Log in

Search

Latest topics

» Retail price mark-up.. how much is enough?by Ken Cook Today at 11:08 am

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Happy 77th birthday Andrew!

by rdw777 Today at 10:04 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Cox works tuned engines

Page 1 of 2

Page 1 of 2 • 1, 2

Cox works tuned engines

Cox works tuned engines

Is anyone aware if Cox sold works tuned engines , and if they did what the tuning work completed involved.I have been offered a works tuned engine (which i intend to buy ) but i have no recollection of Cox ever offering such a service. Apparently the engine was bought directly from Cox by the current owner many years ago as a works tuned version ,,, any ideas -- thanks

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Re: Cox works tuned engines

Re: Cox works tuned engines

Don't know of Cox doing this except that they might have tuned their engines to perform flawlessly and with the greatest power when they did various demonstrations, like for a time with a circle at Disney in Anaheim, CA back in the 1960's and perhaps late 1950's.

I do recall of some speed shops that sold custom parts for Cox. I think one was Cox Kustom Craftsmanship perhaps run by Dale Kirn, used to advertise in the modeling magazines and in the Ace R/C catalog, back in the late 1960's through 1970's. I think they would tune your engine if you sent it to them. Since I didn't keep these catalogs, the memory gets more vague each year.

I do recall of some speed shops that sold custom parts for Cox. I think one was Cox Kustom Craftsmanship perhaps run by Dale Kirn, used to advertise in the modeling magazines and in the Ace R/C catalog, back in the late 1960's through 1970's. I think they would tune your engine if you sent it to them. Since I didn't keep these catalogs, the memory gets more vague each year.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Cox works tuned engines

Re: Cox works tuned engines

Hi GG , thanks for response . your recollections are the same as mine . I know of Kustom Craftsmanship , i have their fine thread needle valves and i also used there modified clamp heads with flat filament but was not aware they would set up a motor for you . The motor i'm looking at has an original Cox needle valve so that probably rules out Kustom involvement . I wonder if Cox offered the opportunity to buy selected matched parts rather than standard production line assembled engines ?? . One tell tale sign with my motor is the slotted prop screw has been replaced with allen head black bolt - i've seen this feature used on a few occasions ..

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Re: Cox works tuned engines

Re: Cox works tuned engines

flytilidie wrote:..........One tell tale sign with my motor is the slotted prop screw has been replaced with allen head black bolt - i've seen this feature used on a few occasions ..

I'm not sure that this would be indicative of any particular tuning. I say that only because I always replace the slotted prop screw with an alloy socket head 5-40. When I do, I will cut the screw to length so that it tightens up just before bottoming out -- I think this stiffens the nose of the crank and adds some strength. But, none of my engines could be classed as tuned.

a--

Re: Cox works tuned engines

Re: Cox works tuned engines

flytilidie wrote:Hi GG , thanks for response . your recollections are the same as mine . I know of Kustom Craftsmanship , i have their fine thread needle valves and i also used there modified clamp heads with flat filament but was not aware they would set up a motor for you . The motor i'm looking at has an original Cox needle valve so that probably rules out Kustom involvement . I wonder if Cox offered the opportunity to buy selected matched parts rather than standard production line assembled engines ?? . One tell tale sign with my motor is the slotted prop screw has been replaced with allen head black bolt - i've seen this feature used on a few occasions ..

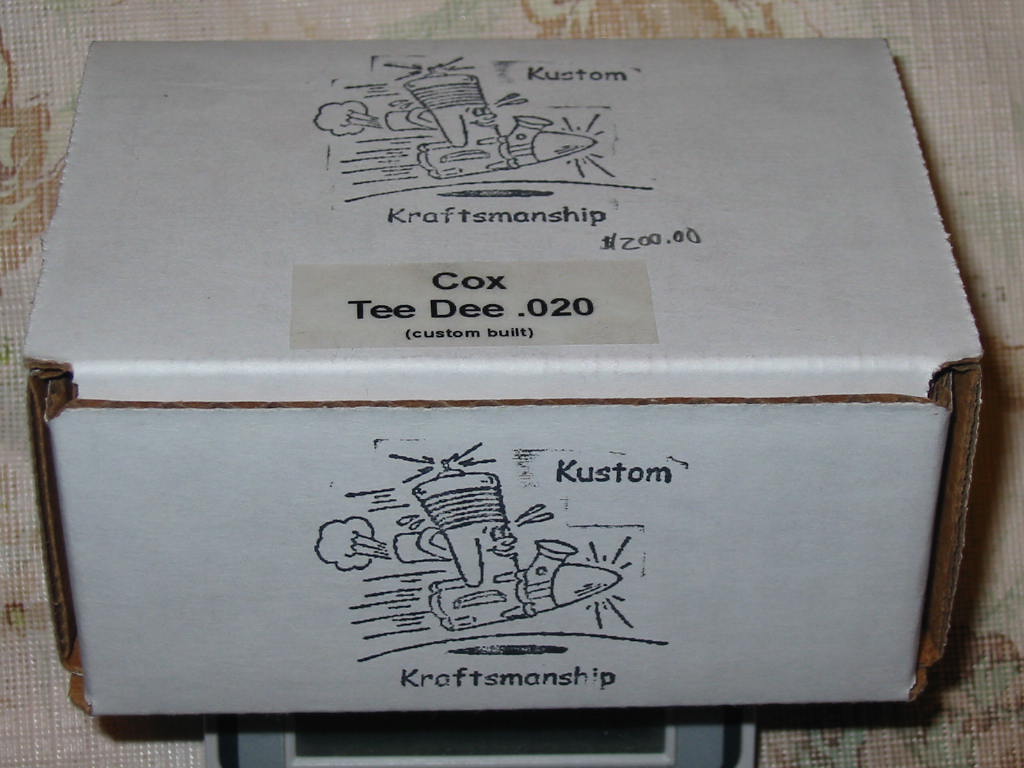

I have one of Kustom Kraftsmanship's catalog from 1996 (need to get it scanned and posted here -- someday).

As for Kustom Kraftsmanship doing "special" work on Cox engines, yes they did.

In their catalog it would give you prices for custom modifications on your engine if you shipped your engine to them.

They also had it where you could purchase a custom engine from them with the modifications made to you spec.

You pay for the "custom" Kustom Kraftsmanship Cox engine and then have it shipped to your house.

I have a "few" of Dale Kirn's Kustom Cox engines.

Prices were almost twice of what an original Cox engine would be.

As for the Allen head bolt, I have replaced the slotted head 5-40 screw for that same Allen head 5-40 bolt.

So, that is nothing special.

Bought a box of 5-40 x 1-3/4 long socket head bolts at my local McMaster-Carr 5 miles away.

There were 10 in a box for $9.95

I asked about quantity purchasing --- yes there is (in person) so, I purchased twenty and the price was dropped to $17.95.

sosam117- Diamond Member

- Posts : 1351

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Cox works tuned engines

Re: Cox works tuned engines

Lots of great information -thanks all . As this motor is brand new (never been run ) and in the same sate as it was received from supplier many many years ago with the allen head screw in place maybe it is a Kustom craft engine . I think we can rule out that it was bought from Cox (otherwise it would have the standard propscrew in place ) . So did Kustom doing any physical machined modifications or did they just add there own select parts to the engines they sold ( maybe i can check internals when i receive engine) .Or did they modify to suit your application ie free flight power ,, 1/2A pylon racing or CL speed . I have a feeling the owner originally bought this for free flight 1/2 power competitions and therefore this may have driven the advised tuning that was done. Can i also assume that the tuning would have also specified the fuel mix to be used , going back to when i used to race these in 1/2A pylon events i think i recall Cox sold a 20% nitro competition mix ? .. thanks again for your help

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Re: Cox works tuned engines

Re: Cox works tuned engines

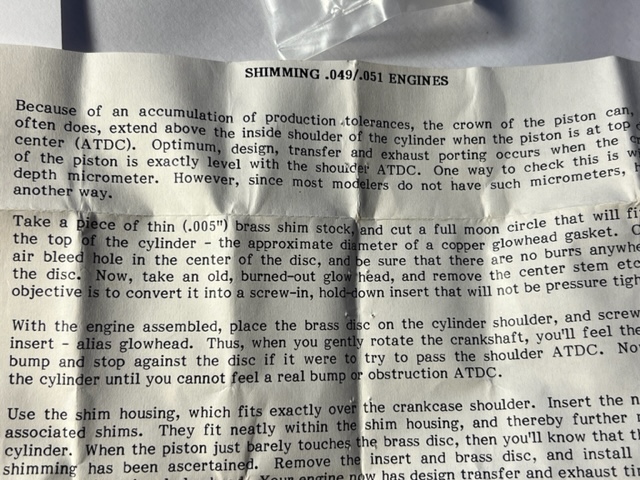

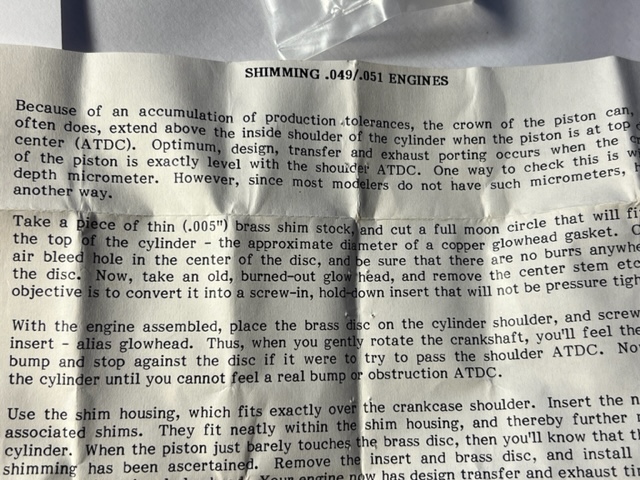

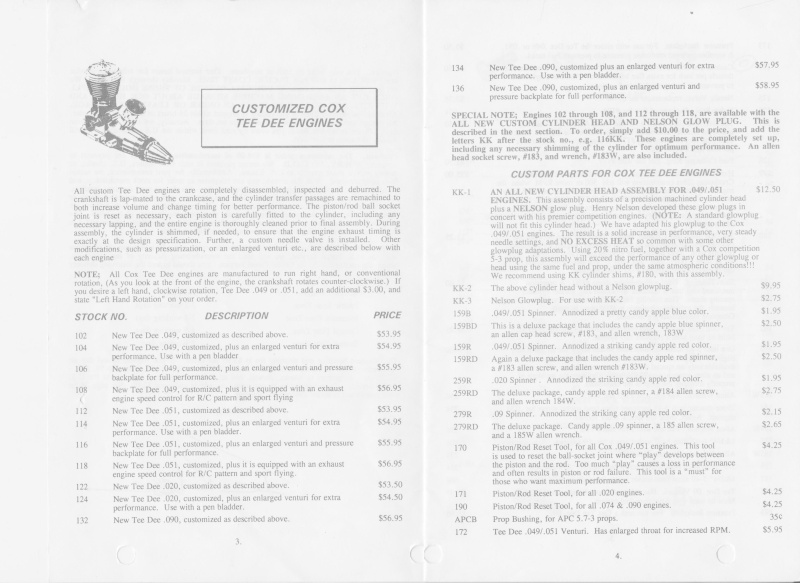

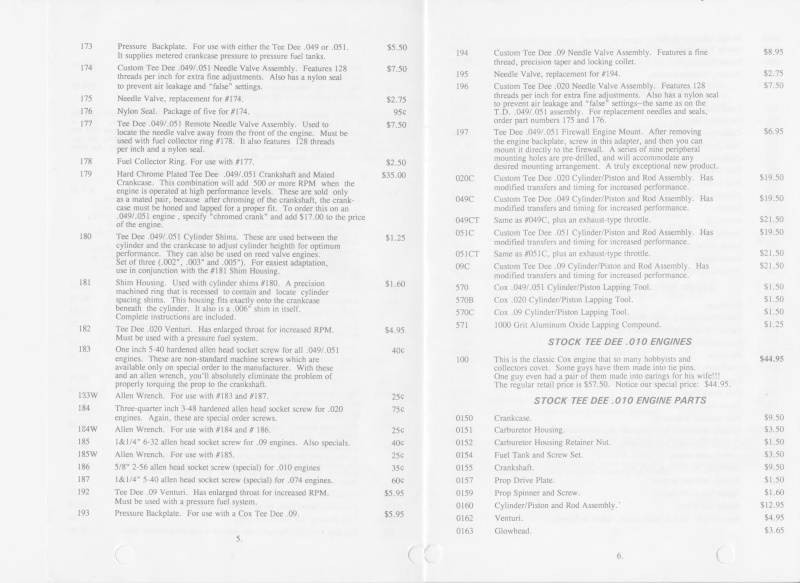

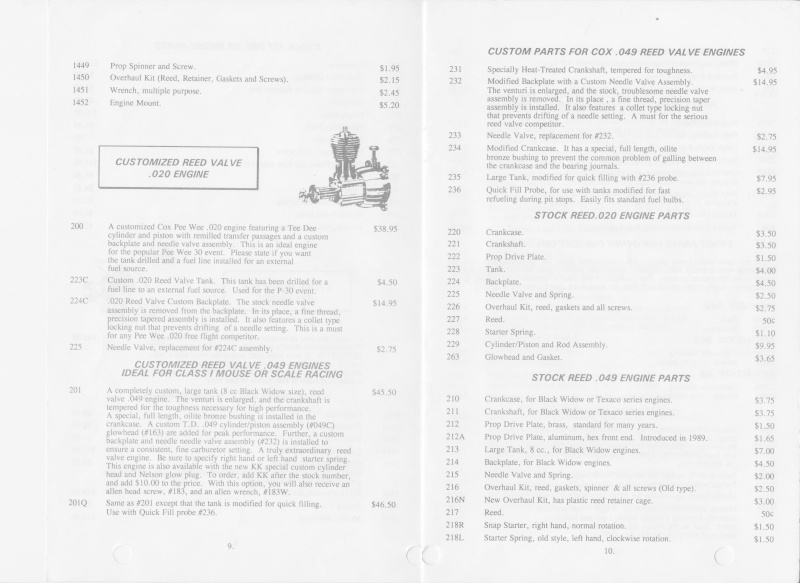

What I got from them (if you look on the top of the boxes) as a high-performance crank, The Tee Dee 49 and 51 have their needle valve assemblies, and they do the shimming of the piston cylinder for timing.

Their catalog gives an entire listing of modifications even for rat racing modified engines.

I just gave the instruction sheet to Jacob last month of how Kustom Kraftsmanship shimmed the cylinder.

It is in the last "kit" that I have from Dale Kirn.

It is available on the left side bar "INFO" section under Instruction sheets.

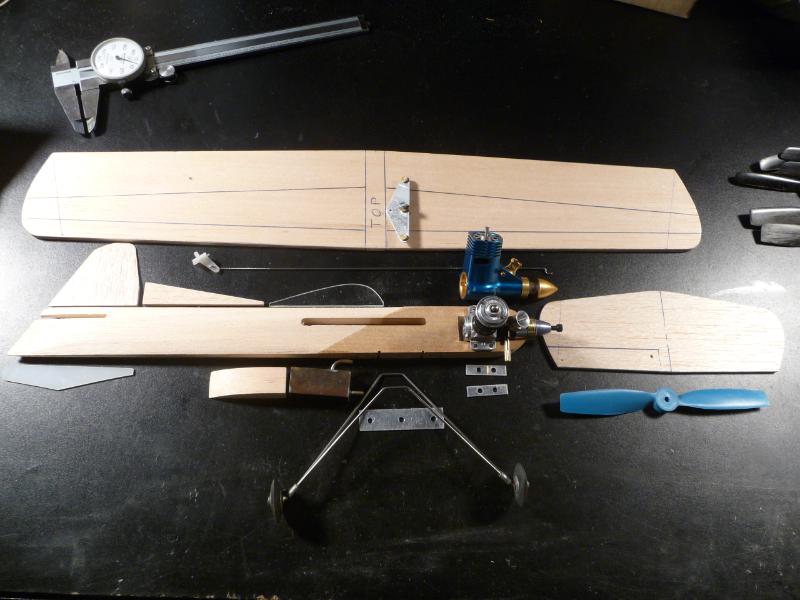

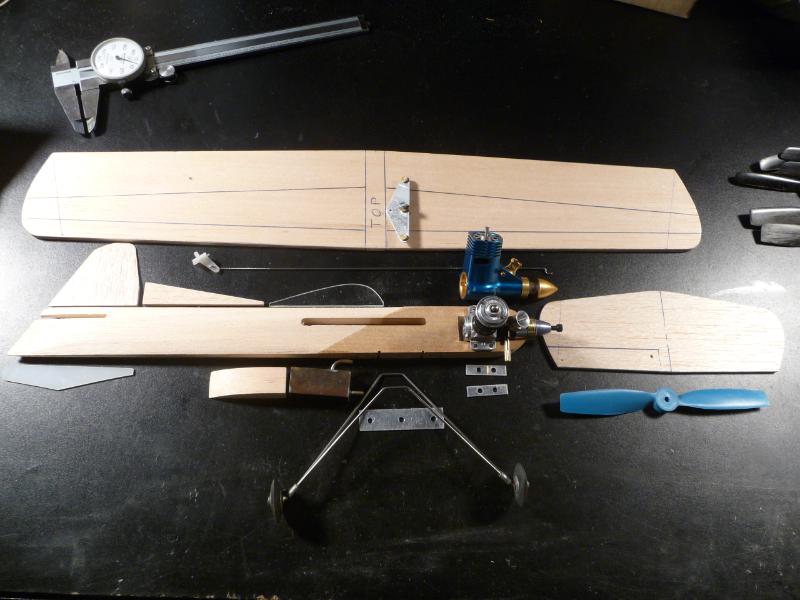

Shims from the kit and guide ring for the shims:

Dale Kirn's needle valve assemblies for Bee back plates:

Kustom Kraftsmanship's Special metal reeds:

And a photo of a Dale Kirn's Kustom Kraftsmanship's modified Tee Dee .049.

With special H.P. crank, Allen head bolt for the prop, Kirn's needle valve assembly, shimmed head kit under the cylinder and high compression glow head.

Missing in the photo is additional shims for under the glow head (as needed).

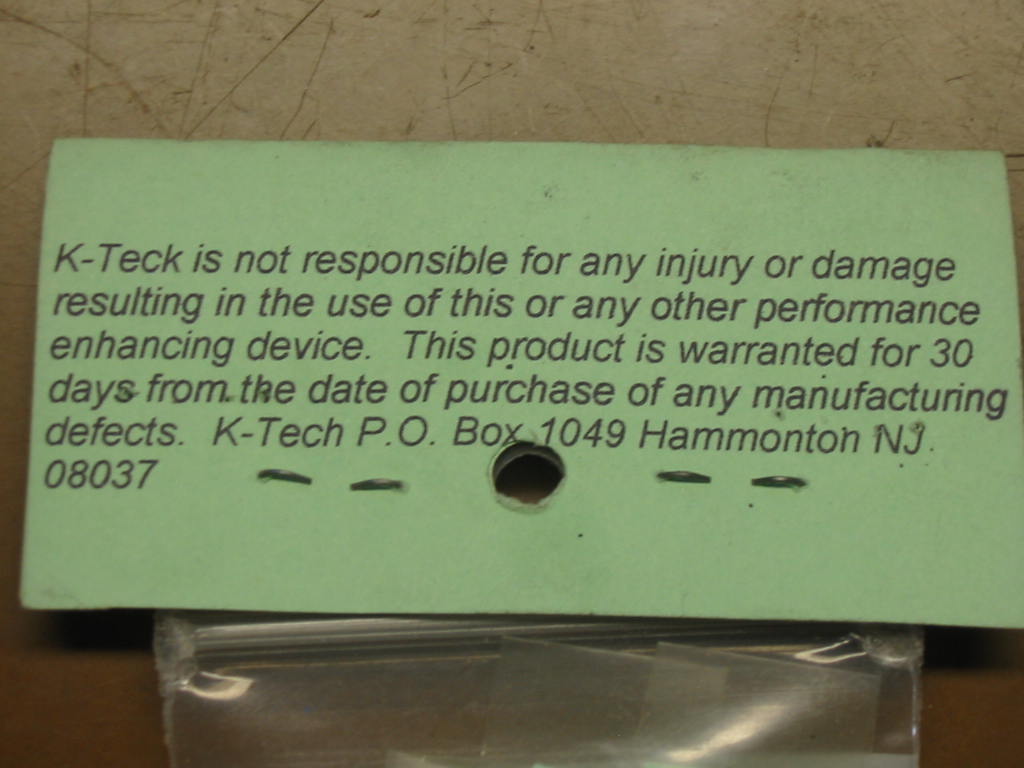

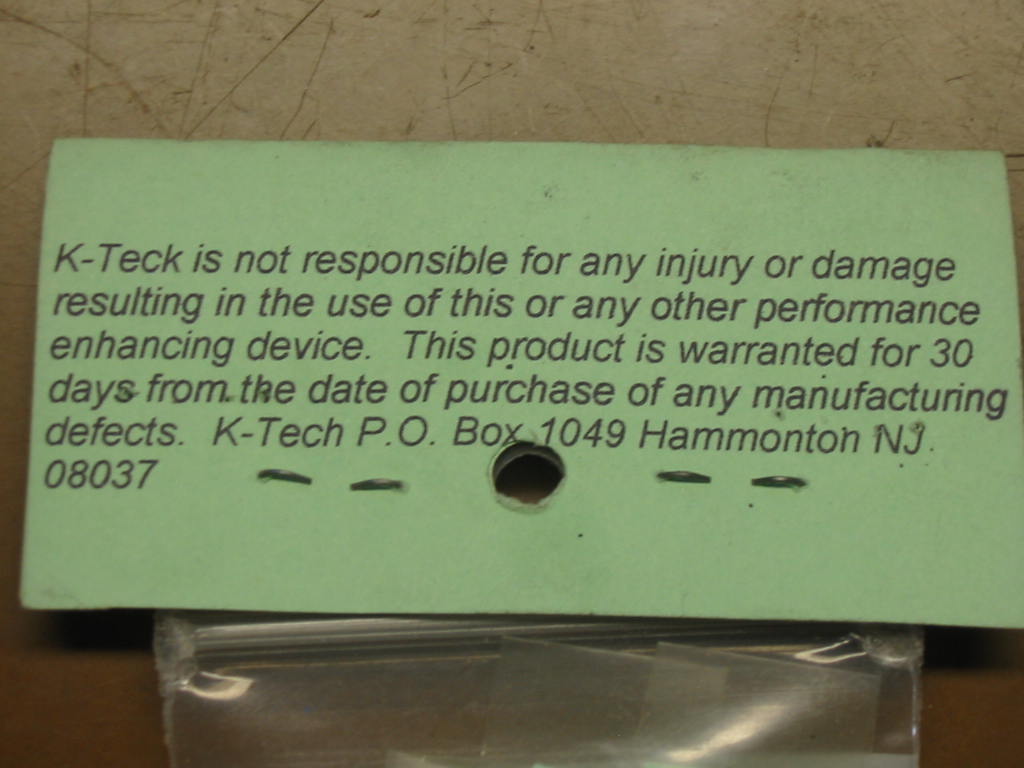

The paper under the engine (on the left of the photo) gives recommendations for fuel, props, and break-in, as well as resetting the piston and if problems with the engine to send it back for evaluation and repair (included is possible repair costs too.)

Also, on the instructions it says that this engine was tested before shipping.

This engine was Kustom made back in 1991 and has never been run by me since Kustom Kraftsmanship ran it, or out of the box until today (Jan.15.2023)

It is not gummed up and free turning with good compression.

Receipt inside the box says it cost me $53.87 for this engine.

So, if your engine looks almost like mine, then it might have been a Kustom Kraftsmanship modified engine?

Their catalog gives an entire listing of modifications even for rat racing modified engines.

I just gave the instruction sheet to Jacob last month of how Kustom Kraftsmanship shimmed the cylinder.

It is in the last "kit" that I have from Dale Kirn.

It is available on the left side bar "INFO" section under Instruction sheets.

Shims from the kit and guide ring for the shims:

Dale Kirn's needle valve assemblies for Bee back plates:

Kustom Kraftsmanship's Special metal reeds:

And a photo of a Dale Kirn's Kustom Kraftsmanship's modified Tee Dee .049.

With special H.P. crank, Allen head bolt for the prop, Kirn's needle valve assembly, shimmed head kit under the cylinder and high compression glow head.

Missing in the photo is additional shims for under the glow head (as needed).

The paper under the engine (on the left of the photo) gives recommendations for fuel, props, and break-in, as well as resetting the piston and if problems with the engine to send it back for evaluation and repair (included is possible repair costs too.)

Also, on the instructions it says that this engine was tested before shipping.

This engine was Kustom made back in 1991 and has never been run by me since Kustom Kraftsmanship ran it, or out of the box until today (Jan.15.2023)

It is not gummed up and free turning with good compression.

Receipt inside the box says it cost me $53.87 for this engine.

So, if your engine looks almost like mine, then it might have been a Kustom Kraftsmanship modified engine?

sosam117- Diamond Member

- Posts : 1351

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Cox works tuned engines

Re: Cox works tuned engines

Kustom Kraftsmanship was Joe Klause's company. Not Dale Kirn (who I believe ran Kirn kraft)

ajcoholic- Beginner Poster

- Posts : 5

Join date : 2017-12-23

Re: Cox works tuned engines

Re: Cox works tuned engines

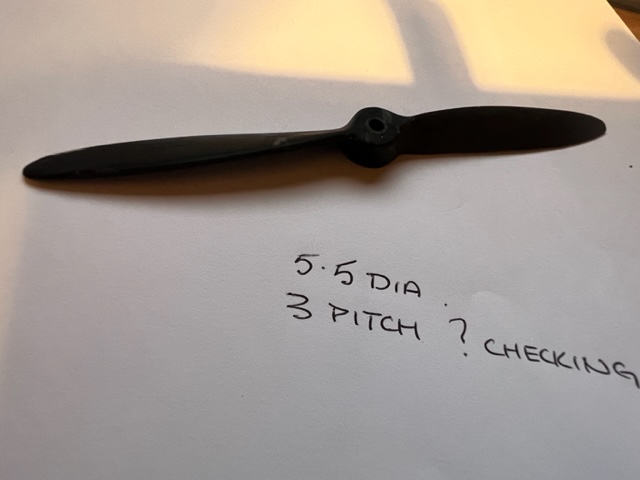

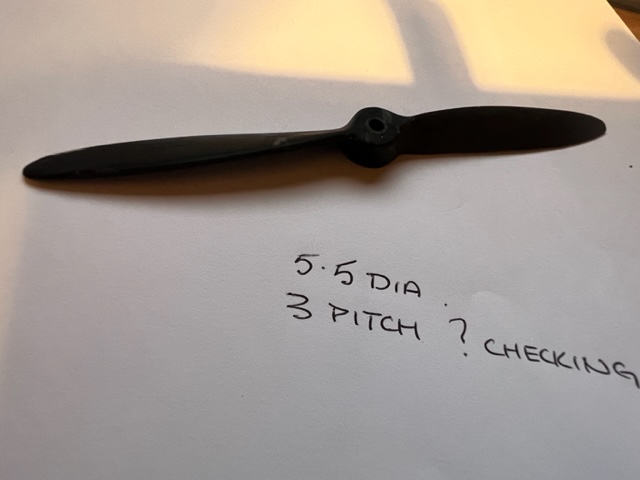

Received my engine today , very pleased as it is in excellent unrun condition as seller advised , and includes a very nice 5.5 nch diam carbon prop that looks around 3inch pitch ( im going to check this later this evening) . comparing to my standard engines the differences are

1) kirn kraft fine thread needle valve assembly fitted

2) allen screw propscrew

3) the venturi intake looks to have been played with , throat diam 3.6mm into crankcase with no gauze filter fitted and intake appears to be cleaned and smooth out

4) pressure nipple fitted into backplate

cant see any difference in exhaust port height when compared with my other engines and no packing washers between cyclinder and crankcase . My only other observation would be that the engine feels very free . Can you advise how i can attach pictures so that i can share with you please - you may be able to spot additional differences . Delighted with my purchase ,,,,

1) kirn kraft fine thread needle valve assembly fitted

2) allen screw propscrew

3) the venturi intake looks to have been played with , throat diam 3.6mm into crankcase with no gauze filter fitted and intake appears to be cleaned and smooth out

4) pressure nipple fitted into backplate

cant see any difference in exhaust port height when compared with my other engines and no packing washers between cyclinder and crankcase . My only other observation would be that the engine feels very free . Can you advise how i can attach pictures so that i can share with you please - you may be able to spot additional differences . Delighted with my purchase ,,,,

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Re: Cox works tuned engines

Re: Cox works tuned engines

Seems you've posted long enough to have photo upload privileges. (Admin set the photo privilege after a few days of becoming a member, to stop potential spammers.)flytilidie wrote:Can you advise how i can attach pictures so that i can share with you please - you may be able to spot additional differences.

In the post composing screen, there is a photo upload icon. The dialogue is not hard to do, but a little different than other forum editing ways. I'm not at my PC currently so mobile cell app is different. Somewhere in the forums is a thread on how to do. You might want to go to the main menu and is probably in the appropriate helps forum and as a sticky (thread fixed at top of list.)

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Cox works tuned engines

Re: Cox works tuned engines

Looks like i have access to photo posting - so here are photos of the engine i purchased and also a rather nice custom made prop ,, i am going to send another post shortly which includes photos of 3 different plug asssembys that i have also purchase along with notes on shimming ports and relevant thickness gaskets to shim liner ..

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Re: Cox works tuned engines

Re: Cox works tuned engines

I also purchased a accessory pack that came with the engine when it was originally purchase , this set comprises set of 3 different types of plugs (16 in all ) - spare liner ( - looks like ports have been machined on the bottom face to adjust height from base of cylinder -) and sets of instructions with various shims of different thickness on how to ensure port timing is set at optimum . Really pleased with purchase and this only seems to add more proof that this engine did come from some organisation that specialised in supplying performance Tee Dees . There is one other engine still left for me to purchase but this one includes a feed into the top of the carb intake probably for free flight flood off function. Does any of this shed light on the origins of where my motor cam from ?? .. Cant include pictures of Cox high comp head as i exceed file upload capacity so will include the rest ,, Does any of this confirm source of my motor ,,, thanks

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Cox works tuned engines

Re: Cox works tuned engines

It's a schnuerle cylinder. I think it was a KK special.

I was watching an ebay listing last week for a TD.049 which ended over 260USD. It wasn't until after that I noticed it was one of these engines.

I was watching an ebay listing last week for a TD.049 which ended over 260USD. It wasn't until after that I noticed it was one of these engines.

gkamysz- Gold Member

- Posts : 417

Join date : 2018-02-22

Location : Chicagoland

Re: Cox works tuned engines

Re: Cox works tuned engines

Hi , my engine does have 2 exhaust ports - to my knowledge the only engine that Cox manufactured with one exhaust port was the version 3 tee dee15 , had a gold anodising on crankcase .. .. Visually my engine is a standard TD 051 apart from the fine thread needle valve .... thanks

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Cox works tuned engines

Cox works tuned engines

Hello there,

NO, the Cox factory(s) never commercially offered what is know as a works (factory modified) engine. When your production run is 12,000 at a time, using high volume screw cutting machines, there was nobody really to do this. The best one could do was visit with Dale Kirn at the factory or a contest & he would love to chat with you about getting high performance from Cox engines. Dale also wrote an engine column in model Builder magazine for a few years, which contained great information.

THAT BEING SAID: There were 2 main individuals who produced either custom modifications or custom parts. I think Dale Kirn was the first with his company Known as Kirn Kraft (K/K). Dale offered custom parts (such as a fine thread needle valve assembly, and left hand crankshafts & props for TD's) and the most excellent kits such as " The Torky " for 1/2A profile proto speed. After building one of these high quality kits, I can tell you absolutely Dale made no money off of them, for all the work involved.

A bit later Joe Klause ran Kustom Kraftsmanship (also K/K) also out of California. in addition to producing custom parts (needle valve assemblies, milled TeeDee glow heads for high compression, pressure check valve fitted TeeDee backplates, custom cylinder shims etc.). Joe also offered both Cox reed Mouse Race & Free Flight TeeDee .049/.051 custom engines. One of the TeeDee versions could be ordered with a special single exhaust schnerle ported cylinder. So, I would say that Joe Klause offered the very closest to a " works tuned " engine although he never worked for Cox. Joe was quite a popular engine tuner among the high performance Cox crowd. Joe also offered custom fiberglass props for 1/2 A & other classes, as well as a Mouse Race Kit. Joe wrote the engine column for many years in Model Builder Magazine & explained a great deal about high performance engines.

In the USA there were a few others who offered high performance Cox .049 engines and parts.

George M. Aldrich from Texas sold some customized Cox .049's but soon gave up as the time required was far too much & the results (after all that work) were sporadic.

Gene Hempel (also from Texas) offered a custom cylinder and crankshaft chroming service & also made some custom Cox cylinders that he milled ports in from factory blank cylinders.

I think those people (all from the USA) were the main players in high performance Cox engines. There of course were a few others like noted engine tuner Bob Oge out of Chicago & Curt Stevens out of California who offered Roger Theobald modified engines for a little while.

The tuning often involved raising the TeeDee cylinder's lefthand port groove ~.015" on each side. Some opened the crank timing on the closing side to 200-210 degrees give or take... the TD venturi was opened from .117 to .140-.150" + the screen was removed. But the REAL performance came from a custom hand fitted piston to cylinder fit. Fit tolerance is 50 - 100 millionths of an inch, and is critical. If this fit was off then all the other mods were for naught. The engine would often still run just fine but not particularly fast!

The reed valve engines had the above cylinder work but also had a custom bronze bushing fitted in the crankcase, and the venturi was opened up from .080" to up to .093" ID.

Today however, most of these wonderful people have passed away and there is hardly anybody left that offers custom Cox performance work.

So if you happen on one of these engines, consider it a true rarity.

Cheers,

Paul Gibeault

NO, the Cox factory(s) never commercially offered what is know as a works (factory modified) engine. When your production run is 12,000 at a time, using high volume screw cutting machines, there was nobody really to do this. The best one could do was visit with Dale Kirn at the factory or a contest & he would love to chat with you about getting high performance from Cox engines. Dale also wrote an engine column in model Builder magazine for a few years, which contained great information.

THAT BEING SAID: There were 2 main individuals who produced either custom modifications or custom parts. I think Dale Kirn was the first with his company Known as Kirn Kraft (K/K). Dale offered custom parts (such as a fine thread needle valve assembly, and left hand crankshafts & props for TD's) and the most excellent kits such as " The Torky " for 1/2A profile proto speed. After building one of these high quality kits, I can tell you absolutely Dale made no money off of them, for all the work involved.

A bit later Joe Klause ran Kustom Kraftsmanship (also K/K) also out of California. in addition to producing custom parts (needle valve assemblies, milled TeeDee glow heads for high compression, pressure check valve fitted TeeDee backplates, custom cylinder shims etc.). Joe also offered both Cox reed Mouse Race & Free Flight TeeDee .049/.051 custom engines. One of the TeeDee versions could be ordered with a special single exhaust schnerle ported cylinder. So, I would say that Joe Klause offered the very closest to a " works tuned " engine although he never worked for Cox. Joe was quite a popular engine tuner among the high performance Cox crowd. Joe also offered custom fiberglass props for 1/2 A & other classes, as well as a Mouse Race Kit. Joe wrote the engine column for many years in Model Builder Magazine & explained a great deal about high performance engines.

In the USA there were a few others who offered high performance Cox .049 engines and parts.

George M. Aldrich from Texas sold some customized Cox .049's but soon gave up as the time required was far too much & the results (after all that work) were sporadic.

Gene Hempel (also from Texas) offered a custom cylinder and crankshaft chroming service & also made some custom Cox cylinders that he milled ports in from factory blank cylinders.

I think those people (all from the USA) were the main players in high performance Cox engines. There of course were a few others like noted engine tuner Bob Oge out of Chicago & Curt Stevens out of California who offered Roger Theobald modified engines for a little while.

The tuning often involved raising the TeeDee cylinder's lefthand port groove ~.015" on each side. Some opened the crank timing on the closing side to 200-210 degrees give or take... the TD venturi was opened from .117 to .140-.150" + the screen was removed. But the REAL performance came from a custom hand fitted piston to cylinder fit. Fit tolerance is 50 - 100 millionths of an inch, and is critical. If this fit was off then all the other mods were for naught. The engine would often still run just fine but not particularly fast!

The reed valve engines had the above cylinder work but also had a custom bronze bushing fitted in the crankcase, and the venturi was opened up from .080" to up to .093" ID.

Today however, most of these wonderful people have passed away and there is hardly anybody left that offers custom Cox performance work.

So if you happen on one of these engines, consider it a true rarity.

Cheers,

Paul Gibeault

flytilidie wrote:Is anyone aware if Cox sold works tuned engines , and if they did what the tuning work completed involved.I have been offered a works tuned engine (which i intend to buy ) but i have no recollection of Cox ever offering such a service. Apparently the engine was bought directly from Cox by the current owner many years ago as a works tuned version ,,, any ideas -- thanks

Last edited by Paulgibeault on Wed Mar 15, 2023 8:23 pm; edited 2 times in total (Reason for editing : photos added)

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Cox works tuned engines

Re: Cox works tuned engines

Paul , thank you so much for imparting this detailed information , and i think now that i am in possession of a real Kustom Kraftmanship TD 051 . I have run TDs from the early 70s in many classes but the feel of my latest engine is without doubt different to that i have ever had before. I would also make the observation that the piston finish is different to all my other engines - visibly . So from your explanation i can advise -

1) Both the engine i have purchased and its sister which i am about to purchase were bought at the same time from the same supplier - way back in time

2) Both engines are fitted with identical pressure nipples fitted into the backplate

3) Both have custom needle valve fitted fine thread

4) The carbon prop was custom made at the same time as engine purchase

5) The second engine has a flood off fitted to venturi

6) neither engine has the gauze fitted into the venturi

7) The venturi on my engine appears to have been reshaped and opened in throat diameter . I can check this when i receive the second engine

the shimming notes i have are the same as those posted by sosam117 earlier in this thread only they have the Kustom Kraftmanship header on the sheet .

the shimming notes i have are the same as those posted by sosam117 earlier in this thread only they have the Kustom Kraftmanship header on the sheet .

9) There is also a custom made backplate which include provision for mounting screws straight onto a bulkhead - maybe this is also one of Joes options for Free Flight

So to many similarities with your notes - i will do some checks on position of port groove . Interestingly i have also been given in the tuning package bought with the engine a new spare cyclinder liner which is strange as i would have thought piston and liners would have been matched - perhaps the porting timing is different ( ill check this ) . I wonder Paul , did Joe ever advise any specific running in procedures for his engines . Also can you recall his preferred fuel mix ?? for max performance . I bought Model Builder by subscription back in the 70-80s so il check to see if i have copies of Joes notes . I would advise the previous owner of these engines was a free flight power man - hence the mod to flood of on the second engine . In you notes you also make note of a gentlemen called Bob Oge who has also given me help in the past . I purchased on ebay a Cox TD15 version 2 ( thicker liner ) however it came with poor compression . I contacted Bob who kindly offered to look at the engine for me - when it was returned it had a rebored and chromed liner plus matching piston - the front crankcase was rebored and chromed in fact it was in Bobs words a complete chrome setup , beautiful piece of workmanship . However once again many thanks for responding to my plea for help ,, greatly appreciated .....

1) Both the engine i have purchased and its sister which i am about to purchase were bought at the same time from the same supplier - way back in time

2) Both engines are fitted with identical pressure nipples fitted into the backplate

3) Both have custom needle valve fitted fine thread

4) The carbon prop was custom made at the same time as engine purchase

5) The second engine has a flood off fitted to venturi

6) neither engine has the gauze fitted into the venturi

7) The venturi on my engine appears to have been reshaped and opened in throat diameter . I can check this when i receive the second engine

9) There is also a custom made backplate which include provision for mounting screws straight onto a bulkhead - maybe this is also one of Joes options for Free Flight

So to many similarities with your notes - i will do some checks on position of port groove . Interestingly i have also been given in the tuning package bought with the engine a new spare cyclinder liner which is strange as i would have thought piston and liners would have been matched - perhaps the porting timing is different ( ill check this ) . I wonder Paul , did Joe ever advise any specific running in procedures for his engines . Also can you recall his preferred fuel mix ?? for max performance . I bought Model Builder by subscription back in the 70-80s so il check to see if i have copies of Joes notes . I would advise the previous owner of these engines was a free flight power man - hence the mod to flood of on the second engine . In you notes you also make note of a gentlemen called Bob Oge who has also given me help in the past . I purchased on ebay a Cox TD15 version 2 ( thicker liner ) however it came with poor compression . I contacted Bob who kindly offered to look at the engine for me - when it was returned it had a rebored and chromed liner plus matching piston - the front crankcase was rebored and chromed in fact it was in Bobs words a complete chrome setup , beautiful piece of workmanship . However once again many thanks for responding to my plea for help ,, greatly appreciated .....

flytilidie- Moderate Poster

- Posts : 10

Join date : 2022-02-13

Cox works tuned engines

Cox works tuned engines

To answer your questions further.

Joe Klause's Tee Dee pressure venturi diameter spec. was between .140"- .150" ID. (I went further up to .165" ID & found no further improvement from .150"ID.)

Joe used a proper tapered reamer to enlarge his venturi holes, rather than just using a regular drill bit.

Indeed a spare cylinder without a matched piston is strange. The best cylinder in the world is useless without a piston matched to it.

Fuels: Dec. 1978 Model Builder mag, in Joe Klaus's FUEL LINES column p. 61 Joe offers three fuel mixes. ** NOTE: Klotz KL-100 is 80% synthetic and 20% Benol (Castor)

This means in reality these fuels only have 5% castor oil & 15% all synthetic oil. Note** This differs from Dale Kirn who wrote he prefers a minimum of 10% castor oil in his fuels. My takeaway is that except for all out competition, Dale's fuel is easier to set the needle with and a bit safer fuel for protection against over lean runs.

Sport: 15% Nitro 20% Klotz, 65% methanol

Racing 40% Nitro 20% Klotz 40% methanol

Speed 65% Nitro 20% Klotz 15% propylene oxide. ** This also

Klause Break-in procedure: This required a bunch of research back into my Model Builder Klause FUEL LINES files:

BRIEFLY: Joe recommends starting out with a small 5"D X 3"P prop. Start with 15% nitro fuel & 3 head shims. First several minutes, run it slightly rich. Next run it rich & peak it for ~ 10 seconds every minute. Don't yet run the engine extra lean other than momentarily. Repeat this for the next 15- 30 minutes OR UNTIL THE THE ENGINE RUNS SMOOTHLY & STEADILY WITHOUT ANY SAGGING OR RPM LOSS. At this point you can up the nitro content if you wish and also start lowering the head by removing shims. Lastly, check for carbon /varnish build-up & if necessary remove from cylinder with 000 plain steel wool wrapped around a wooden dowel with solvent & clean THOROUGHLY afterwards.

Dale Kirn's fastest record setting speed formula was 60% nitro / 15% Klotz / 23% Prop. oxide and 2% Lubricin. Similar, but tweaked a bit.

Dale's break-in process was to cut down a prop so that it could turn up to 24,000 RPM RICH. (I used a Cox 5 X 3 cut down to 4-1/2 diameter.)

Then with your intended fuel, run it up to 2 dozen tanks cycling the RPM to peak & then back rich. The idea being to run-in your engine at the RPM you intend to fly it at in the air. Because the small prop allows you to hit 24K while still RICH, you're not going to damage the engine. You will however get the piston to bed in at the RPM regime you want. Dale mentioned the factory tried very hard once to reproduce the fit of an exceptionally well running engine. It turned out to be a big failure. The final & BEST FIT can only be achieved through running.

Both men harp on keeping the engine scrupulously clean at all times, saying traces of dirt will cause rapid performance drops.

I hope that helps you out. It's best to run such an engine in a model, because once you're gone a casual looker will just as soon toss it in the dumpster when cleaning up! Joe preferred his engines were FLOWN AND ENJOYED and not collected...

Cheers,

Paul

p.s. Who am I talking to & where do you live?

Photo is My wife Dianne & I after setting the Portuguese Team Flying Event (European record) at The Tournament of the Millennium in Santarem, Portugal.

Joe Klause's Tee Dee pressure venturi diameter spec. was between .140"- .150" ID. (I went further up to .165" ID & found no further improvement from .150"ID.)

Joe used a proper tapered reamer to enlarge his venturi holes, rather than just using a regular drill bit.

Indeed a spare cylinder without a matched piston is strange. The best cylinder in the world is useless without a piston matched to it.

Fuels: Dec. 1978 Model Builder mag, in Joe Klaus's FUEL LINES column p. 61 Joe offers three fuel mixes. ** NOTE: Klotz KL-100 is 80% synthetic and 20% Benol (Castor)

This means in reality these fuels only have 5% castor oil & 15% all synthetic oil. Note** This differs from Dale Kirn who wrote he prefers a minimum of 10% castor oil in his fuels. My takeaway is that except for all out competition, Dale's fuel is easier to set the needle with and a bit safer fuel for protection against over lean runs.

Sport: 15% Nitro 20% Klotz, 65% methanol

Racing 40% Nitro 20% Klotz 40% methanol

Speed 65% Nitro 20% Klotz 15% propylene oxide. ** This also

Klause Break-in procedure: This required a bunch of research back into my Model Builder Klause FUEL LINES files:

BRIEFLY: Joe recommends starting out with a small 5"D X 3"P prop. Start with 15% nitro fuel & 3 head shims. First several minutes, run it slightly rich. Next run it rich & peak it for ~ 10 seconds every minute. Don't yet run the engine extra lean other than momentarily. Repeat this for the next 15- 30 minutes OR UNTIL THE THE ENGINE RUNS SMOOTHLY & STEADILY WITHOUT ANY SAGGING OR RPM LOSS. At this point you can up the nitro content if you wish and also start lowering the head by removing shims. Lastly, check for carbon /varnish build-up & if necessary remove from cylinder with 000 plain steel wool wrapped around a wooden dowel with solvent & clean THOROUGHLY afterwards.

Dale Kirn's fastest record setting speed formula was 60% nitro / 15% Klotz / 23% Prop. oxide and 2% Lubricin. Similar, but tweaked a bit.

Dale's break-in process was to cut down a prop so that it could turn up to 24,000 RPM RICH. (I used a Cox 5 X 3 cut down to 4-1/2 diameter.)

Then with your intended fuel, run it up to 2 dozen tanks cycling the RPM to peak & then back rich. The idea being to run-in your engine at the RPM you intend to fly it at in the air. Because the small prop allows you to hit 24K while still RICH, you're not going to damage the engine. You will however get the piston to bed in at the RPM regime you want. Dale mentioned the factory tried very hard once to reproduce the fit of an exceptionally well running engine. It turned out to be a big failure. The final & BEST FIT can only be achieved through running.

Both men harp on keeping the engine scrupulously clean at all times, saying traces of dirt will cause rapid performance drops.

I hope that helps you out. It's best to run such an engine in a model, because once you're gone a casual looker will just as soon toss it in the dumpster when cleaning up! Joe preferred his engines were FLOWN AND ENJOYED and not collected...

Cheers,

Paul

p.s. Who am I talking to & where do you live?

Photo is My wife Dianne & I after setting the Portuguese Team Flying Event (European record) at The Tournament of the Millennium in Santarem, Portugal.

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Cox works tuned engines

Re: Cox works tuned engines

Hi Paul,

I like learning. Thanks.

The local hobbyshop was within an easy bikeride for us. It was the 70s.

There were three U shaped schools that had asphalt, that were cool to fly from.

Flew 'Mouse Racers' from plans we got from magazines of the day.

Our goal was to get two in the air. Got three one time... BabyBees...

The 'echo' effect noise was very cool, got kicked out, moved to the next school.

Just part of our 'summer'.

Before the Beatles got here.

And if there was an adult near us?

They told us to have fun.

Those were the days,

Respect,

Dave

I like learning. Thanks.

The local hobbyshop was within an easy bikeride for us. It was the 70s.

There were three U shaped schools that had asphalt, that were cool to fly from.

Flew 'Mouse Racers' from plans we got from magazines of the day.

Our goal was to get two in the air. Got three one time... BabyBees...

The 'echo' effect noise was very cool, got kicked out, moved to the next school.

Just part of our 'summer'.

Before the Beatles got here.

And if there was an adult near us?

They told us to have fun.

Those were the days,

Respect,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: Cox works tuned engines

Re: Cox works tuned engines

The engine in the photo is a Cox .049 with only "one" single port.

The engine is sitting in front of its original box and the paper the engine is sitting on is the instructions for shimming the cylinder with the included shim kit and instructions for breaking in the engine.

To this day I have not run that "special" engine and this engine hasn't been out of its box until this photo was taken.

Special ordered and purchased it from "Kustom Kraftsmanship" back in 1991 from Joe Klause.

While there I spent a lot of cash purchasing needle valve assemblies, shim kits, and some engines.

I have two banker boxes full of Kustom Kraftsmanship engines that I have purchased over the years.

Almost all of the engines have never been run.

Kustom Kraftsmanship had a guarantee that their engines will start "when the instructions were followed" with no problems.

If so, return the engine back to them. If nothing was found wrong -- no charge. But if there was, they would call you and tell you how much the cost would be.

1st box of Kustom Kraftsmanship engines:

2nd box of Kustom Kraftsmanship engines:

Kustom Kraftsmanship engine in box as ordered:

Also, at his booth I signed up to receive his "catalog" for all of the products Joe Klause was producing for Cox engines.

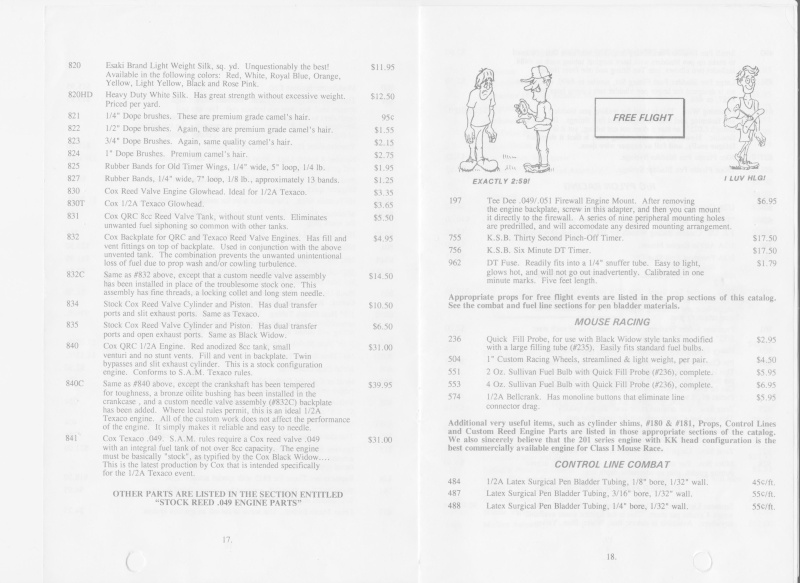

Here is the last catalog I received from Kustom Kraftsmanship.

Bad thing trying to copy the catalog, it a printed out on "light blue" paper so you really can't get a nice crisp scan?

This is the best I could get of it after scanning. I think Joe did this on purpose so his catalogs couldn't be copied?

Last edited by sosam117 on Fri Mar 17, 2023 2:13 pm; edited 2 times in total (Reason for editing : miss spellings)

sosam117- Diamond Member

- Posts : 1351

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Cox works tuned engines

Re: Cox works tuned engines

This is most definitely the .049. There proportions of the fine thread needle and head fit the .049 engine.

gkamysz- Gold Member

- Posts : 417

Join date : 2018-02-22

Location : Chicagoland

Re: Cox works tuned engines

Re: Cox works tuned engines

Hi All,

I have two 70s era TD.049s that are broken in. (for a twin)

I would love to know the extra rpms/hp you get from fancy Cox.049 setups.

But,

I am having fun with single port Cox.049s.

75% of the ultimate power? No big deal.

Fire it up, go flying,

Take care,

Have fun,

Dave

I have two 70s era TD.049s that are broken in. (for a twin)

I would love to know the extra rpms/hp you get from fancy Cox.049 setups.

But,

I am having fun with single port Cox.049s.

75% of the ultimate power? No big deal.

Fire it up, go flying,

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

did you check the ball joint?

did you check the ball joint?

Am no specialist but have found that resetting the ball joint improved performance.

Shimming the cylinder appears to be a easy and reversible thing to try.

How much you gain... no idea

Shimming the cylinder appears to be a easy and reversible thing to try.

How much you gain... no idea

cmulder- Gold Member

- Posts : 279

Join date : 2022-02-10

Cox works tuned engines

Cox works tuned engines

Hi Dave, that's a tough question to answer with any certainty.

Personally I prefer to run my TeeDee's at 20,000 RPM minimum. This is not too difficult to achieve with a Cox balanced 5 X 3 prop and Sig 35% nitro fuel. Correctly fitted & running on pressure, the RPM can go up to 22,000. So that's ~ 2,000 RPM give or take. With lighter load props RPM can climb to ~24,000 give or take. With 65% nitro & propylene oxide easily another +1,000 RPM.

I would guess shimming can give +500 - 1,000 RPM depending on where the shims are placed and how many.

If your engine spec's are in the ball park to start with, shimming doesn't do all that much. If your spec's are

way out of whack, then proper shimming can certainly add some RPM.

The piston to cylinder & crankshaft to crankcase fits are so critical, 1,000's of RPM can come & go making all these

engines "individuals". Many tuners are puzzled when a certain mod works well in one engine but not in a seemingly

identical engine. For example the Doug Galbraith performance head fitted with a Nelson plug can add up to 1,000 RPM,

but can also cause another engine to lose 500 RPM. So experienced fliers will often say " Such & such mod works for me,

but I don't know if it'll necessarily work for you." And they won't be lying!

AND YES, both Dale Kirn, Joe Klause & most everybody else are in complete agreement for the owner to keep his engine's ball-socket joint tight

(~.002") in order to have reasonable engine longetivity. On 65% nitro + Prop oxide, I have found my engine life is about 15 minutes between ball-socket resets, or the rod & piston will fail (often taking out the cylinder with it).

I don't know of anybody who knows the actual HP. Please note all my RPM figures are on the test bench. One can realisticly add several more thousand RPM when the motor is unloaded in the air. How much, I've never been able to measure...

Cheers,

Paul

Personally I prefer to run my TeeDee's at 20,000 RPM minimum. This is not too difficult to achieve with a Cox balanced 5 X 3 prop and Sig 35% nitro fuel. Correctly fitted & running on pressure, the RPM can go up to 22,000. So that's ~ 2,000 RPM give or take. With lighter load props RPM can climb to ~24,000 give or take. With 65% nitro & propylene oxide easily another +1,000 RPM.

I would guess shimming can give +500 - 1,000 RPM depending on where the shims are placed and how many.

If your engine spec's are in the ball park to start with, shimming doesn't do all that much. If your spec's are

way out of whack, then proper shimming can certainly add some RPM.

The piston to cylinder & crankshaft to crankcase fits are so critical, 1,000's of RPM can come & go making all these

engines "individuals". Many tuners are puzzled when a certain mod works well in one engine but not in a seemingly

identical engine. For example the Doug Galbraith performance head fitted with a Nelson plug can add up to 1,000 RPM,

but can also cause another engine to lose 500 RPM. So experienced fliers will often say " Such & such mod works for me,

but I don't know if it'll necessarily work for you." And they won't be lying!

AND YES, both Dale Kirn, Joe Klause & most everybody else are in complete agreement for the owner to keep his engine's ball-socket joint tight

(~.002") in order to have reasonable engine longetivity. On 65% nitro + Prop oxide, I have found my engine life is about 15 minutes between ball-socket resets, or the rod & piston will fail (often taking out the cylinder with it).

I don't know of anybody who knows the actual HP. Please note all my RPM figures are on the test bench. One can realisticly add several more thousand RPM when the motor is unloaded in the air. How much, I've never been able to measure...

Cheers,

Paul

HalfaDave wrote:Hi All,

I have two 70s era TD.049s that are broken in. (for a twin)

I would love to know the extra rpms/hp you get from fancy Cox.049 setups.

Dave

Last edited by Paulgibeault on Sat Mar 18, 2023 10:56 am; edited 2 times in total (Reason for editing : more info added)

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Cox works tuned engines

Re: Cox works tuned engines

Hi Paul,

Thanks for the reply.

I was thinking back to the summers we did the Mouse racing. (scale-ish Goodyear type planes)

It was just a fun thing to do. (twice the noise and fun with two planes up )

)

No one kept score.

Combat was just an excuse to tie a streamer on, and avoid crashing.

So,

Call 25K an ultimate Cox.049 run.

A Cox.049 not running = 0.

Therefore, 12.5K is an average run...

My single ports can easily do north of that.

I just like firing up Cox engines,

Setting the needle,

And trying to run the tank dry...

Take care,

Have fun,

Dave

Thanks for the reply.

I was thinking back to the summers we did the Mouse racing. (scale-ish Goodyear type planes)

It was just a fun thing to do. (twice the noise and fun with two planes up

No one kept score.

Combat was just an excuse to tie a streamer on, and avoid crashing.

So,

Call 25K an ultimate Cox.049 run.

A Cox.049 not running = 0.

Therefore, 12.5K is an average run...

My single ports can easily do north of that.

I just like firing up Cox engines,

Setting the needle,

And trying to run the tank dry...

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Stock muffler+ tuned pipe on a TD09..any chance this combo works?

» Tuned Cox Tee Dee09

» PAW 15 TBR Combat tuned

» Tee Dee .049/.051 tuned pipe?

» PAW 19 Combat Tuned CT3

» Tuned Cox Tee Dee09

» PAW 15 TBR Combat tuned

» Tee Dee .049/.051 tuned pipe?

» PAW 19 Combat Tuned CT3

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules