Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 10:46 am

» Duende V model from RC Model magazine 1983.

by MauricioB Today at 10:29 am

» A Little 400 Mile Hop for Some Memory Lane Stuff, and to Hit a Swap Meet.

by getback Today at 7:48 am

» Free Flight Radio Assist

by getback Today at 6:39 am

» Happy 77th birthday Andrew!

by Kim Yesterday at 9:18 am

» Promote the forum with flyers!

by Admin Yesterday at 1:35 am

» Engine choice

by GallopingGhostler Mon Nov 25, 2024 4:03 pm

» My N-1R build log

by roddie Mon Nov 25, 2024 9:19 am

» Night flying at Walters RC park

by 1975 control line guy Sun Nov 24, 2024 7:29 pm

» Cox films/videos...

by GallopingGhostler Sun Nov 24, 2024 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Sun Nov 24, 2024 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Sun Nov 24, 2024 5:08 pm

Cox Engine of The Month

T-Bee-D1 (a Rod-de-sign)

Page 2 of 8

Page 2 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

roddie wrote:

I never realized how short my lines were.. when I started flying C/L. I flew at home back then, in an area of my yard that had safe-clearance for about a 52' diameter circle. That's a 26' radius. My lines had to be shorter than that.. by at least 3 feet. I couldn't fly on 23' lines now. My last flight was on 35' lines that were the Dyneema-braided "Spider-Wire" brand 15lb. fishing line. It was a maiden-flight for the particular model.. so it's difficult to make an assessment of either.. because it was also my first time using a non-dacron line. It had also been a very long time since I had a handle in my hand.. I must "Do it Again" soon..

Short lines are really good for your reflexes and also for practicing being smooth. You get ragged on short lines and your in the ground.

So great practice for improving control etc. on longer lines.

So great practice for improving control etc. on longer lines.@roddie I know this is going to be a dumb question, But why does your Balsa say "this way up" on it. Am I missing something about storing balsa? I store a fair bit, hence question for in case there is something I do or dont do that would be better that I do or dont do. Hmmmm Bit like the unknown unknowns.............

Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Hi Yabby,

It seems most Canadians, are Jiggers ! Thanks.

The first airfoil the Wright Brothers tested was a flat plate.

They moved on.

Just for some perspective,

For what you are doing,

Happy trails,

My friend,

Dave

It seems most Canadians, are Jiggers ! Thanks.

The first airfoil the Wright Brothers tested was a flat plate.

They moved on.

Just for some perspective,

For what you are doing,

Happy trails,

My friend,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Yabby wrote:

Short lines are really good for your reflexes and also for practicing being smooth. You get ragged on short lines and your in the ground.So great practice for improving control etc. on longer lines.

Roddie, I know this is going to be a dumb question, But why does your Balsa say "this way up" on it. Am I missing something about storing balsa? I store a fair bit, hence question for in case there is something I do or dont do that would be better that I do or dont do. Hmmmm Bit like the unknown unknowns.............

Yabby

Hey Yabby, It's not at all a dumb question.. but it does NOT refer to storage. This particular balsa was leftover "scrap wood" from a job I had years ago. Picture in your mind if you will; a solid plank of laminated balsa that measures 1.75" thick X 24" width X 96" length. The laminations were pieces of 1.75" thickness X 6" width X 36" lengths.. finger-jointed..

.. and glued to make that large panel for a 3D "sign" that I was cutting frequently on their CNC router machine. The balsa wood sign component was "X" shaped. Four of these shapes would fit.. and were "nested" on the big 2' X 8' sheet. The scrap got tossed afterward.. and it used to make me cringe when I think of how much useful balsa was being thrown out.

I rough-cut some of it on a panel-saw into strips which varied widely in lengths between 18" to as much as 30".. to a couple of thicknesses that were at least 1/16" over finish thickness.

Many strips had some "rash" on one side.. with the other side being of a more consistent smoothness. "This side up" was an orientation-note for how to feed the stack into the sanding machine where I work now. These types of machines have been named "Time-Saver" and the one where I work now is an "Ironwood". The machine has feed-rollers to pull the stock through.. and the sanding is done "above".. on the upper side of the work-piece. My rough-cut strips measured approx. .200" strong to finish-out nearest to .187" (3/16") and .150" strong.. to finish-out nearest to .125" (1/8"). This "is" the wood that I am using for this T-Bee-D design series.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

That balsa is "all over the road" as far as grading/density is concerned. I would love to know how and where it was originally procured. There's actually some very lightweight wood there.. but definitely not the majority.

There's a LOT more wood that needs to be precision-sanded. I have two boxes of the rough-cut wood.

LOTS of wood there.. but it all needs to be sorted for precision-sanding. A laborious task.. if having to do by hand.. but not too bad; one model at a time. right?

There's a LOT more wood that needs to be precision-sanded. I have two boxes of the rough-cut wood.

LOTS of wood there.. but it all needs to be sorted for precision-sanding. A laborious task.. if having to do by hand.. but not too bad; one model at a time. right?

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

BTW Yabby...... I've stored this wood for the past 20 years in a cardboard box.. on the cement floor (Braided-rug atop) in my basement.. which has been dry thus far. The cardboard box storage works for kits..... and it's worked to keep this stock of wood good. Granted; it would be safer to store it between the floor-joists in the basement ceiling.. and that's on my bucket-list.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Thanks for the explanation Roddie  Nice having a source of balsa even if you have to do some work to get it how you want it! I will set mine up in some cardboard boxes also. Seems like a nice simple way to go about storing it, and whjilst I dont have huge amounts I do have a couple hundred dollars worth at home, at Aust $9.00 a sheet generally for 100mm x 1000mm for 1.0mm through to 6.5mm , more expensive as it gets thicker but sheet size here is generally 1000 x 100 mm or 3 ft x 4 inches, plus I have expensive leading edge balsa, so it doesnt take a lot to add up and be worth the effort to store a bit better than I do.

Nice having a source of balsa even if you have to do some work to get it how you want it! I will set mine up in some cardboard boxes also. Seems like a nice simple way to go about storing it, and whjilst I dont have huge amounts I do have a couple hundred dollars worth at home, at Aust $9.00 a sheet generally for 100mm x 1000mm for 1.0mm through to 6.5mm , more expensive as it gets thicker but sheet size here is generally 1000 x 100 mm or 3 ft x 4 inches, plus I have expensive leading edge balsa, so it doesnt take a lot to add up and be worth the effort to store a bit better than I do.

We have a Balsa sheet and ply sheet making factory nearby that have their own plantation. They make beutiful almost perfect balsa sheets, but pricy, they are mainly for the Craft market. But their balsa that is end cut, end sanded, out of spec type balsa they put on a trolley in bundles and you can take two bundles for free, which is pretty cool. They say they would prefer it to be free and get used than throw it away!!

You are really going one step further than all of us who claim to be "from scratch" builders, and making your own balsa sheets. Now that is truly from scratch!

Yabby

Nice having a source of balsa even if you have to do some work to get it how you want it! I will set mine up in some cardboard boxes also. Seems like a nice simple way to go about storing it, and whjilst I dont have huge amounts I do have a couple hundred dollars worth at home, at Aust $9.00 a sheet generally for 100mm x 1000mm for 1.0mm through to 6.5mm , more expensive as it gets thicker but sheet size here is generally 1000 x 100 mm or 3 ft x 4 inches, plus I have expensive leading edge balsa, so it doesnt take a lot to add up and be worth the effort to store a bit better than I do.

Nice having a source of balsa even if you have to do some work to get it how you want it! I will set mine up in some cardboard boxes also. Seems like a nice simple way to go about storing it, and whjilst I dont have huge amounts I do have a couple hundred dollars worth at home, at Aust $9.00 a sheet generally for 100mm x 1000mm for 1.0mm through to 6.5mm , more expensive as it gets thicker but sheet size here is generally 1000 x 100 mm or 3 ft x 4 inches, plus I have expensive leading edge balsa, so it doesnt take a lot to add up and be worth the effort to store a bit better than I do.We have a Balsa sheet and ply sheet making factory nearby that have their own plantation. They make beutiful almost perfect balsa sheets, but pricy, they are mainly for the Craft market. But their balsa that is end cut, end sanded, out of spec type balsa they put on a trolley in bundles and you can take two bundles for free, which is pretty cool. They say they would prefer it to be free and get used than throw it away!!

You are really going one step further than all of us who claim to be "from scratch" builders, and making your own balsa sheets. Now that is truly from scratch!

Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Yabby wrote:Thanks for the explanation RoddieNice having a source of balsa even if you have to do some work to get it how you want it! I will set mine up in some cardboard boxes also. Seems like a nice simple way to go about storing it, and whjilst I dont have huge amounts I do have a couple hundred dollars worth at home, at Aust $9.00 a sheet generally for 100mm x 1000mm for 1.0mm through to 6.5mm , more expensive as it gets thicker but sheet size here is generally 1000 x 100 mm or 3 ft x 4 inches, plus I have expensive leading edge balsa, so it doesnt take a lot to add up and be worth the effort to store a bit better than I do.

We have a Balsa sheet and ply sheet making factory nearby that have their own plantation. They make beutiful almost perfect balsa sheets, but pricy, they are mainly for the Craft market. But their balsa that is end cut, end sanded, out of spec type balsa they put on a trolley in bundles and you can take two bundles for free, which is pretty cool. They say they would prefer it to be free and get used than throw it away!!

You are really going one step further than all of us who claim to be "from scratch" builders, and making your own balsa sheets. Now that is truly from scratch!

Yabby

Hello Yabby! Thanks for the post. I assume that the 3ft. (1000mm?) length that's sold as hobby balsa, seems to be fairly standard globally.

Regarding the balsa supplier nearby to you; get as much of that stock as you can store. It will never be cheaper.. and if you don't use it.. it's biodegradable..

I have a couple of "blocks" of the 1.75" thick wood, that are large/long enough to cut blanks from, to use as "hollow-log" type fuselages.

"Blackhawk Models" has a few designs that use a block for the fuse. It can look a LOT nicer than a profile fuselage.. but at a BIG weight penalty. Carving "your own" from a virgin block of wood is not for the faint of heart.

Short pieces/blocks of that nearby supplier's wood could be cut on a small table-saw into useful stock for making a stack of wing-ribs.. bulkheads, formers, and when building 1/2A.... tail-plane components. You can use hole-saws to form the openings in bulkheads.. just finish-off with an X-acto straight-blade and steel rule (straight edge).

Yes.. I consider myself a scratch-builder. The satisfaction alone... is worth the time spent................ for me that is.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

So... I plan to cut the pieces for the sheet-wing. It's constant-chord is X2 the width of the stock I'm using.. which equals 3.5". The span is 21" at the trailing tip and 20" at the leading tip. This computes to 71.75 sq. in. and will use the 1/8" wood. It will be X4 pieces; 2@ 16"L. and X2@ 5"L. using staggered butt-joints fastened with thick/Gel CA glue. I use recycled wax-paper that I save......... for just such an occasion. A nice flat table-top with wax-paper works very well for butt-jointing your work pieces together.. without any sticking to the table.

The wing-tip profile can be formed instantly with a razor-saw. At this point.. your wing is made..

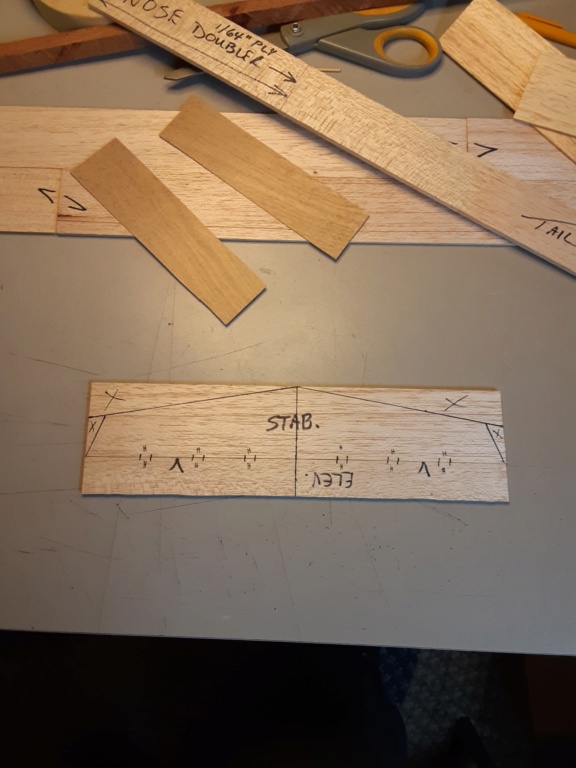

Here is about 20 mins. work laying-out/cutting the pieces for the wing.

The stabilizer will be 1/2 the chord of the wing @1.75". The span is a planned 11". The elevator span is the same as the stab. with a chord measuring 50% (or .875")

The wing-tip profile can be formed instantly with a razor-saw. At this point.. your wing is made..

Here is about 20 mins. work laying-out/cutting the pieces for the wing.

The stabilizer will be 1/2 the chord of the wing @1.75". The span is a planned 11". The elevator span is the same as the stab. with a chord measuring 50% (or .875")

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Tonight I cut the sheet-stab./elev. pieces from my 1/8" thickness balsa. It's beginning to take shape.

I'll weigh all of the wood components prior to assembly. I still need to fabricate a fuselage (w/doublers), engine-mount system and fin/rudder. The wing and tail-plane will also have "swept-tips" once finished. The fin/rudder will be a low-profile arrangement...

I'll weigh all of the wood components prior to assembly. I still need to fabricate a fuselage (w/doublers), engine-mount system and fin/rudder. The wing and tail-plane will also have "swept-tips" once finished. The fin/rudder will be a low-profile arrangement...

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

roddie wrote:

Yes.. I consider myself a scratch-builder. The satisfaction alone... is worth the time spent................ for me that is.

Good ideas Roddie! Yes, the free balsa has been used to cut ribs, rudders, tailplanes, all sorts of things. I really like the peoples mindset that they would rather give it away than throw it away. Its not a common thing these days.

I also consider my self a scratch builder, and mostly my own designs. I do it that way, for probably the same reason. The satisfaction when it comes together and I fly it. my design, my build. my plane. for better or worse.

and there has been plenety of worse HaHaHa. The only down side, is I dont actually enjoy building models particularly. But I love the design process ( ideas, reading, looking at other planes, trying to learn) and the flying part. I dont mind building slab wing profiles as they are relatively simple for me to build and I have found regardless of what people say, there is a Lot of room to make a slab wing profile perform quite well and on quite long lines. But it takes some fiddling the design to get there. I enjoy that a lot.

and there has been plenety of worse HaHaHa. The only down side, is I dont actually enjoy building models particularly. But I love the design process ( ideas, reading, looking at other planes, trying to learn) and the flying part. I dont mind building slab wing profiles as they are relatively simple for me to build and I have found regardless of what people say, there is a Lot of room to make a slab wing profile perform quite well and on quite long lines. But it takes some fiddling the design to get there. I enjoy that a lot. I have never deliberately built any speed planes, so I think that is something I might start building / designing this afternoon. Its tippped over the 108 deg where I am. Too hot to go flying thats for sure.

So, Ill sit inside and read up on the various CL 049 speed classes/rules/comps etc. and maybe design and build a speed plane. I think that will be fun to build also. As it will be different but not too tricky.

So, Ill sit inside and read up on the various CL 049 speed classes/rules/comps etc. and maybe design and build a speed plane. I think that will be fun to build also. As it will be different but not too tricky. Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Yabby wrote:roddie wrote:

Yes.. I consider myself a scratch-builder. The satisfaction alone... is worth the time spent................ for me that is.

Good ideas Roddie! Yes, the free balsa has been used to cut ribs, rudders, tailplanes, all sorts of things. I really like the peoples mindset that they would rather give it away than throw it away. Its not a common thing these days.

I also consider my self a scratch builder, and mostly my own designs. I do it that way, for probably the same reason. The satisfaction when it comes together and I fly it. my design, my build. my plane. for better or worse.and there has been plenety of worse HaHaHa. The only down side, is I dont actually enjoy building models particularly. But I love the design process ( ideas, reading, looking at other planes, trying to learn) and the flying part. I dont mind building slab wing profiles as they are relatively simple for me to build and I have found regardless of what people say, there is a Lot of room to make a slab wing profile perform quite well and on quite long lines. But it takes some fiddling the design to get there. I enjoy that a lot.

I have never deliberately built any speed planes, so I think that is something I might start building / designing this afternoon. Its tippped over the 108 deg where I am. Too hot to go flying thats for sure.So, Ill sit inside and read up on the various CL 049 speed classes/rules/comps etc. and maybe design and build a speed plane. I think that will be fun to build also. As it will be different but not too tricky.

Yabby

Hi Gary! It's very interesting to read your replies to me. We have similar interests regarding small slab-wing profiles for control-line flying.

This afternoon, I am setting-up for when it's time to use CA adhesive. I have an allergy to CA (upper-respiratory/sinus-congestion). When CA "kicks".. vapors are released which I should avoid.

In contrast; it's a bit colder here in Northern Rhode Island (USA).. so working outdoors is unfavorable. Providing "fresh-air" to indoors would be key.. but the next best thing is to provide some air circulation in the immediate area where I'm working. I'm not working with the CA for very long.. but exposure can happen quickly.. if measures aren't taken to divert vapors away from the work area.

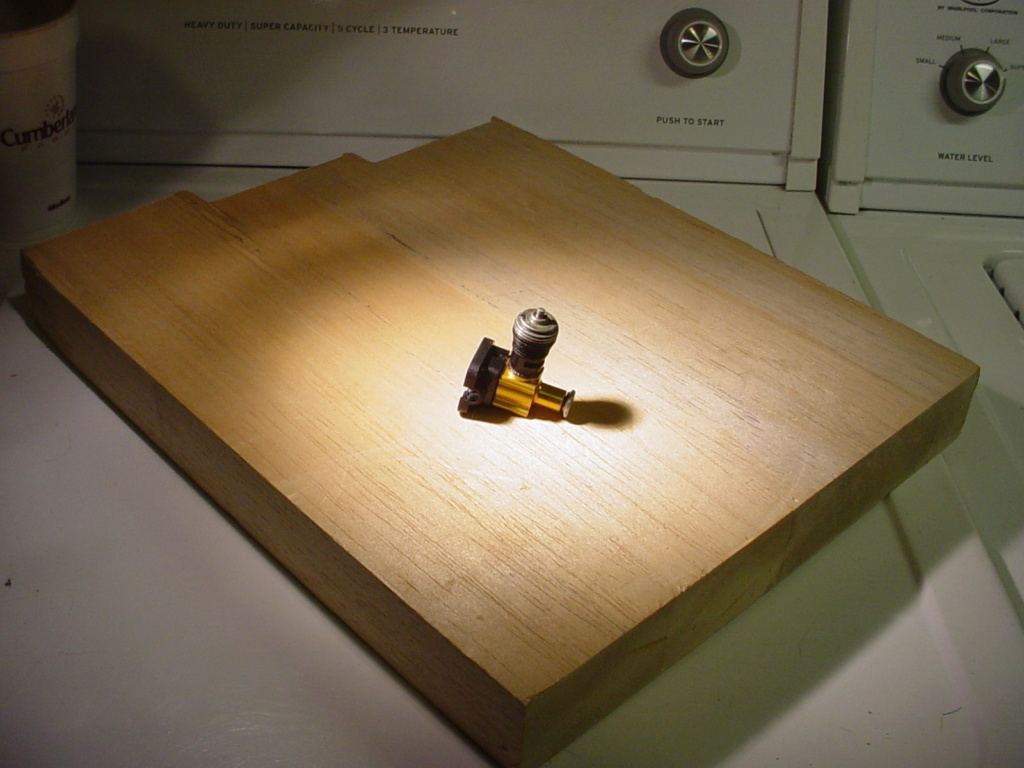

The below photo shows an upstream set-up that has worked for me.

A bit of a PIA to hang a box-fan blowing behind me.. but nothing compared to an allergic reaction to the CA.

The four wing panels will be edge-glued/butt-jointed together to form a 21" span/3.5" chord sheet-wing blank. I use gel-type CA for this and lay out wax-paper to work over. Glued parts won't stick to wax paper.

Before the CA application, I will layout the 3/16" balsa for the fuse and cut the 1/64" (wing-skin) ply for the doublers. The doublers will also be applied with the thick (gel) CA. The fuselage; where the doublers contact, can and will be perforated using sewing-pin "pricks" in a grid-pattern to help with leveling.. which can be done when using any liquid-glue or adhesive.

I'll cut the slot for the wing.. after the doublers are applied. That's always been the tricky part for me; cutting sheet-wing/stab slots as close to 90 degrees to the fuse as possible.

The next step will be to cut two square hardwood blocks for the "radial" engine mounts. These mounts will be drilled to accept through-pins (round birch toothpicks) from one side to the other.. and be epoxy-glued as an assembly, to the nose of the fuse. The 3/16" (.187"/4.8mm) balsa that I'm using for the fuse, is C-grain and pretty tough in itself.. without the doublers.. but the nose will be stronger with them.. at a minimum weight penalty. It's just one of my quirky ways of designing.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

A fairly productive day with the TBD1 today. I picked through my 3/16" thickness X 1.75"w. balsa for a piece best suited for my profile fuse. I then set up my old table-saw to rip a 1.5"w. piece from a 19.5" length.

Then I measured-out and cut the pair of 1/64" ply nose-doublers with my sharpest scissors. Cuts as easy as cardstock..

I mentioned previously that this balsa came from a large laminated "plank" that was finger-jointed together. My fuse piece has a joint which shows the difference in wood-grain/density.

The "C" grain is biassed toward the nose, where the extra strength/density can do the most good.

Then I measured-out and cut the pair of 1/64" ply nose-doublers with my sharpest scissors. Cuts as easy as cardstock..

I mentioned previously that this balsa came from a large laminated "plank" that was finger-jointed together. My fuse piece has a joint which shows the difference in wood-grain/density.

The "C" grain is biassed toward the nose, where the extra strength/density can do the most good.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Hey Roddie, love the way you can cut through the ply like card. Looks like you have good cutters for them and also some excelletn nice thin ply. That is something I cannot obtain over here at close to reasonable price. Balsa yes, ply No. Like the old machine with the huge machine sized square for squaring things. As I said before Roddie you are absolutely the most Scratch builder. Only thing you could do more would be to grow your own balsa trees.

I look foward to watching each installment of the TDB1 build log.

GaryB

'Yabby'

I look foward to watching each installment of the TDB1 build log.

GaryB

'Yabby'

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Yabby wrote:Hey Roddie, love the way you can cut through the ply like card. Looks like you have good cutters for them and also some excelletn nice thin ply. That is something I cannot obtain over here at close to reasonable price. Balsa yes, ply No. Like the old machine with the huge machine sized square for squaring things. As I said before Roddie you are absolutely the most Scratch builder. Only thing you could do more would be to grow your own balsa trees.

I look foward to watching each installment of the TDB1 build log.

GaryB

'Yabby'

Thanks Gary!

A bit more done over the last day and half.. The stab./elev. was further laid-out.

Then I decided to cut a pair of 1/2" sq. hardwood blocks for the radial engine mount. (the type I usually make)

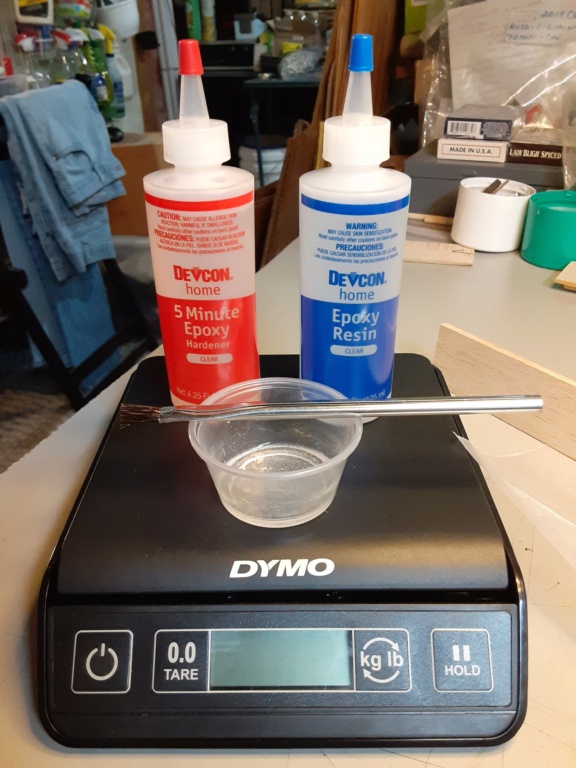

I'm using fast-curing (5 min.) epoxy for the first time.. and decided to weigh the separate components for an accurate 50/50 mix.

I trim the flux-brush's bristles shorter with scissors to aid in the mixing and spreading process.

I wanted enough of a mix to glue my 1/64" ply nose-doublers onto the 3/16" balsa fuse. It turned-out that 8 gr. (4/4) was probably twice as much as I needed.

After the doublers had cured, I glued-up and clamped the two engine mount blocks.

That's enough for tonight.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Interesting log Roddie! I think, (I know) I am going to learning a lot of building tricks and methods watching you do this. Its good to learn and understand other methods of building as it improves my builds, simple as they are, and I enjoy watching the builds and the picture logs as they evolve. A hint from @balogh recently about using a small piece of balsa above and below holes in the wing but with the grain crossed to help stop splitting has been so helpful. I had used balsa pieces top and bottom but didnt place them cross grain to the wing. These hints and watching builds are really helpful as I often miss the obvious.

Good progress so far Roddie!

GaryB

'Yabby'

Good progress so far Roddie!

GaryB

'Yabby'

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Thought I would drop by and see what's happening over here , Looking good so far brother , I am sure it will bee another gorgeous plane for the fleet .

Thought I would drop by and see what's happening over here , Looking good so far brother , I am sure it will bee another gorgeous plane for the fleet .

getback- Top Poster

Posts : 10448

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Plus one from me Roddie…Like how you “read” the wood for the fuse….. Methodical thought process, nice so far!!

Robert

Robert

rdw777- Diamond Member

Posts : 1723

Join date : 2021-03-11

Location : West Texas

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

I see you are using 'Devcon' products Roddie! Excellent products. I havent used them for many years.

Used to use them for modifying inlet and exhaust ports of barrells where we would machine the ports completely (Machine an entire external Reed Block away )out and then build them up with Devcon Aluminium paste and later they could be machined into the new shape with the new volume etc. Devcon was the only product I knew that worked on inlets as when mixed properly and let set properly it did not go porous and leak air like some other did.

Not common product line in Oz, not at least where I shop. They also made/make a grey rubber type gasket sealant that doesnt ball up and go through engines and block oil galleries like some sealants. I just looked them up on the net and now I remember the other thing about Devcon was its $$$$$price, but then again it worked

GaryB

'Yabby'

Used to use them for modifying inlet and exhaust ports of barrells where we would machine the ports completely (Machine an entire external Reed Block away )out and then build them up with Devcon Aluminium paste and later they could be machined into the new shape with the new volume etc. Devcon was the only product I knew that worked on inlets as when mixed properly and let set properly it did not go porous and leak air like some other did.

Not common product line in Oz, not at least where I shop. They also made/make a grey rubber type gasket sealant that doesnt ball up and go through engines and block oil galleries like some sealants. I just looked them up on the net and now I remember the other thing about Devcon was its $$$$$price, but then again it worked

GaryB

'Yabby'

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Yabby wrote:Interesting log Roddie! I think, (I know) I am going to learning a lot of building tricks and methods watching you do this. Its good to learn and understand other methods of building as it improves my builds, simple as they are, and I enjoy watching the builds and the picture logs as they evolve. A hint from @balogh recently about using a small piece of balsa above and below holes in the wing but with the grain crossed to help stop splitting has been so helpful. I had used balsa pieces top and bottom but didnt place them cross grain to the wing. These hints and watching builds are really helpful as I often miss the obvious.

Good progress so far Roddie!

GaryB

'Yabby'

Thanks again Gary. Always remember that it's always better to build "light" than strong. If you can find compromise between the two.. then you're on the right track. My builds tend to be heavier than they should be. They've been 1/2A C/L slab-wing profile models.. "Kitwood" built models are lighter than any of mine.

When I designed and built my entry for the first CEF "Reed Speed" contest (2014); a profi-scale event.. very similar to the/our AMA sanctioned national event. We were building straight-line/roundy-round models. "Kits" were non-existent. Entrants needed to get creative. The first year contest was well attended.. and worth searching CEF back-threads to see what we were building.

Anyway.. thanks again Gary; for your continued interest in my modeling. I'm building another over-built model I'm afraid.. but that's how I roll.

Last edited by roddie on Tue Jan 31, 2023 6:29 pm; edited 1 time in total (Reason for editing : grammar)

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

getback wrote:

Thought I would drop by and see what's happening over here , Looking good so far brother , I am sure it will bee another gorgeous plane for the fleet .

Hey! Come on in you old bugger...

them for points.

them for points.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

rdw777 wrote:Plus one from me Roddie…Like how you “read” the wood for the fuse….. Methodical thought process, nice so far!!

Robert

Hi Robert.. and "Thank You". The way the fuse is looking so far... is plenty-long..

I knew that it "might be".. but not as much as it looks like it should be..

I knew that it "might be".. but not as much as it looks like it should be.. yea..

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

Yabby wrote:I see you are using 'Devcon' products Roddie! Excellent products. I havent used them for many years.

Used to use them for modifying inlet and exhaust ports of barrells where we would machine the ports completely (Machine an entire external Reed Block away )out and then build them up with Devcon Aluminium paste and later they could be machined into the new shape with the new volume etc. Devcon was the only product I knew that worked on inlets as when mixed properly and let set properly it did not go porous and leak air like some other did.

Not common product line in Oz, not at least where I shop. They also made/make a grey rubber type gasket sealant that doesnt ball up and go through engines and block oil galleries like some sealants. I just looked them up on the net and now I remember the other thing about Devcon was its $$$$$price, but then again it worked

GaryB

'Yabby'

Hi Gary, The Devcon 5min. epoxy came from my local "Lowes" home centers; Lowes serves N. America only. Your experience with "Devcon-products" in a production-environment fascinates me.. as well as your electronics knowledge. We learn a lot from each other here on CEF.

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

roddie wrote: Always remember that it's always better to build "light" than strong. If you can find compromise between the two.. then you're on the right track. My builds tend to be heavier than they should be. They've been 1/2A C/L slab-wing profile models.. "Kitwood" built models are lighter than any of mine.I intended for this one to be my lightest-weight attempt on an acrobatic design.

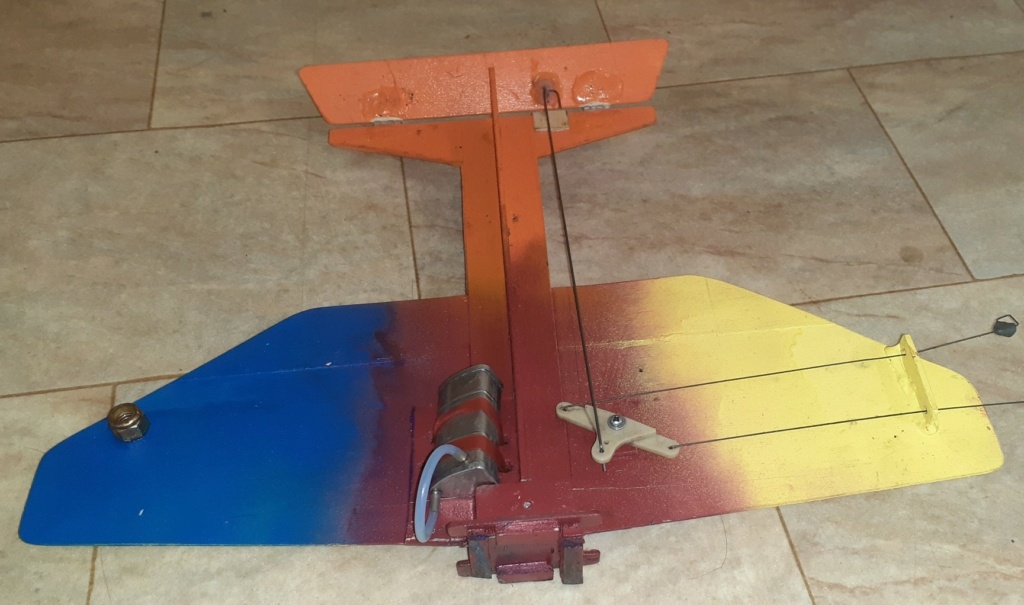

Goodaye Roddie, Keep building a bit on the heavy side, my experience of going t0o light follows; I flew my own design X1202 Slab/profile yesterday. Pictured below. It is light. It is fast, The wing area is concerntated heavily in the centre with narrow wing tips and deep centre chord. It glides really well for a slab. It is built entirely from 2mm or 1/16 balsa, excluding the engine mounts, and has a very fast TD 049 on it. The fuse is created using an 'I' beam approach to be very light, narrow and not flex much. The wing shape allows it to be flown very hard aerobatically. I fly it on 42 foot .008 steel and fly it very hard, especially entry and exits from wingovers. It is awesome fun to fly!

The wing has splits in it from flying ( 4 flights) which is dissapointing as it the best flying plane Ive designed and flown. It is splitting across the entire wing from behind the engine mount reinforcement blocks. The force in the turns of the engine is flexing and splitting the wing. I will have to reinforce my next one ( this one is scrap although I will keep the rear half and use it on another plane) and am debating going to 2.5mm - roughly 3/32 for the wing only and reinforcing it below the wing, with a plate the width of the engine mount going back 100mm. This has worked on other models I have built but adds weight.

Finding the compromise can be hard. But I think I have found one side of the compromise and now need to come back a fraction unfortunately.

I wish I could get that beutiful 1/64 ply here at an acceptable price. I think used judiciously it probably provides a positive weight strength compromise. Watching your build will be more so interesting for your techniques and design as slab / profile is my real interest in modelling so its directly applicable to my own builds.

GaryB

'Yabby'

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: T-Bee-D1 (a Rod-de-sign)

Re: T-Bee-D1 (a Rod-de-sign)

roddie wrote:

Hi Gary, The Devcon 5min. epoxy came from my local "Lowes" home centers; Lowes serves N. America only. Your experience with "Devcon-products" in a production-environment fascinates me.. as well as your electronics knowledge. We learn a lot from each other here on CEF.

Hi Roddie, yes the forum is and can be a great source of knowledge and sharing knowledge and ideas ( ideas are very important) and huge amounts are learnt from each other on the forum. My modelling and enjoyment of modelling has progressed a huge amount since I joined the forum from all of the posts and threads and help and sharing from people.

I have certainly learnt how I am going to build a starter not only from your posts and threads but all of the others that responded with ideas and different experiences, which in the end distilled down into a very solid common design for a starter. I see you bumped your muffler thread a while ago, that also interests me quite a bit.

I have certainly learnt how I am going to build a starter not only from your posts and threads but all of the others that responded with ideas and different experiences, which in the end distilled down into a very solid common design for a starter. I see you bumped your muffler thread a while ago, that also interests me quite a bit.  And as you build slab/profile its great to see you logging the build. My build skills and techniques are poor and I do learn a real a lot from logs such as yours and some very notable other members (rather mention none than leave one out) .

And as you build slab/profile its great to see you logging the build. My build skills and techniques are poor and I do learn a real a lot from logs such as yours and some very notable other members (rather mention none than leave one out) . GaryB

'Yabby'

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Page 2 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Similar topics

Similar topics» Stopped by the local sign shop today.

» Sign of the times

» ***The Traveling Engine TD .049*** SIGN UP!

» Brodak Stop Sign

» Can't sign up for Yahoo - But Comet RTF question

» Sign of the times

» ***The Traveling Engine TD .049*** SIGN UP!

» Brodak Stop Sign

» Can't sign up for Yahoo - But Comet RTF question

Page 2 of 8

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules