Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Motor Starting Better One Way Than Another

Page 1 of 1

Motor Starting Better One Way Than Another

Motor Starting Better One Way Than Another

Got a first for me. I have a later Widow about 78 I think. I put a new condition #1 cylinder on it and brass backplate as the plastic one was toasted. Running pretty good. With a 6x4 getting about 16,800 RPM so because big prop I'll say I'm satisfied. Plane does about 75 mph +-.

Now here is the question. The motor if I spin it rotation (counter clockwise) it takes 10 or more spins at cold to fire. If I spin it clockwise (backward rotation) Fires and starts after first or second maximum third spin. When the motor has made a run it doesn't really matter anymore just when cold. I always start by hand w/o snap starter.

I have no idea. As performance is good after first start or after 3-4 tankfulls all same. Just starting direction is goofy.

Any thoughts?

Thanks

Iceberg

Now here is the question. The motor if I spin it rotation (counter clockwise) it takes 10 or more spins at cold to fire. If I spin it clockwise (backward rotation) Fires and starts after first or second maximum third spin. When the motor has made a run it doesn't really matter anymore just when cold. I always start by hand w/o snap starter.

I have no idea. As performance is good after first start or after 3-4 tankfulls all same. Just starting direction is goofy.

Any thoughts?

Thanks

Iceberg

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

Involved in other tasks, please excuse horrible syntax...

I'm guessing as I've seen this on a few of mine:

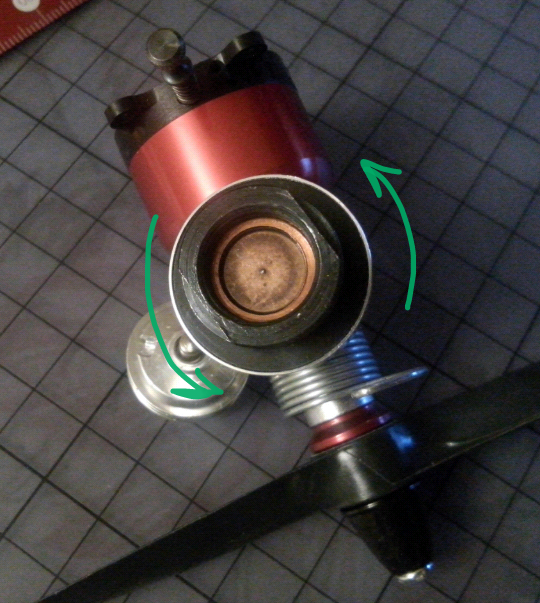

Cold block and crank will allow crankcase pressure leakdown difference between puller configuration and pusher configuration since the thrust bearing is on different ends of the block bushing. The pull thrust pushes the crank against the inside of the crankcase about vs push thrust pushing the prop drive plate against the outside of the crankcase.

To validate my suspicion, try two similar, but counter-rotaring props to effectively change the thrust forces, but in same rotation. This will also allow baselining push-pull on same prop in one direction, and the baselining push-pull in the other direction. Then the only difference will be oiling-of-the-crank differences due to internal pressure while in push vs pull.

I hope that makes sense....will check later for response.

I'm guessing as I've seen this on a few of mine:

Cold block and crank will allow crankcase pressure leakdown difference between puller configuration and pusher configuration since the thrust bearing is on different ends of the block bushing. The pull thrust pushes the crank against the inside of the crankcase about vs push thrust pushing the prop drive plate against the outside of the crankcase.

To validate my suspicion, try two similar, but counter-rotaring props to effectively change the thrust forces, but in same rotation. This will also allow baselining push-pull on same prop in one direction, and the baselining push-pull in the other direction. Then the only difference will be oiling-of-the-crank differences due to internal pressure while in push vs pull.

I hope that makes sense....will check later for response.

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

Jim said it a little more intelligently than me, but put simply you will have better compression seal on the piston/cylinder fit on the side less used. You can feel it if you finger flip counter and clockwise. You will have more “pop” in the direction used less.

If you picture the way a piston moves and wears within a cylinder one side presses hard as it comes up on the compression stroke and the other side kind of just drags down the cylinder with less pressure. There is a term for it, but it alludes me at the moment.

If you picture the way a piston moves and wears within a cylinder one side presses hard as it comes up on the compression stroke and the other side kind of just drags down the cylinder with less pressure. There is a term for it, but it alludes me at the moment.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

I think the wear on the cylinder will be faster on the side which is pressed by the piston not during compression, but during expansion because the latter occurs after the ignition of fuel air mix is followed by a high pressure build up in the cylinder which is way higher than the pressure during compression stroke..

It means that facing the engine and running a puller prop counter clockwise it is the right side of the cylinder that in my opinion gets higher load and maybe wear from the piston..Given the balljoint in the piston allowing it to rotate around its axis, the piston wall is expected to have uniform wear around its circumference.

But by the time this assymetric wear becomes manifest the engine loses so much compression that only an electric starter can help.

Sorry if I misunderstood your explanation.

It means that facing the engine and running a puller prop counter clockwise it is the right side of the cylinder that in my opinion gets higher load and maybe wear from the piston..Given the balljoint in the piston allowing it to rotate around its axis, the piston wall is expected to have uniform wear around its circumference.

But by the time this assymetric wear becomes manifest the engine loses so much compression that only an electric starter can help.

Sorry if I misunderstood your explanation.

Last edited by balogh on Wed Aug 05, 2020 4:19 pm; edited 1 time in total (Reason for editing : typo corrected)

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

LH RH crankshafts??

LH RH crankshafts??

944_Jim wrote:Involved in other tasks, please excuse horrible syntax...

I'm guessing as I've seen this on a few of mine:

Cold block and crank will allow crankcase pressure leakdown difference between puller configuration and pusher configuration since the thrust bearing is on different ends of the block bushing. The pull thrust pushes the crank against the inside of the crankcase about vs push thrust pushing the prop drive plate against the outside of the crankcase.

To validate my suspicion, try two similar, but counter-rotaring props to effectively change the thrust forces, but in same rotation. This will also allow baselining push-pull on same prop in one direction, and the baselining push-pull in the other direction. Then the only difference will be oiling-of-the-crank differences due to internal pressure while in push vs pull.

I hope that makes sense....will check later for response.

Guys: I know that a few Tee Dee crankshafts were made for LH rotation, from the pilots view, but were any of the babe bee type crankshafts made that way too, i.e. car, and boat pushers, with a little offset in the piston pin? Or were the baby engines just prone to go either way? I have never noticed any offset in the baby bee cranks, but have seen a few of the Tee Dee cranks.

Judy wondering.

Happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

HD a reedy will run happily in any direction because the suction timing is by crankcase depression and not by rotation valve design like the TeeDees. It would be pointless to make LH and RH cranks for reedies. The only performance difference between RH and LH rotation of a reedy ( or more exactly, between puller and pusher modes) comes from the difference in the friction of the thrust bearings i.e the crank shoulder in puller and the prop drive plate in pusher mode.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

Gee whiz, Balogh. You said the same thing I did in about half as many words. I've been told I talk too much!

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

balogh wrote:I think the wear on the cylinder will be faster on the side which is pressed by the piston not during compression, but during expansion because the latter occurs after the ignition of fuel air mix is followed by a high pressure build up in the cylinder which is way higher than the pressure during compression stroke..

It means that facing the engine and running a puller prop counter clockwise it is the right side of the cylinder that in my opinion gets higher load and maybe wear from the piston..Given the balljoint in the piston allowing it to rotate around its axis, the piston wall is expected to have uniform wear around its circumference.

But by the time this assymetric wear becomes manifest the engine loses so much compression that only an electric starter can help.

Sorry if I misunderstood your explanation.

Balogh,

You are correct, I had it backwards. The major thrust side of the piston is on the downstroke after ignition. The minor thrust side is as it comes up during compression. Either way it explains why the cylinder wears more on one side than the other. This allows better compression when started In the opposite direction as the major becomes the minor thrust side. A new engine shouldn’t experience this problem, but only after being worn some. On the plus side it made me search for the correct terms!

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

Ah Ron, your wearing the eraser down on your pencil.

Probably the problem with that Cox Corsair engine I sent you. I was flipping it in one direction and it wouldn't start, you just flipped it opposite and voila!

Bob

Probably the problem with that Cox Corsair engine I sent you. I was flipping it in one direction and it wouldn't start, you just flipped it opposite and voila!

Bob

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

Rotating cylinder 180 degrees around it's axis can solve this problem? Can it be start better at flipping counter clockwise?

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

I guess rotating i.e. unscrewing the cylinder 180 degrees will compromise compression ratio and change cylinder timing?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

The cylinder is in super nice condition. I got it through Gibault. I suspect the crank pushing or pulling and sealing better. The motor OFTEN prefers to run pushing air back towards the motor. This ads further to the suspicion. However once it starts it runs beautifully and fast. Jim I'll try reverse prop hopefully today but it's raining might be tomorrow. That will answer this part of the puzzle.

Thanks

Iceberg

Thanks

Iceberg

Last edited by Iceberg on Thu Aug 06, 2020 11:48 am; edited 1 time in total (Reason for editing : Spelling mistakes)

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

balogh wrote:I guess rotating i.e. unscrewing the cylinder 180 degrees will compromise compression ratio and change cylinder timing?

Yes, you are right. Rotating piston 180 degrees?

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

Levent I think the COX piston rotates freely thanks to the balljoint. So despite setting it in a position initially, nothing will keep it from rotating after the engine starts. A piston with a gudgeon pin would certainly stay as mounted.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

balogh wrote:Levent I think the COX piston rotates freely thanks to the balljoint. So despite setting it in a position initially, nothing will keep it from rotating after the engine starts. A piston with a gudgeon pin would certainly stay as mounted.

Andras, you are right about this. I think that piston do not rotate too much, yet I don't know rotating degrees of piston while running. Perhaps piston rotates right and left at equal degrees, or rotates to left continously. I have not info about this.

Perhaps piston bottom shaves cylinder at one side, because it's bottom has no rounding, but it's top is rounded.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

May have something to do with the spiral honing marks in a new cylinder? The fine marks may act like a thread in a nut?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

balogh wrote:May have something to do with the spiral honing marks in a new cylinder? The fine marks may act like a thread in a nut?

Interesting.

It has dual bypass with boost ports one per side. This make any effect?

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

I tried another piston and cylinder, and piston didn't rotate any. I understood that piston rotating is random in every other engine and has no relationship with booster ports.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Motor Starting Better One Way Than Another

Re: Motor Starting Better One Way Than Another

Hi Jim

In response to your comments about push pull props. Yes you are correct. The pusher prop had the exact opposite effect. The engine preferred to start counter clockwise instead of clockwise with a normal prop. The force pushing back towards the block must have marginally sealed the crankcase and better starting was noticed as you suggested. This I have never seen before.

However as I said before once started the correct way the widow performed very well indeed. I ran it today and I think it was almost 18K although I didn't Tach it. I can hear from the pitch of the motor I have trained my ear to hear it. I got almost 2.8 minutes per 8 CC tnk. I feel that good as the high RPM often chews more fuel. The cylinder is an extremely nice one I got through Gibeault. Maybe since the compression is high the efficiency is good.

However the starting of my old Widow block is as you said Jim prop plate pushing towards block assists starting.

Thanks good to have such knowledgeable ones on the Forum Jim.

Ice

In response to your comments about push pull props. Yes you are correct. The pusher prop had the exact opposite effect. The engine preferred to start counter clockwise instead of clockwise with a normal prop. The force pushing back towards the block must have marginally sealed the crankcase and better starting was noticed as you suggested. This I have never seen before.

However as I said before once started the correct way the widow performed very well indeed. I ran it today and I think it was almost 18K although I didn't Tach it. I can hear from the pitch of the motor I have trained my ear to hear it. I got almost 2.8 minutes per 8 CC tnk. I feel that good as the high RPM often chews more fuel. The cylinder is an extremely nice one I got through Gibeault. Maybe since the compression is high the efficiency is good.

However the starting of my old Widow block is as you said Jim prop plate pushing towards block assists starting.

Thanks good to have such knowledgeable ones on the Forum Jim.

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Similar topics

Similar topics» .049 starting?

» Starting qs

» Help starting

» Starting a New Tee Dee 049

» [solved]Is cox still in business? I cant find anything on their site!

» Starting qs

» Help starting

» Starting a New Tee Dee 049

» [solved]Is cox still in business? I cant find anything on their site!

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules