Log in

Search

Latest topics

» A Little 400 Mile Hop for Some Memory Lane Stuff, and to Hit a Swap Meet.by rsv1cox Today at 10:23 am

» Promote the forum with flyers!

by roddie Today at 9:27 am

» My N-1R build log

by roddie Today at 9:19 am

» Engine choice

by 1975 control line guy Today at 8:29 am

» Roger Harris revisited

by rsv1cox Today at 7:45 am

» Night flying at Walters RC park

by 1975 control line guy Yesterday at 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Yesterday at 7:10 pm

» Cox films/videos...

by GallopingGhostler Yesterday at 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Yesterday at 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Yesterday at 5:08 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 10:34 am

Cox Engine of The Month

Repairing a crack in a hard nylon part

Page 1 of 2

Page 1 of 2 • 1, 2

Repairing a crack in a hard nylon part

Repairing a crack in a hard nylon part

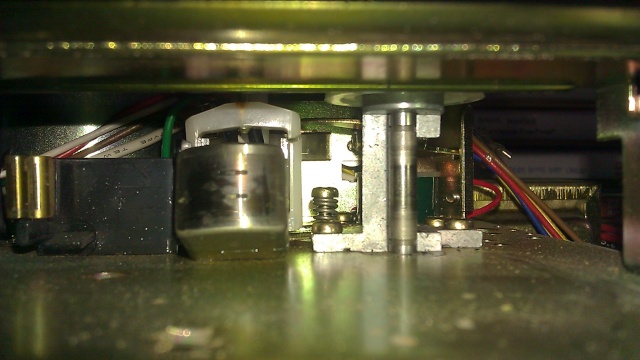

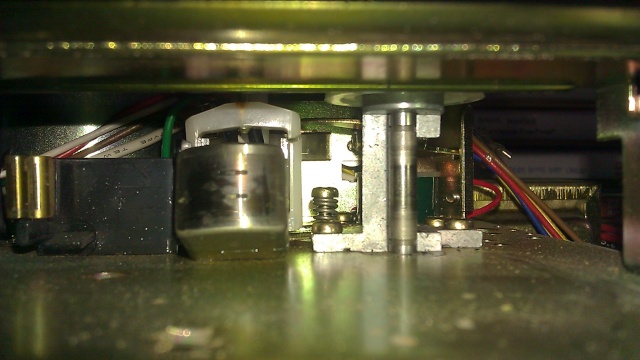

Well, today if discovered a dreaded issue in one of my 8-track players. This is a mid 70s Soundesign 8-track/stereo receiver that I bought from a thrift store a few weeks back, but because of family medical emergencies, it hasn't been touched until today. The tuner works fine, but when I popped in a tape the sound started to get softer and softer and shifting out of alignment. I pulled out the tape to see that the head has been pushed back and that it was caused by a crack in the head mount. After ripping the player apart, I took a closer look and confirmed that the part is indeed nylon. Yes I know that nylon is known to be almost impossible to glue but I know there has to be ways. I tried my CA glue anyway which just flaked right off shortly after setting. Instead of trying a bunch of different glues and ways just to have them possibly fail, I thought I would look up ideas and ask if any of you guys know of any good methods. I have thought about doing something like plastic brazing, but this would be only if no glue will do. Whichever way I use to repair the crack in the head mount, the repair has to be able to withstand the quick action movement of the head switching programs. The repair also has to be able to withstand the pressure of holding the head tightly in the mount using the screw on the top. The part is complex so making a new one wouldn't be the easiest. I only paid $7 for the 8-track/receiver so I'm not entirely bummed LOL...I really should stay out of those thrift stores

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Can you drill a couple of tiny holes in it and splint it with a strip of aluminum, or 1/16" ply or stainless steel wire? I was about to suggest plastic welding until you mentioned you'd thought already of that .

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

.

Last edited by Mudhen on Mon Nov 15, 2021 9:05 am; edited 1 time in total

Mudhen- Gold Member

- Posts : 489

Join date : 2011-09-19

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

RknRusty wrote:Can you drill a couple of tiny holes in it and splint it with a strip of aluminum, or 1/16" ply or stainless steel wire? I was about to suggest plastic welding until you mentioned you'd thought already of that .

That's an idea. I'll have to look into that.

LOL, I currently have a little bit of JB Weld on it with a little weight pressing the crack together just because its going to be sitting overnight. If it holds, it holds, if it doesn't then I guess I'll have to try something else. LOL

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Mudhen wrote:I've had weird stuff to fix as well.

I called 3M. You can try them here: 1-800-234-8068

Web Page: Here

Hope it helps.

As a last resort, you might try the manufacturer. They may have the part available...even if it is old.

LOL, I could drive over to 3M. I did find the exact part I needed... http://www.surplusshed.com/pages/item/r3074.html but I slept too long to buy it. I was going to buy a few of these units awhile back just for spare parts or projects but I never got around to doing it. That unit is the exact unit that is in my player.

Usually it is hard to find parts for these old players, there were so many different players that had different designed parts. Parts are usually available for the most popular players but most of those parts were from players that people parted out.

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

The mention of plastic brazing brought back the memories of a toy I had as a kid and built lotsa stuff with.

Gentlemen, I give you a pic of the 1974 Mattel Spinwelder.

http://www.ebay.com/itm/1974-Mattel-SPINWELDER-toy-ad-page-9x12-/350567502018?pt=LH_DefaultDomain_0&hash=item519f7390c2

Little plastic welding rod that you set on the end of the gun tool to friction weld plastic kits together. Very doubtful that it would hold your nylon high stress head piece together.

Gentlemen, I give you a pic of the 1974 Mattel Spinwelder.

http://www.ebay.com/itm/1974-Mattel-SPINWELDER-toy-ad-page-9x12-/350567502018?pt=LH_DefaultDomain_0&hash=item519f7390c2

Little plastic welding rod that you set on the end of the gun tool to friction weld plastic kits together. Very doubtful that it would hold your nylon high stress head piece together.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Nylon is tough and nothing will stick to it.

Your only option is a mechanical splice.

My solution would be to drill a couple of tiny holes on either side of the break and blob some JB weld across the break and into the holes.

The JB Weld will not bite on the nylon unless it is roughed up and your part is too small to endure the grinding process.

Your only option is a mechanical splice.

My solution would be to drill a couple of tiny holes on either side of the break and blob some JB weld across the break and into the holes.

The JB Weld will not bite on the nylon unless it is roughed up and your part is too small to endure the grinding process.

lousyflyer- Gold Member

- Posts : 342

Join date : 2012-06-25

Age : 64

Location : Garden City Ga

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Yes, nylon lacks the porousity to absorb an adhesive to create a firm bond.

The above split idea has merit IMO.

But it really depends on how badly you want to revive an $8 thrift shop 8 track. Personally. I wouldn't bother.

The above split idea has merit IMO.

But it really depends on how badly you want to revive an $8 thrift shop 8 track. Personally. I wouldn't bother.

Last edited by SuperDave on Sun Oct 14, 2012 11:51 am; edited 1 time in total

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Back from the days when we and toy manufacturers both pointed our kids toward developing fun and useful skills.PV Pilot wrote:The mention of plastic brazing brought back the memories of a toy I had as a kid and built lotsa stuff with.

Gentlemen, I give you a pic of the 1974 Mattel Spinwelder.

http://www.ebay.com/itm/1974-Mattel-SPINWELDER-toy-ad-page-9x12-/350567502018?pt=LH_DefaultDomain_0&hash=item519f7390c2.

Good idea, the same effect as the splinting idea but simpler.lousyflyer wrote:My solution would be to drill a couple of tiny holes on either side of the break and blob some JB weld across the break and into the holes.

Dave, I don't think it's about the value, it's about the nostalgia and the challenge.SuperDave wrote:...But it really depends on how badly you want to revive an $8 thrift shop 8 track. Personally. I wouldn't bother.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

"And that" as Yoda would say, "is why you fail"

lousyflyer- Gold Member

- Posts : 342

Join date : 2012-06-25

Age : 64

Location : Garden City Ga

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Besides that, chicks dig 8 tracks.

lousyflyer- Gold Member

- Posts : 342

Join date : 2012-06-25

Age : 64

Location : Garden City Ga

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

lousy:

Yeah but the "chicks" are now in their late seventies.

Yeah but the "chicks" are now in their late seventies.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Rusty:

"Dave, I don't think it's about the value, it's about the nostalgia and the challenge."

Last time I tried something like that was on a AM/FM tape deck in my '65 Mustang convertible. I wound up with a pile of parts and a fevered mind.

Not wanting to crowd my "envelope" and further I pacified myself by purchasing a NEW unit. And so it is with ALL electronic devises today except if you are some sort of masochist and actuall y ENJOY punishing yourself.

"Dave, I don't think it's about the value, it's about the nostalgia and the challenge."

Last time I tried something like that was on a AM/FM tape deck in my '65 Mustang convertible. I wound up with a pile of parts and a fevered mind.

Not wanting to crowd my "envelope" and further I pacified myself by purchasing a NEW unit. And so it is with ALL electronic devises today except if you are some sort of masochist and actuall y ENJOY punishing yourself.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Why bother with vintage reed valve engines?

Because it's fun.

Because it's fun.

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Matt:

Because parts are available from our great vendors like Bernie at Cox International and Matt at EX Model Engines.

Parts for old eight-tracks aren't available to my knowledge but MAYBE....SOMEWHERE.. there's an undiscovered "stash". I'll stick with old Cox "reedies" thank you.

"Hope springs eternal." sayeth Alexander Pope

Because parts are available from our great vendors like Bernie at Cox International and Matt at EX Model Engines.

Parts for old eight-tracks aren't available to my knowledge but MAYBE....SOMEWHERE.. there's an undiscovered "stash". I'll stick with old Cox "reedies" thank you.

"Hope springs eternal." sayeth Alexander Pope

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

I see this turned into a "why bother fixing that worthless POS, 8 track is stupid" thread. This was supposed to be about repairing nylon parts, not directly about a busted 8 track head mount.

It doesn't really matter how much I paid for it or how much its worth. Its just another hobby. The reason I ask about repairing the crack is because I don't want to go find a replacement part or make the effort to recreate the part. Knowing that Soundesign is a "low end" brand and that the player itself looks to have had its day, I really don't want to put much into it until I know what it can already do. Now If this player was a Pioneer H-R100, I would put a lot more work into it.

The JB Weld on the head mount did take hold. Its been working so far, but we'll have to see how long it lasts. After I reinstalled and cleaned the head, I popped a tape in to hear how it sounds. While the left channel sounded alright, the right channel was almost dead. I tapped on the right and left head connections on the circuit board to make a little popping noise in the speakers just to ensure there was no electronic problem. I then took a little close look at the head to see the right channel pickup was still a little dirty. I removed the head completely from the player and used some Noxon 7 metal polish to shine the head up. I reinstalled the head and popped a tape in, it sounded much better with the right channel loud and clear again. After a little alignment adjusting, the player actually sounds good, better than some of my others. The JB Welded head mount put up with me installing, removing and then reinstalling the head as well as playing different tapes continuously for the last 3 hours. We'll see how long it lasts. Since I had some JB Weld mixed up, I thought I would put some on a busted nylon gear as a second test. The JB Weld didn't seem to want to come off and it took some force to break it loose from the nylon gear. It did come off but it wasn't like it just fell off.

It could use a little cleaning up and I see one of the dial lights are out but both the tape and radio sound good.

SuperDave wrote:

But it really depends on how badly you want to revive an $8 thrift shop 8 track. Personally. I wouldn't bother.

It doesn't really matter how much I paid for it or how much its worth. Its just another hobby. The reason I ask about repairing the crack is because I don't want to go find a replacement part or make the effort to recreate the part. Knowing that Soundesign is a "low end" brand and that the player itself looks to have had its day, I really don't want to put much into it until I know what it can already do. Now If this player was a Pioneer H-R100, I would put a lot more work into it.

The JB Weld on the head mount did take hold. Its been working so far, but we'll have to see how long it lasts. After I reinstalled and cleaned the head, I popped a tape in to hear how it sounds. While the left channel sounded alright, the right channel was almost dead. I tapped on the right and left head connections on the circuit board to make a little popping noise in the speakers just to ensure there was no electronic problem. I then took a little close look at the head to see the right channel pickup was still a little dirty. I removed the head completely from the player and used some Noxon 7 metal polish to shine the head up. I reinstalled the head and popped a tape in, it sounded much better with the right channel loud and clear again. After a little alignment adjusting, the player actually sounds good, better than some of my others. The JB Welded head mount put up with me installing, removing and then reinstalling the head as well as playing different tapes continuously for the last 3 hours. We'll see how long it lasts. Since I had some JB Weld mixed up, I thought I would put some on a busted nylon gear as a second test. The JB Weld didn't seem to want to come off and it took some force to break it loose from the nylon gear. It did come off but it wasn't like it just fell off.

It could use a little cleaning up and I see one of the dial lights are out but both the tape and radio sound good.

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

I have a neighbor/friend that has collected over 300 brass garden hose nozzles and I know another guy that collects old flashlights. Both have these "treasures" proudly displayed in their homes. Mind you no two items in these collections are the same.

"Different Strokes for Different Folks" - Sly and the Family Stone

"Different Strokes for Different Folks" - Sly and the Family Stone

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

I find that JB weld holds best when the mating parts are roughed up a bit with 120 grit sandpaper. For thin or small parts where you cannot use a lot of glue I will use thread to wrap around the part break to help hold it together. Large flat parts I will use fiberglass cloth or carbon fiber tape to help add strength.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

I used Lock-Tite CA for plastics to repair the door handel on a microwave oven. The handel lated longer than the oven.

jsesere- Rest In Peace

- Posts : 1606

Join date : 2010-09-05

Location : Salem Oregon

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Check these guys out.

Small family owned business with world class products,-

http://www.shop4glue.com/polyweld-58ml-thin-plastic-plas-weld-glue-adhesive-perspex-polystyrene-acrylic-abs-hips-fivestar-51-p.asp

If this doesn't do the trick they have a cyano type product that

Will bond even PTFE.

Small family owned business with world class products,-

http://www.shop4glue.com/polyweld-58ml-thin-plastic-plas-weld-glue-adhesive-perspex-polystyrene-acrylic-abs-hips-fivestar-51-p.asp

If this doesn't do the trick they have a cyano type product that

Will bond even PTFE.

John Goddard- Diamond Member

- Posts : 2447

Join date : 2011-11-24

Age : 60

Location : Leyton North East London

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

I was thinking something along the lines of Oaties PVC pipe primer and glue. I had used that stuff to fix a nylon looking drive wheel inside of a older Mitsubishi VCR player I had. It worked for years after that fix till the power source quit.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

John Goddard wrote:Check these guys out.

Small family owned business with world class products,-

http://www.shop4glue.com/polyweld-58ml-thin-plastic-plas-weld-glue-adhesive-perspex-polystyrene-acrylic-abs-hips-fivestar-51-p.asp

If this doesn't do the trick they have a cyano type product that

Will bond even PTFE.

Its unlikely the Polyweld will do it ive tried a few similar bits on old cassette players i use on my 1980s computers and they have been Delrin or Nylon that will not weld , the StarLoc Universal Repair Pack should as it bonds all plastics , the primer makes the plastic bond and the toughened adhesive is also modified to bond with plastics better also has additives to give a high sheer strength to the bond.

http://www.shop4glue.com/universal-glue-bond-adhesive-repair-pack-metal-all-plastics-ptfe-polyethylene-polypropylene-silicone-81-p.asp

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

The JB Weld is still holding! I have been using it a lot in the last few days and its still going strong!

Re: Repairing a crack in a hard nylon part

Re: Repairing a crack in a hard nylon part

Ka-chunk...(sound of 8 track)

lousyflyer- Gold Member

- Posts : 342

Join date : 2012-06-25

Age : 64

Location : Garden City Ga

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Repairing a Dell Laptop

» My Shoestring Stunter is RTF

» Repairing other Cox parts

» Pt19 Fledgling wing crack

» Spacebug-Style Crankshaft Repair

» My Shoestring Stunter is RTF

» Repairing other Cox parts

» Pt19 Fledgling wing crack

» Spacebug-Style Crankshaft Repair

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules