Log in

Search

Latest topics

» Happy 77th birthday Andrew!by Admin Today at 12:34 pm

» Roger Harris revisited

by getback Today at 12:30 pm

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 12:23 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Cox 049 Crankcases - First production run

Page 1 of 1

Cox 049 Crankcases - First production run

Cox 049 Crankcases - First production run

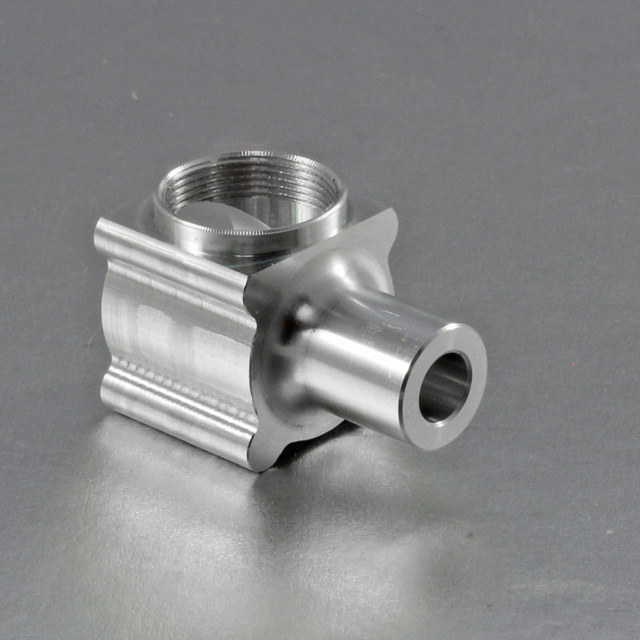

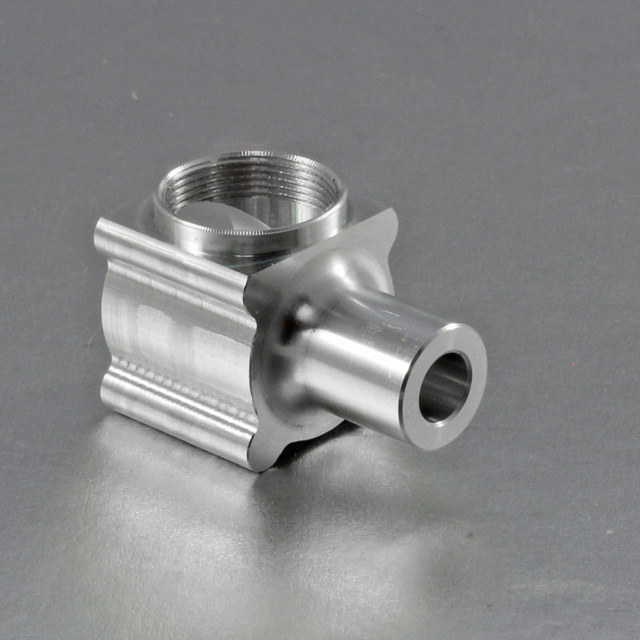

We just received our production run of 049 crankcases and the cranks fit nice and tight, just like the ones from the 70's & 80's, and way tighter tolerances than the Estes ones:

https://coxengines.ca/front-end/cox-049-051-crankcase-silver.html

https://coxengines.ca/front-end/cox-049-051-crankcase-silver.html

What alloy are they made off?

What alloy are they made off?

Do you know what "version" of alluminium alloy they are made off?

Most alloys have a number and then we can look up what kind of performance we can expect like lifespan.

Most alloys have a number and then we can look up what kind of performance we can expect like lifespan.

cmulder- Gold Member

- Posts : 279

Join date : 2022-02-10

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Bernie, those look really nice, ultra high quality, calidad alta.

Official Cox International photo.

Official Cox International photo.

I see the difference now and then. Originally, I gather that Cox purchased their aluminum bars with the 3 sides already shaped with the rounded ridges where the machine screws for the back would be placed or they had special machines to do this. They did it in the tens of thousands at a time. In this case, even considering the amount of machining involved, your prices are very good considering the effort required today to make these.

Just looking at the photos, I can tell the quality done because the 90% edges along front and back and at the cylinder mount area are nicely camfered. Back in the old days, there might be a team of machinist assistants with fine files, quickly breaking the edges by hand. The mark of a quality job then was how evenly the filing was done along those edges.

Official Cox International photo.

Official Cox International photo.

I see the difference now and then. Originally, I gather that Cox purchased their aluminum bars with the 3 sides already shaped with the rounded ridges where the machine screws for the back would be placed or they had special machines to do this. They did it in the tens of thousands at a time. In this case, even considering the amount of machining involved, your prices are very good considering the effort required today to make these.

Just looking at the photos, I can tell the quality done because the 90% edges along front and back and at the cylinder mount area are nicely camfered. Back in the old days, there might be a team of machinist assistants with fine files, quickly breaking the edges by hand. The mark of a quality job then was how evenly the filing was done along those edges.

Last edited by GallopingGhostler on Mon Mar 20, 2023 9:56 pm; edited 1 time in total

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

cmulder wrote:Do you know what "version" of alluminium alloy they are made off?

Most alloys have a number and then we can look up what kind of performance we can expect like lifespan.

Same as Cox used, T6061. We stuck with that alloy because it anodizes well.

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Cox International wrote:Same as Cox used, T6061. We stuck with that alloy because it anodizes well.

Back in the mid 1970's, as student help (spell cheap labor

) a 110 foot long vessel that traveled worldwide to place and retrieve these off coastal waters for seismic activity studies done by the university's Geophysics Department.

) a 110 foot long vessel that traveled worldwide to place and retrieve these off coastal waters for seismic activity studies done by the university's Geophysics Department.For the pressure casings, they were using T6061 aluminum because of its toughness and ability to hold up under water pressure.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

GallopingGhostler wrote:Cox International wrote:Same as Cox used, T6061. We stuck with that alloy because it anodizes well.

Back in the mid 1970's, as student help (spell cheap labor), I worked part time at Research Corp., an entity on the University of Hawaii campus who made all the oceanbottom seismometer casings and electronics, and had (I think size wise

) a 110 foot long vessel that traveled worldwide to place and retrieve these off coastal waters for seismic activity studies done by the university's Geophysics Department.

For the pressure casings, they were using T6061 aluminum because of its toughness and ability to hold up under water pressure.

In addition to its strength properties then this aluminum grade should also be saltwater resistant, if used in seawater duties.

Normal aluminum quickly disintegrates in salt laden atmosphere...once in a power plant near the Singapore seashore I saw an air cooled heat exchanger dropping its aluminum fins like fine powder when touched, due to salt corrosion..

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Cox International wrote:

Same as Cox used, T6061. We stuck with that alloy because it anodizes well.

6061 aluminum, and its various grades of tempering, T6 being the most common, has been one of the GoTo's among homebuilt aircraft. It has good tensile, yield and shear properties and, as is obvious from the photos, machinability characteristics.

It would be nice if Bernie could publish a photograph of the crankcase from the rear looking forward to give us a peak at the thrust bearing surface of the case.

GallopingGhostler wrote:.............

Just looking at the photos, I can tell the quality done because the 90% edges along front and back and at the cylinder mount area are nicely camfered. .......

I had noticed that straight away -- excellent machining practice. The chamfering at the cylinder mount looks almost like tool chatter, but it is very uniform -- I wonder if it were rolled?

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

It was probably done by CNC. Aluminum has a faster cutting rate than steel. Since the chamfer is hidden once cylinder is mounted, it didn't need a second or slower first pass, IMO. Added work increases time with cost. It still looks professional.Andrew wrote:I had noticed that straight away -- excellent machining practice. The chamfering at the cylinder mount looks almost like tool chatter, but it is very uniform -- I wonder if it were rolled?GallopingGhostler wrote:Just looking at the photos, I can tell the quality done because the 90% edges along front and back and at the cylinder mount area are nicely chamfered.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

I see where in the crank bore there a passageway for fuel/oil is lubrication.

On most of my Cox crankcases I really don't see that?

Good idea, as there is a slight relief on the crankshafts I have seen on Cox's cranks.

On most of my Cox crankcases I really don't see that?

Good idea, as there is a slight relief on the crankshafts I have seen on Cox's cranks.

sosam117- Diamond Member

- Posts : 1351

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Agreed these are improved, I see the reliefs for oil distribution, should give very good service life.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Bernie,

Will these crankcases work with your aluminum backplates?

Will these crankcases work with your aluminum backplates?

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

944_Jim wrote:Bernie,

Will these crankcases work with your aluminum backplates?

Why would they not work? After all, the backplates go onto the tanks and not the crankcases.

To note is that the crankcases are 100% identical to the ones Cox made, as we used the OEM Cox drawings to have them made.

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Ok...been thinking.

Non-SPI piston and cylinder;

Medallion head (or go High Compression);

Tee Dee/Medallion crank (preferably the other direction)

New machined bottom end BUT with the Tee Dee or Medallion cut-out on main bearing...machine the snout for the intake ala Front Rotary Valve;

New machined aluminum backplate BUT don't drill out the center or the NVA holes....leave it closed. It is only a radial mount backplate (no intake at this point). Use the Bee backplate gasket and screws,.time with cylinder base gaskets, and control compression with respect to nitro with head gaskets.

That gets me the other direction engine for better line tension, a radial mount, Medallion or Tee Dee based on front end.

I want one for under $125 each (one for proto, three more to complete two twins). If it runs well, sell me three more.

I see a BMJR twin and a Grumman F5F around these four

Non-SPI piston and cylinder;

Medallion head (or go High Compression);

Tee Dee/Medallion crank (preferably the other direction)

New machined bottom end BUT with the Tee Dee or Medallion cut-out on main bearing...machine the snout for the intake ala Front Rotary Valve;

New machined aluminum backplate BUT don't drill out the center or the NVA holes....leave it closed. It is only a radial mount backplate (no intake at this point). Use the Bee backplate gasket and screws,.time with cylinder base gaskets, and control compression with respect to nitro with head gaskets.

That gets me the other direction engine for better line tension, a radial mount, Medallion or Tee Dee based on front end.

I want one for under $125 each (one for proto, three more to complete two twins). If it runs well, sell me three more.

I see a BMJR twin and a Grumman F5F around these four

Last edited by 944_Jim on Thu Mar 23, 2023 5:37 pm; edited 2 times in total

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

But essentially944_Jim wrote:That gets me the other direction engine for better line tension, a radial mount, Medallion or Tee.Dee based on front end. I want one for under $125 each. If it runs well, sell me three more.

isn't that the new .049 Tee Dee that Bernie's proposing to bring out soon at an introductory price of $89.95?

isn't that the new .049 Tee Dee that Bernie's proposing to bring out soon at an introductory price of $89.95?

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Ah, but with radial mount and opposite spin cranks...and I don't want to cut-off mounting flanges with no way to mount the engine...well, there is the "other guy's" backplate (I'll remember in a minute...I have a couple of his standard plug in-head adapters for all Cox, AP, and NorVel smalls, and radial backplates for Front Rotary Intake Cox engines).

Closing up the back end with four small screws and a horseshoe/product backplate blank ensures I have an indexed back-end/mount with respect to the top end. And I get to clock it one of four ways (90 degrees apart) at my desire

An engine set up like this means I only need a firewall for my plane...and I'm a Cox Front Rotary Valve engine (Medallion/Tee.Dee) sitting on a backplate, not engine bearers).

Closing up the back end with four small screws and a horseshoe/product backplate blank ensures I have an indexed back-end/mount with respect to the top end. And I get to clock it one of four ways (90 degrees apart) at my desire

An engine set up like this means I only need a firewall for my plane...and I'm a Cox Front Rotary Valve engine (Medallion/Tee.Dee) sitting on a backplate, not engine bearers).

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Beautiful Work

Beautiful Work

The finish on those looks a lot better than the crankcases of the dozens of crankcases I have. The chamfers on the tank mounting bolt holes is not seen on any of the units I have.

Well done. Excellent work.

Thanks.

Well done. Excellent work.

Thanks.

SABOO- Moderate Poster

- Posts : 10

Join date : 2019-10-03

Location : HALIFAX NS

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

I'm no expert, but...

So take the new Bee bottom end and add only the Front Rotary Intake (FRI) cut and front end threading to the file. That sounds like two more passes under the CNC Router.

Remove from the machined back-end the NVA cross-drill, intake port center-drill, and whatever can be eliminated with respect to the Product or Bee Reed spring/retaining groove...there has to be several steps there. Leave a bit in the backplate.where the reed.usually lives for a "stuffer" back end. Maybe remove the outside blanked-off intake to save some weight.

FRI crank in reverse rotation (better line tension) with the window cut as Medallion or Tee Dee depending on front end (I have no preference).

Top end remains the same. Front end as desired...aluminum or plastic (I prefer plastic for weight).

My preference is for a radial mount Medallion, just for the lower parts count.

So take the new Bee bottom end and add only the Front Rotary Intake (FRI) cut and front end threading to the file. That sounds like two more passes under the CNC Router.

Remove from the machined back-end the NVA cross-drill, intake port center-drill, and whatever can be eliminated with respect to the Product or Bee Reed spring/retaining groove...there has to be several steps there. Leave a bit in the backplate.where the reed.usually lives for a "stuffer" back end. Maybe remove the outside blanked-off intake to save some weight.

FRI crank in reverse rotation (better line tension) with the window cut as Medallion or Tee Dee depending on front end (I have no preference).

Top end remains the same. Front end as desired...aluminum or plastic (I prefer plastic for weight).

My preference is for a radial mount Medallion, just for the lower parts count.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

We would like to re-iterate that we will only manufacture to exact Cox OEM drawings; meaning if there is no drawing (or the part can't be reverse-engineered), we will not make that part.

We are a small (2-person) company and neither of us two has an engineering background. We are admin/sales people and are loath to get into experimental design changes that, it they don't work, will cost us dearly; aside that this would also irk our customers. Further, we certainly don't have the financial means to develop and manufacture non-Cox standard items on top of the standard Cox items.

Our mission is to duplicate OEM Cox parts and accessories, so that modellers may continue to enjoy the Cox legacy. This also applies to the potential production run of all the parts required to assemble TD 049 engines. We plan to assemble some engines and to also list all the parts individually, so that modellers can repair their existing TD 049 engines.

We are a small (2-person) company and neither of us two has an engineering background. We are admin/sales people and are loath to get into experimental design changes that, it they don't work, will cost us dearly; aside that this would also irk our customers. Further, we certainly don't have the financial means to develop and manufacture non-Cox standard items on top of the standard Cox items.

Our mission is to duplicate OEM Cox parts and accessories, so that modellers may continue to enjoy the Cox legacy. This also applies to the potential production run of all the parts required to assemble TD 049 engines. We plan to assemble some engines and to also list all the parts individually, so that modellers can repair their existing TD 049 engines.

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

I haven't checked in lately to say so, but ALL your efforts--from the beginning 'till now--- are HIGHLY appreciated.

Already got me a plane lined up for my "Bernie Engine"!

Already got me a plane lined up for my "Bernie Engine"!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Cox 049 Crankcases - First production run

Re: Cox 049 Crankcases - First production run

Cases look Good Bernie and Co. for suppling us with new OEM parts for our engines and that maybe in the future our children can enjoy the thrill of Cox Engines on Fun Powered Toys !

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» A simpler / cheaper .049 Tee Dee Engine suggestion

» TD and Medallion crankcases?

» Identifying crankcases

» Vintage Crankcases

» Inspecting Crankcases - What are the thresholds?

» TD and Medallion crankcases?

» Identifying crankcases

» Vintage Crankcases

» Inspecting Crankcases - What are the thresholds?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules