Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Engine positioning

Page 1 of 2

Page 1 of 2 • 1, 2

Re: Engine positioning

Re: Engine positioning

i'd wait till its all built, you might be able to slide engine back or forth as needed to help with CG. (#2 socket head screws)

Last edited by Mark Boesen on Tue Nov 17, 2020 10:58 pm; edited 1 time in total

Re: Engine positioning

Re: Engine positioning

Mark...thats what I was afraid of. ...I gave that a thought...would be much easier to do BEFORE final assembly though!

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

Ohbee, you can wrap the engine with rubber bands on mount and align the CG

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Engine positioning

Re: Engine positioning

Engine position will also affect fuel tank position...so....how do you juggle all that to get correct CG?....that I assume will change between a full tank and an empty tank?!

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

Mount the fuel tank on CG or very close to CG. If it is impossible I always balance the model with an empty tank.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Engine positioning

Re: Engine positioning

Gotcha....thanks!

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

Seeing as that appears to be a profile CL model the fuel tank will be residing directly behind the engine and not on the CG. Check CG with everything in place and tank empty. Alter tank and engine positions if needed until you get the CG where you want it.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Engine positioning

Re: Engine positioning

Well I guess that'll be awhile!..... the holes in that engine arn't far enough apart to even get into the meat of the hardwood mounts!

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

What are the model dimensions? Would an .09 work?

What type of glue did you use to adhere the doublers?

Ron

What type of glue did you use to adhere the doublers?

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Engine positioning

Re: Engine positioning

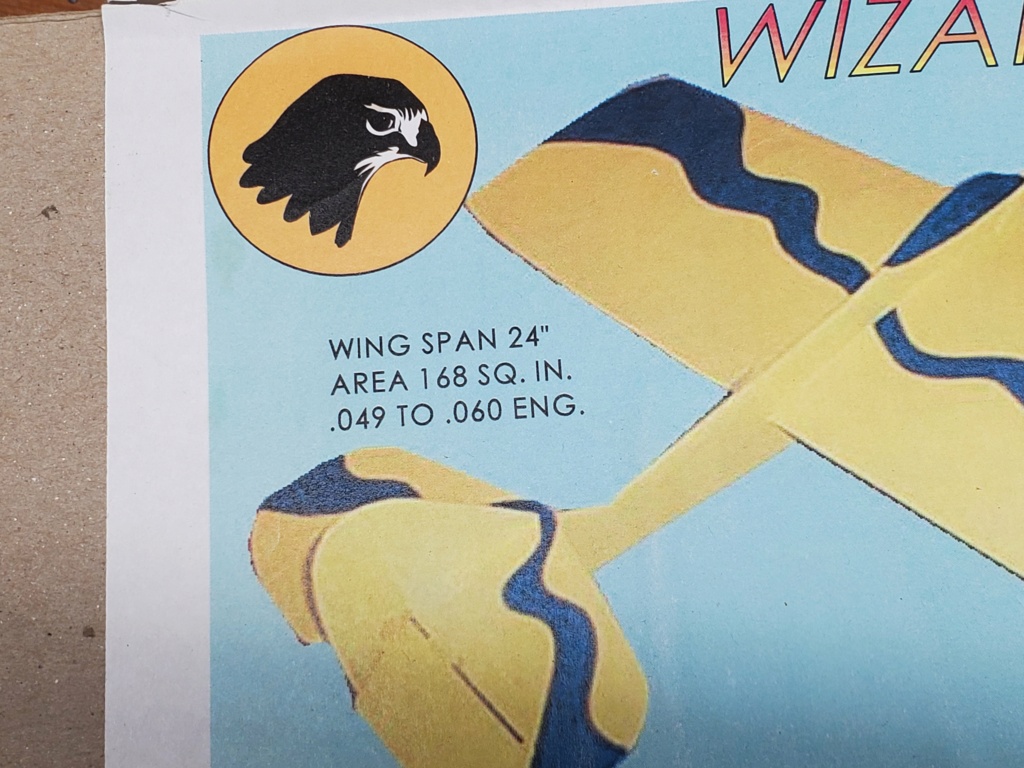

Box says .049-.060 engines. 24" wingspan,7" wing chord 20" fuselage length. It's an old Blackhawk Wizard kit. Assembled with titebond II and CA.

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

OhBee,

Feel free to cheat. Cut a 1/8" thick light aluminum plate (or a bit thinner) with a bolt pattern bigger than any engine you may have for this airframe. The plate would then be drilled for this engine. Then you can make a couple of different ones with differing holes, or rows of holes that let you move a given engine back and forth. The fuel tank can be rubber-banded or zip-tied, or a quick, light tank plate made and mounted whereby even the tank mount is adjustable.

Once the plane is completed, then you make adjustments. Everything can then be hard-mounted after flying and tweeking to your satisfaction.

PS...I like to check the hardwood mount.spacing before fitting to the fuselage...sometimes I add material...sometimes I take it away.

Feel free to cheat. Cut a 1/8" thick light aluminum plate (or a bit thinner) with a bolt pattern bigger than any engine you may have for this airframe. The plate would then be drilled for this engine. Then you can make a couple of different ones with differing holes, or rows of holes that let you move a given engine back and forth. The fuel tank can be rubber-banded or zip-tied, or a quick, light tank plate made and mounted whereby even the tank mount is adjustable.

Once the plane is completed, then you make adjustments. Everything can then be hard-mounted after flying and tweeking to your satisfaction.

PS...I like to check the hardwood mount.spacing before fitting to the fuselage...sometimes I add material...sometimes I take it away.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Engine positioning

Re: Engine positioning

Ya...the instructions with this kit were vague at best... I'm kinda winging it,and apparantly forgot more about this stuff than I knew! About ready to just quit while I'm ahead. Dosn't seem to be my thing anymore,and nobody around here has even basic supplys. After an entire day in town I couldn't even find anyone that carried Deft products. And I don't have a well equipped shop!.....plus I seem to be allergic to balsa dust!!.....

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

What is it that you are needing?

Just ask, I’ve got plenty of stuff to share. Pretty sure you have a mask to wear when sanding...

I was hoping you had used epoxy on the doublers, it would be easy to remove the doublers with heat and install wider bearers.

I could have sworn I read somewhere that the Wizard which I believe is a Musciano design was .049-.09

I saw a pic of one sporting an O.S. Engine probably a .10-.15.

Ron

Edit: found the pics online looks like a .15 I think an .09 would work fine it’s a pretty large 1/2A

https://cdn-global-hk.hobbyking.com/media/file/8768903X63449X33.JPG

Just ask, I’ve got plenty of stuff to share. Pretty sure you have a mask to wear when sanding...

I was hoping you had used epoxy on the doublers, it would be easy to remove the doublers with heat and install wider bearers.

I could have sworn I read somewhere that the Wizard which I believe is a Musciano design was .049-.09

I saw a pic of one sporting an O.S. Engine probably a .10-.15.

Ron

Edit: found the pics online looks like a .15 I think an .09 would work fine it’s a pretty large 1/2A

https://cdn-global-hk.hobbyking.com/media/file/8768903X63449X33.JPG

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

I think a .15 would be too heavy and major overkill on this thing!

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

It might be built just for racing. And I agree way too much for stunt. That’s why I suggested a .09 better yet a Medallion .09 better fuel draw than a TD and less power.

Most 1/2A’s hover around 20-22” wingspan. Some larger some smaller. I really do think it would be a good fit. There are plenty around. Not much point building a model 3/4 of the way and putting it on the shelf...

Something to consider I guess. You could always just install larger bearers or do what’s been suggested.

I’m interested in seeing this one finished!

I don’t think it’s scaled up as the plans and kit box are in the pics, unless Blackhawk kitted two different sizes.

Most 1/2A’s hover around 20-22” wingspan. Some larger some smaller. I really do think it would be a good fit. There are plenty around. Not much point building a model 3/4 of the way and putting it on the shelf...

Something to consider I guess. You could always just install larger bearers or do what’s been suggested.

I’m interested in seeing this one finished!

I don’t think it’s scaled up as the plans and kit box are in the pics, unless Blackhawk kitted two different sizes.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Engine positioning

Re: Engine positioning

I did notice the boxes are different.....probably an age difference.,and sometimes pics are decieving! ...ya,I really don't want to change to a radial mount and stick a Babe Bee on it...probably bee a pooch!. What size tank is good for 2-4 mins. with a TD .049. All I have is a 3/8oz. tank......maybe I just need a differnt motor like you said. Not much out there from the perusing I've done....at least not cheap enough for my budget.

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

OhBee,

It may be worth trying a plywood engine mount cut as I described for the aluminum mount above. I wouldn't expect it to last long, but it should hold up well enough to fly a few times while you work out the details.

Or...

Would you consider finding a slightly bigger engine? Or are you working hard to avoid the sippery slope known as "engine hording?" (Yes, I am thus afflicted)

I bet a Norvel Big Mig .074 would slip right in, and it would pull this plane around with authority. Every now and then an older Enya or similar pops up on the ' Bay for peanuts.

It may be worth trying a plywood engine mount cut as I described for the aluminum mount above. I wouldn't expect it to last long, but it should hold up well enough to fly a few times while you work out the details.

Or...

Would you consider finding a slightly bigger engine? Or are you working hard to avoid the sippery slope known as "engine hording?" (Yes, I am thus afflicted)

I bet a Norvel Big Mig .074 would slip right in, and it would pull this plane around with authority. Every now and then an older Enya or similar pops up on the ' Bay for peanuts.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Engine positioning

Re: Engine positioning

I thought the TD would be plenty enough engine for this plane. But....I DO like engines! It was my livelyhood for 42 yrs! These arn't as labor intensive to work on! .I'm partial to the Enyas and older OS engines.

OhBee- Platinum Member

- Posts : 698

Join date : 2016-03-23

Age : 73

Location : Minnesota

Re: Engine positioning

Re: Engine positioning

A plywood doubler as Jim described with plenty of polyurethane or another fuel proofer is a good solution.

Other than this, you can epoxy an aluminum strip under each engine mounting lug.

I always smear epoxy or polyurethane fuel proofer inside of screw holes on plywood, because screw holes absorbs fuel.

Other than this, you can epoxy an aluminum strip under each engine mounting lug.

I always smear epoxy or polyurethane fuel proofer inside of screw holes on plywood, because screw holes absorbs fuel.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Engine positioning

Re: Engine positioning

Hi OhBee,

What are the dimensions of the engine mount opening? Maybe we can figure out what engine fits.

I know you have few options as far as engine choice is concerned, but I think something can be worked out.

What are the dimensions of the engine mount opening? Maybe we can figure out what engine fits.

I know you have few options as far as engine choice is concerned, but I think something can be worked out.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Engine positioning

Re: Engine positioning

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Page 1 of 2 • 1, 2

Similar topics

Similar topics» tank placing

» Spray bar holes positioning

» *Cox Engine of The Month* Submit your pictures! -June 2014- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -June 2016- *ENGINE GIVEAWAY*

» **Black Lynx Engine Giveaway June 2018** Cox Engine of the Month

» Spray bar holes positioning

» *Cox Engine of The Month* Submit your pictures! -June 2014- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -June 2016- *ENGINE GIVEAWAY*

» **Black Lynx Engine Giveaway June 2018** Cox Engine of the Month

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules