Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Wen Mac .049 - Conditioning.

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

It's so good to see you give life to the sad little engine. He is not sad anymore..

It's so good to see you give life to the sad little engine. He is not sad anymore..  Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

¡Bravo!, excelente, Mauricio, las rotaciones del motor de 15,500 por minuto son músicas en mis orejas.

Bravo! Excellent, Mauricio, the engine rotations of 15,500 per minute are music in my ears.

También, tu obra dura muestra que el motor ahora parece muy hermoso, ¡perfecto!

Also, your hard work shows that the engine now looks very beautiful, perfect!

Bravo! Excellent, Mauricio, the engine rotations of 15,500 per minute are music in my ears.

También, tu obra dura muestra que el motor ahora parece muy hermoso, ¡perfecto!

Also, your hard work shows that the engine now looks very beautiful, perfect!

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

YEAH BOY!!!!!!!!!!!!!

It's great to see some "Wen Mac Love" !!!!!!

Congrats and Bravo!!!!!!!!!!!

It's great to see some "Wen Mac Love" !!!!!!

Congrats and Bravo!!!!!!!!!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Fantastic !! Very good work and the engine sounds GREAT , good RPMs with the 5x3 prop .. The lathe is your Friend and you have got using it down path . Very happy for you to revive this piece of history !

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

The engine runs strong and steady Mauricio!!!…. The repairs are tastefully made…. Always nice to see and hear one perform after repairs and rebuild…..Excellent work friend

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Once again great work the engine seems to work well I like what you did with this engine the modification of the engine crankcase and the manufacturing of the neadle valve beautiful work friend

You could perhaps make the restrictor ring out of aluminum with cooling purposes ading fins Could help. the drawing suggests making it in two pieces the system seems perfect and I can't wait to see the final result

You could perhaps make the restrictor ring out of aluminum with cooling purposes ading fins Could help. the drawing suggests making it in two pieces the system seems perfect and I can't wait to see the final result

You could perhaps make the restrictor ring out of aluminum with cooling purposes ading fins Could help. the drawing suggests making it in two pieces the system seems perfect and I can't wait to see the final result

You could perhaps make the restrictor ring out of aluminum with cooling purposes ading fins Could help. the drawing suggests making it in two pieces the system seems perfect and I can't wait to see the final result

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Thanks guys!

Finally I made the acceleration ring....

..you can see it here:

Finally I made the acceleration ring....

..you can see it here:

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

¡Mauricio, tu creación, el carburador de escape está funcionando perfectamente!

Mauricio, your creation, the exhaust carburetor is working perfectly!

Tu obra dura ha dado los frutos buenos. ¡Felicidades!

Your hard work has born good fruit. Congratulations!

Creo que tu amigo estará disfrutarlo mucho.

I think that your friend will be enjoying it a lot.

Mauricio, your creation, the exhaust carburetor is working perfectly!

Tu obra dura ha dado los frutos buenos. ¡Felicidades!

Your hard work has born good fruit. Congratulations!

Creo que tu amigo estará disfrutarlo mucho.

I think that your friend will be enjoying it a lot.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Good work Mauricio!  Nice to have throttle control on a small engine. It makes a much more scale-like experience for a small airplane.. and you can "land" before running out of fuel.. or if something needs adjustment on a maiden flight.

Nice to have throttle control on a small engine. It makes a much more scale-like experience for a small airplane.. and you can "land" before running out of fuel.. or if something needs adjustment on a maiden flight.

Nice to have throttle control on a small engine. It makes a much more scale-like experience for a small airplane.. and you can "land" before running out of fuel.. or if something needs adjustment on a maiden flight.

Nice to have throttle control on a small engine. It makes a much more scale-like experience for a small airplane.. and you can "land" before running out of fuel.. or if something needs adjustment on a maiden flight.  Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

It's great, this engine is now unique, a special rc Wenmac. A special craftsmanship by Mauricio. Friend you should put a signature on the engines you modify

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

I'm very glad you like the work.

It really was a whole process where the engine accompanied the work at all times.

What do I mean? That the Wen-Mac engine seems to collaborate at all times to get it working again. All steps were direct and with good results. The engine, its own soul, had every desire to run again.

The connection that exists between the operator (in my case) and the rescue of these irons (engines) is very special, each one has a story behind it and I think they deserve the opportunity when one can dedicate a little aeromodelling affection to them.

There the result, it seems that everything is going well. Maybe I should make some more spray bars in the future and test, but in general terms the engine is already available to fly a model suitable for it.

Thank you to everyone who contributed information, since without that information it is impossible to plan a job.

Cox Engines Forum is a school for me, where its very supportive members transmit their knowledge and we all learn.

Remember: What someone contributes here, somewhere in the world an engine will work again. That's thanks to you!....Long Live CEF!

Me alegro mucho les guste el trabajo.

Realmente fue todo un proceso en donde en todo momento el motor acompaño la obra.

Que quiero decir?, que el motor Wen-Mac parese colaborar en todo momento para volver a funcionar. Todos los pasos fueron directo y con buenos resultados. El motor su propia alma tenia todas las ganas de volver a funcionar.

La conección que se da entre el operador (en mi caso) y el rescate de estos fierros (motores) es muy especial, cada uno tiene una historia por detras y creo que merecen la oportunidad cuando uno puede dedicarles un poco de cariño aeromodelista.

Allí el resultado, parese que todo va bien. Quizás debo hacer algunos spray bar más en el futuro y probar, pero en líneas generales el motor ya esta disponible para hacer volar un modelo adecuado para él.

Gracias s todos los que colaboraron con información, ya que sin esa información es imposible poder proyectar un trabajo.

Cox Engines Forum, es una escuela para mí, donde sus integrantes muy solidarios transmiten su conocimiento y todos aprendemos.

Recuerden: Lo que alquien aporta aquí, en algun lugar del mundo un motor funcionará de nuevo. Eso es gracias a Ustedes!....Larga Vida a CEF!

It really was a whole process where the engine accompanied the work at all times.

What do I mean? That the Wen-Mac engine seems to collaborate at all times to get it working again. All steps were direct and with good results. The engine, its own soul, had every desire to run again.

The connection that exists between the operator (in my case) and the rescue of these irons (engines) is very special, each one has a story behind it and I think they deserve the opportunity when one can dedicate a little aeromodelling affection to them.

There the result, it seems that everything is going well. Maybe I should make some more spray bars in the future and test, but in general terms the engine is already available to fly a model suitable for it.

Thank you to everyone who contributed information, since without that information it is impossible to plan a job.

Cox Engines Forum is a school for me, where its very supportive members transmit their knowledge and we all learn.

Remember: What someone contributes here, somewhere in the world an engine will work again. That's thanks to you!....Long Live CEF!

Me alegro mucho les guste el trabajo.

Realmente fue todo un proceso en donde en todo momento el motor acompaño la obra.

Que quiero decir?, que el motor Wen-Mac parese colaborar en todo momento para volver a funcionar. Todos los pasos fueron directo y con buenos resultados. El motor su propia alma tenia todas las ganas de volver a funcionar.

La conección que se da entre el operador (en mi caso) y el rescate de estos fierros (motores) es muy especial, cada uno tiene una historia por detras y creo que merecen la oportunidad cuando uno puede dedicarles un poco de cariño aeromodelista.

Allí el resultado, parese que todo va bien. Quizás debo hacer algunos spray bar más en el futuro y probar, pero en líneas generales el motor ya esta disponible para hacer volar un modelo adecuado para él.

Gracias s todos los que colaboraron con información, ya que sin esa información es imposible poder proyectar un trabajo.

Cox Engines Forum, es una escuela para mí, donde sus integrantes muy solidarios transmiten su conocimiento y todos aprendemos.

Recuerden: Lo que alquien aporta aquí, en algun lugar del mundo un motor funcionará de nuevo. Eso es gracias a Ustedes!....Larga Vida a CEF!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Mi presentimiento es, porque el volumen interno es muy pequeño y el motor tiene pequeño poder, lo quizá más problema que marece la pena el esfuerzo. Los motores más grandes son menos sensitivos. No obstante, esa es mi opinión.

My hunch is, because the internal volume is very small and the motor has little power, it is perhaps more of a problem than worth the effort. Larger motors are less sensitive. However, that is my opinion.

My hunch is, because the internal volume is very small and the motor has little power, it is perhaps more of a problem than worth the effort. Larger motors are less sensitive. However, that is my opinion.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Hello Mauricio

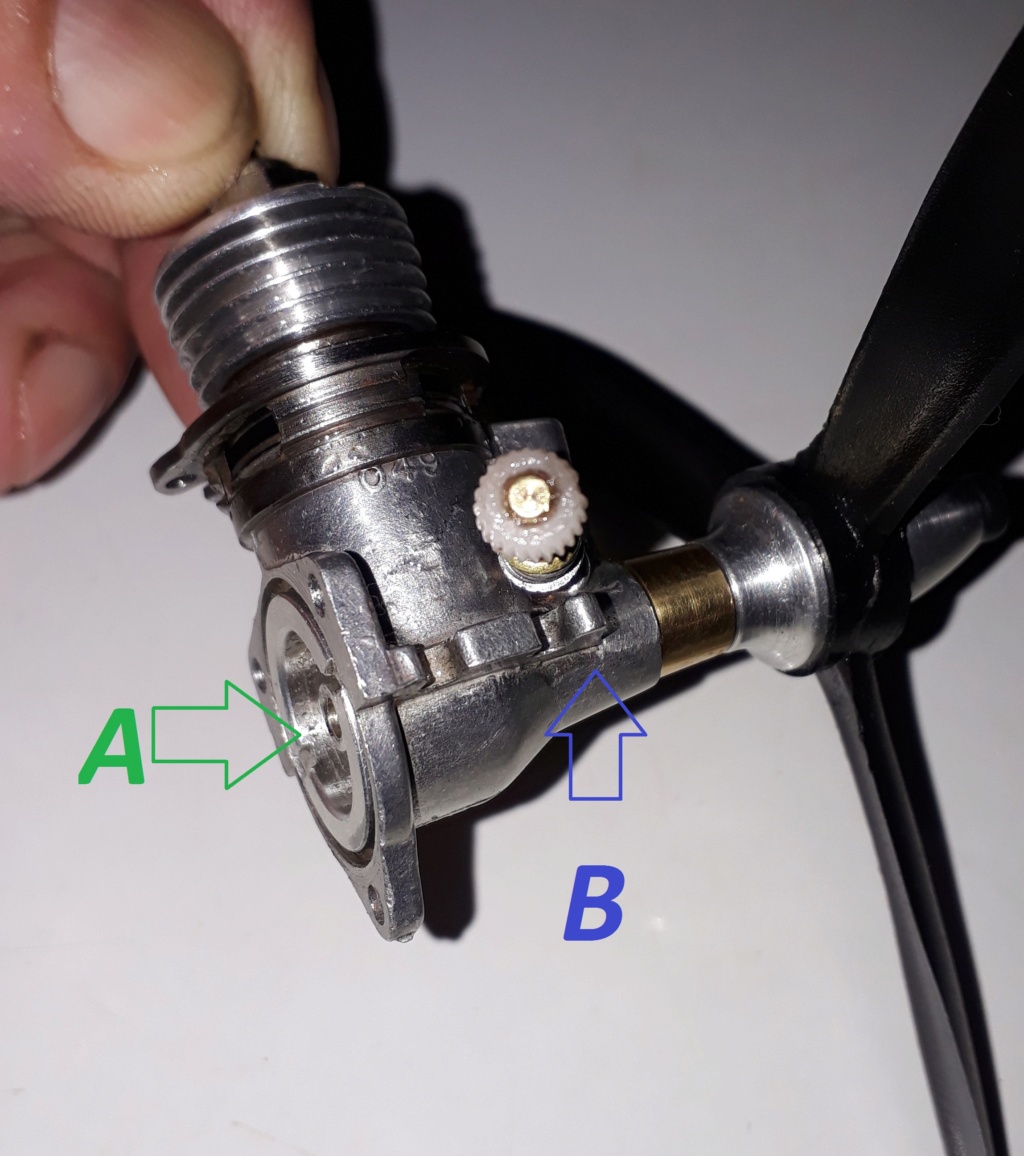

I think that installing a pressure fitting on the backplate would be the easiest since the crankcase casting is real thin on the B point you mention. I haven`t used pressure with a throttle ring so I think that trying to run the engine at low RPM will be a problem due to excess fuel. I have a Fuji.05 that I reworked and to add a pressure fitting I used JB weld And placed in the exhaust side a small aluminum disc that I drilled and tapped for a 3mm pressure fitting. It worked real good as I had made a radial mount and placing the fitting on the back would not work for me. I got the engine to turn over 25K rpm with open exhasut. Here is a picture where you can see the fitting installation.

Juan

I think that installing a pressure fitting on the backplate would be the easiest since the crankcase casting is real thin on the B point you mention. I haven`t used pressure with a throttle ring so I think that trying to run the engine at low RPM will be a problem due to excess fuel. I have a Fuji.05 that I reworked and to add a pressure fitting I used JB weld And placed in the exhaust side a small aluminum disc that I drilled and tapped for a 3mm pressure fitting. It worked real good as I had made a radial mount and placing the fitting on the back would not work for me. I got the engine to turn over 25K rpm with open exhasut. Here is a picture where you can see the fitting installation.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Thank you Jorge for your appreciation, really worth taking into account.

Juan, thanks for the sample, the Fuji .05 is a beautiful engine!!

This Wen-Mac .049 engine, since its original state, has changed absolutely, so it is a good element to experiment with, I think that placing a pressurizer nozzle in the cylinder head will not be a problem, since it has a threaded anchor to It will surely support a fuel tank, so I can place a spout there and in any case if it does not add to the operation of the engine, I can place a screw neatly as a cap.

Juan, thanks for the sample, the Fuji .05 is a beautiful engine!!

This Wen-Mac .049 engine, since its original state, has changed absolutely, so it is a good element to experiment with, I think that placing a pressurizer nozzle in the cylinder head will not be a problem, since it has a threaded anchor to It will surely support a fuel tank, so I can place a spout there and in any case if it does not add to the operation of the engine, I can place a screw neatly as a cap.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Hola Mauricio!…. The acceleration ring for the Wen-Mac works excellent and adds to the little engine’s alma…  …. Will be interested to see what model you will design for it… Will be unique for sure!!!

…. Will be interested to see what model you will design for it… Will be unique for sure!!!

Regarding the pressure tap; I have no experience with them other than I have one for a

Norvel AME .061…. It was made into the backplate and the orifice is .015” (.381 mm)…The engine was quite strong when I used it and had good fuel draw so I never tried the pressure fitting…. Hopefully the fotos and measurement will help your project…

Regarding the pressure tap; I have no experience with them other than I have one for a

Norvel AME .061…. It was made into the backplate and the orifice is .015” (.381 mm)…The engine was quite strong when I used it and had good fuel draw so I never tried the pressure fitting…. Hopefully the fotos and measurement will help your project…

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

El corazón del motor parece muy fuerza, especialmente después tus modificaciones.

The engine's heart seems very strong, especially after your modifications.

The engine's heart seems very strong, especially after your modifications.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Hello Mauricio

If you decide to try the pressure fitting on the side of the crankcase on another project you have to make sure that the fitting doesn`t get on the way of the connecting rod. I`m doing it to a Cox TD using a Fox 4-40 fitting and I will be grinding the fitting because it sticks out a little and I don`t want the rod getting damaged Here is a picture. You are doing a great job on the rebuild.

Juan

If you decide to try the pressure fitting on the side of the crankcase on another project you have to make sure that the fitting doesn`t get on the way of the connecting rod. I`m doing it to a Cox TD using a Fox 4-40 fitting and I will be grinding the fitting because it sticks out a little and I don`t want the rod getting damaged Here is a picture. You are doing a great job on the rebuild.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Thanks guys! You are offering a lot of very interesting and important information!...thank you!

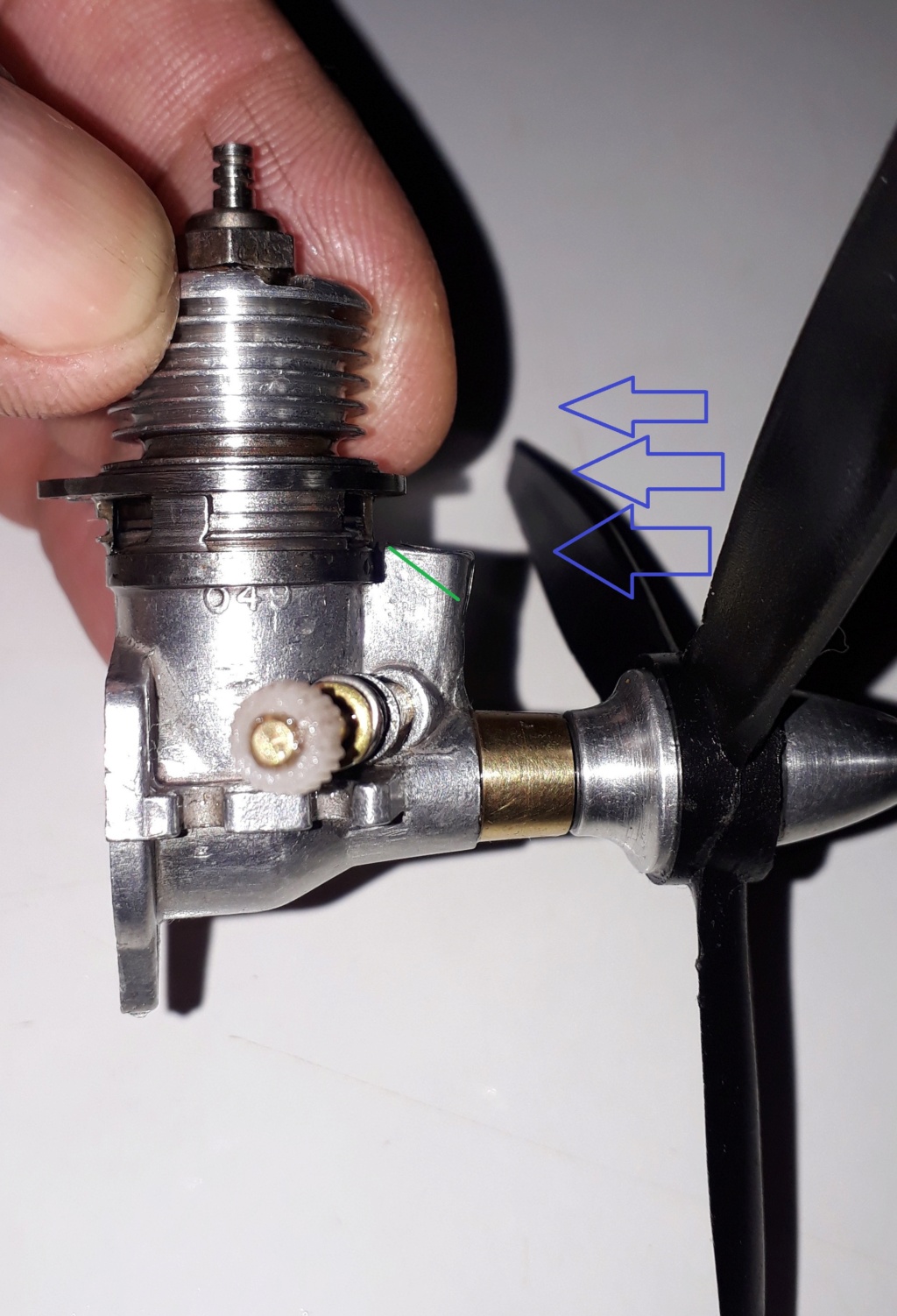

So I keep trying, today I used a Cox Surestar type backplate spraybar and needle, the result is the same as my own needle and spraybar assembly, so it occurred to me to put a Cox medallion .049 needle and spraybar, I want to see what it throws essay. I'll tell you shortly...

On the other hand, I wonder...the air intake tube is quite long compared to other engines, in addition, the spraybar is almost attached to the crankshaft, what would happen if it were a few millimeters higher??, maybe the mixture is not Would it fit into the crankcase so heavy, maybe it would fit more dispersed in spray?...I don't know, there are some doubts I have...

In the photo I show the Wen-Mac .049 with medallion needle and spraybar....I will share the experience shortly.

So I keep trying, today I used a Cox Surestar type backplate spraybar and needle, the result is the same as my own needle and spraybar assembly, so it occurred to me to put a Cox medallion .049 needle and spraybar, I want to see what it throws essay. I'll tell you shortly...

On the other hand, I wonder...the air intake tube is quite long compared to other engines, in addition, the spraybar is almost attached to the crankshaft, what would happen if it were a few millimeters higher??, maybe the mixture is not Would it fit into the crankcase so heavy, maybe it would fit more dispersed in spray?...I don't know, there are some doubts I have...

In the photo I show the Wen-Mac .049 with medallion needle and spraybar....I will share the experience shortly.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

A longer venturi above the needle helps to provide laminar air flow. This means that the extra length helps to smooth the air so it flows smoothly around the spray bar, so you get maximum consistent suction of fuel to air for more efficient air-fuel mixing.

Un venturi más largo encima de la aguja ayuda a proporcionar un flujo de aire laminar. Esto significa que la longitud adicional ayuda a suavizar el aire para que fluya suavemente alrededor de la barra rociadora, de modo que obtenga la máxima succión constante de combustible al aire para una mezcla más eficiente de aire y combustible.

No levantaría más el conjunto de la válvula de aguja.

I would not lift the needle valve assembly any higher.

Un venturi más largo encima de la aguja ayuda a proporcionar un flujo de aire laminar. Esto significa que la longitud adicional ayuda a suavizar el aire para que fluya suavemente alrededor de la barra rociadora, de modo que obtenga la máxima succión constante de combustible al aire para una mezcla más eficiente de aire y combustible.

No levantaría más el conjunto de la válvula de aguja.

I would not lift the needle valve assembly any higher.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

No, misma razón, derrota a la longitud. (No, same reason, defeats the length.)

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

GallopingGhostler wrote:No, misma razón, derrota a la longitud. (No, same reason, defeats the length.)

Ok Jorge!!....then I'll leave it as is!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Hello Mauricio

I thought about the best way to add the pressure fitting and decided that it was better to make a fitting out of aluminum to press in the hole I already made in the side of the cox crankcase. I made the stub that was going into the hole a 2 thousands bigger. I applied JB weld and with a cylinder and backplate in place I pressed the pressure fitting in. Now all I have to do is wait till it dries and with my dremel remove the excess of the stub that poked into the crankcase. I think this idea is better than using the fox pressure fitting that I have. The hole I made in the fitting is .030 thousand. You can make the fitting in your lathe. On the intake the sharp edge on the lip needs to be radiused,sharp edges create turbulence that affects air inlet into the engine. You can use an exacto knife to shave the sharp edge. Every little bit helps.I hope this helps.

Juan

I thought about the best way to add the pressure fitting and decided that it was better to make a fitting out of aluminum to press in the hole I already made in the side of the cox crankcase. I made the stub that was going into the hole a 2 thousands bigger. I applied JB weld and with a cylinder and backplate in place I pressed the pressure fitting in. Now all I have to do is wait till it dries and with my dremel remove the excess of the stub that poked into the crankcase. I think this idea is better than using the fox pressure fitting that I have. The hole I made in the fitting is .030 thousand. You can make the fitting in your lathe. On the intake the sharp edge on the lip needs to be radiused,sharp edges create turbulence that affects air inlet into the engine. You can use an exacto knife to shave the sharp edge. Every little bit helps.I hope this helps.

Juan

F4D Phantom II- Gold Member

- Posts : 245

Join date : 2019-04-08

Re: Wen Mac .049 - Conditioning.

Re: Wen Mac .049 - Conditioning.

Setting:

Spraybar: Cox Medallion .049

Needle: Cox Medallion .049

Propeller: APC 5 x 3

Control Ring: Own manufacturing.

Fuel: Castor20%/Nitro20%/Rest Methanol

RPM range: 8200/13500

Glow Plug: O.S. 8

Conclusion:

This is the best performance I have obtained for this engine using the self-made acceleration ring.

Thanks to everyone who contributed information (Friends of Cox Engine Forum and Horacio Banus).

Spraybar: Cox Medallion .049

Needle: Cox Medallion .049

Propeller: APC 5 x 3

Control Ring: Own manufacturing.

Fuel: Castor20%/Nitro20%/Rest Methanol

RPM range: 8200/13500

Glow Plug: O.S. 8

Conclusion:

This is the best performance I have obtained for this engine using the self-made acceleration ring.

Thanks to everyone who contributed information (Friends of Cox Engine Forum and Horacio Banus).

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Page 2 of 3 •  1, 2, 3

1, 2, 3

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules