Log in

Search

Latest topics

» Landing-gear tipsby roddie Today at 6:17 pm

» Roger Harris revisited

by TD ABUSER Today at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Today at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 1:37 pm

» Happy 77th birthday Andrew!

by getback Today at 11:52 am

» My latest doodle...

by roddie Today at 10:43 am

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

“Aero Car” 3d printed, peewee powered plane build

Page 2 of 4

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

You can see the cf rod in the 3rd photo. The previous boom design tapers towards the back of the airplane, so with some work re-work I will be able to fit a larger diameter rod, if needed

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Hi Kyle, I think that the 3mm CF rod should be sufficient.. as long as you can "lock it in" to sockets that will secure it on each end; the fuselage-end in particular. There will be "twisting-loads" exerted on that rod.. which will test the integrity of its mounting points. Have you considered using a square CF rod?

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thanks roddie, I’ll definitely consider the square cf tubing. I was already trying to figure out a mounting method and that would make everything so much easier. Thank you for the suggestion friend

Tonight I am working on figuring out the issue with the 3d printer. Hopefully everything goes well, I am thinking of trying to print a model out with a new printer profile in the slicing software.

I am also struggling to model the correct airfoil profiles for the stabilizer and wings. Both have a tapered airfoil towards the tips. The method I was using is called “loft” which basically generates material to fit between two separate faces that you designate. Using this tool does get a close profile, but it gets weird after a certain point and creates profiles that will not work for the airplane.

Tonight I am working on figuring out the issue with the 3d printer. Hopefully everything goes well, I am thinking of trying to print a model out with a new printer profile in the slicing software.

I am also struggling to model the correct airfoil profiles for the stabilizer and wings. Both have a tapered airfoil towards the tips. The method I was using is called “loft” which basically generates material to fit between two separate faces that you designate. Using this tool does get a close profile, but it gets weird after a certain point and creates profiles that will not work for the airplane.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Okay, here is the new design to the tail boom. Total length is a little over 226mm, I have divided this into 4 sections, with a 1mm thick bottom at the base of each section allowing contact between each section and the carbon fiber rod. The current weight of all four sections, including cf rod (according to my cad program, and based off of pla as material) is 6.89g for the tail boom. The tail boom, minus cf rod weighs in at 3.47g, when I print the actual parts I will be using lw pla as mentioned on the last page so the weight should be roughly half of that

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

roddie wrote:Hi Kyle, I think that the 3mm CF rod should be sufficient.. as long as you can "lock it in" to sockets that will secure it on each end; the fuselage-end in particular. There will be "twisting-loads" exerted on that rod.. which will test the integrity of its mounting points. Have you considered using a square CF rod?

Indeed the carbon fiber rods and pipe are not withstanding torsion well, they may respond to torsion loads with fiber splitting, unless you let a few drops of CA glue flow along its internal surfaces. Drop the thin CA glue in on one end, and rotate the rod or pipe along its axis while the glue flows towards the other end. Repeat a few times. May use a bicycle spoke, pushing down the rod to improve glue dustribution. Allow glue to cure.

This process will prevent fiber splitting under torsional loads...done that on the tail boom of my COX TeeDee010 powered RC Lil SpeeDee plane, ending up with a 5mm carbon fiber boom of enhanced torsional strength...weight of CA glue added less than 1 gramm.

Last edited by balogh on Fri Aug 09, 2024 1:32 am; edited 1 time in total

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thank you for the tip, I wouldn’t have thought of that

The way I have the tail boom designed currently I should be able to glue the cad rod like you suggested, then insert each segment of the boom, glue and repeat.

On a side note, I uploaded a new printer profile in cura and I am currently doing some tuning, but I don’t seem to be experiencing the issues I had before. So we should be back in business now.

I’m currently saving some money right now so I can purchase the electronics and hardware, the cf rod and thin ca will be among the first items ordered.

The way I have the tail boom designed currently I should be able to glue the cad rod like you suggested, then insert each segment of the boom, glue and repeat.

On a side note, I uploaded a new printer profile in cura and I am currently doing some tuning, but I don’t seem to be experiencing the issues I had before. So we should be back in business now.

I’m currently saving some money right now so I can purchase the electronics and hardware, the cf rod and thin ca will be among the first items ordered.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Would you suggest going up to 5mm square? I think the 3mm will be fine personally, I’m not looking to fly a stunt plane lol, just a lazy flier lol but on a side note. Some extra strength is always nice

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

KyleRManeti95 wrote:Would you suggest going up to 5mm square? I think the 3mm will be fine personally, I’m not looking to fly a stunt plane lol, just a lazy flier lol but on a side note. Some extra strength is always nice

My Lil SpeeDee has a 5mm carbon fibre pipe for a boom, and with the CA glue internal lining it is more than enough. My similar, prior boom suffered fiber splitting, now CA makes the replacement boom very strong.

3mm for me would have been too small for reliably fixing the tail section...however, purely strength-wise, a 3mm with CA lining would have also worked...I am not sure about the dimensions and proportions of your aerocar, though.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thank you for posting that image, your plane looks like it would be an absolute blast to fly, I think I’m going to order 3 & 5mm square tubing to do some testing on both versions of the boom. I definitely see what you are saying, the proportions of this airplane are very strange, hopefully it flies okay. I’m not sure how big I should make the control surfaces on the elevator and wings.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thanks...there may be some rules of thumb regarding control surface proportions, but with the adjustable servo throws such surface proportions can vary in a wide range and your plane will still fly with good control..

I built my Lil SpeeDee on the photo without any blueprint, just out of my head, and while I would build its successor with some modifications like smaller firewall to reduce drag, at the end it proved to fly very well and the ailerons and elevator control were adjusted by servo throw setting, no matter if the control surface proportion rules were exactly met or not..

I built my Lil SpeeDee on the photo without any blueprint, just out of my head, and while I would build its successor with some modifications like smaller firewall to reduce drag, at the end it proved to fly very well and the ailerons and elevator control were adjusted by servo throw setting, no matter if the control surface proportion rules were exactly met or not..

Last edited by balogh on Fri Aug 09, 2024 11:03 pm; edited 1 time in total

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Of course my friend  I see what you are saying about the proportion of control surfaces. I’ll do a little bit of research on them tonight but will largely compensate with the servo throw.

I see what you are saying about the proportion of control surfaces. I’ll do a little bit of research on them tonight but will largely compensate with the servo throw.

Props on your construction method on your plane, it’s been years since I’ve built anything up out of balsa, I miss it at times but I don’t really have the space right now for that method of construction to be viable for me personally. Do you have any videos of it flying? Also what servos and battery are you using?

Props on your construction method on your plane, it’s been years since I’ve built anything up out of balsa, I miss it at times but I don’t really have the space right now for that method of construction to be viable for me personally. Do you have any videos of it flying? Also what servos and battery are you using?

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Here is my post about the Lil SpeeDee build project, with the flight video on its page 3:

https://www.coxengineforum.com/t16888-spee-dee-010-a-new-build-project?highlight=Spee+dee

Or, you can skip the build post and watch it here:

My Sony headcam is a bit outdated and its resolution is weak.

For battery I use a single cell 400mAh LiPo battery.with a small step-up converter that brings the voltage from the nominal 3.7V of the LiPo to 5V.

I use Hitec nano servos or similar. For a COX010 TeeDee powerplant you need the lightest electronic components in a speed plane.

https://www.coxengineforum.com/t16888-spee-dee-010-a-new-build-project?highlight=Spee+dee

Or, you can skip the build post and watch it here:

My Sony headcam is a bit outdated and its resolution is weak.

For battery I use a single cell 400mAh LiPo battery.with a small step-up converter that brings the voltage from the nominal 3.7V of the LiPo to 5V.

I use Hitec nano servos or similar. For a COX010 TeeDee powerplant you need the lightest electronic components in a speed plane.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thank you for posting the link to your build log, you did a fantastic job man, I’ll be using some of the things you talked about in this build. Your plane also looks like a fun little flier, I’m thinking of going the balloon route for the tank in this airplane but I might still go for a 1/4oz tank from perfect or brodak.

I’ve gotten a little bit more done on the airplane tonight, I’ve finalized the mating surface where the printed boom cover and 3mm sq rod go into the fuselage. I’ve also added in some structural supports to help strengthen things up and make it a tab bit easier to print. Pictures to come tomorrow of the printed prototype.

I’ve gotten a little bit more done on the airplane tonight, I’ve finalized the mating surface where the printed boom cover and 3mm sq rod go into the fuselage. I’ve also added in some structural supports to help strengthen things up and make it a tab bit easier to print. Pictures to come tomorrow of the printed prototype.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

I can second the recommendation for a ballon tank Kyle…. I have two .020 R/C planes that use them and they provide solid runs from beginning to end..,.. The air is evacuated out after filling but the tank is not under pressure…. Only atmospheric from externally….. Works great on throttled engines as well…..

.

.

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thanks Rdw, you guys have convinced me lol, balloon tank it is

Here are a couple of photos of the prototype I printed out last night. Unfortunately the print failed part way through but it isn’t a total loss as there is enough there to allow me to change some things to make the rest of the airplane print correctly

Here are a couple of photos of the prototype I printed out last night. Unfortunately the print failed part way through but it isn’t a total loss as there is enough there to allow me to change some things to make the rest of the airplane print correctly

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

True industrial quality! Regarding dimensions, proportions etc., do you have some estimates on the expectable oz/ sq.ft wing load? I am not sure what the specific weight of the 3D print parent material is, but you may want to check the wing loading so that the plane should be able to generate sufficient lift. Sorry if I was asking something you have already thought of..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thank you buddy, it’s taken quite a few redesigns to get to this point. I have not thought about that yet. I am also currently unsure on the total complete weight of the airframe right now as there is still more structural changes I am making to the final design for the fuselage, wing and stabilizer.

I have not thought about that yet. I am also currently unsure on the total complete weight of the airframe right now as there is still more structural changes I am making to the final design for the fuselage, wing and stabilizer.

Currently I have finished printing version 1.6 of the rear portion of the fuselage, which also happens to be the first complete tail section to print. This version prints with .8mm walls, 1mm thick supports that protrude to the interior of the fuselage about 2.5-3mm. In addition I have printed all four sections of the tail boom and I am currently waiting for the glue to dry befor I post the final picture of the rear tail section and tail boom.

The tail boom still needs more work as to tolerances to allow for a light press fit of the boom into the tail section, and the 3mm square rod into the boom. I also still need to add the detail for the rear stabilizer mount.

Here’s a photo of the tail section with the 4 boom sections before gluing, another picture will come later once the sections are dry.

Tonight I am going to work on hollowing out the remaining section of fuselage, split the cowl from the firewall, add support structures and finally print version 1.7 which will only need work on the landing gear and hardware mounting.

Currently I have finished printing version 1.6 of the rear portion of the fuselage, which also happens to be the first complete tail section to print. This version prints with .8mm walls, 1mm thick supports that protrude to the interior of the fuselage about 2.5-3mm. In addition I have printed all four sections of the tail boom and I am currently waiting for the glue to dry befor I post the final picture of the rear tail section and tail boom.

The tail boom still needs more work as to tolerances to allow for a light press fit of the boom into the tail section, and the 3mm square rod into the boom. I also still need to add the detail for the rear stabilizer mount.

Here’s a photo of the tail section with the 4 boom sections before gluing, another picture will come later once the sections are dry.

Tonight I am going to work on hollowing out the remaining section of fuselage, split the cowl from the firewall, add support structures and finally print version 1.7 which will only need work on the landing gear and hardware mounting.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Okay I’m back for one more post tonight. Version 1.7 is about to start printing and will take about 6 hours to finish. The total weight for the mk1.7 fuselage as it sits right now is 39g. This is using standard pla filament, I will be printing the actual airplane out of light weight pla which weighs half as much. So in the current configuration the fuselage should weigh about 19-20g alone.

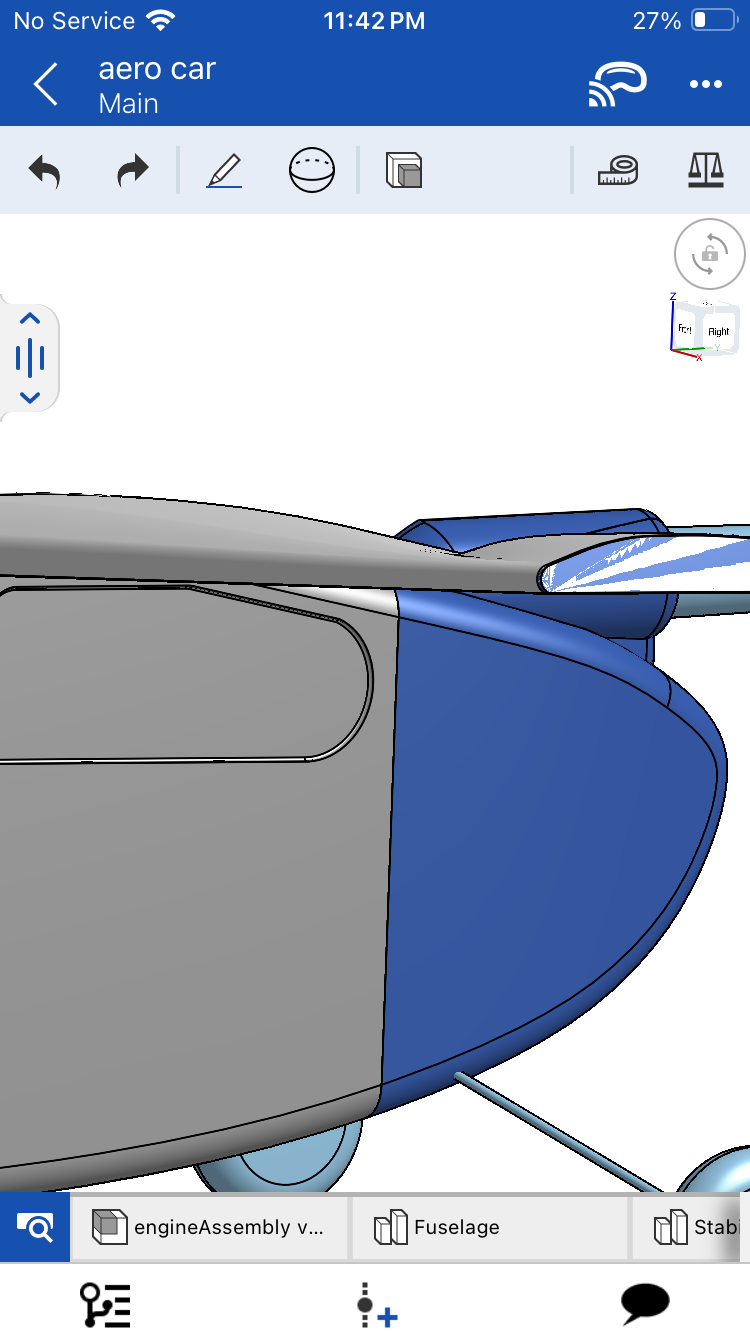

Here is what 1.7 looks like. I mirrored the one half of the fuselage to create the complete fuselage in prep of printing. I will be posting a picture of the printed fuselage in the morning

Here is what 1.7 looks like. I mirrored the one half of the fuselage to create the complete fuselage in prep of printing. I will be posting a picture of the printed fuselage in the morning

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

The print looks good from the photo  …..You might consider to drill some relief openings for the screws in the heli backplate or draw them in before next print so it can sit flush on the firewall…..Looking forward to your progress…..

…..You might consider to drill some relief openings for the screws in the heli backplate or draw them in before next print so it can sit flush on the firewall…..Looking forward to your progress…..

…..You might consider to drill some relief openings for the screws in the heli backplate or draw them in before next print so it can sit flush on the firewall…..Looking forward to your progress…..

…..You might consider to drill some relief openings for the screws in the heli backplate or draw them in before next print so it can sit flush on the firewall…..Looking forward to your progress…..

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Thank you buddy. I’m still working out everything on the firewall. I currently have screws for mounting screws but I’ll likely change a couple more things.

I’ll be back working on the model tonight, so I’ll check back later with a progress update.

I’ll be back working on the model tonight, so I’ll check back later with a progress update.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

I think tonight I’m going to figure out landing gear. I have some 1mm stainless rod but I feel that is far to thin, unless there’s a certain way to bend the wire, build up and solder, or bend to a shape and print some small fairings to go around the wire to help stiffen it up?

What are your thoughts? I’d like to be able to print the landing gear mount feature as part of the fuselage but I’m fairly certain I have an idea to help figure that out.

Another thing that I was thinking, mounting of the cowl. One method I was thinking would involve printing the cowl with a solid bottom, locking tabs to lock onto the front face of fuselage body and finally the engine mounted to secure everything together, another much simpler option would be mounting the cowl the standard way. The electronics hatch still needs to be figured out but I will work on that in a day or so.

What are your thoughts? I’d like to be able to print the landing gear mount feature as part of the fuselage but I’m fairly certain I have an idea to help figure that out.

Another thing that I was thinking, mounting of the cowl. One method I was thinking would involve printing the cowl with a solid bottom, locking tabs to lock onto the front face of fuselage body and finally the engine mounted to secure everything together, another much simpler option would be mounting the cowl the standard way. The electronics hatch still needs to be figured out but I will work on that in a day or so.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

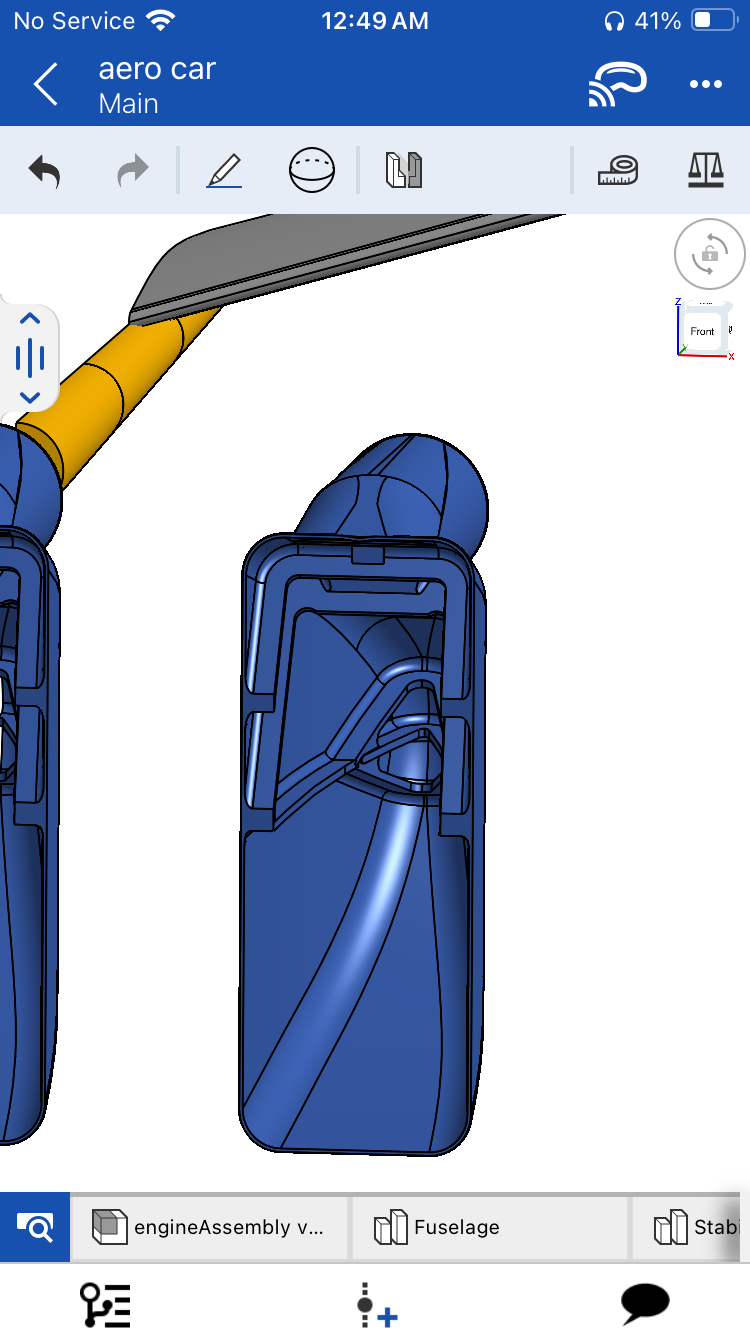

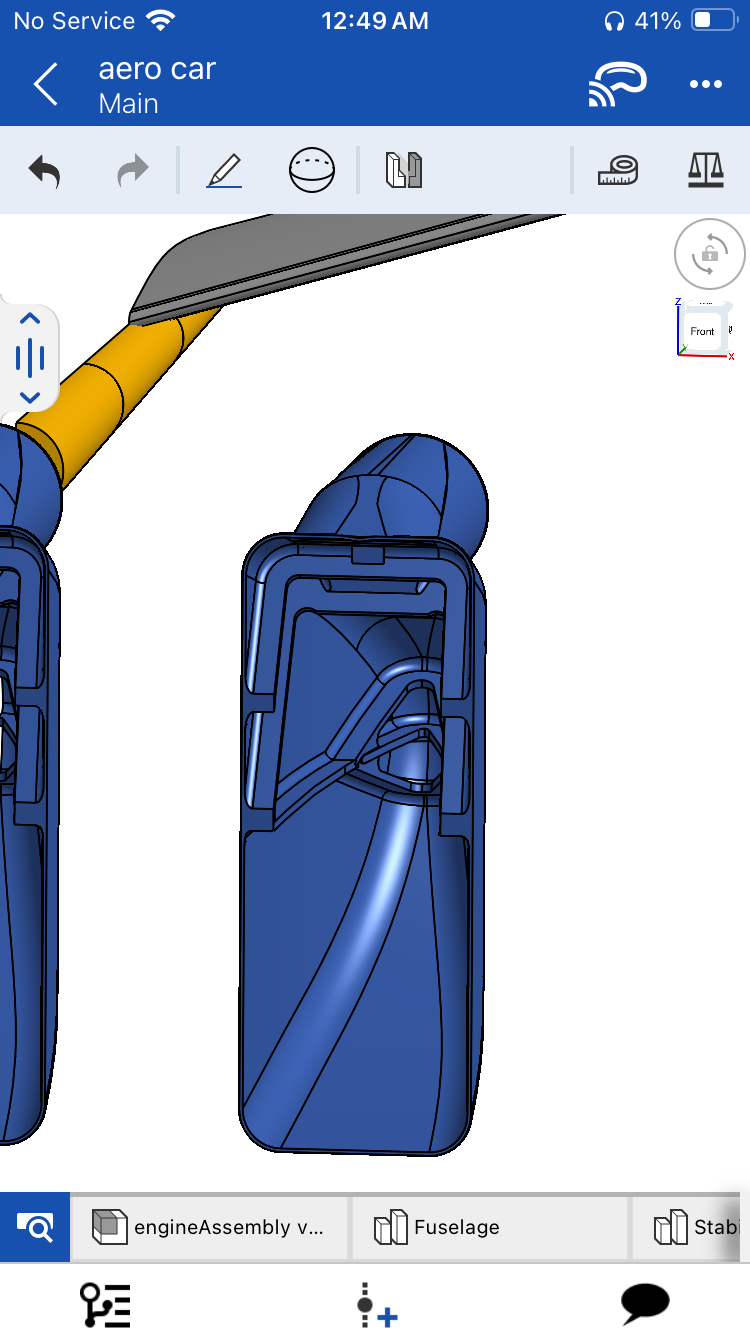

Alright, I’ve gotten some more work done on the cad models tonight for version 1.8. In this version I have added some material to the tail boom to help strengthen it, and to help with the glue joints. The previous version printed in 4 sections where as this prints in two. I also modeled the cowl as well as one way of mounting that I am considering. The new fuselage and down will be held together with tabs on either side of the fuselage, I still need to work out the details to make the tabs removable but at least they are there to start with. That about sums up what I got done within the last hour or so. I have started printing out all the different parts for version 1.8 and should have everything printed by tomorrow evening. Here are a couple of photos showing v1.8 as it currently sits, the landing gear still needs to be figured out, as well as wing mounting and stabilizer mounting.

The total estimated weight of all parts in this assembly is 50g. Using lw-pla will give us a lighter model, but it’s hard to estimate the weight of aircraft without actually doing some tests. The way that lw-pla works is this. There is a “puffing” agent which depending on the temperature that you are printing causes different rates of expansion in the material, or foaming. Higher temps lead to more foaming, less material used, less weight but also yields a weaker part. I’ve seen estimates between 30-50% weight reduction when using this type of filament but we won’t have really any idea until I start running tests on said filament.

The total estimated weight of all parts in this assembly is 50g. Using lw-pla will give us a lighter model, but it’s hard to estimate the weight of aircraft without actually doing some tests. The way that lw-pla works is this. There is a “puffing” agent which depending on the temperature that you are printing causes different rates of expansion in the material, or foaming. Higher temps lead to more foaming, less material used, less weight but also yields a weaker part. I’ve seen estimates between 30-50% weight reduction when using this type of filament but we won’t have really any idea until I start running tests on said filament.

KyleRManeti95- Silver Member

- Posts : 66

Join date : 2024-07-22

Age : 29

Location : Faribault, Minnesota

Re: “Aero Car” 3d printed, peewee powered plane build

Re: “Aero Car” 3d printed, peewee powered plane build

Looks good, I like it. Not sure how near the cowling wall to the engine exhaust is. At least old stock COX airplanes - the only Super Sport Trainer I ever had - were prone to melting the cowling area near the engine exhaust...the 3D print materials may better withstand heat, though.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» My latest free flight plane: a PeeWee powered jet fighter (don't miss the vid)

» RJ.bee rc cars build tee dee powered

» build log at RCG, Lastick, .020 powered

» 3D printed RC plane videod by a drone

» PeeWee Pitts Profile Practice Plane

» RJ.bee rc cars build tee dee powered

» build log at RCG, Lastick, .020 powered

» 3D printed RC plane videod by a drone

» PeeWee Pitts Profile Practice Plane

Page 2 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules