Log in

Search

Latest topics

» TEE DEE Having issuesby balogh Today at 7:42 am

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 7:36 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

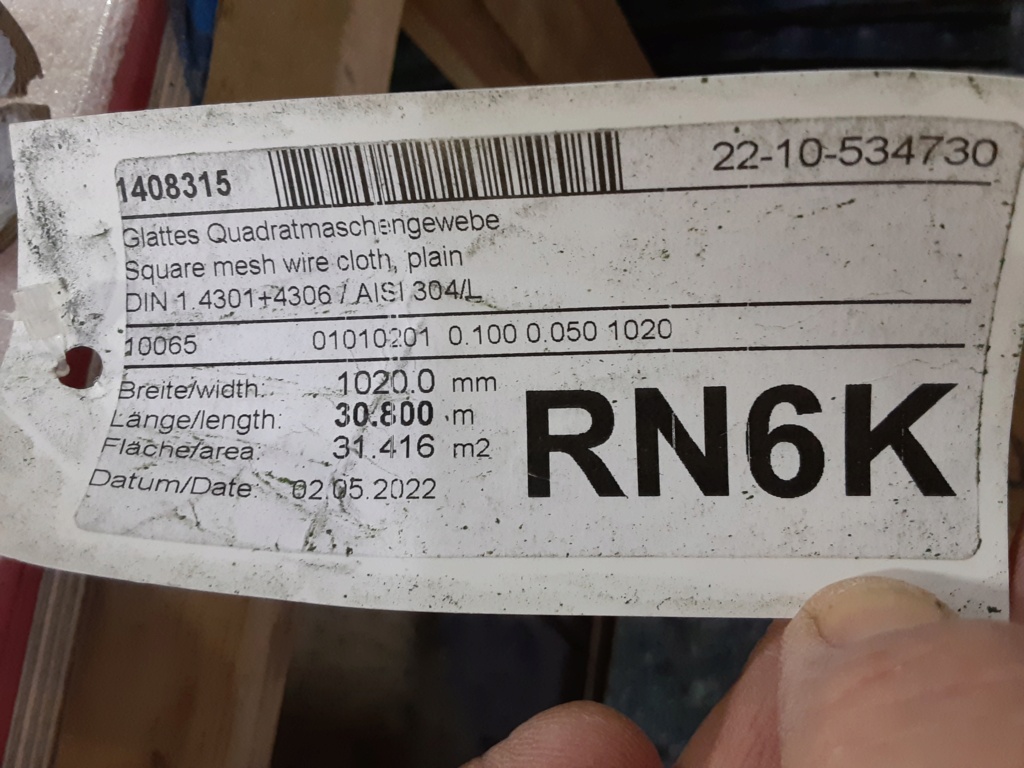

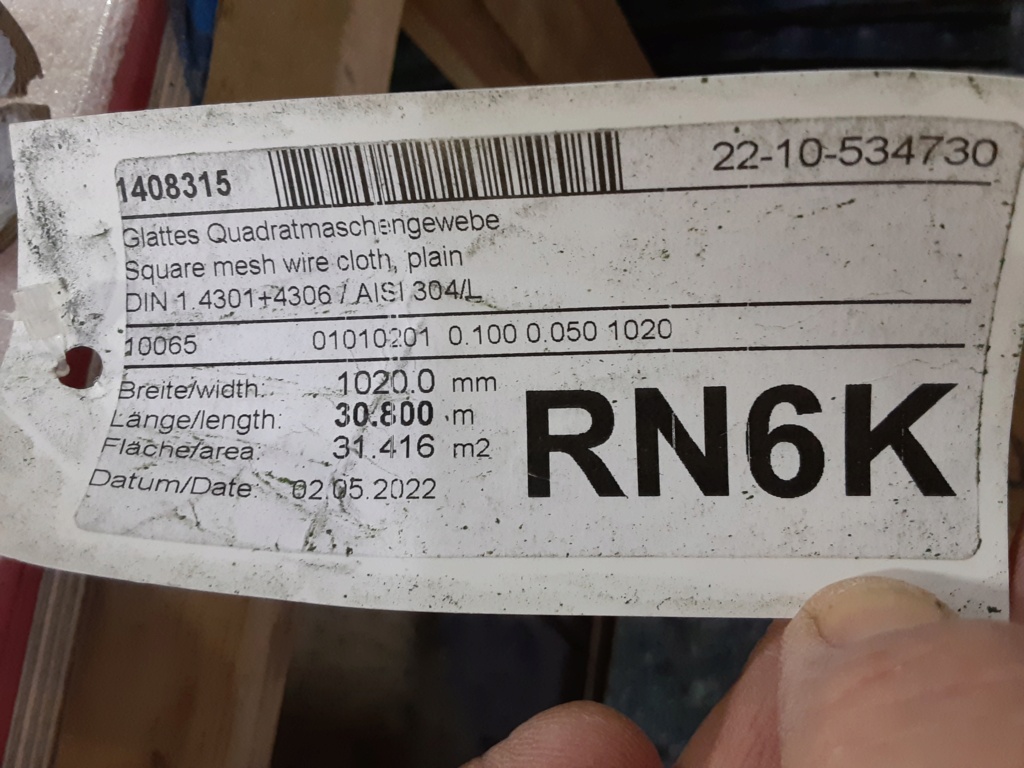

nano-mesh (T304L)

Page 1 of 1

nano-mesh (T304L)

nano-mesh (T304L)

I have some of this material. My employer sources it for our WR (Weather Resistant) speaker enclosures. The grilles which protect the drivers mounted in these enclosures are backed with acoustic Polyurethane foam which is resistant to UV. The foam is then backed with this; what I call nano-mesh and is used to prevent the ingress of wind-driven precipitation on the enclosure's drivers.

[EDIT-ADD] The sheet is .004" thickness T304L stainless steel and is non magnetic.

It would be expected to have a service-life of at least 10 years exposure to the elements for its intended use. [EDIT-END]

I grabbed a scrap piece from the trash to make an evaluation as to whether I/we could utilize it somewhere in our modeling hobby.. or possibly other applications as a filtering-media.

Some photos..

It could possibly be used in place of glass-mat/screen when used with epoxy. [EDIT-ADD] Brazing applications would also be possible.

[EDIT-ADD] The sheet is .004" thickness T304L stainless steel and is non magnetic.

It would be expected to have a service-life of at least 10 years exposure to the elements for its intended use. [EDIT-END]

I grabbed a scrap piece from the trash to make an evaluation as to whether I/we could utilize it somewhere in our modeling hobby.. or possibly other applications as a filtering-media.

Some photos..

It could possibly be used in place of glass-mat/screen when used with epoxy. [EDIT-ADD] Brazing applications would also be possible.

Last edited by roddie on Fri Dec 23, 2022 5:56 pm; edited 2 times in total (Reason for editing : more discovery)

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

Hi roddie,

Using it as a lightning rod covering,

To fly a Cox engine through a lightning strike ?

All puns are intended...

Take care,

Have fun,

Dave

Using it as a lightning rod covering,

To fly a Cox engine through a lightning strike ?

All puns are intended...

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

I looked at it and thought - something to replace the deteriorating filtering mesh in my Rx-7s fuel tank.

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

I would bet that would strengthen up a fuselage quite nicely if doped on. I know Allen Brickhaus was using 3/4 oz. glass applied with Minwax water based poly. He would use the mesh as a reference. After two additional coats of the poly, he would use Rustoleum lacquer primer and spray the entire model. Next was to wet sand down to the mesh. Put it on, sand it off so to speak. I would think this material Roddie would go around compound curves quite effectively unlike carbon veil.

Ken Cook- Top Poster

- Posts : 5641

Join date : 2012-03-27

Location : pennsylvania

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

I was thinking similar to Ken. Possibly used for wrapping a wing center section instead of glass cloth?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

rsv1cox wrote:I looked at it and thought - something to replace the deteriorating filtering mesh in my Rx-7s fuel tank.

PM me with the approximate size you need, and I'll mail you some Robert.

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

NEW222 wrote:I was thinking similar to Ken. Possibly used for wrapping a wing center section instead of glass cloth?

This material comes in a roll and is laser-cut in our shop, to fit numerous sizes of speaker grilles. I'll ask the laser operator to save what would normally be discarded.. and we'll see what sizes those remnants are.

I have yours, Ken's and Robert's addresses on file and can mail you some samples to try.

more discovery

more discovery

So.. today I checked for a material spec. and found this to be T304L stainless steel. I edited my opening post to reflect that information. I believe that the "L" designation imparts a "Low Carbon" grade of 304 stainless steel.

I also discovered the existence of another "thicker" (.010") sheet which has a brighter (silver-tone) appearance. It's noticeably heavier at more than twice the wire-size/diameter.

What surprises me; is that such a fine mesh can be acoustically-transparent. Apparently the "pressure-wave" of high-output audio penetrates-through the fine screen.. and blows-off any accumulated moisture.. Yea.. I'm going with that.

Yea.. I'm going with that.

I also discovered the existence of another "thicker" (.010") sheet which has a brighter (silver-tone) appearance. It's noticeably heavier at more than twice the wire-size/diameter.

What surprises me; is that such a fine mesh can be acoustically-transparent. Apparently the "pressure-wave" of high-output audio penetrates-through the fine screen.. and blows-off any accumulated moisture..

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

If water droplets can't get through it, does this suggest it could shed spent castor?

How heavy is it compared to the same size sheet of tissue?

I'm wondering if it could be used to sheet a wing...the engine running may impart enough of a harmonic vibration to shake off exhaust.

How heavy is it compared to the same size sheet of tissue?

I'm wondering if it could be used to sheet a wing...the engine running may impart enough of a harmonic vibration to shake off exhaust.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

944_Jim wrote:If water droplets can't get through it, does this suggest it could shed spent castor?

How heavy is it compared to the same size sheet of tissue?

I'm wondering if it could be used to sheet a wing...the engine running may impart enough of a harmonic vibration to shake off exhaust.

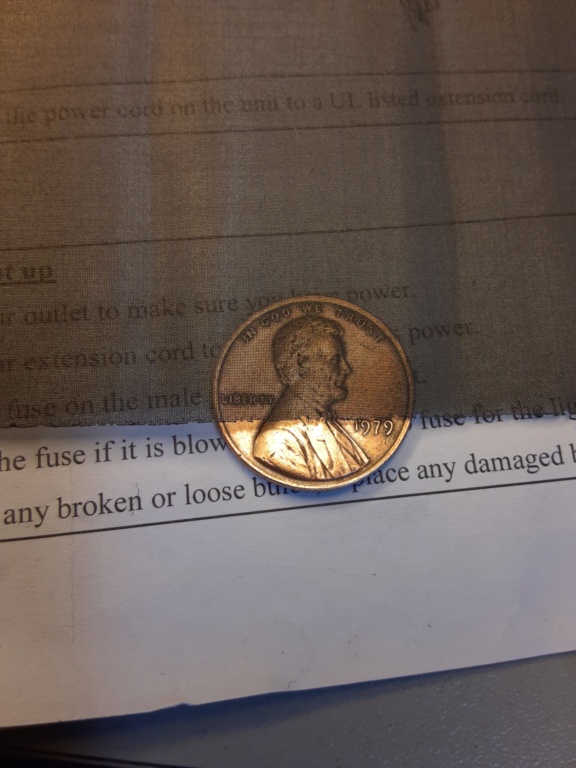

Compared to any tissue paper or silk-screen.. this .004" stainless steel screen is heavier. Heavier than actual "silk"..?? I would think so.. but I'm not certain.

It would be interesting to sheet a handful of model-airfoils with this screen material adhered to the framework.. but not doped/sealed in-between.. for some wind-tunnel testing. Maybe such a "skin" could provide stealth characteristics.. along with enhanced maneuverability. Can air be grabbed.. like a tire grabs a road-surface? Sub-Sonic Vs. Super-Sonic Vs. Hyper-Sonic.

Some cool photos I found while searching for Valkyrie aircraft. 1st photo is of a modern drone designated XQ-58A.

The North American XB-70 is a very interesting subject to read about. HERE

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

Screen for an air filter, fuel filter replacement, or maybe an exhaust baffle if it doesn't plug up.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

aspeed wrote:Screen for an air filter, fuel filter replacement, or maybe an exhaust baffle if it doesn't plug up.

Yes Alan.. Filtering comes to mind 1st off.. but the screen is quite small.. and could be too small to "free-flow' either air or liquid, depending on the application. For "our" purposes; its use as a fuel-filter element should work... if placed downstream from a pressure-bladder feed.

I'll reiterate; the actual application for this mesh is to prevent wind-driven precipitation from getting into a permanently-installed outdoor enclosure and its electronics.. through the "front" (projection) port(s).

I haven't tried this.. but I'd bet that if I held a sheet under running-water.. that it would not readily pass though; but would mostly deflect away. In a vertically installed app (as it's intended).. any ingress of water merely drips as "droplets" down into a drain channel just behind the grille.

I need a magnifying-glass to see the actual resolution of the screen. A loupe is preferred for making comparisons with other sizes.

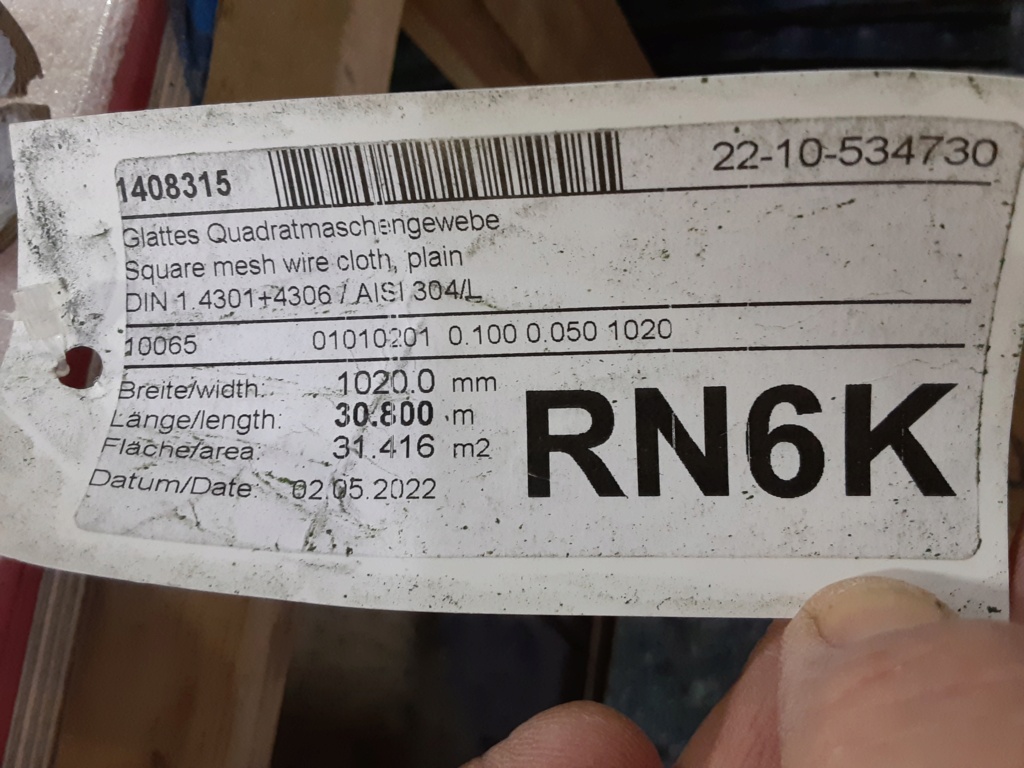

Below is a photo of the "tag" that came on the roll.

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

I would use it for filtration. I use a 100 mesh for filtering and water flows right through. This is 200 mesh and I would expect no difference. I think Cox intake screens are about 100 mesh. Mesh is openings per inch. For something like wing centers, glass cloth will be much lighter and easier to work with.

This stuff is ~390 g/m^2 and opaque monokote is 70-80 g/m^2.

The mesh on a microwave window reflects 100% of the radiation inside.

This stuff is ~390 g/m^2 and opaque monokote is 70-80 g/m^2.

The mesh on a microwave window reflects 100% of the radiation inside.

gkamysz- Gold Member

- Posts : 416

Join date : 2018-02-22

Location : Chicagoland

Re: nano-mesh (T304L)

Re: nano-mesh (T304L)

Sounds like some expensive stuff , I would think glassing with it would work well and according to those figures fuel filter insert . Probably have a look to it after glassing but maybe not soak through to get epoxy all over your fingers .

Sounds like some expensive stuff , I would think glassing with it would work well and according to those figures fuel filter insert . Probably have a look to it after glassing but maybe not soak through to get epoxy all over your fingers .

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» Cox .01 /.02 /.05 /.09 /.15 Speed Planes

» Plane for a nano bee

» Non-Cox Engine of the Month Contest?

» The Last Valentine Nano Bee

» Mesh screen .049 Cox engines

» Plane for a nano bee

» Non-Cox Engine of the Month Contest?

» The Last Valentine Nano Bee

» Mesh screen .049 Cox engines

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules