Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Tether Car Speed entry

Page 1 of 1

Tether Car Speed entry

Tether Car Speed entry

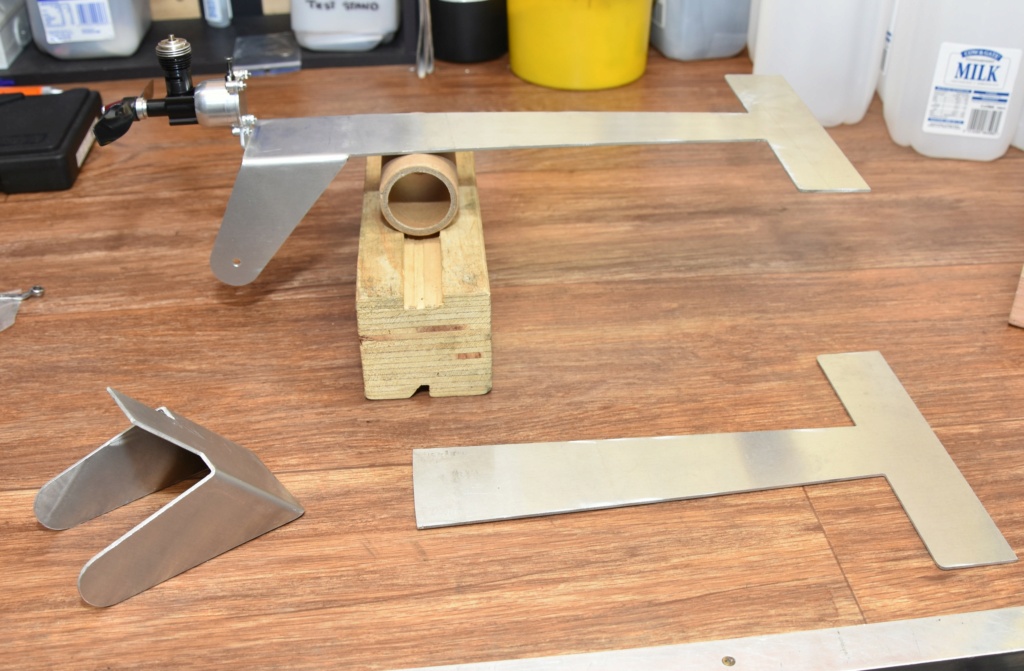

Having posted the general idea of my entry into the Tether Car Speed competition I will post the build here.

This Russian Speed Tether Car gave me the idea for the type of design I decided to build.

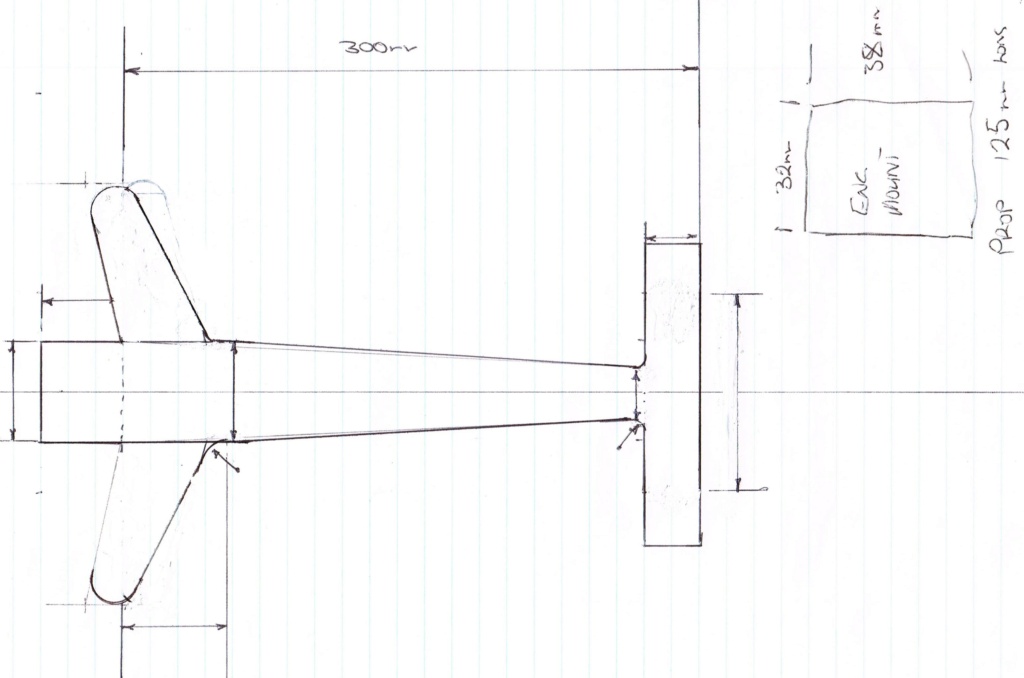

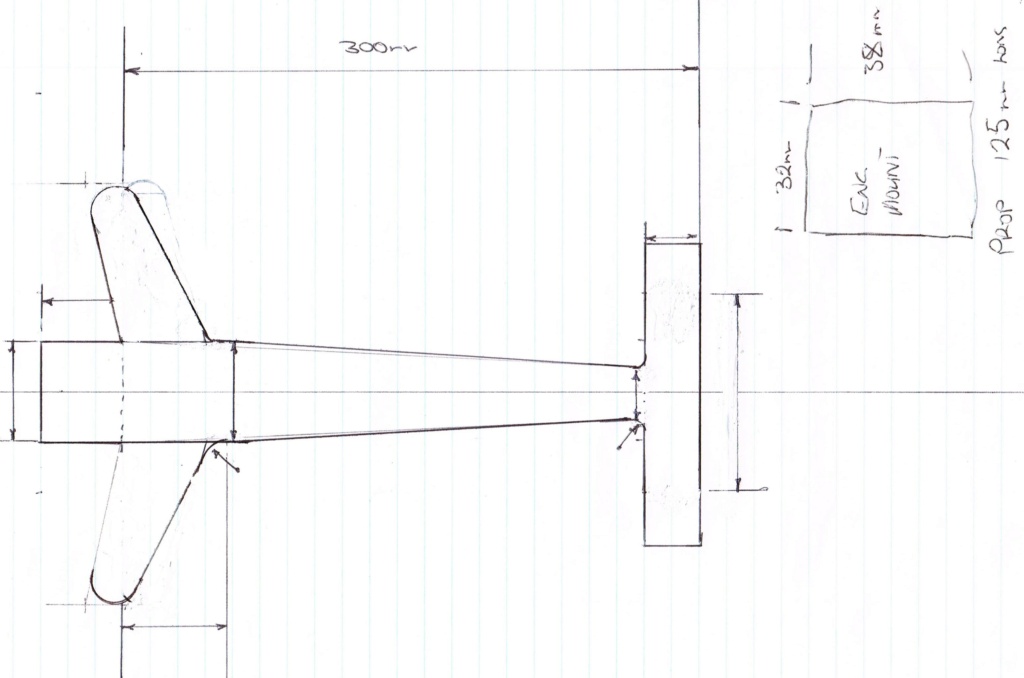

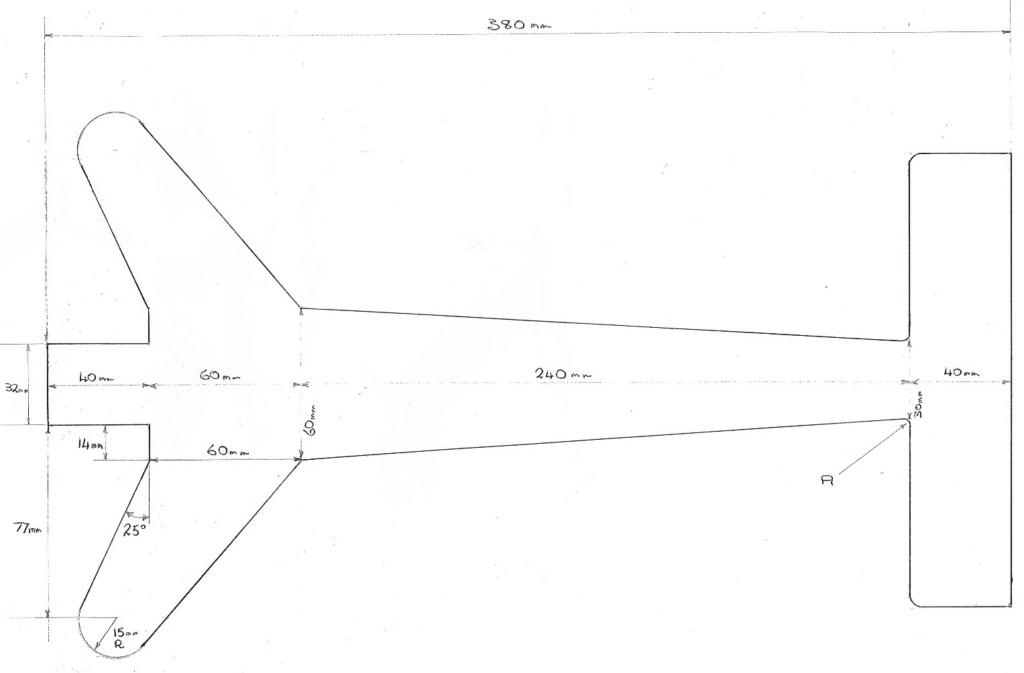

Rough sketch of design.

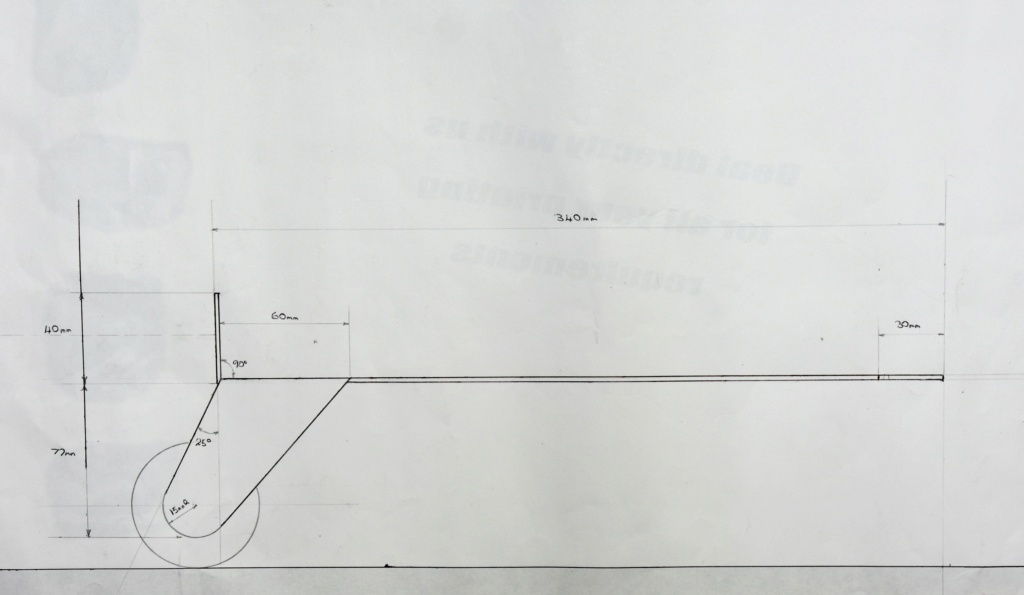

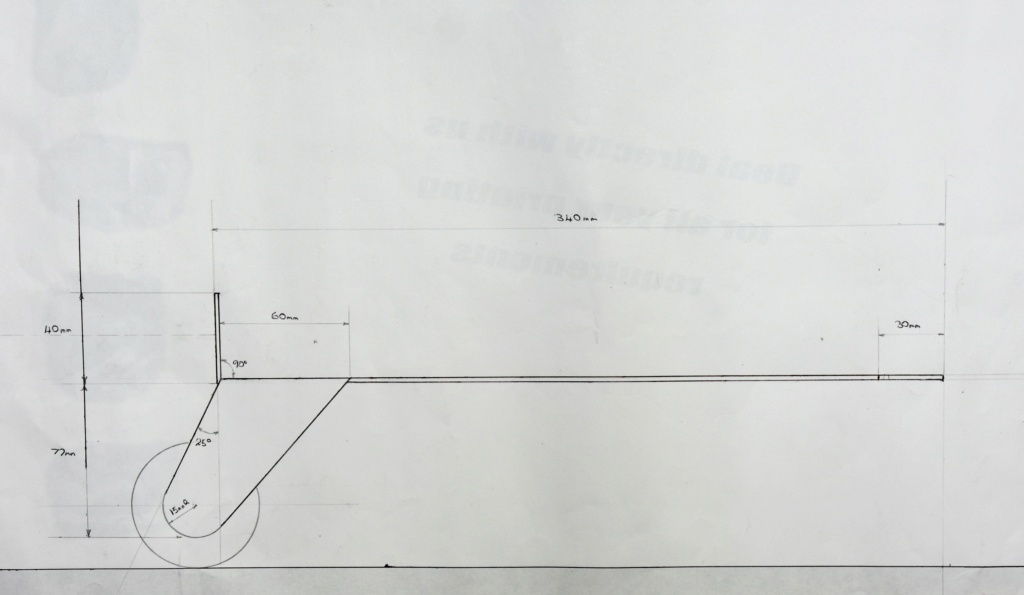

Scale side view mainly to work out prop ground clearance

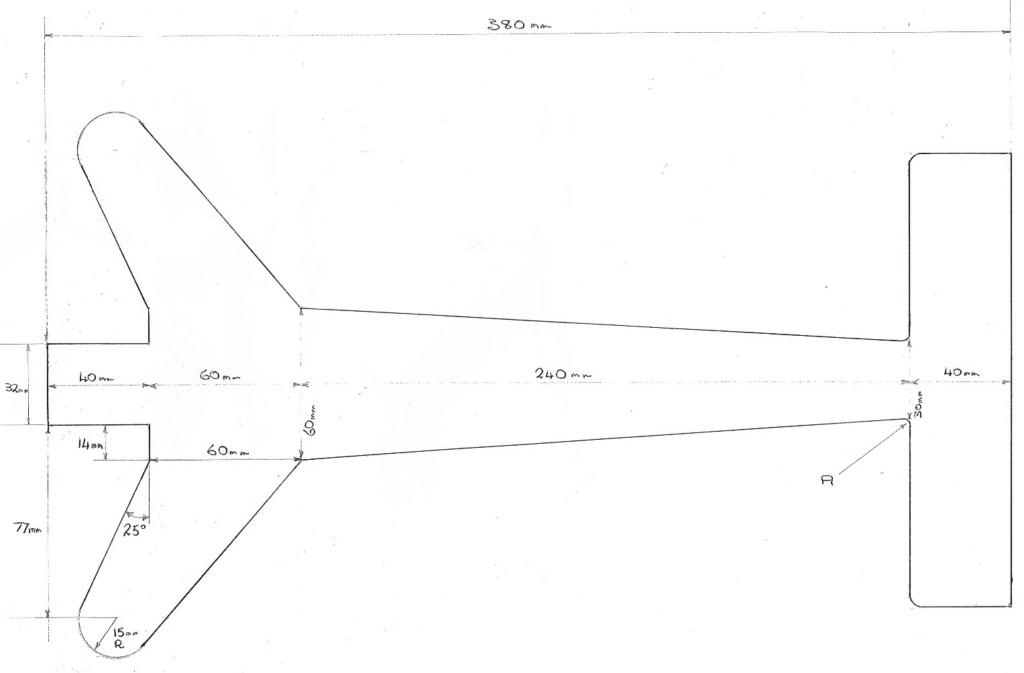

Scale drawing of final measurements sent to Waterjet Cutters

Since most of the cost involved is the programming it’s only material cost for an extra one.

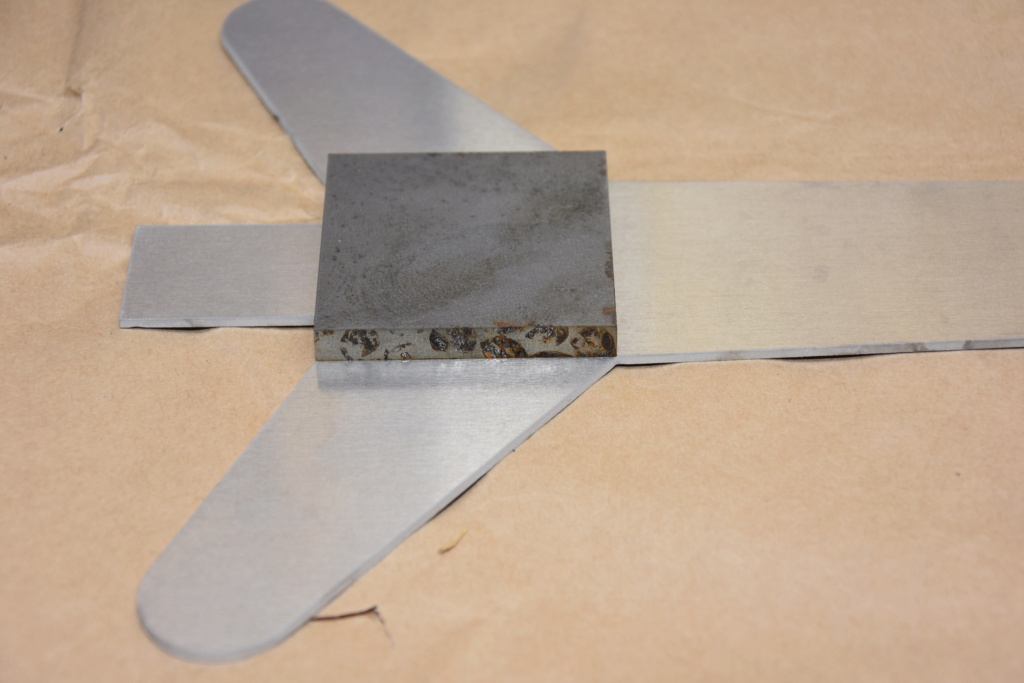

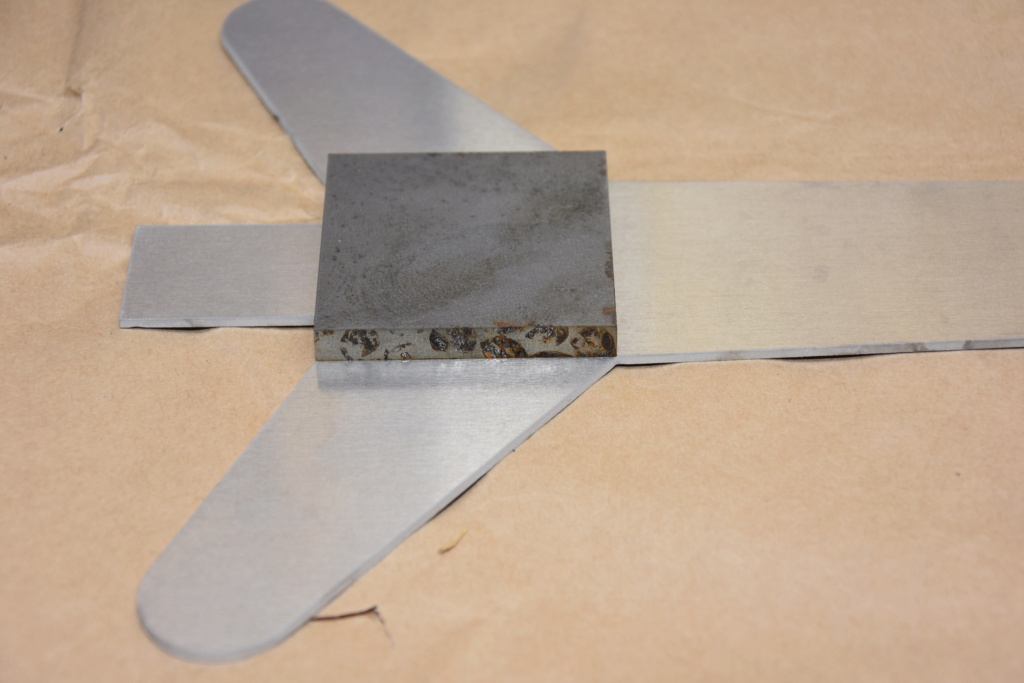

Also had a piece of steel cut 60mm x 60mm x 8mm thick, which the reason for will become obvious in the next photos.

The steel piece will be used as a former to help shape the bends accurately.

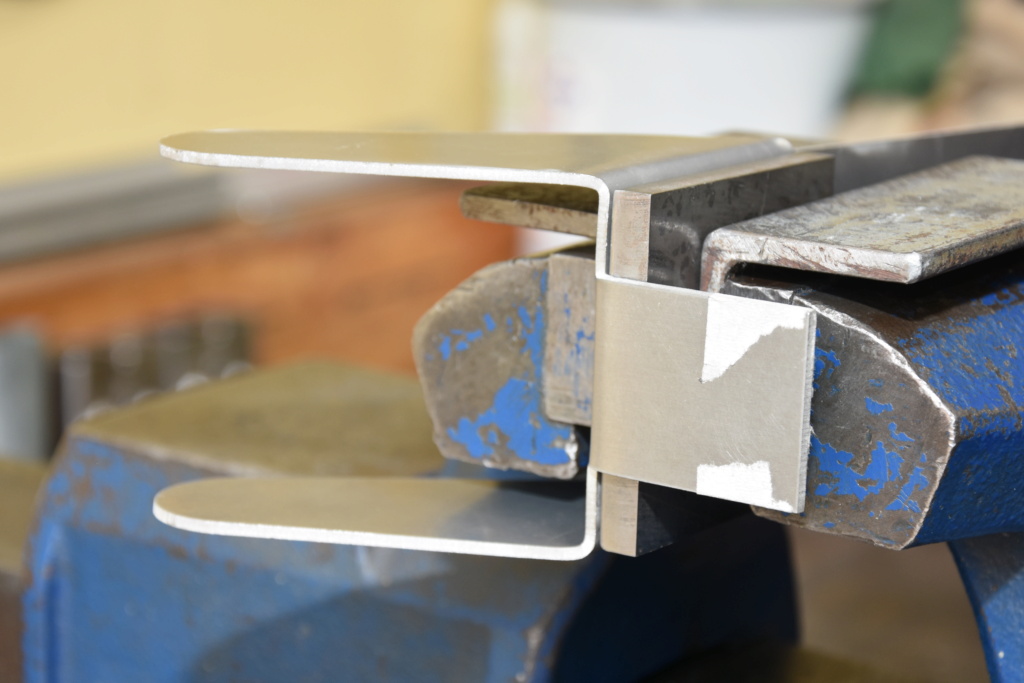

Rounded the sharp edges of one side so as to provide a small radius in the bends

Piece of cake with the former held tightly in place.

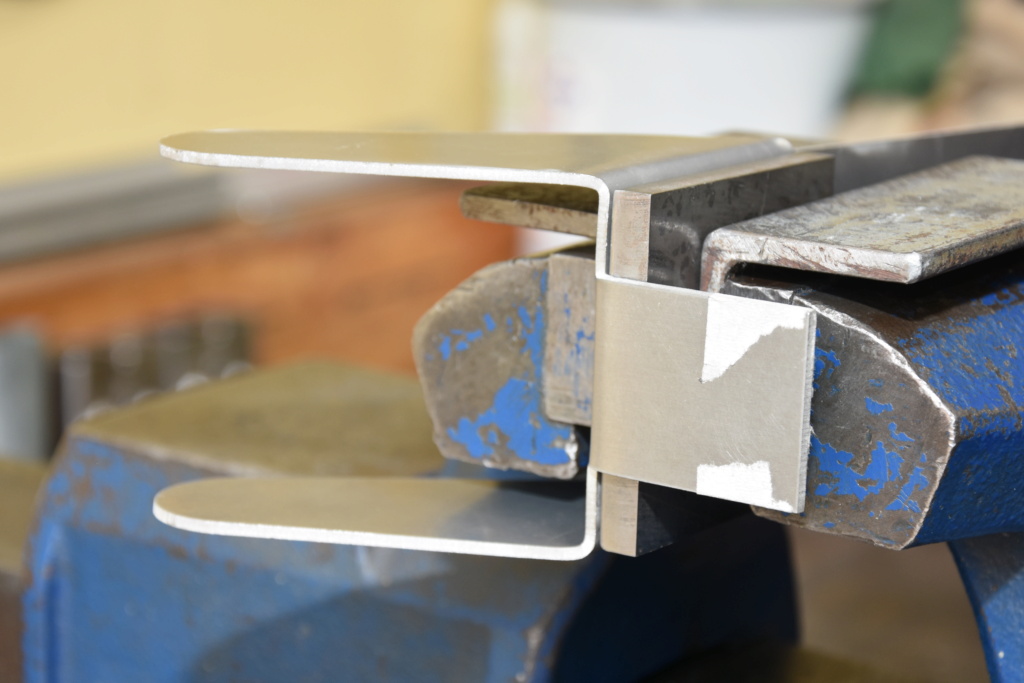

Now for the engine mount.

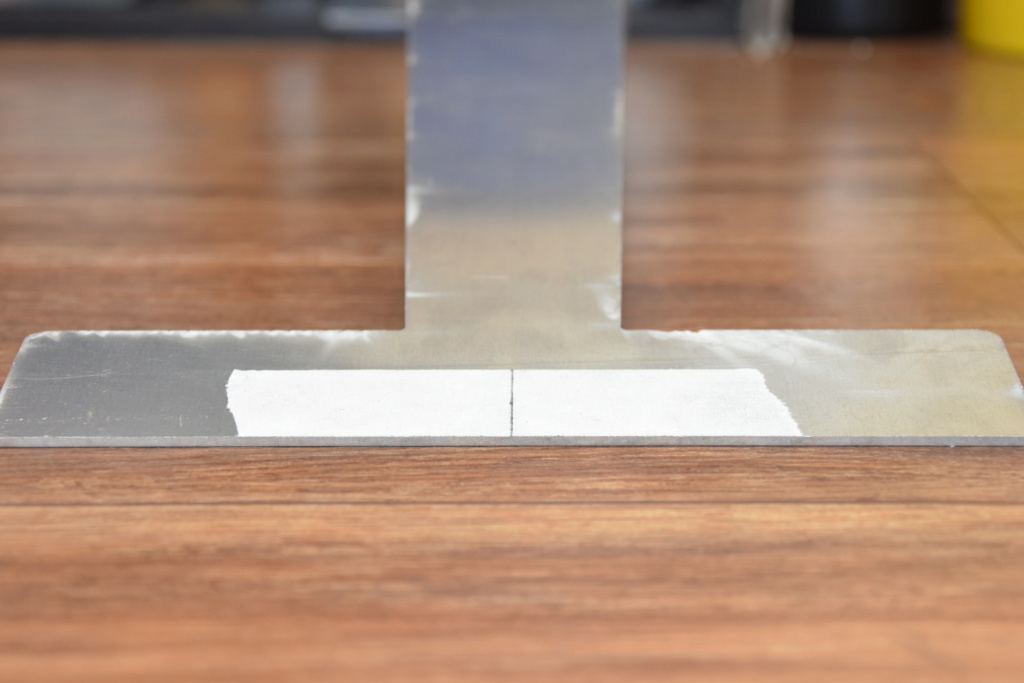

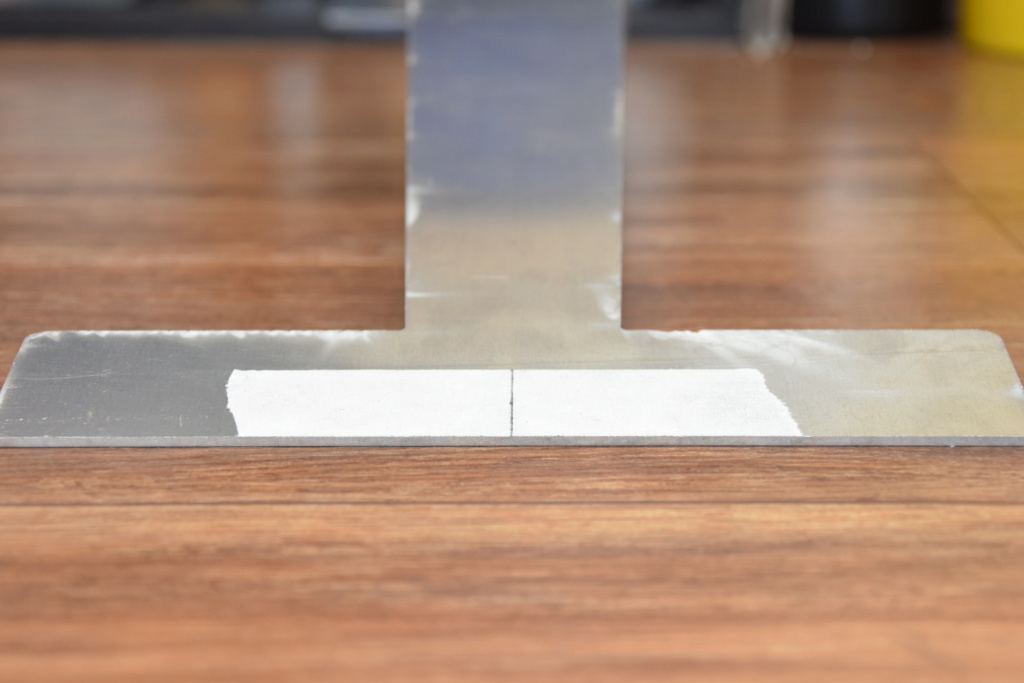

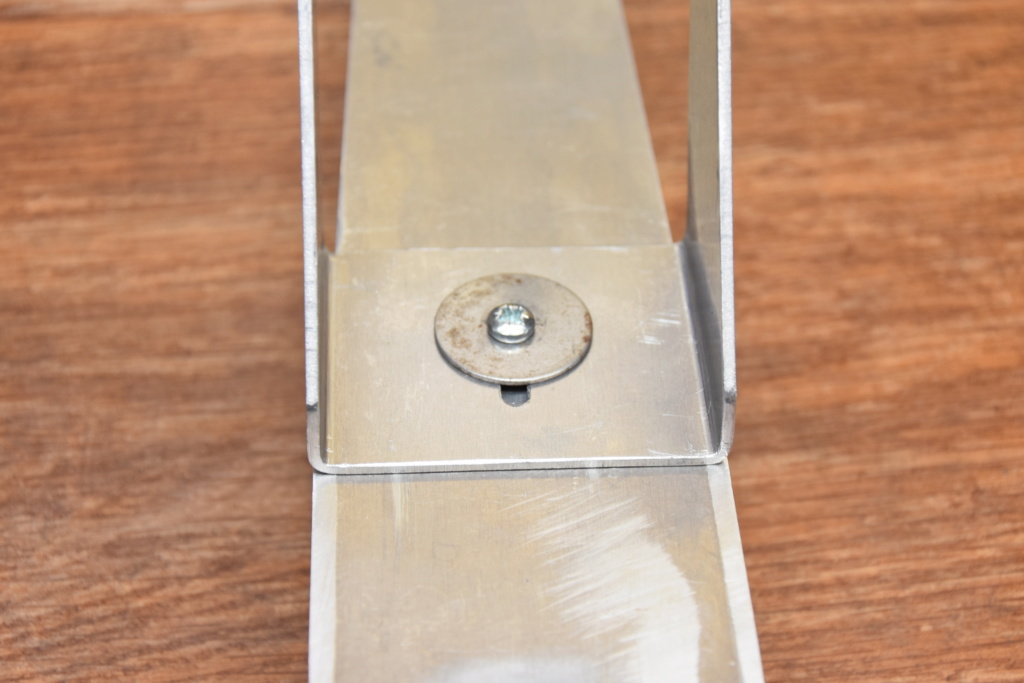

Final checks, everything looks square

Rear portion sitting perfectly flat.

I start to get a bit nervous when everything seems to go right without a problem.

That feeling that there's something I've missed which is going to bite me further down the line

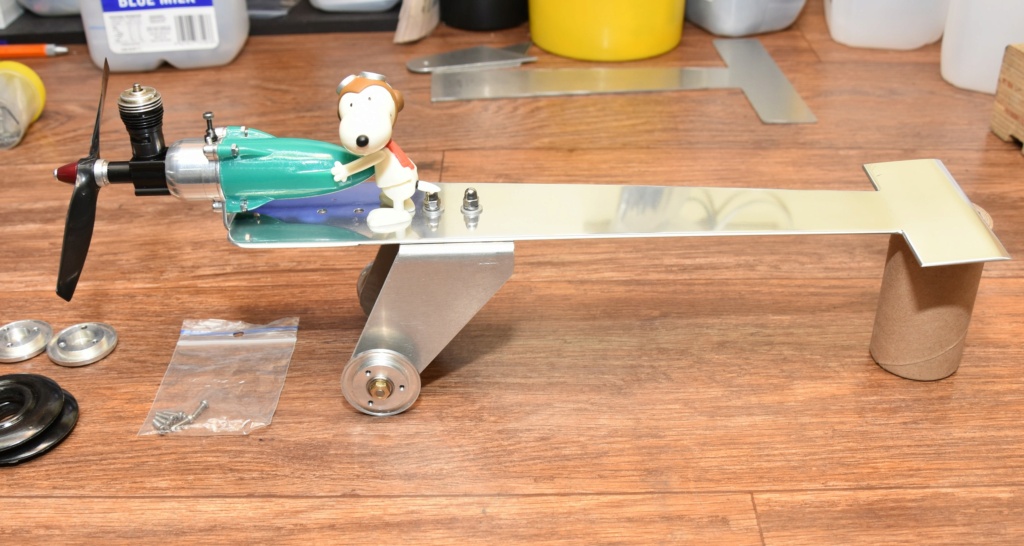

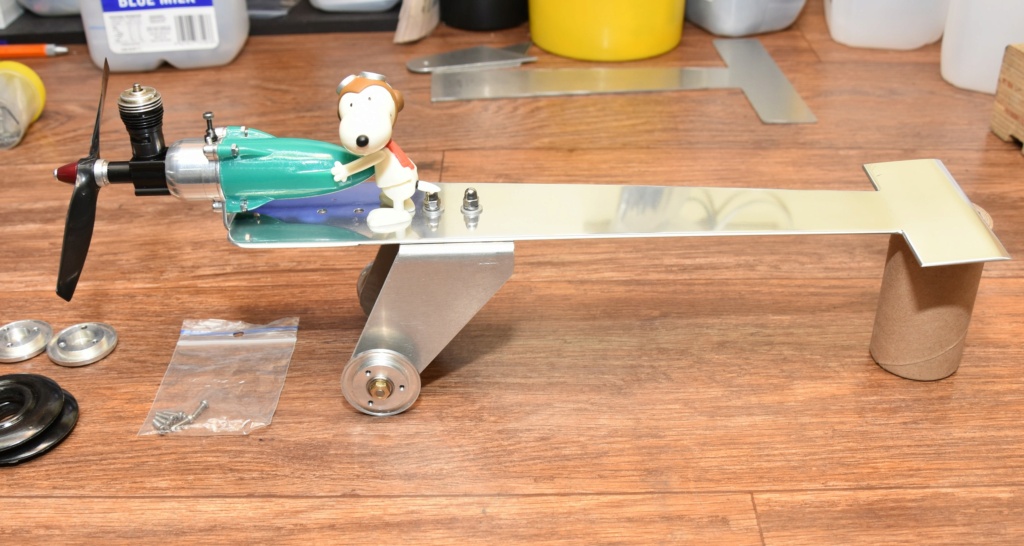

Final checks and a high five from the Chief Test Pilot as the Snoopworth Camel takes shape.

This Russian Speed Tether Car gave me the idea for the type of design I decided to build.

Rough sketch of design.

Scale side view mainly to work out prop ground clearance

Scale drawing of final measurements sent to Waterjet Cutters

Since most of the cost involved is the programming it’s only material cost for an extra one.

Also had a piece of steel cut 60mm x 60mm x 8mm thick, which the reason for will become obvious in the next photos.

The steel piece will be used as a former to help shape the bends accurately.

Rounded the sharp edges of one side so as to provide a small radius in the bends

Piece of cake with the former held tightly in place.

Now for the engine mount.

Final checks, everything looks square

Rear portion sitting perfectly flat.

I start to get a bit nervous when everything seems to go right without a problem.

That feeling that there's something I've missed which is going to bite me further down the line

Final checks and a high five from the Chief Test Pilot as the Snoopworth Camel takes shape.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Tether Car Speed entry

Re: Tether Car Speed entry

Hey man thats looking good ! I hate to tell you and should have been announced but Luke bowed out of the CD position. I don't know what the plan is now ?  Here on page 3 https://www.coxengineforum.com/t15880p50-prop-rod-2022-a-cef-contest-idea We need to figure something out on this .

Here on page 3 https://www.coxengineforum.com/t15880p50-prop-rod-2022-a-cef-contest-idea We need to figure something out on this .

Last edited by getback on Thu Feb 03, 2022 5:59 am; edited 1 time in total (Reason for editing : change meaning)

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Tether Car Speed entry

Re: Tether Car Speed entry

I did see that but decided to build it anyway, probably should have said this "would" have been my entry.

I'm not worried about the competition not going ahead, I'm just glad it gave me the motivation to start this build.

I just want to see if it works.

I'm not worried about the competition not going ahead, I'm just glad it gave me the motivation to start this build.

I just want to see if it works.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Tether Car Speed entry

Re: Tether Car Speed entry

I think that any interested forum members should still work on a design. Dave (from New Zealand) is obviously serious about competing! Lets build off his energy!

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Snoopworth Camel

Snoopworth Camel

Part 2

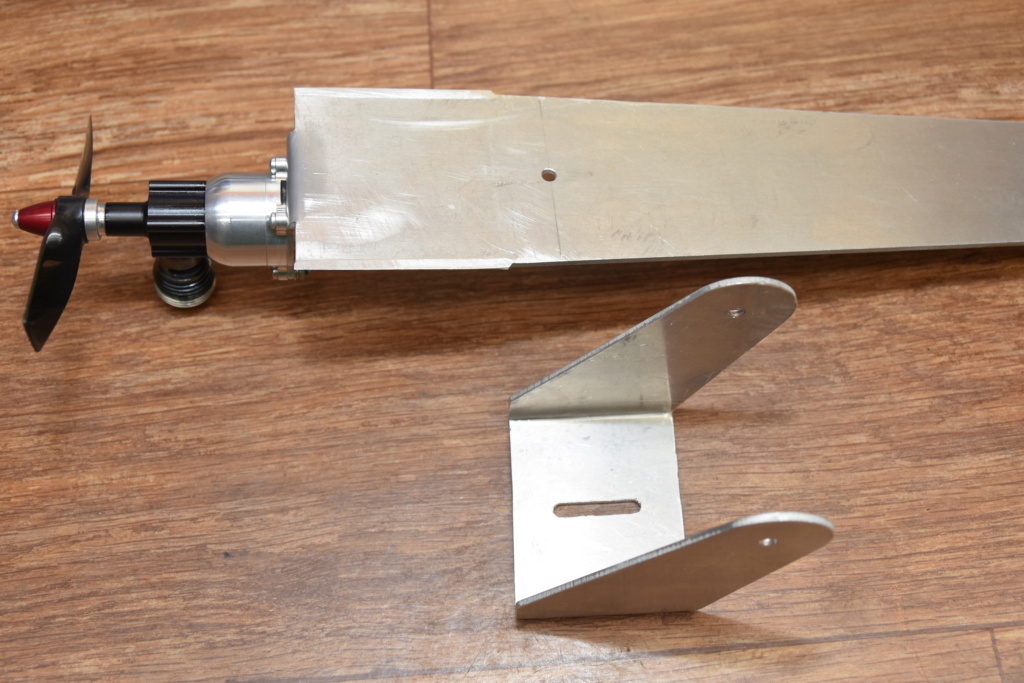

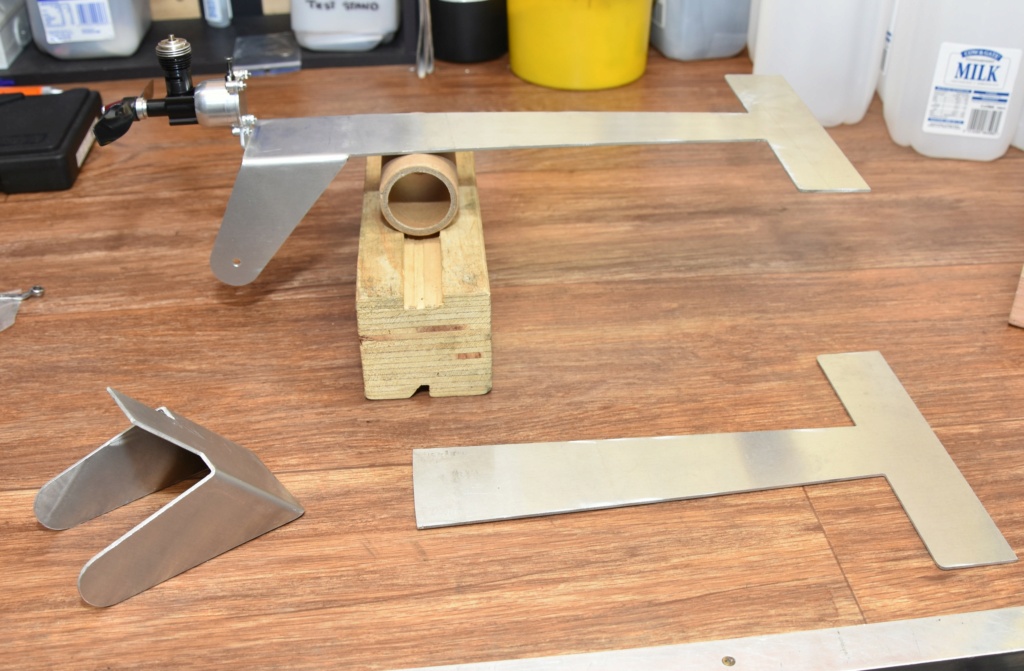

It was here while undergoing air flow tests (compressed air) that it became obvious I had greatly underestimated the weight of the rear section of the vehicle and overestimated the weight of the engine. This can happen frequently when using the guesstimation formula so it's one of the reasons I had two templates made.

I say to people there are no mistakes (nice way of putting it) in my rubbish bin but, “there are a lot of prototypes”.

So I cut the axle mounting section out of the spare template and folded it into shape.

Then cut the axle sections off the main chassis

Briefly experimented with different mounting positions

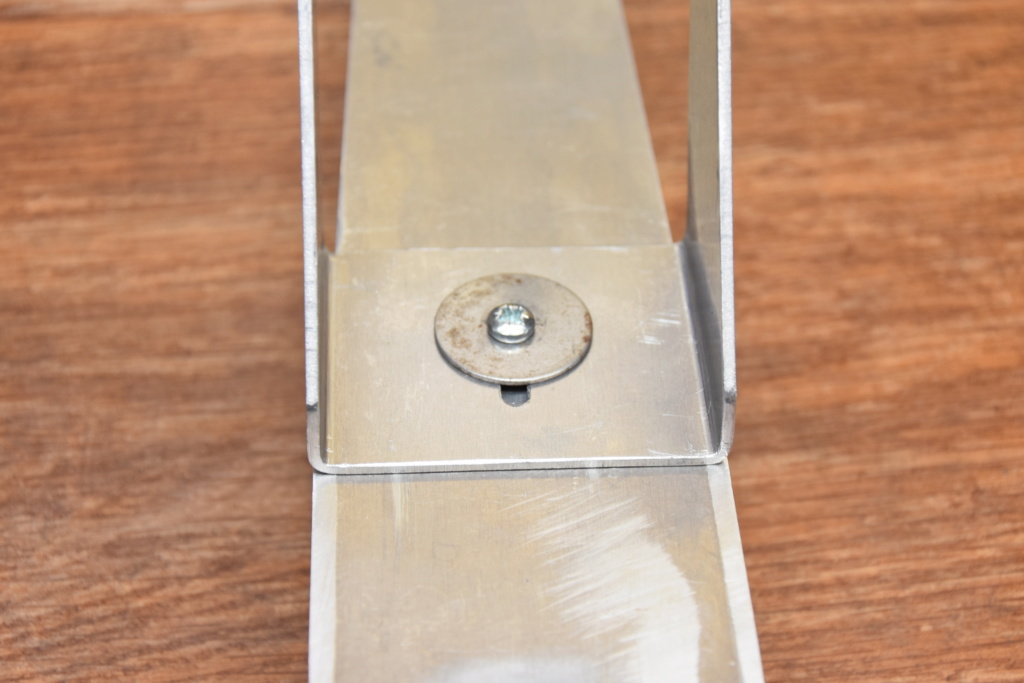

Decided it needed to be adjustable

I cut 40mm off each side of the rear spoiler to reduce weight in that area and also added some more holes for more adjustment.

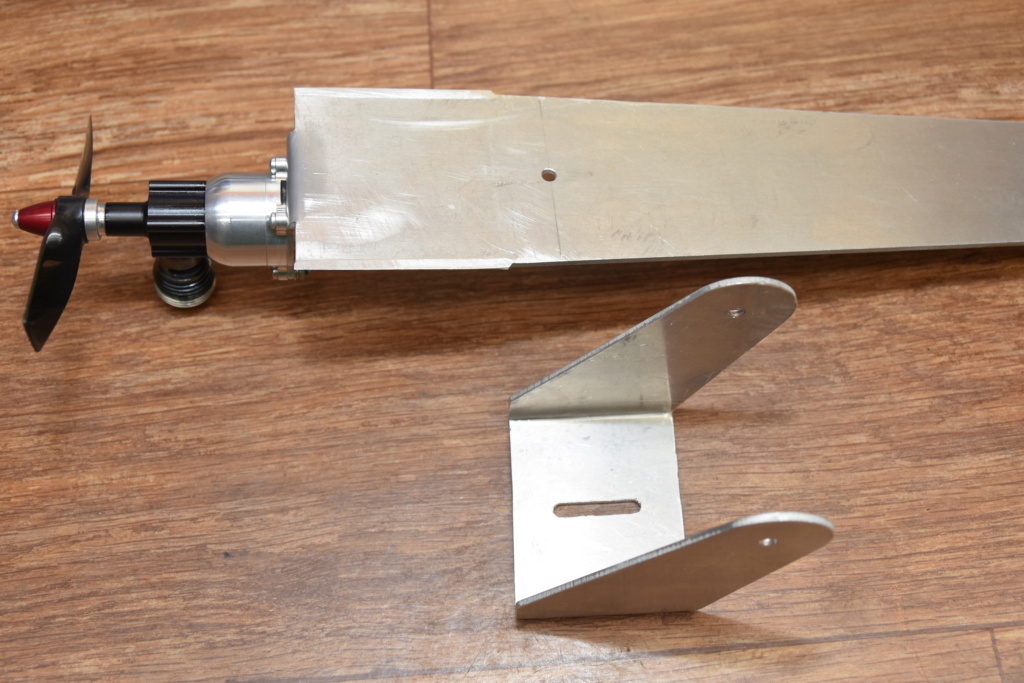

Then shaped and cleaned up the chassis.

Starting to get somewhere.

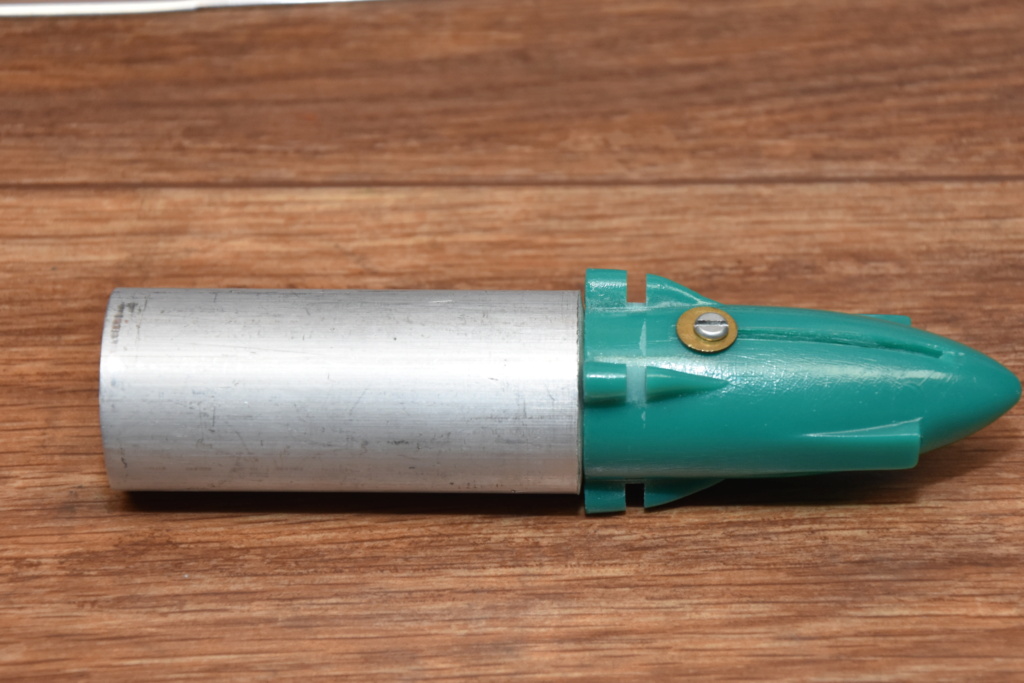

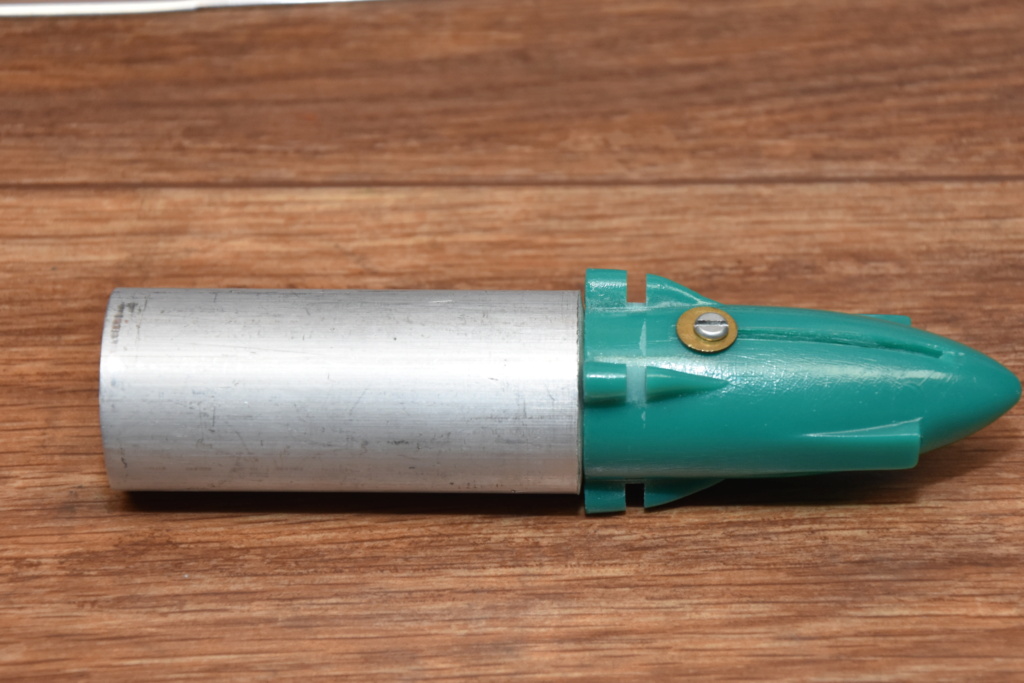

Had a spare nacelle in the cupboard thanks to Chris Vaughn at Red Venom Repros. I’d sent him some nos Cox Shrike parts to make new moulds and get colour matches and when he sent my ones back, he put a lot of other bits in. Real nice guy.

I’m not a fan of the self-tapping screw mounting arrangement so for custom builds I like to modify the nacelles for machine screws and nuts.

Happy with the progress so far. Added two more holes for adjustment. Always have plenty of holes in stock though sometimes finding the right size can be difficult.

Snoopy seems happy with it

Next job is to clean up the axle mount

It was here while undergoing air flow tests (compressed air) that it became obvious I had greatly underestimated the weight of the rear section of the vehicle and overestimated the weight of the engine. This can happen frequently when using the guesstimation formula so it's one of the reasons I had two templates made.

I say to people there are no mistakes (nice way of putting it) in my rubbish bin but, “there are a lot of prototypes”.

So I cut the axle mounting section out of the spare template and folded it into shape.

Then cut the axle sections off the main chassis

Briefly experimented with different mounting positions

Decided it needed to be adjustable

I cut 40mm off each side of the rear spoiler to reduce weight in that area and also added some more holes for more adjustment.

Then shaped and cleaned up the chassis.

Starting to get somewhere.

Had a spare nacelle in the cupboard thanks to Chris Vaughn at Red Venom Repros. I’d sent him some nos Cox Shrike parts to make new moulds and get colour matches and when he sent my ones back, he put a lot of other bits in. Real nice guy.

I’m not a fan of the self-tapping screw mounting arrangement so for custom builds I like to modify the nacelles for machine screws and nuts.

Happy with the progress so far. Added two more holes for adjustment. Always have plenty of holes in stock though sometimes finding the right size can be difficult.

Snoopy seems happy with it

Next job is to clean up the axle mount

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Tether Car Speed entry

Re: Tether Car Speed entry

Beautiful work Dave, what are you going to use for tires?

Do you have your own water jet cutter or are you sending it out?

This is interesting:

https://www.plantservices.com/blogs/plant-nexus/diy-make-your-own-water-jet-cutter-for-less-than-200/

Do you have your own water jet cutter or are you sending it out?

This is interesting:

https://www.plantservices.com/blogs/plant-nexus/diy-make-your-own-water-jet-cutter-for-less-than-200/

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: Tether Car Speed entry

Re: Tether Car Speed entry

Looking Good Dave , glad you had a change in design before you got to far . Nice work!

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Tether Car Speed entry

Re: Tether Car Speed entry

Hi Bob

You can just see the tires in the bottom left corner of the last photo. They're the knife edge speed type I've used on previous builds.

I get the waterjet cutting done by a company that just does that. I've dealt with them since they started, they understand my scribblings, don't mind doing small jobs and send it straight back by courier and email me the bill later.

The pressure cleaner turned waterjet cutter is an interesting read but it's a bit like welding.

I just don't do enough to justify the setup and learn how to do it properly to be able to do it myself.

Hi Eric

I kind of knew before I started that this build would be a series of constant changes as it progressed but that’s part of the challenge and the fun for me.

Overcoming each issue as it arises. Might be able to get it to work okay, might not.

Might end up the “Looked Good, Went Rubbish” cabinet

You can just see the tires in the bottom left corner of the last photo. They're the knife edge speed type I've used on previous builds.

I get the waterjet cutting done by a company that just does that. I've dealt with them since they started, they understand my scribblings, don't mind doing small jobs and send it straight back by courier and email me the bill later.

The pressure cleaner turned waterjet cutter is an interesting read but it's a bit like welding.

I just don't do enough to justify the setup and learn how to do it properly to be able to do it myself.

Hi Eric

I kind of knew before I started that this build would be a series of constant changes as it progressed but that’s part of the challenge and the fun for me.

Overcoming each issue as it arises. Might be able to get it to work okay, might not.

Might end up the “Looked Good, Went Rubbish” cabinet

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Tether Car Speed entry

Re: Tether Car Speed entry

Thanks Dave, I see them now. Your water jet cutting company sounds like a great place to do business. Setting an example that others should follow.

Bob

Bob

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: Tether Car Speed entry

Re: Tether Car Speed entry

Cleaned and sorted the axle mount and also did a drawing of the tether arm and sent that off to the Waterjet cutters.

The template arrived and, in my haste, I didn’t have it properly secured in the mill where it came loose and promptly became a prototype.

I tell people there are no mistakes (nice word here) in my workshop bin but there are quite a few prototypes.

Anyway, I had to make the embarrassing call, admit my error (much laughter on the other end of the phone) and ask to have not one but two cut so that this time, I had a spare. Should have done that in the first place.

Got the milling done this time no problem at all and made a slotted hole in the end for the tether wire.

Usually always goes that way when you have a spare.

Had some spare time so shaped the edges and gave it a good polish.

This build has been dragging on a bit and poor Snoopy was almost at the end of his tether.

So, I decided to get into it and keep at it until it was finished

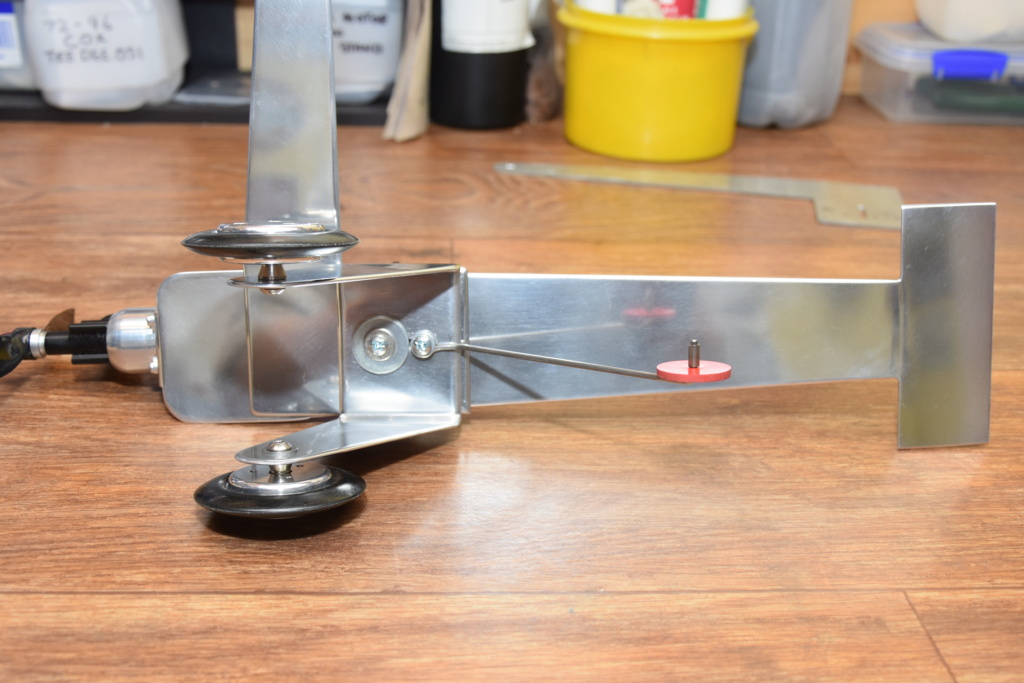

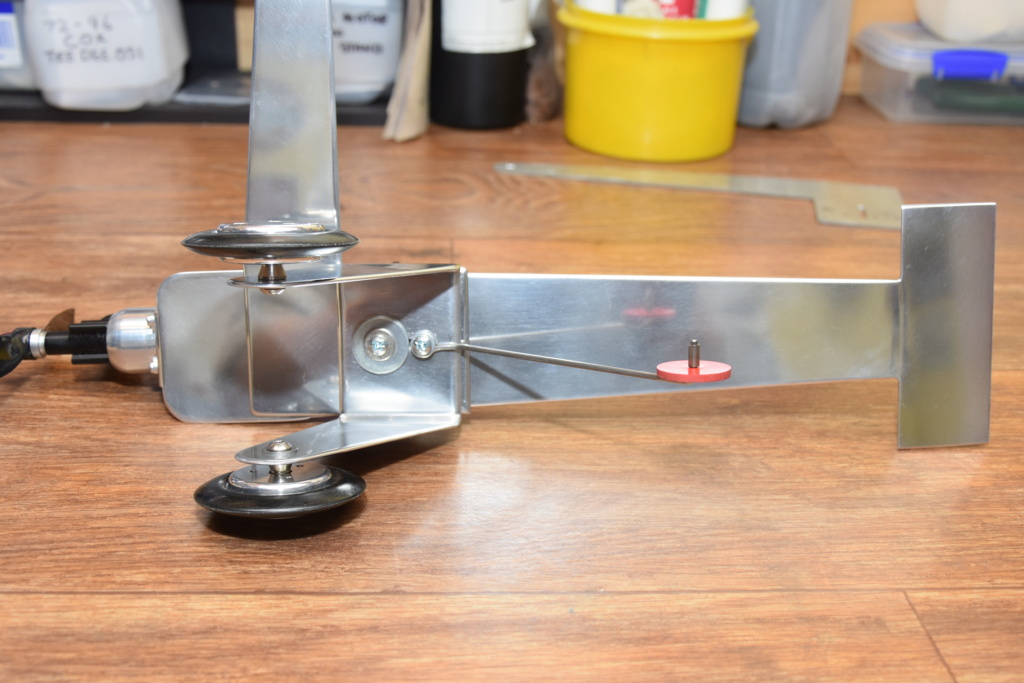

The underside arrangement with a little bit of outwards thrust on the engine.

An old plastic pill container (have heaps of those in several sizes) got cut up to make a seat and the top off another one became the cushion.

The final product with one happy pilot

The template arrived and, in my haste, I didn’t have it properly secured in the mill where it came loose and promptly became a prototype.

I tell people there are no mistakes (nice word here) in my workshop bin but there are quite a few prototypes.

Anyway, I had to make the embarrassing call, admit my error (much laughter on the other end of the phone) and ask to have not one but two cut so that this time, I had a spare. Should have done that in the first place.

Got the milling done this time no problem at all and made a slotted hole in the end for the tether wire.

Usually always goes that way when you have a spare.

Had some spare time so shaped the edges and gave it a good polish.

This build has been dragging on a bit and poor Snoopy was almost at the end of his tether.

So, I decided to get into it and keep at it until it was finished

The underside arrangement with a little bit of outwards thrust on the engine.

An old plastic pill container (have heaps of those in several sizes) got cut up to make a seat and the top off another one became the cushion.

The final product with one happy pilot

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Tether Car Speed entry

Re: Tether Car Speed entry

It Looks Fast ! Hope you got snoopy secured good LOL  Good Fun . You going to run it ?

Good Fun . You going to run it ?

Good Fun . You going to run it ?

Good Fun . You going to run it ?

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Tether Car Speed entry

Re: Tether Car Speed entry

Yep sure will Eric.

Went and saw my mate today who has the yard where we ran the car that's my avatar. Will give that a run at the same time.

Went and saw my mate today who has the yard where we ran the car that's my avatar. Will give that a run at the same time.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Similar topics

Similar topics» Reed Speed 2.0 qualifying photos

» The CEF Reed Speed Contest… a very late entry

» Wen Mac tether car with speed control

» Fellow speed freaks, help me build a pair of speed Bees.

» March Engine of the month submissions, post them here!

» The CEF Reed Speed Contest… a very late entry

» Wen Mac tether car with speed control

» Fellow speed freaks, help me build a pair of speed Bees.

» March Engine of the month submissions, post them here!

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules