatively quickly (I briefly worked for Oil States Industries as a production control technician. They make low production rate rubber parts for the oil industry)

40 ton press with electric or steam heated platens

Pre heater for the powder

Top and bottom mold of 18"x 18" could easily do 50 of these at a time

Time to clean mold, spray release agent, dump fill the hot powder, slide into press, run up (or down) the platen, dwell time to "cook", open the platen, slide mold to lift table, open mold and dump parts then start a new cycle, was probably under 5 minuets per batch....reject rate could be controlled to under 2% (rejects most likely would be incomplete fill unless they used a vibration table)

Bottom line is to get same production rate with traditional machining is labor and equipment expensive

Sorry this is long...boring cold Sunday here waiting for my new Fox 36X Mark VI and 1 liter ultrasonic cleaner from e-bay to get on their way to me

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: What is this engine?

Re: What is this engine?

Admin wrote:We all have to remember that this is Dan Sitter's engine, for all we know he could have gotten engines straight Cox that were made to be in a model that just never happened to be built and released. Cox would probably rather sell the pre-built engines "as-is" instead of have more employees sit down and disassemble them.

Cox did not pre-build engines for models that were never built, that just doesn't make sense and sure there might of been a prototype here and there, but that's a term, many are quick to throw out there because it's an unknown engine, fact is there were very few real prototypes.

Yes, and Dan has been known to throw stuff together, remember the Rivets engine earlier this year? I'm not say the engine is or isn't...it's a U.C.E (Unidentified Cox Engine)

Re: What is this engine?

Re: What is this engine?

Ahhhh! So that's how it works. I wonder how it worked in real life?

Thanks Mark.

Ron

Thanks Mark.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: What is this engine?

Re: What is this engine?

FYI. Cox did go to the 'horseshoe' backplate in the Mustang, but not until later (c. '85) also they rotated cylinder upright. The 'Combat Mustang' with two speed throttle was no longer advertised in catalog after '79. However the o'l 'stang did reappear again in '81 as the 'Invasion Mustang' thru '90 making it one of the longest running versions of the Mustang!

Miss America (c.'90)

Miss America (c.'90)

Similar topics

Similar topics» *Cox Engine of The Month* Submit your pictures! -June 2017- *ENGINE GIVEAWAY*

» **Black Lynx Engine Giveaway Jan-June 2023** Cox Engine of the Month

» *Cox Engine of The Month* Submit your pictures! -June 2018- *ENGINE GIVEAWAY*

» **Black Lynx Engine Giveaway June 2017** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2019** Cox Engine of the Month

» **Black Lynx Engine Giveaway Jan-June 2023** Cox Engine of the Month

» *Cox Engine of The Month* Submit your pictures! -June 2018- *ENGINE GIVEAWAY*

» **Black Lynx Engine Giveaway June 2017** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2019** Cox Engine of the Month

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules