Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

My Latest Scratch build Cox powered car

Page 1 of 1

My Latest Scratch build Cox powered car

My Latest Scratch build Cox powered car

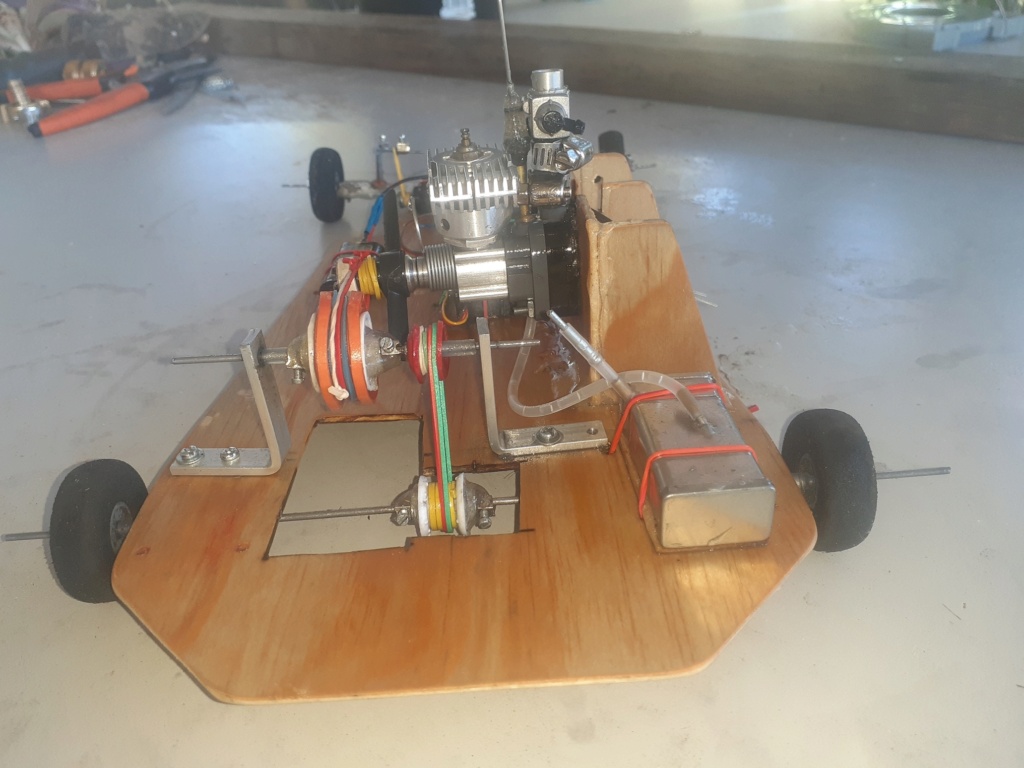

The photos below are of my latest cox 049 powered RC car platform. It continues the process of development through my previous Air Cars, through my test bench, of concepts, techniques, integration, and engineering I have been performing to arrive at the actual car I hope to eventually build. The car below is just another step in the process of shaking out problems, solving them through implementation and testing in what a (DOD) Defense Program would call a Concept or Technology Demonstrator. I know lots of people know how to build the end product properly, but I dont, so I am following the same process I use in developing technology or concept demonstrators for the Department of Defense.

The platform shown in the images above is finished with now. I will put a roll bar on it to protect the carby and engine and my son can drive and thrash it all he likes.It has served its purpose for me. It runs very well and is quite fast and fun to drive :-).

During the build I sorted out getting the OS 10g carby to work properly with the sure start engine and to throttle nicely and smoothly from approx 16k rpm to 3k RPM. I confirmed that my idea for a drive chain can work and got a better handle on the gearing ratios required. One of the biggest issues I found and solved with this jigger was the engine overheating even with a heatsink which during one full power run ended up melting the grey plastic horseshoe backplate and reed assembly to the point pieces of gasket broke and were hanging out through the huge gap between the assembly and the crankcase caused by the heat. The black gear on the front of the crank had melted into the the crank casing. The addition of a cut down prop acting as a fan helped resolve the problem and provided an easy way to use a spring to start the motor.

On my next platform I aim to build an aluminum engine framework/pod to hold/mount the engine, fuel tank and servo for the carby, such that I can transfer it easily between platforms and it is properly mounted and supported. Im thinking of puting a duct/shroud around the engine to channel the air from the fan on the front to see if it helps cooling further. I will implement a rough form of suspension to help with handling, look at some better hardware for the drive chain that will last longer. The steering mechanism has proven to be better than I thought or expected so I wont alter that for the short term. I dont know if it will be the next platform or the following one, but definitely want to build the drive chain with the ability to change through two or three gears via the RC and servos. There are some simple non gearbox ways this could be done by using say three lots of drive bands and idler/tension pulleys against each......... more thinking needed. Lol. Some form of brakes need to be designed and implemented as the potential speed is higher than I expected.

Eventually I aim to mount some electronics on it to monitor acceleration, vibration extremes, engine temperature, engine rpm, GPS data feed, and a live video cam. Ill do the electronics through a separate board rather than trying to hack the RC stuff. The electronics are not really for a car platform (very very fast boat project that uses flaps etc. to control its level etc. with the water) but its a good and easy platform to test them on. :-)

I guess in a way, its not really modelling :-) but it is at least based on the awesome Cox engines which are like internal combustion engineering clay for so many possible projects. So many options and variations and so easy to modify and configure to do things you could not do with any other available engine. And the price is such that you can afford to take risks and wreck stuff testing ideas to get things right.

Yabby.

The platform shown in the images above is finished with now. I will put a roll bar on it to protect the carby and engine and my son can drive and thrash it all he likes.It has served its purpose for me. It runs very well and is quite fast and fun to drive :-).

During the build I sorted out getting the OS 10g carby to work properly with the sure start engine and to throttle nicely and smoothly from approx 16k rpm to 3k RPM. I confirmed that my idea for a drive chain can work and got a better handle on the gearing ratios required. One of the biggest issues I found and solved with this jigger was the engine overheating even with a heatsink which during one full power run ended up melting the grey plastic horseshoe backplate and reed assembly to the point pieces of gasket broke and were hanging out through the huge gap between the assembly and the crankcase caused by the heat. The black gear on the front of the crank had melted into the the crank casing. The addition of a cut down prop acting as a fan helped resolve the problem and provided an easy way to use a spring to start the motor.

On my next platform I aim to build an aluminum engine framework/pod to hold/mount the engine, fuel tank and servo for the carby, such that I can transfer it easily between platforms and it is properly mounted and supported. Im thinking of puting a duct/shroud around the engine to channel the air from the fan on the front to see if it helps cooling further. I will implement a rough form of suspension to help with handling, look at some better hardware for the drive chain that will last longer. The steering mechanism has proven to be better than I thought or expected so I wont alter that for the short term. I dont know if it will be the next platform or the following one, but definitely want to build the drive chain with the ability to change through two or three gears via the RC and servos. There are some simple non gearbox ways this could be done by using say three lots of drive bands and idler/tension pulleys against each......... more thinking needed. Lol. Some form of brakes need to be designed and implemented as the potential speed is higher than I expected.

Eventually I aim to mount some electronics on it to monitor acceleration, vibration extremes, engine temperature, engine rpm, GPS data feed, and a live video cam. Ill do the electronics through a separate board rather than trying to hack the RC stuff. The electronics are not really for a car platform (very very fast boat project that uses flaps etc. to control its level etc. with the water) but its a good and easy platform to test them on. :-)

I guess in a way, its not really modelling :-) but it is at least based on the awesome Cox engines which are like internal combustion engineering clay for so many possible projects. So many options and variations and so easy to modify and configure to do things you could not do with any other available engine. And the price is such that you can afford to take risks and wreck stuff testing ideas to get things right.

Yabby.

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: My Latest Scratch build Cox powered car

Re: My Latest Scratch build Cox powered car

Cool ! Looks interesting for sure , a lot of gadgets on one platform , Would love to see it run as you say it faster than anticipated. I would call it modeling in my book and designing at the same time !

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: My Latest Scratch build Cox powered car

Re: My Latest Scratch build Cox powered car

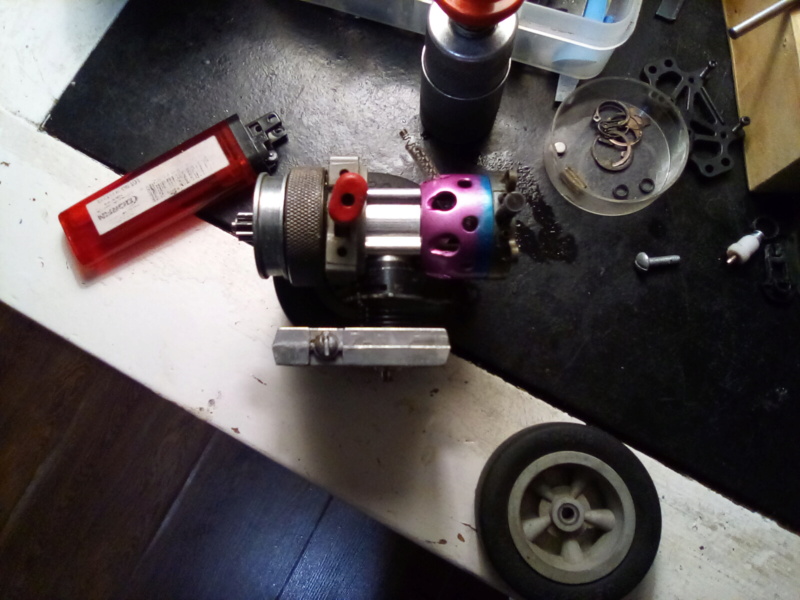

Very cool as a small project good idea to solve the problem of overheating  me i use a bee back plate like this

me i use a bee back plate like this

This one is anodized with big holes but you can drill several small holes to ventilate it to use as a heat sink But can't use this carburetor sistem It would take a cylinder ring restrictor

me i use a bee back plate like this

me i use a bee back plate like this

This one is anodized with big holes but you can drill several small holes to ventilate it to use as a heat sink But can't use this carburetor sistem It would take a cylinder ring restrictor

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: My Latest Scratch build Cox powered car

Re: My Latest Scratch build Cox powered car

Ha

another funny build from you

but to be honnest how do you overheat a cox engine

I have had many rc cox engines

with the normal coaling head and they never melt the backplate

another funny build from you

but to be honnest how do you overheat a cox engine

I have had many rc cox engines

with the normal coaling head and they never melt the backplate

robot797- Platinum Member

- Posts : 787

Join date : 2013-07-28

Age : 34

Re: My Latest Scratch build Cox powered car

Re: My Latest Scratch build Cox powered car

Goodness Yabby, that is complex, involved, and darn right innovative. I like it.

Bob

Bob

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: My Latest Scratch build Cox powered car

Re: My Latest Scratch build Cox powered car

robot797 wrote:Ha

another funny build from you

but to be honnest how do you overheat a cox engine

I have had many rc cox engines

with the normal coaling head and they never melt the backplate

Goodaye robot797, photo below

Its not a car engine and was put in a car with no front fan and the round cox muffler with the standard little hole in it as really wanted to keep noise down. I think the muffler melted the plastic first, then the muffler started spinning around the cylinder, which ground the starter spring down and broke the starter spring, and the crankcase got hot enough to melt the black cog on the front into the crankcase as you can see the melted indent from the picture. The car was moving quite slowly at absolute full revs as I had the gearing so wrong. I obviously pulled the engine apart later and there is no internal damage! Piston and cylinder fit is fine, conrod connection is ok, no pickup on cylinder or piston, crank and crankcase inside are fine, no discoloration anywhere, no slop or unusual wear etc. infact the same engine with a new backplate and the cut down prop as a fan and a muffler with bigger hole in it, runs great and no problems now!

Its not a car engine and was put in a car with no front fan and the round cox muffler with the standard little hole in it as really wanted to keep noise down. I think the muffler melted the plastic first, then the muffler started spinning around the cylinder, which ground the starter spring down and broke the starter spring, and the crankcase got hot enough to melt the black cog on the front into the crankcase as you can see the melted indent from the picture. The car was moving quite slowly at absolute full revs as I had the gearing so wrong. I obviously pulled the engine apart later and there is no internal damage! Piston and cylinder fit is fine, conrod connection is ok, no pickup on cylinder or piston, crank and crankcase inside are fine, no discoloration anywhere, no slop or unusual wear etc. infact the same engine with a new backplate and the cut down prop as a fan and a muffler with bigger hole in it, runs great and no problems now! Thanks for the suggestion on the way you use the bee backplate David.

Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: My Latest Scratch build Cox powered car

Re: My Latest Scratch build Cox powered car

getback wrote:Cool ! Looks interesting for sure , a lot of gadgets on one platform , Would love to see it run as you say it faster than anticipated. I would call it modeling in my book and designing at the same time !

I a going to see if my Son can film it for me and put it on youtube so as that I can show it going on the forum. I cannot do this as there are issues my DOD Security clearance that prevent it or just make my life difficult if I do. My son is intellectually disabled , but still pretty ok, but he has a paranoia about socilal media, so he may not do it for me. See how we go Eric.

Yabby

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Similar topics

Similar topics» New P-38 profile scratch build log

» Qtee scratch build

» Scratch-Build 2021

» Scratch build BRM - a first

» La Stick Scratch Build for Cox Pee Wee .020

» Qtee scratch build

» Scratch-Build 2021

» Scratch build BRM - a first

» La Stick Scratch Build for Cox Pee Wee .020

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules