Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

fish-mouth dowel joint tool

Page 1 of 1

fish-mouth dowel joint tool

fish-mouth dowel joint tool

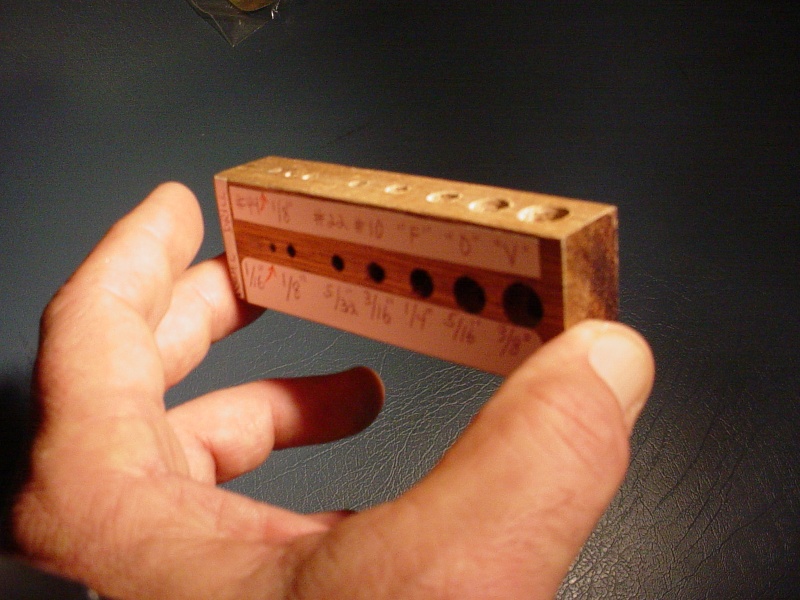

Another tool gadget adaptation from RCM's "For What it's Worth" publication. Someday you may want to build an early scale model... or duplicate a tube framework using wood dowels. This is a nice tool to have for forming the "fish-mouth" welded-joint look, at frame intersections. This tool makes a 90 deg. joint, and is not difficult tool to build.

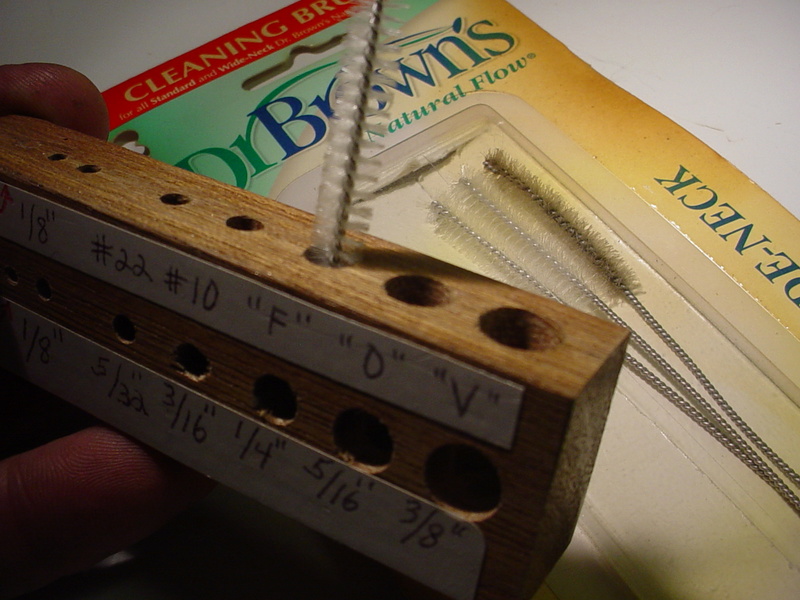

A small hardwood block (alum. block for longevity), assorted "graded" wood dowels, thin CA glue, drill-press and drill bits for ea. dowel size are needed to build.

The block is drilled; using the drill-press... drilling "thru" on the top and side, for each size dowel... MOST IMPORTANT; is the intersection of the bores being on center. NOTE: the "vertical" bores do NOT have to be drilled "thru"... but just deep enough to pass through the side-hole intersection... for example; when using a rectangular block, as "I" did.

After drilling... and one at a time; insert a dowel into its "side-hole" in the block, until it is "flush" on the opposite (back) side. CA glue the dowel at this location. Continue, one by one... until all the dowels are glued into the block.

Using the drill press again; trace-drill each top hole, cutting down through each dowel.

When done, pull out all the dowels, blow out the chips and clean with a dental pick.

It's now ready to use. Inserting a dowel, positions it's end "half way" into the bore intersection. Holding the dowel firmly while drill-chasing the blocks' top-holes, reveals the 90 deg. fish-mouth joint on removal.

Blocks could be made for 45 deg. angles, but strut-length calculations are critical. Easier to "rasp-out" the opposing ends of a cut to length 90 deg. struts' joints, and fill the opposite sides of the joints with micro-balloons.

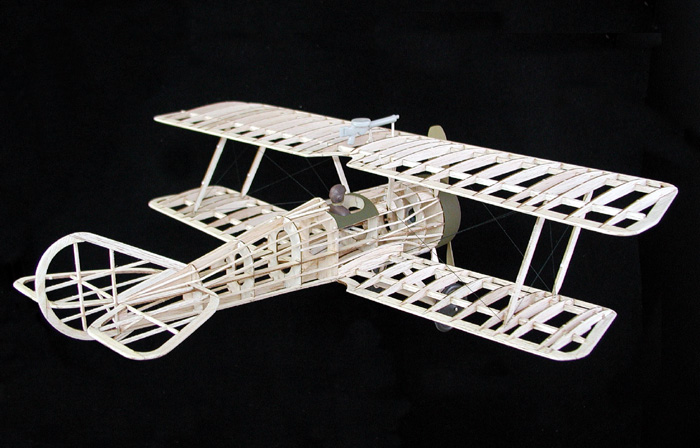

Imagine building something like a "Bleriot" or "Wright Flyer" this Winter... and for Cox power?

Note on pics: Alpha/# designations listed above side holes, are the "drill sizes" of my dowel stock. The lower designations are "nominal" dowel size.

A small hardwood block (alum. block for longevity), assorted "graded" wood dowels, thin CA glue, drill-press and drill bits for ea. dowel size are needed to build.

The block is drilled; using the drill-press... drilling "thru" on the top and side, for each size dowel... MOST IMPORTANT; is the intersection of the bores being on center. NOTE: the "vertical" bores do NOT have to be drilled "thru"... but just deep enough to pass through the side-hole intersection... for example; when using a rectangular block, as "I" did.

After drilling... and one at a time; insert a dowel into its "side-hole" in the block, until it is "flush" on the opposite (back) side. CA glue the dowel at this location. Continue, one by one... until all the dowels are glued into the block.

Using the drill press again; trace-drill each top hole, cutting down through each dowel.

When done, pull out all the dowels, blow out the chips and clean with a dental pick.

It's now ready to use. Inserting a dowel, positions it's end "half way" into the bore intersection. Holding the dowel firmly while drill-chasing the blocks' top-holes, reveals the 90 deg. fish-mouth joint on removal.

Blocks could be made for 45 deg. angles, but strut-length calculations are critical. Easier to "rasp-out" the opposing ends of a cut to length 90 deg. struts' joints, and fill the opposite sides of the joints with micro-balloons.

Imagine building something like a "Bleriot" or "Wright Flyer" this Winter... and for Cox power?

Note on pics: Alpha/# designations listed above side holes, are the "drill sizes" of my dowel stock. The lower designations are "nominal" dowel size.

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

Can you show the results this tool produces? I am fussy on the function. It seems like a tubing notcher, but I am unsure.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

Maybe a tubing notcher would produce the same results. I've never seen one. This tool was tested and the only thing I would change on mine is the smallest (1/16) "nominal" size bore intersection. It's off-center. It doesn't take much; even when "peck drilling" for a sm. drill-bit to "walk" off-center... and mine did slightly. It's the only size that gave me trouble. Shortening bore-lengths would decrease the risk of this. (note the distance down to the side-hole in the pic, for the sm. 1/16" size... it could have been located a lot more toward the top) An aluminum block would produce a nice tool, but most modelers are more likely to have a pc. of hardwood in their shop.pkrankow wrote:Can you show the results this tool produces? I am fussy on the function. It seems like a tubing notcher, but I am unsure.

Phil

To re-cap... an inserted dowel stops 1/2 way into the intersecting "top" bore that the drill passes through, because of the of the captive "glued-in" dowels that were drilled-thru, when the tool was made. In use; the drill is "notching" a radius 1/2 way into the dowels end.

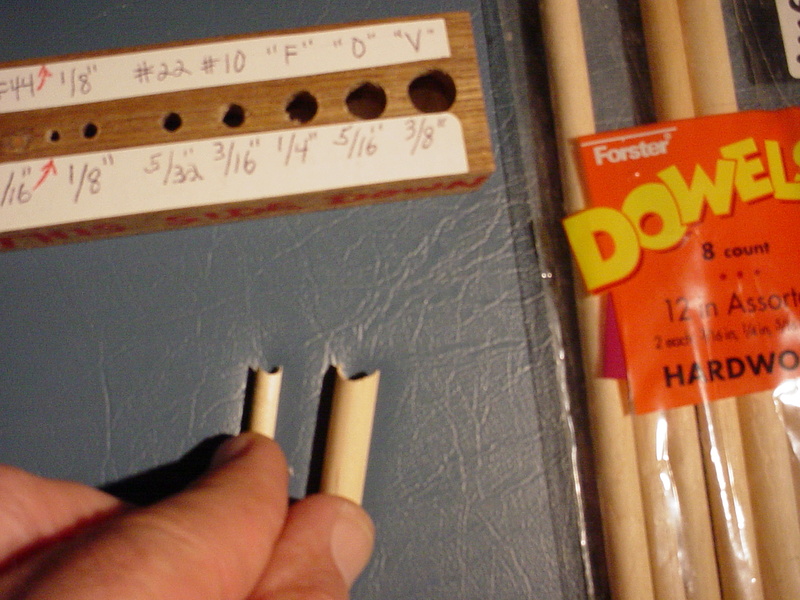

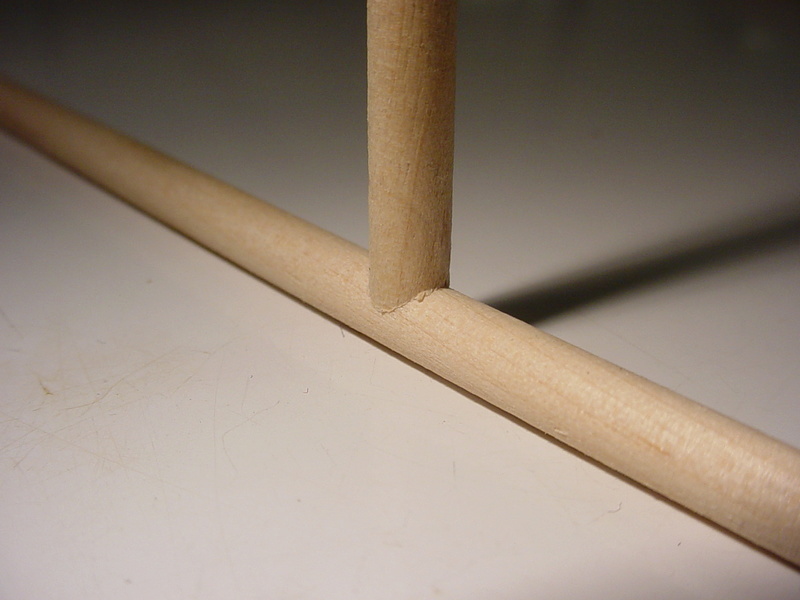

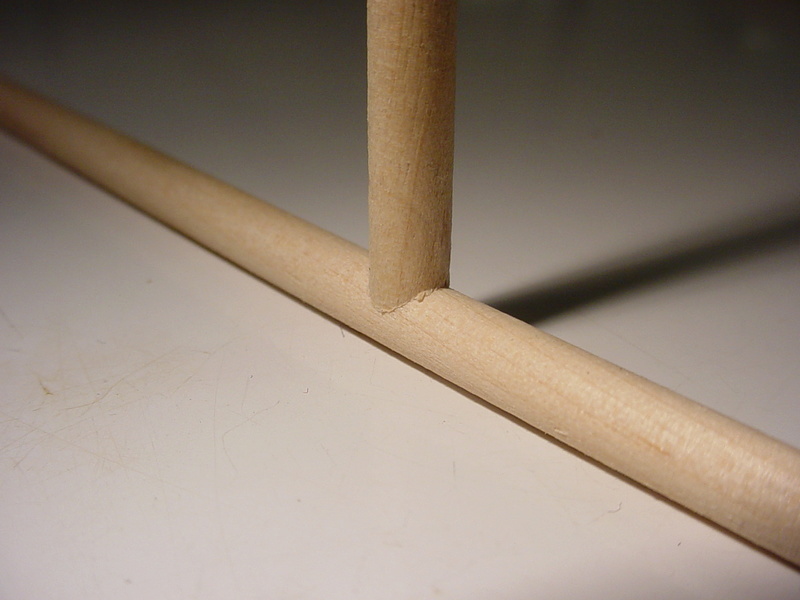

pic shows 3/16" and 5/16" dia. "fish-mouthed" dowels.

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

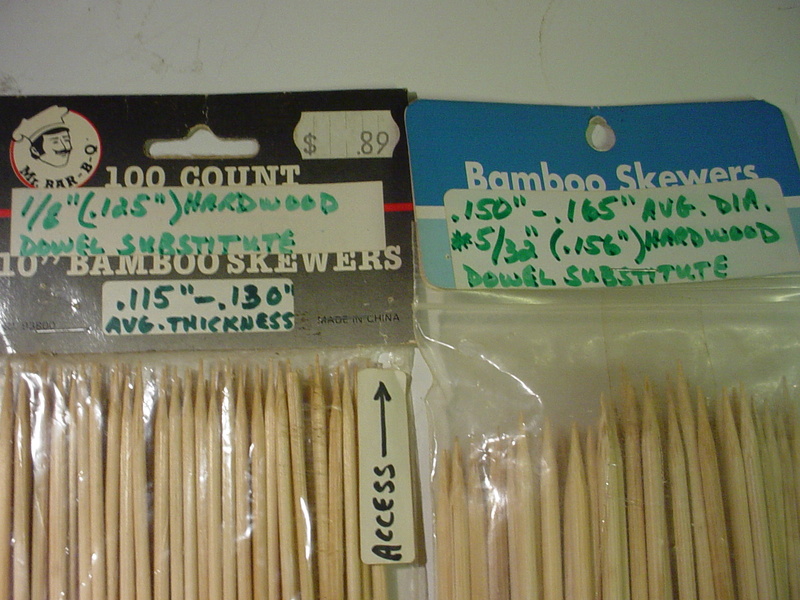

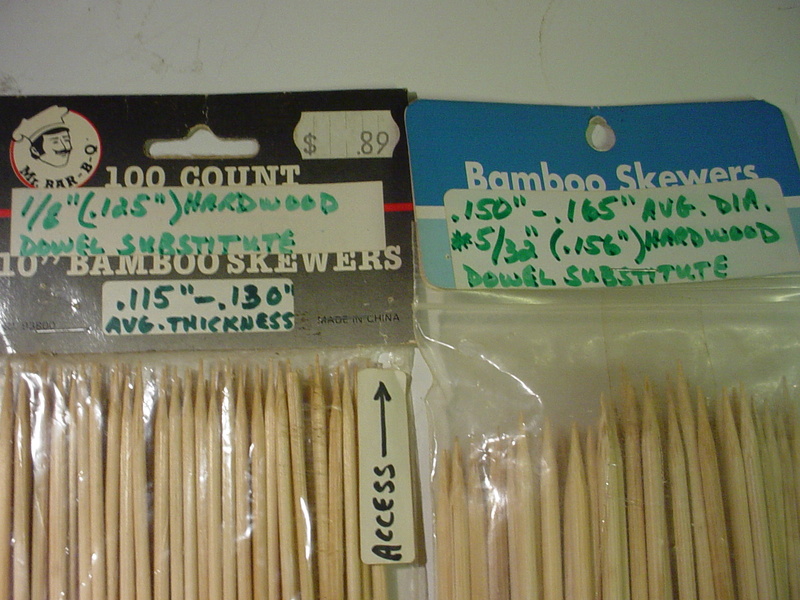

Dowels may vary significantly from their "nominal" size"... and clearance holes for dowels will vary... and are usually larger than the "nominal" dowel size. For instance... a given lot of 3/16" (.187") dia. dowels may "actually" average .190" in dia. and may require a #10 (.193" dia.) clearance hole without binding.

It is very useful to own a vernier/caliper and maintain a full "machinists" drill index, with 1/16" thru 1/2" dia. "fractional" drills, "wire-gage" drills #1 thru 60 and "letter" drills A thru Z... which provide sizes a few "thousandths" of an inch apart... often needed in model building and especially engine/metal work.

It is very useful to own a vernier/caliper and maintain a full "machinists" drill index, with 1/16" thru 1/2" dia. "fractional" drills, "wire-gage" drills #1 thru 60 and "letter" drills A thru Z... which provide sizes a few "thousandths" of an inch apart... often needed in model building and especially engine/metal work.

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

Yes, exactly like a tubing notcher fixed at one angle. Very nice results.

Thank you for the extra pictures.

Phil

Thank you for the extra pictures.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

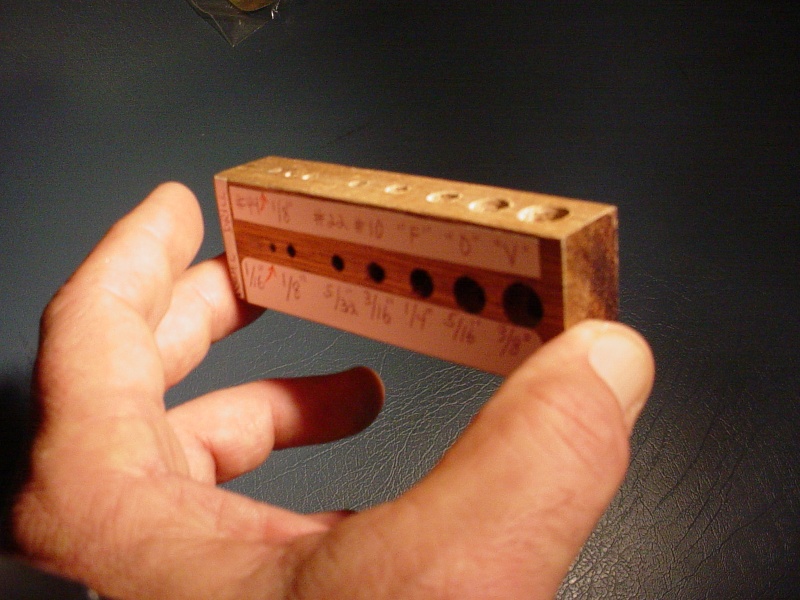

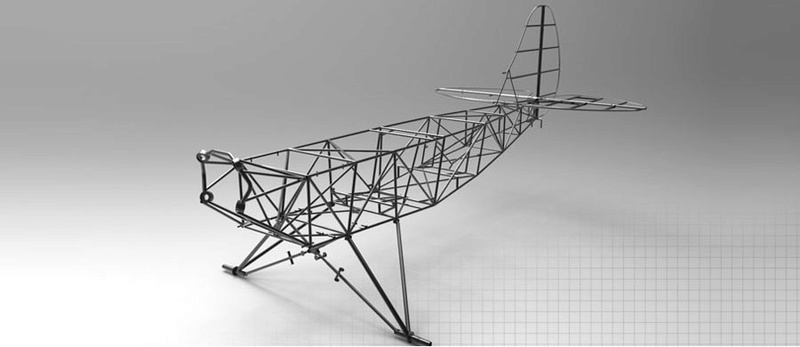

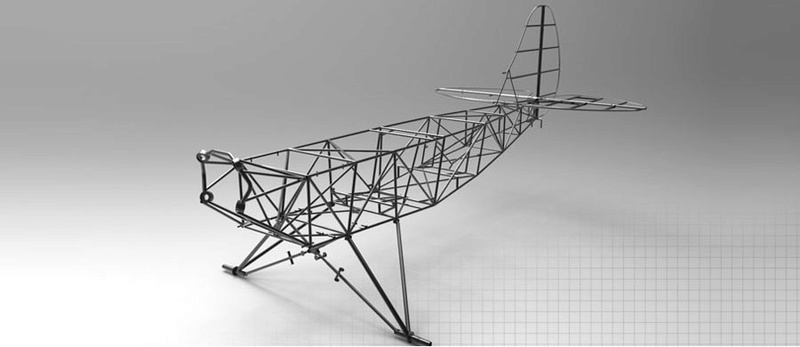

I'm bumping this old thread.. because I want to try this jig using common/cheap bamboo skewers. I'll need to make another jig-block for the size (diameter) of the skewers that I have on hand.

They generally come 100/package.. for around $1.00 and are reasonably straight. This may not appeal to everyone.. but the desire to build a small scale tube-frame fuse might come along someday. Bamboo is very strong and lightweight. Any of the joints that are not perpendicular can have their joint-angles "dressed" slightly to fit, using a rat-tail sanding-stick made from a dowel or nail with sandpaper wrapped around it. Wood-gluing the assembly would likely resemble an authentic "welded-joint" with a bit of sanding... using that same rat-tail sanding stick.

Bulkheads could have their tube-joints drilled with the same diameter bit as the skewer, for a nice radius-fit.

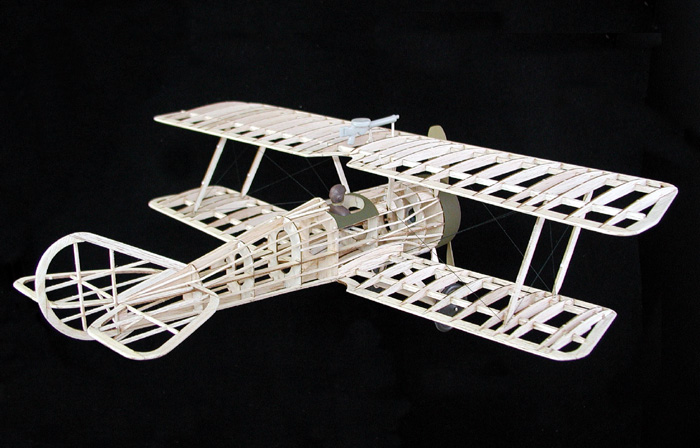

Imagine building a model like this Thomas Morse "Scout".. using this method.

They generally come 100/package.. for around $1.00 and are reasonably straight. This may not appeal to everyone.. but the desire to build a small scale tube-frame fuse might come along someday. Bamboo is very strong and lightweight. Any of the joints that are not perpendicular can have their joint-angles "dressed" slightly to fit, using a rat-tail sanding-stick made from a dowel or nail with sandpaper wrapped around it. Wood-gluing the assembly would likely resemble an authentic "welded-joint" with a bit of sanding... using that same rat-tail sanding stick.

Bulkheads could have their tube-joints drilled with the same diameter bit as the skewer, for a nice radius-fit.

Imagine building a model like this Thomas Morse "Scout".. using this method.

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

I have several packages of those bamboo skewers roddie along with a variety of "tongue" depressors. But I find that the bamboo tends to "thread" when cut due to it's longitudinal grain. I'm not sure if they would notch well if that is your intention. Although a drop or two of CA should cure that if applied prior to cutting or notching.

Those packages of bamboo sticks reminded me of the move "Rainman" 247 tooth picks....."There are three left in the box." Creepy.

I'm glad you ID'd that model as a "Scout", I was trying to make it a Spad or Nieuport 28, but some things didn't match.

Bob

Those packages of bamboo sticks reminded me of the move "Rainman" 247 tooth picks....."There are three left in the box." Creepy.

I'm glad you ID'd that model as a "Scout", I was trying to make it a Spad or Nieuport 28, but some things didn't match.

Bob

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

You've got an impressive measuring device there, Roddie. I'm less ambitious, drill bits in a metal case from my late father are graduated in 1/64" and 1/32" in the smaller sizes. I use those to give me a good comparison. I had no idea that smaller dowels could be off by so much.

But now, a 2x4 in a lumber store is 1.5"x3.5". Our former house in Long Beach built prior to the depression, an old Dutch style house had 1" outside lap boards (in redwood all framed in redwood no less!) for siding. Back in 1926, a 1"x8" board was 1"x8" finished, not 7.5"x0.75".

I'm glad balsa and aircraft ply aren't graduated to construction industry standards.

But now, a 2x4 in a lumber store is 1.5"x3.5". Our former house in Long Beach built prior to the depression, an old Dutch style house had 1" outside lap boards (in redwood all framed in redwood no less!) for siding. Back in 1926, a 1"x8" board was 1"x8" finished, not 7.5"x0.75".

I'm glad balsa and aircraft ply aren't graduated to construction industry standards.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

Bob and George, thanks for the comments.

Bob, I know what you mean about the bamboo. It's "stringy". Soaking the ends with thin CA as you mentioned, might help hold the fibers together for a firm radius to be cut. Maybe soaking an end with thin CA and dipping in a cup of baking-soda would harden the end enough for a clean cut? My God.. wouldn't that be great? If not.. I think there would still be enough of a radius to establish a decent joint. The wood-glued joint-assembly would bridge any gaps.. and once sanded, would be clean and strong.

The "Scout" is a Guillows kit. I have one that was built for FF/rubber-power by my Uncle Len back in the 70's/80's?

It's one of three Guillows WWI models that he built. I also have the other two; a Nieuport II and Fokker Dr1. All were rubber-powered.

It's amazing that they've survived this long without any significant damage. They're all extremely fragile.. and kinda' special to me. I think of the work he did; building three small stick and tissue airplanes.. one after the other. I don't remember him flying those particular models.. but I do remember him flying other rubber-jobs. I got these when my cousin (his son) was moving his family, sometime in the early 90's. That's when I acquired these three models. They were "flyable" then.. rubber-motors not too old... no holes in the silkspan. Three "moves" later.. Now they're sitting atop a Rubbermaid portable wardrobe.. reasonably safe from harm.. but all have some hangar-rash, in the way of torn tissue and detached bits. I've never tried to fly any of them. I always make an effort to save detached-pieces of models. I usually put them in a sandwich-bag and attach it to the model somehow. It's part of my anal/OCD personality.. but gives me peace of mind that I'll (or someone else..) will be able to rebuild the model someday.. in the case that the plan is not available.

George, My grandfather gave me his 1" micrometer before he passed away. He used it at the "mill".. where he worked until he retired.

I would use this instrument in later years when running machines. I was lucky enough to work for an employer who offered to fill a full English drill-index with tools.. providing I bought the index. I did.. and it was filled with fractional, # and letter drills as promised. I've kept that index full over the years.

Along with the caliper for measuring the precise OD.. I can drill accurate hole/bores in small construction. I've found it enjoyable; when designing components that fit together with a wood-screw, machine-screw.. or a bushing.

Who knows how our modelling-materials will change in measurement moving forward. We'll always be able to gage the correct measurement with tools/math. That's what make's it your own.

Bob, I know what you mean about the bamboo. It's "stringy". Soaking the ends with thin CA as you mentioned, might help hold the fibers together for a firm radius to be cut. Maybe soaking an end with thin CA and dipping in a cup of baking-soda would harden the end enough for a clean cut? My God.. wouldn't that be great? If not.. I think there would still be enough of a radius to establish a decent joint. The wood-glued joint-assembly would bridge any gaps.. and once sanded, would be clean and strong.

The "Scout" is a Guillows kit. I have one that was built for FF/rubber-power by my Uncle Len back in the 70's/80's?

It's one of three Guillows WWI models that he built. I also have the other two; a Nieuport II and Fokker Dr1. All were rubber-powered.

It's amazing that they've survived this long without any significant damage. They're all extremely fragile.. and kinda' special to me. I think of the work he did; building three small stick and tissue airplanes.. one after the other. I don't remember him flying those particular models.. but I do remember him flying other rubber-jobs. I got these when my cousin (his son) was moving his family, sometime in the early 90's. That's when I acquired these three models. They were "flyable" then.. rubber-motors not too old... no holes in the silkspan. Three "moves" later.. Now they're sitting atop a Rubbermaid portable wardrobe.. reasonably safe from harm.. but all have some hangar-rash, in the way of torn tissue and detached bits. I've never tried to fly any of them. I always make an effort to save detached-pieces of models. I usually put them in a sandwich-bag and attach it to the model somehow. It's part of my anal/OCD personality.. but gives me peace of mind that I'll (or someone else..) will be able to rebuild the model someday.. in the case that the plan is not available.

George, My grandfather gave me his 1" micrometer before he passed away. He used it at the "mill".. where he worked until he retired.

I would use this instrument in later years when running machines. I was lucky enough to work for an employer who offered to fill a full English drill-index with tools.. providing I bought the index. I did.. and it was filled with fractional, # and letter drills as promised. I've kept that index full over the years.

Along with the caliper for measuring the precise OD.. I can drill accurate hole/bores in small construction. I've found it enjoyable; when designing components that fit together with a wood-screw, machine-screw.. or a bushing.

Who knows how our modelling-materials will change in measurement moving forward. We'll always be able to gage the correct measurement with tools/math. That's what make's it your own.

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

I've always been a tool lover and a lover of using tools. This is all very entertaining. I've never worked with precision equipment, but if I had one of those impossible do-overs, I'd make it a point to learn at least the basics of machinists' craft.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

Impressive tool the Fish Mouth jig would for sure make it easier to put the frame work together on the older style models , never seen one of these before but have seen the joints made in some metal work applications.

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

getback wrote:Impressive tool the Fish Mouth jig would for sure make it easier to put the frame work together on the older style models , never seen one of these before but have seen the joints made in some metal work applications.

Eric, The Fish-Mouth jig can also be used with alloy-tubing. Brass with soldered-joints would look beautiful.. but not your lightest-weight choice for a flying-model. Aluminum-tube would look nice too.. maybe with JB-weld (grey-color) epoxy, applied with a scrap-piece of the AL tubing, to form a radius at the joint.

I used a square.. to initially mark the intersections in my jig-block. I then used an awl to mark/start the drill-points. This is where you need to be careful. Use a sharp tool.. and "peck-drill" the bore to keep the bit from grabbing/walking sideways in the bore.

One of the last steps in making the jig, is to insert a piece of your dowel/tube stock "through" the intersection and glue it into the "rear" side of the block only. Then the drill of that diameter is fed-down through the top, and through the stock. The stock is then retracted from the jig and leaves a piece which serves as a shoulder/"stop".. for making production-joints. When they're cut; only 1/2 of the diameter is actually "nibbled" off the end. This minimizes chips and is helpful for accurately measuring the length of the pieces. The jig-block needs to be square (90-degrees at all corners) and the bore-intersections need to intersect/bisect each other squarely. The vertical bore (tool-bore) should be a thru-hole to help clear the block of chips between cuts. That point isn't mentioned in the RCM "FWIW" article.. and I actually didn't drill the holes through in my block. I figure it's a step worth taking.. and if done; a brush for cleaning baby-bottle nipples would work well for clearing any leftover chips from the bore. An air-compressor/blow-gun would be ideal if you have one. I don't. Blowing through a drinking-straw to clean-out the bore would probably be adequate.

A pipe-cleaner would also work. Most of the chips will eject out the top of the jig-block, because of the up-spiral design of the drill-bit. Chips should be cleared between every cut, to ensure that a full 180 degree radius is cut on the end of the work-piece. Leftover chips can prevent the stock from being inserted fully into the block.

When making a cut, the stock needs to be inserted into the block against the backstop, and held firmly from any rotation. Production-cuts could be made using a VSR/hand-drill by clamping the jig-block in a vise. A drill-press would be better though. The block-bore(s) will last longer being drilled "squarely" with less side-load. A drill-press vise should be used to align the spindle/tool with the bore in the block. This allows holding the stock firmly with one hand while advancing the drill with the other.

Either way.. a "pecking" feed on the drill will also help to make a cleaner cut.. with reduced "walking" (side-load) being subjected to the bore. One hardwood jig-block should last long enough to make several joints. If the cuts start becoming non-symmetrical.. make a new block. It's easier after you've made the first one. Making different sizes is simple.. after learning the method.

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

I have a 3/4" square x 6" long brass bar that's been part of my heavy tools for decades. It lives next to my vice with a center punch and my 1-lick stick(mini-sledge). I used the drill press to bore a row of common small bit sizes from 1/16" up to 1/4" and it makes a great guide for boring straight holes like profile engine mounts, etc. I could turn that into a tool like this.

I sure wish I had some more of that bar stock. Originally I used it for gripping the edge of a collar or something pressed onto a transmission shaft or the like. Also seating a pilot bearing into the back of a crankshaft, millions of uses to protect a metal object from the direct impact of the steel 1-lick stick. I call it a grip bar but I think a "Drift" is the proper name for it. If I use the bar as a drill guide I have to grind the mushroomed edges off the ends that are left over from pounding other things with it. One of my treasures that would make me ill if I lost it.

I sure wish I had some more of that bar stock. Originally I used it for gripping the edge of a collar or something pressed onto a transmission shaft or the like. Also seating a pilot bearing into the back of a crankshaft, millions of uses to protect a metal object from the direct impact of the steel 1-lick stick. I call it a grip bar but I think a "Drift" is the proper name for it. If I use the bar as a drill guide I have to grind the mushroomed edges off the ends that are left over from pounding other things with it. One of my treasures that would make me ill if I lost it.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

RknRusty wrote:I have a 3/4" square x 6" long brass bar that's been part of my heavy tools for decades. It lives next to my vice with a center punch and my 1-lick stick(mini-sledge). I used the drill press to bore a row of common small bit sizes from 1/16" up to 1/4" and it makes a great guide for boring straight holes like profile engine mounts, etc. I could turn that into a tool like this.

I sure wish I had some more of that bar stock. Originally I used it for gripping the edge of a collar or something pressed onto a transmission shaft or the like. Also seating a pilot bearing into the back of a crankshaft, millions of uses to protect a metal object from the direct impact of the steel 1-lick stick. I call it a grip bar but I think a "Drift" is the proper name for it. If I use the bar as a drill guide I have to grind the mushroomed edges off the ends that are left over from pounding other things with it. One of my treasures that would make me ill if I lost it.

Yes, I remember you mentioning having that Drift bar a while back. I'd recommend using a hardwood block to make a prototype first though. You'll find that the bore for the round-stock that you have on hand; be it wood-dowels, alloy-tubing etc. will need to be a few thousandths larger than the stock's diameter to prevent binding. That's why it's really helpful to have a machinist's drill-index and a vernier/caliper. A number/letter/fractional index's sizes are in approx. .003" graduations. A 3/16" hardwood dowel might be +/- .005" or more.. rather than exactly .187". Alloy tubes have a more precise OD.. but a 3/16" tube would actually require a #11 (.189") or #12 (.191") drill/bore for a non-binding clearance-fit in the block.

Notice my Mahogany block's bore-sizes, marked at their corresponding bores.

The 3/16" dowels that I had were oversize to the point where I needed a #10 (.193") drill to make the bore. If I bought more 3/16" hardwood dowels tomorrow.. they could be smaller in diameter.. and fit too loosely in the #10 bore.

The multi-size block shown above, was made to merely prove the concept with all the different sizes of stock that I had on hand. I'd recommend single-size jig-blocks; custom-made for a "run" in the size you plan to use. If using wood-dowels.. measure several pieces to see if there are variations in their diameters. They should be "close" if they came from the same production-run.

Re: fish-mouth dowel joint tool

Re: fish-mouth dowel joint tool

Here's an example of a 90 degree 3/16" diameter hardwood dowel joint that I made using the jig.

That's right out of the jig.. with no sanding. You can imagine how a "full-tube" replicated fuse would look on an old vintage scale-model tail-dragger! Making cross/connector tubes (double-ended) can be done accurately by keying a piece of stock into the previously-cut joint (forming a "tee") for proper indexing in the jig, to cut the other end. A cross-tube's uncut length would be longer.. by the diameter of the stock, in order to fit between two parallel rails.

Not mine.. but check-out these for some inspiration..

That's right out of the jig.. with no sanding. You can imagine how a "full-tube" replicated fuse would look on an old vintage scale-model tail-dragger! Making cross/connector tubes (double-ended) can be done accurately by keying a piece of stock into the previously-cut joint (forming a "tee") for proper indexing in the jig, to cut the other end. A cross-tube's uncut length would be longer.. by the diameter of the stock, in order to fit between two parallel rails.

Not mine.. but check-out these for some inspiration..

Similar topics

Similar topics» Cox powered boat litle shrimp hidroplane

» Putting my money where my mouth is.

» Putting my money where my mouth is.

» Caravan 1/2 A

» Cox works tuned engines

» Putting my money where my mouth is.

» Putting my money where my mouth is.

» Caravan 1/2 A

» Cox works tuned engines

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules