Log in

Search

Latest topics

» Did you spot the Cox engine in this NASA research video?by balogh Today at 5:08 pm

» Roger Harris revisited

by rsv1cox Today at 3:44 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 2:54 pm

» Happy 77th birthday Andrew!

by Admin Today at 12:34 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

Cox Engine of The Month

Po'boy's exhaust throttle for thin wall cylinder

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Its so cold the plug wont stay light and if i lean mutch i have more rpm gain excep it stop if try To rc i try make larger opening and hope for best result as is now y can stop the engine runing its Not correct it. Should rpm down just To point it want To stop and keap runing slow rpm without leaning at same time

Last edited by davidll1984 on Thu Mar 11, 2021 2:53 pm; edited 1 time in total

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

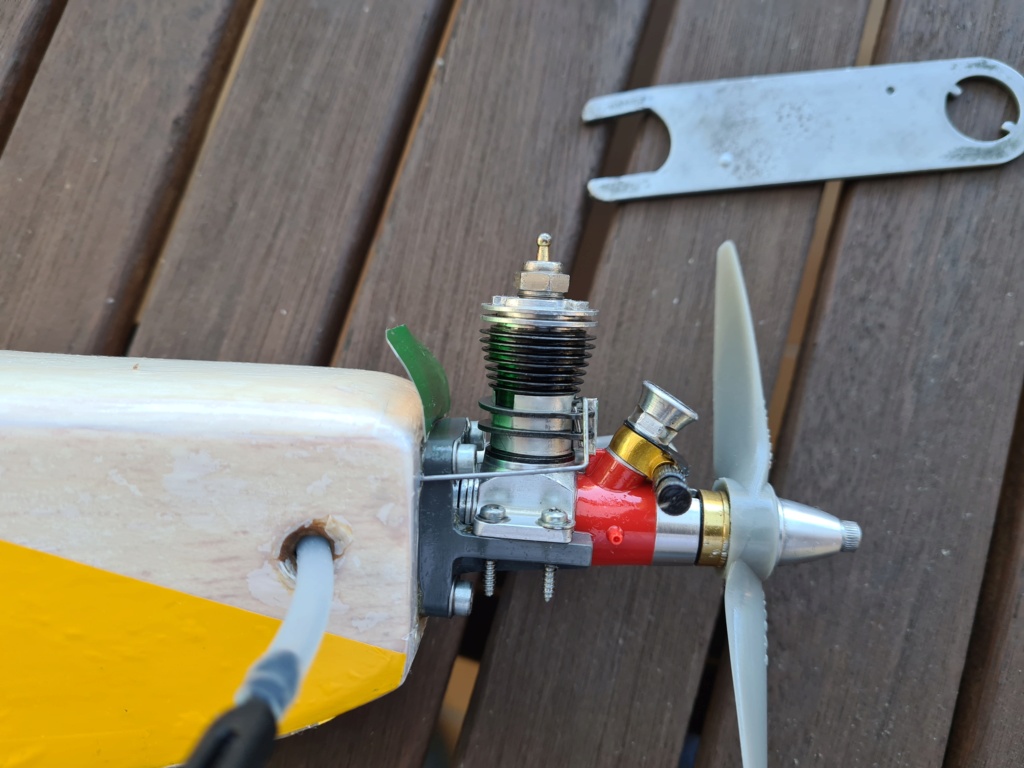

Here is my finalized prototype.

I stayed with the doubled aluminum strip cut out from a beer can, hand-wound around the thin wall part of the cylinder (between the bottom rim and lowermost fin, the strip width is near 9.5 mm) . A standard circlip for a 15mm shaft (inner diameter of clip: 13.8mm) keeps the aluminum strip wound on the thin wall cylinder (thin wall has 13mm outer diameter, and the 2x2 layers of aluminum strip adds about 0.6mm to the cylinder diameter.) So there remains in principle some 0.1mm radial/0.2mm diagonal gap between the alu throttle strip and the cylinder. This can be reduced further by flexing the circlip with a plyer a couple times in closing direction before applying on the throttle band.

I cut and bent down 2 tabs from the strip where the exhaust openings overlap for full speed. The openings are only about 60% of the cylinder exhaust port width each. The tabs also help keep the circlip near half the height of the throttle strip for optimum radial sealing.

A back bent end tab of the aluminum throttle strip sits in between the circlip ends and prevents the circlip to slip around the aluminum strip. The circlip end holes lend themselves for pushrod connection.

Well, the throttling efficiency leaves behind much to be wished ...the old-stock 051 TeeDee engine bench runs, unthrottled, near 22k with a 4.7*4.5 APC prop, and full throttle drops the speed a tad below 18k. Obviously, the sealing by a hand-wound aluminum strip with overlapping ends is not to be compared to that by lathe-machined, and fitted exhaust throttle barrels.

I do not give up though, and think about ways of improving the strip-to-cylinder seal. I have no other choice.

As written before, there is no other way of efficiently throttling a thin wall SPI cylinder, when the stock throttle drums sold by Bernie and Matt match thin wall and step wall cylinders only, and - thanks to their bottom rim - do not slip on the old-stock thin wall cylinders...

I stayed with the doubled aluminum strip cut out from a beer can, hand-wound around the thin wall part of the cylinder (between the bottom rim and lowermost fin, the strip width is near 9.5 mm) . A standard circlip for a 15mm shaft (inner diameter of clip: 13.8mm) keeps the aluminum strip wound on the thin wall cylinder (thin wall has 13mm outer diameter, and the 2x2 layers of aluminum strip adds about 0.6mm to the cylinder diameter.) So there remains in principle some 0.1mm radial/0.2mm diagonal gap between the alu throttle strip and the cylinder. This can be reduced further by flexing the circlip with a plyer a couple times in closing direction before applying on the throttle band.

I cut and bent down 2 tabs from the strip where the exhaust openings overlap for full speed. The openings are only about 60% of the cylinder exhaust port width each. The tabs also help keep the circlip near half the height of the throttle strip for optimum radial sealing.

A back bent end tab of the aluminum throttle strip sits in between the circlip ends and prevents the circlip to slip around the aluminum strip. The circlip end holes lend themselves for pushrod connection.

Well, the throttling efficiency leaves behind much to be wished ...the old-stock 051 TeeDee engine bench runs, unthrottled, near 22k with a 4.7*4.5 APC prop, and full throttle drops the speed a tad below 18k. Obviously, the sealing by a hand-wound aluminum strip with overlapping ends is not to be compared to that by lathe-machined, and fitted exhaust throttle barrels.

I do not give up though, and think about ways of improving the strip-to-cylinder seal. I have no other choice.

As written before, there is no other way of efficiently throttling a thin wall SPI cylinder, when the stock throttle drums sold by Bernie and Matt match thin wall and step wall cylinders only, and - thanks to their bottom rim - do not slip on the old-stock thin wall cylinders...

Last edited by balogh on Wed Mar 10, 2021 10:09 am; edited 1 time in total

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

On m'y prototype seal is Good Posible To stop the engine

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

During the manufacture of the piece I thought that it would be possible to use it as a closing spring control no hole just strap that close on the cylinder y tink is possible To build simple desing wit Similar result

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

David, I can see that it's pretty COLD where you are.

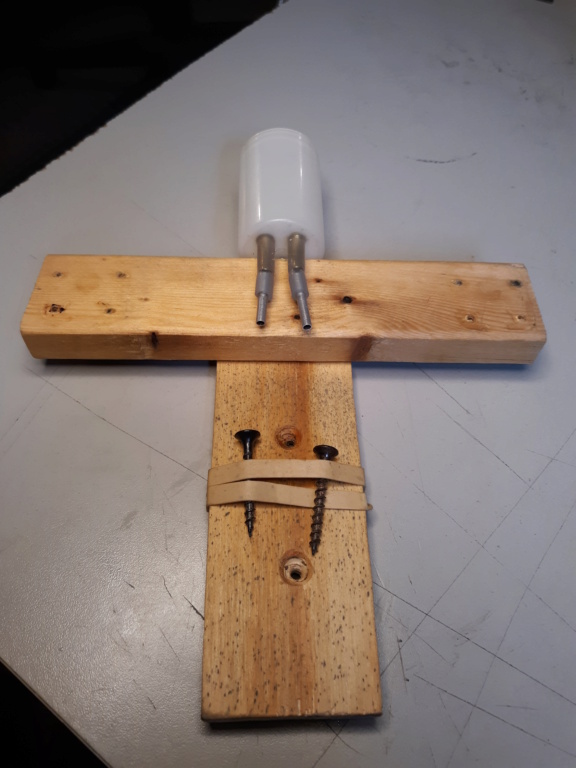

I see your hand shaking.. while holding-tight to that little engine. There seems to be a lot more throttle-resolution now. Have you thought about making bench-mounts for running your model engines? I enjoy making engine-mounts and test-fixtures.

Have you thought about making bench-mounts for running your model engines? I enjoy making engine-mounts and test-fixtures.

I see your hand shaking.. while holding-tight to that little engine. There seems to be a lot more throttle-resolution now.

Have you thought about making bench-mounts for running your model engines? I enjoy making engine-mounts and test-fixtures.

Have you thought about making bench-mounts for running your model engines? I enjoy making engine-mounts and test-fixtures. Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

balogh wrote:Great result Roddie (cookies included). Too bad there are no milled flats on the top fin for the wrench. Like on my old stock 051 cylinder. These cylinders tend to bake into the crankcase and removing them without the wrench is not easy. I have never managed to remove a cylinder with the leather strap no matter if I preheated the aluminum crankcase..not that it needs to be removed so often. But the exhaust throttle will not make it easier either.

Will you bench test it? One of the claim points in the Proportional Exhaust Throttle patent by the inventor Mr. Roger Freiheit was the bimetallic throttle and cylinder combo, that will allow more blow-by thru the throttle when the engine runs hot and the brass throttle expands more than the steel cylinder, and better fit for throttling when idling with the engine temperature dropping lower...so fitting it tight when cold is just good the way you did it Roddie..

Hi Andras! Yes.. the cookies

Regarding the exhaust-throttle.. I never thought about the cylinder-removal.

I also have a few different strap-wrenches that I can try. I guess I've been lucky not to have any Cox cylinders that were stuck-tight in a crankcase.

I also have a few different strap-wrenches that I can try. I guess I've been lucky not to have any Cox cylinders that were stuck-tight in a crankcase. I'd hoped to run an engine, with my "brass-band" po-boy exhaust-throttle tonight.. but I got distracted by another model-engine accessory that needed maintenance; a bench-mount for twin Cox .049 product-engines that I'd made; having a single-tank/dual-feed arrangement for running two engines simultaneously. It "did" work.. and I posted a hideous video a while back; running a pair of DAL brand 5"d. X 4"p. 2-blade drone-propellers "right-hand" and "left-hand" rotation. Those engines were tested for.. and are now mounted on my P-38 Lightning.

I think that the po' boy exhaust throttle idea has merit Andras. We will make it so.

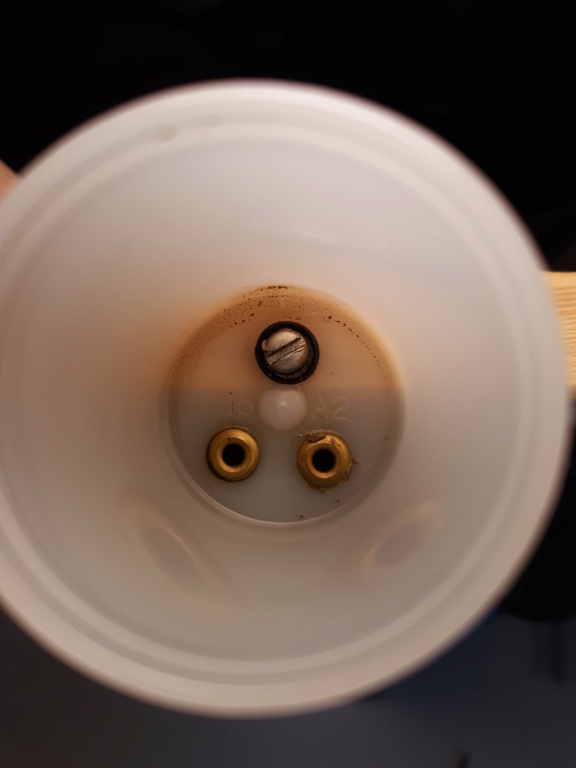

Last night I found the twin-engine bench-mount while dragging-out my power-panel. The twin-mount utilizes a plastic (translucent) 35mm film-canister having dual (gravity) feed-lines and is mounted on top of a small "T"-shaped fixture. The canister (tank...) was mounted with a single small wood-screw through the bottom.. with something I'd used for a gasket. Well.. upon inspection, the gasket material had deteriorated.. and needed replacement. I used some thin butyl-rubber to make a new gasket.

The cap of the film canister has a small hole drilled in it for a vent.

I know it's show & tell.. but it's all I've got for tonight..

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Ha ha  Yes somtime i use bench To run larger engine or the Most powerful tee dee .051 that want To Leave my hands the .010 is fun To hold litle triky engine i like them y have at the time use one old engine .049 read valve engines that after start for the first time wit crazy rpm Suddenly so much that I was afraid that he would take off from my hands Surprising and scary at the same time

Yes somtime i use bench To run larger engine or the Most powerful tee dee .051 that want To Leave my hands the .010 is fun To hold litle triky engine i like them y have at the time use one old engine .049 read valve engines that after start for the first time wit crazy rpm Suddenly so much that I was afraid that he would take off from my hands Surprising and scary at the same time

i want To build test stand for trust

i want To build test stand for trust

Yes somtime i use bench To run larger engine or the Most powerful tee dee .051 that want To Leave my hands the .010 is fun To hold litle triky engine i like them y have at the time use one old engine .049 read valve engines that after start for the first time wit crazy rpm Suddenly so much that I was afraid that he would take off from my hands Surprising and scary at the same time

Yes somtime i use bench To run larger engine or the Most powerful tee dee .051 that want To Leave my hands the .010 is fun To hold litle triky engine i like them y have at the time use one old engine .049 read valve engines that after start for the first time wit crazy rpm Suddenly so much that I was afraid that he would take off from my hands Surprising and scary at the same time

i want To build test stand for trust

i want To build test stand for trustLast edited by davidll1984 on Thu Mar 11, 2021 11:05 pm; edited 1 time in total

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

How was the ideal Andreas ? Can you open the hole up or adjust to center better with the exhaust ? Looks Good !

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Daved your a Nut ! LOL  Cool /cold video

Cool /cold video

Cool /cold video

Cool /cold video

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

getback wrote:How was the ideal Andreas ? Can you open the hole up or adjust to center better with the exhaust ? Looks Good !

Thanks Eric, the opening on the ring is OK. But the sealing between the ring and cylinder is not sufficient to throttle down to low idle. I need to work on a better seal. The construction otherwise is simple and can be made at home quickly.

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

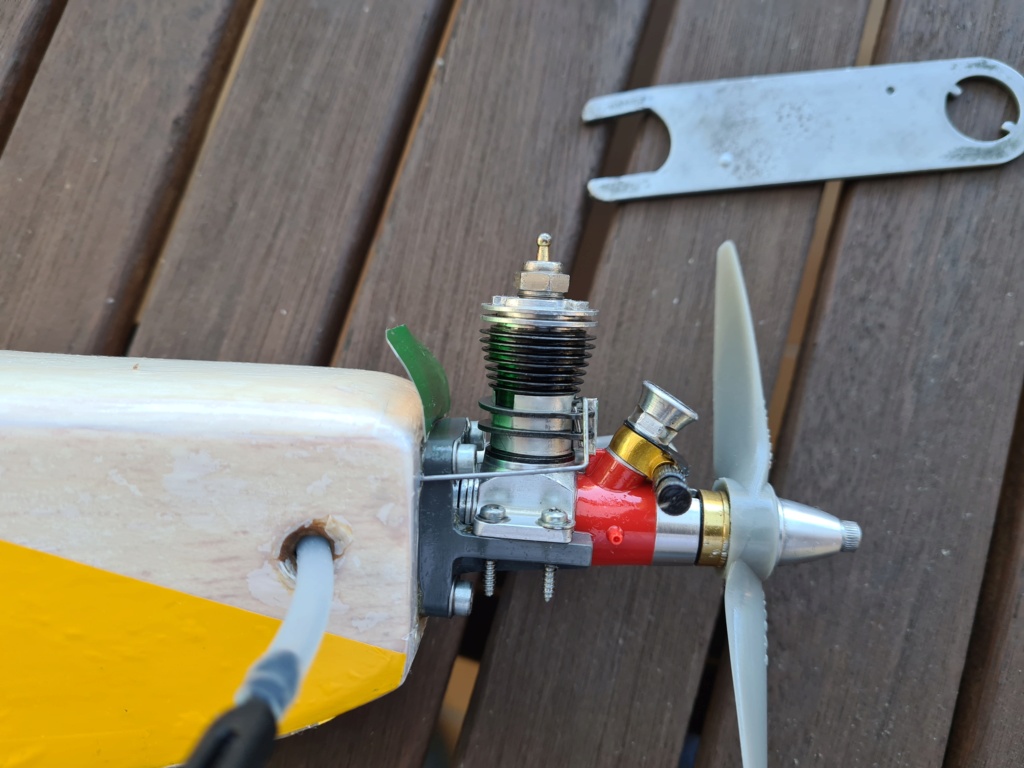

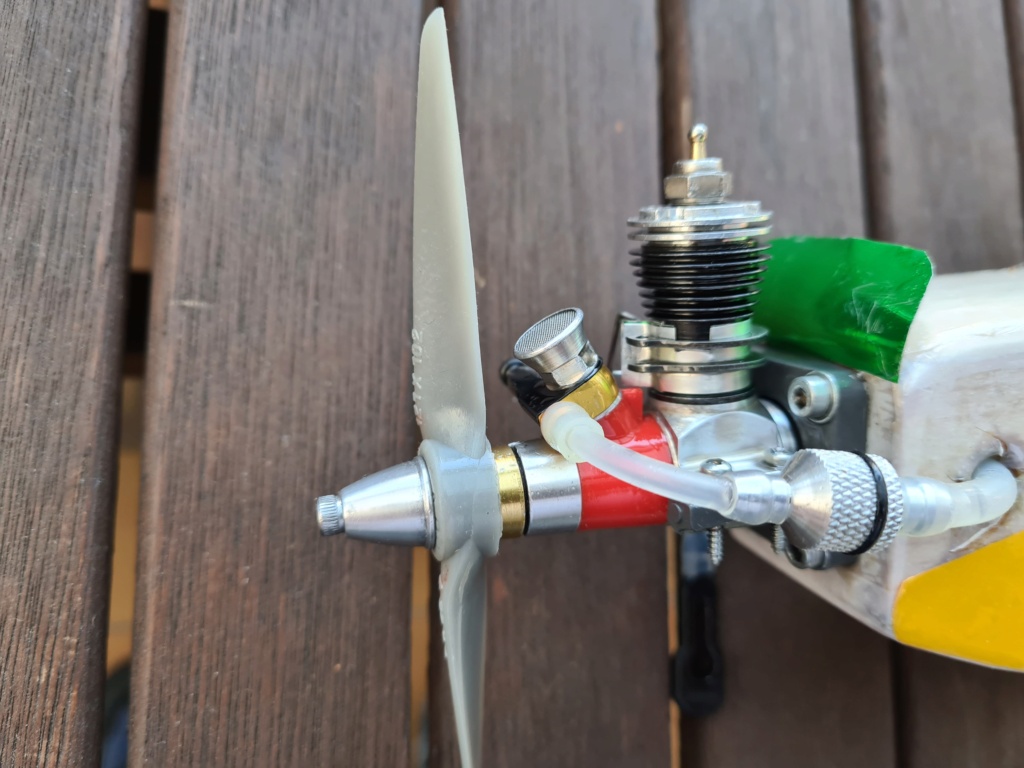

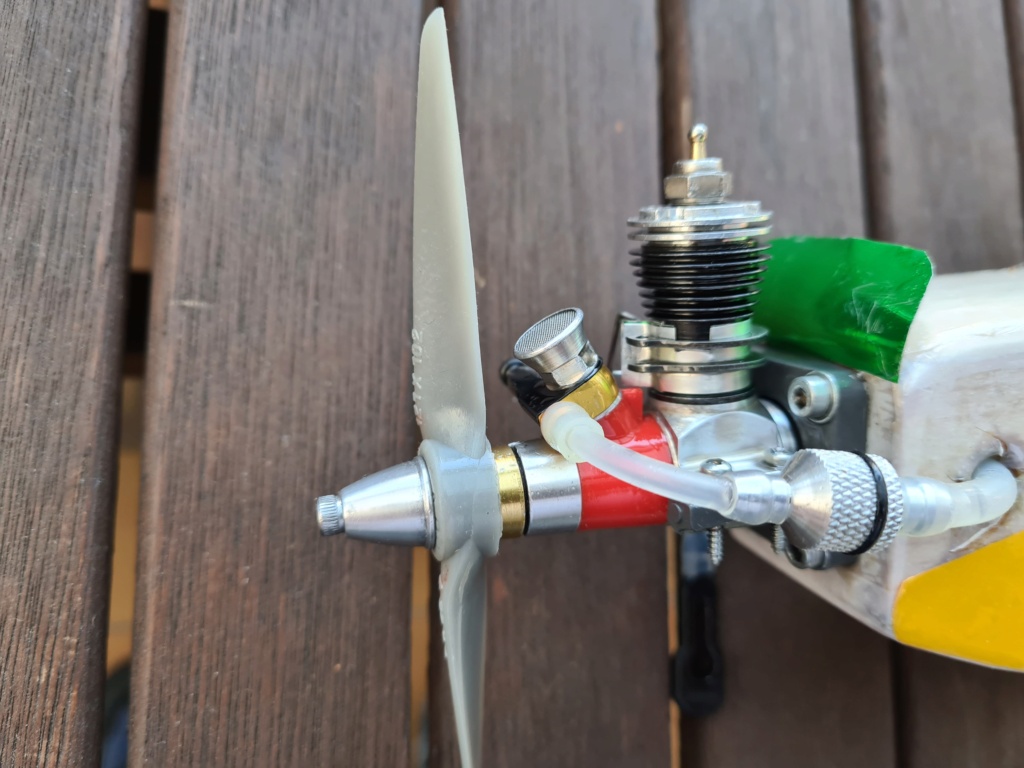

I have not given up, and developed the prototype po'boy's exhaust throttle concept a bit further, concentrating on improving the seal between the ring and the cylinder wall:

1. Eliminated the overlap between the 2 ends of the ring

2. Added a 2nd circlip to better press the ring around the cylinder circumference.

3. During the "bench run" (actually in the nose of the Toucan RC bird) , trimmed the throttle pushrod to the "sweet spot" of the ring where the rpm was the lowest

The results are encouraging:

The prototype I made a week or so ago brought the rpm down from 22k to 18k...this one brings it - from 22k - to 11k !!! I think this is not bad for a home made exhaust throttle ring. The stock rings sold by Bernie and Matt - not suitable for thin wall cylinders unfortunately, hence my home made efforts - are advertised to throttle down to idles around 7k..I am not sure if that refers to a reedie that normally spins the prop near 17k and throttles down to 7k with the stock exhaust throttle ring?...or, the 7k is true for TeeDee051-s?

(Next time I will check that with one of my other TeeDee-s having thick, or stepped wall cylinders..)

I am glad to have finally devised a rpm control tool for a thin wall SPI No.5 (or even No. 4) cylinder, and can only encourage y'all, to make one for yourselves, if your old-stock thin-wall cylinder COX is left without any other rpm control solution..

1. Eliminated the overlap between the 2 ends of the ring

2. Added a 2nd circlip to better press the ring around the cylinder circumference.

3. During the "bench run" (actually in the nose of the Toucan RC bird) , trimmed the throttle pushrod to the "sweet spot" of the ring where the rpm was the lowest

The results are encouraging:

The prototype I made a week or so ago brought the rpm down from 22k to 18k...this one brings it - from 22k - to 11k !!! I think this is not bad for a home made exhaust throttle ring. The stock rings sold by Bernie and Matt - not suitable for thin wall cylinders unfortunately, hence my home made efforts - are advertised to throttle down to idles around 7k..I am not sure if that refers to a reedie that normally spins the prop near 17k and throttles down to 7k with the stock exhaust throttle ring?...or, the 7k is true for TeeDee051-s?

(Next time I will check that with one of my other TeeDee-s having thick, or stepped wall cylinders..)

I am glad to have finally devised a rpm control tool for a thin wall SPI No.5 (or even No. 4) cylinder, and can only encourage y'all, to make one for yourselves, if your old-stock thin-wall cylinder COX is left without any other rpm control solution..

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

That is a very neat installation! Using a circlip as a spring is a good idea, and using the gap of the circlip and the tabs on the aluminum as a non-slip is genious. Congrats

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Po'boy's exhaust throttle for thin wall cylinder

Re: Po'boy's exhaust throttle for thin wall cylinder

Thank you Kari..I wanted to create a really very simple DIY option for the otherwise less versatile old stock thin wall cylinders..I highly value the old stock COX products made during the heyday with utmost pecision, but must admit they are sometimes less handy than later products. So I attempted to raise the user value of old stock stuff and I am happy to have given my shelf queens extended functionality. Many of my oldstock engines will now queue up for service in actual duty.

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Cox thin-wall .049 Cylinder...

» What is a thin cylinder wall?

» Wanted: unstamped thin wall #1 cylinder

» Early thin walled cylinder??

» 020 cylinder with exhaust throttle on ebay

» What is a thin cylinder wall?

» Wanted: unstamped thin wall #1 cylinder

» Early thin walled cylinder??

» 020 cylinder with exhaust throttle on ebay

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules