Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

shure start air intake break

Page 1 of 1

shure start air intake break

shure start air intake break

Hello everyone.

A while back I started having running problems on my shure start.

When I adjusted the RPM and launched the model into the air, the engine stopped within seconds of running.

This added to the fact that it was difficult for me to find the optimal needle adjust.

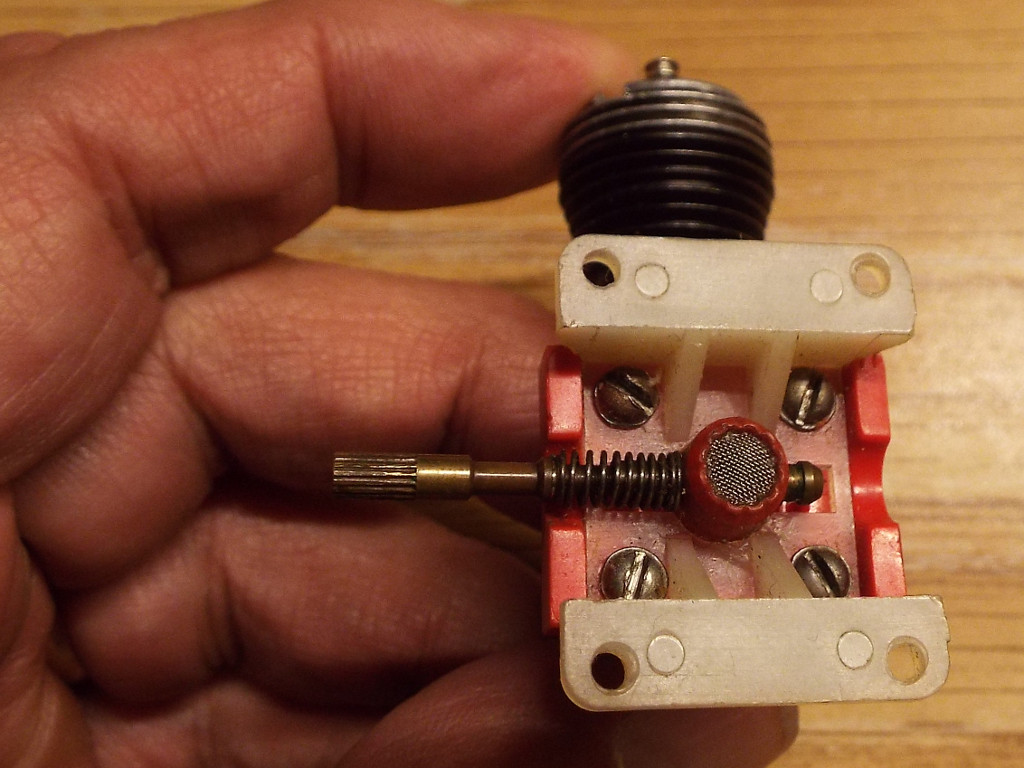

A few days ago I took the engine apart to check if it did not have any dirt in the carburetor, and when removing the air intake I find a crack in the engine air intake.

I suppose that this crack occurs because the spay bar got too tight when they installed it when manufacturing it.

Speaking to another colleague, he told me that exactly the same failure happened to him in another shure start.

If anyone has any way to solve this problem without changing the part I would appreciate it if you could tell me.

I have thought about cleaning the part well so that there is no oil left and trying to solve it with epoxy resin.

I thank you in advance for any advice you can give me.

greetings to all from Argentina

A while back I started having running problems on my shure start.

When I adjusted the RPM and launched the model into the air, the engine stopped within seconds of running.

This added to the fact that it was difficult for me to find the optimal needle adjust.

A few days ago I took the engine apart to check if it did not have any dirt in the carburetor, and when removing the air intake I find a crack in the engine air intake.

I suppose that this crack occurs because the spay bar got too tight when they installed it when manufacturing it.

Speaking to another colleague, he told me that exactly the same failure happened to him in another shure start.

If anyone has any way to solve this problem without changing the part I would appreciate it if you could tell me.

I have thought about cleaning the part well so that there is no oil left and trying to solve it with epoxy resin.

I thank you in advance for any advice you can give me.

greetings to all from Argentina

nico010- Bronze Member

- Posts : 53

Join date : 2019-04-15

Re: shure start air intake break

Re: shure start air intake break

epoxy it may work if intake tube is glue to back plate just canot pul of tube from back plate after y did use treebond 515 permatex motoseal grey gasket maker it may work remember som time engine stal after hard hand lunch engine is to lean dont try get very max rpm let engine get its operating temp it change in flight as engine go forward rpm increase nead more fuel from statick operation on bench my use fuel tube for filing tank to presurize tube is place right behind prop after looping tube dont clog wit fuel hope u get it back to god runing condition

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

When did you buy the backplate?

When did you buy the backplate?

How long ago did you buy the backplate and whom did you buy it from? I’m sure that our favorite cox parts suppliers would be interested in knowing if there was a bad batch of these parts sitting in a stock bin somewhere. These could have been made years ago, or are being made currently. Only the sellers know for sure.

It couldn’t hurt to ask.

Happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: shure start air intake break

Re: shure start air intake break

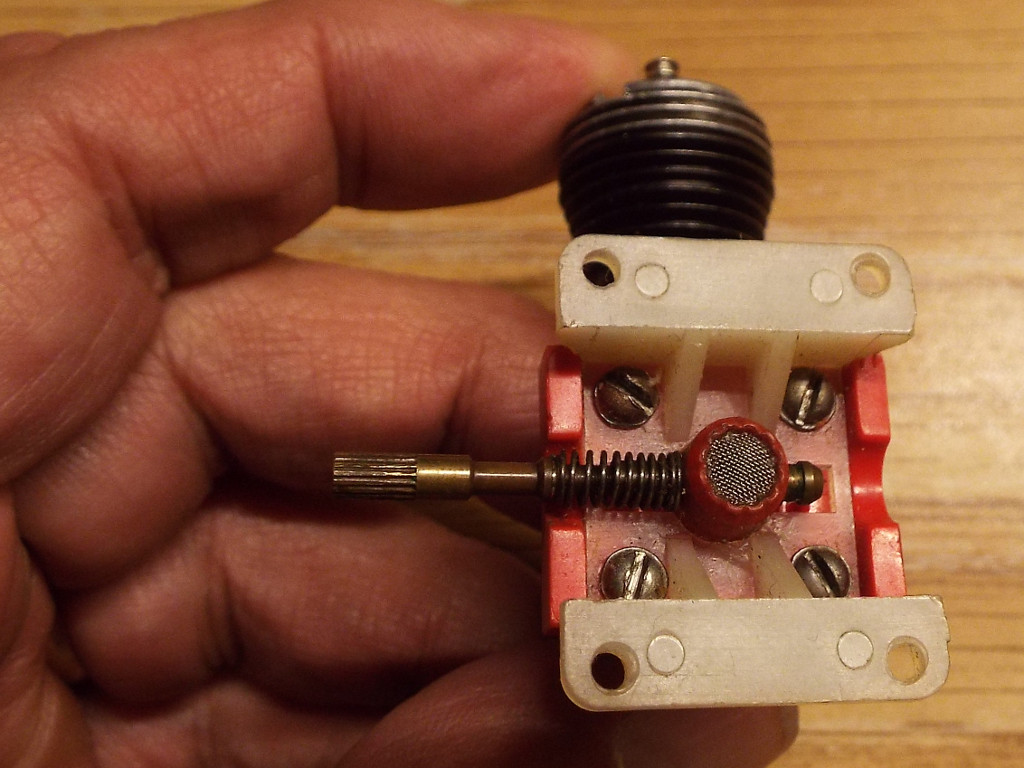

I have a few of them all bought from COX International some 8 or so years ago and most are broken the same way. They must have been made in the late Estes era where the "COX" quality was already a thing of distant past. If the spraybar does not move, it should not impact the engine run. The crack allows a bit more air entry like after removing the screen from the tube. If the spraybar moves/rotates though, then setting the NV is not easy and the hole on the spraybar will not stay at the point of lowest depression and fuel suction is impaired.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: shure start air intake break

Re: shure start air intake break

balogh wrote:I have a few of them all bought from COX International some 8 or so years ago and most are broken the same way. They must have been made in the late Estes era where the "COX" quality was already a thing of distant past. If the spraybar does not move, it should not impact the engine run. The crack allows a bit more air entry like after removing the screen from the tube. If the spraybar moves/rotates though, then setting the NV is not easy and the hole on the spraybar will not stay at the point of lowest depression and fuel suction is impaired.

Ditto! I had a couple the same.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: shure start air intake break

Re: shure start air intake break

It is interesting that you experienced a break in those Sure Start backs caused by the stresses from the forces of friction fitting undertension by the spray bar inserted into the venturi, Balogh. My 1960's postage stamp backs made of red Delrin nylon still show no signs of any cracking even though they are now easily 50 years old.

Yet, a Cox .074 Queen Bee that I bought in the late 1980's / early 2000's before the Cox Division was sold to Estes developed cracks in the bosses of the carb spacer where the sheet metal screws held the plastic carb in place. The stresses of the sheet metal screws wedged into the holes under pressure caused the bosses to split. I don't have a photo of that as I bought a replacement a while back, which fixed the problem. Here's a photo of the parts, the one I am talking about is in the upper left:

I gather that the failure is due not so much to the proportions of the part as it is to the properties of the gray plastic used in this case, appears weaker and more brittle. The red Delrin appears to have similar thickness proportions of the venturi, yet it did not crack even 50+ years later.

I am thinking there may be a good possibility that the cracked gray backs may possibly be Cox produced but from a run of parts where the gray plastic selected was not up to the quality needed to prevent cracking. Towards the end of the Cox division prior to sale, with changes in the engine line Cox produced a failed line, the Queen Bee, a Cox "Edsel". (Edsel was a Ford car manufacturing luxury model brought out in the late 1950's, which was a sales failure due to its unpopularity. It was ugly. The Queen Bee at 4 oz. weight was heavy, same weight as my Enya .09-III TV.) Fact my QB carb mount screw mount ears split just from all things of storage only tells me that some cost cutting decisions over the quality of the plastic used may have not been the best thing after all, perhaps out of desperation toward the end of the Cox division.

I saw similar acts of desperation at McDonnell Douglas, Douglas Aircraft made by management before I left the company in 1993. (They took all engineers off the E-mail system to reduce IT costs, only supervisors had E-mail, we went back to 3 part hand written speed memos. It was a throwback to notes passing in high school in an era when there were no cellphones and texting. )

)

Fortunately there appears to be ample parts backs still in stock.

Yet, a Cox .074 Queen Bee that I bought in the late 1980's / early 2000's before the Cox Division was sold to Estes developed cracks in the bosses of the carb spacer where the sheet metal screws held the plastic carb in place. The stresses of the sheet metal screws wedged into the holes under pressure caused the bosses to split. I don't have a photo of that as I bought a replacement a while back, which fixed the problem. Here's a photo of the parts, the one I am talking about is in the upper left:

I gather that the failure is due not so much to the proportions of the part as it is to the properties of the gray plastic used in this case, appears weaker and more brittle. The red Delrin appears to have similar thickness proportions of the venturi, yet it did not crack even 50+ years later.

I am thinking there may be a good possibility that the cracked gray backs may possibly be Cox produced but from a run of parts where the gray plastic selected was not up to the quality needed to prevent cracking. Towards the end of the Cox division prior to sale, with changes in the engine line Cox produced a failed line, the Queen Bee, a Cox "Edsel". (Edsel was a Ford car manufacturing luxury model brought out in the late 1950's, which was a sales failure due to its unpopularity. It was ugly. The Queen Bee at 4 oz. weight was heavy, same weight as my Enya .09-III TV.) Fact my QB carb mount screw mount ears split just from all things of storage only tells me that some cost cutting decisions over the quality of the plastic used may have not been the best thing after all, perhaps out of desperation toward the end of the Cox division.

I saw similar acts of desperation at McDonnell Douglas, Douglas Aircraft made by management before I left the company in 1993. (They took all engineers off the E-mail system to reduce IT costs, only supervisors had E-mail, we went back to 3 part hand written speed memos. It was a throwback to notes passing in high school in an era when there were no cellphones and texting.

Fortunately there appears to be ample parts backs still in stock.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: shure start air intake break

Re: shure start air intake break

GallopingGhostler wrote:It is interesting that you experienced a break in those Sure Start backs caused by the stresses from the forces of friction fitting undertension by the spray bar inserted into the venturi, Balogh. My 1960's postage stamp backs made of red Delrin nylon still show no signs of any cracking even though they are now easily 50 years old.

I don't think that it is the stress from the actual mounting but rather due to ageing properties of the chosen plastics. Most plastics contain softeners that will evaporate with time and the plastic can shrink and become brittle. So if the backplates were made in the Estes era or perhaps just before, they are certainly old enough to simply break due to the built in strain and changes in material properties.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: shure start air intake break

Re: shure start air intake break

I've posted this same issue some time ago on the forum. I purchased 10 Sure Starts from Estes at $4 a piece. Everyone of them including the 3 still in the bubble wrap are cracked the same way. It's not hard to believe because cheap sells. Why use good quality material when you can put out cheap materials that work long enough to pacify the end user? Its like everything else we buy today. If it breaks you buy another. Thankfully we have vendors still offering the needed parts.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: shure start air intake break

Re: shure start air intake break

Surfer_kris wrote:GallopingGhostler wrote:It is interesting that you experienced a break in those Sure Start backs caused by the stresses from the forces of friction fitting undertension by the spray bar inserted into the venturi, Balogh. My 1960's postage stamp backs made of red Delrin nylon still show no signs of any cracking even though they are now easily 50 years old.

I don't think that it is the stress from the actual mounting but rather due to ageing properties of the chosen plastics. Most plastics contain softeners that will evaporate with time and the plastic can shrink and become brittle. So if the backplates were made in the Estes era or perhaps just before, they are certainly old enough to simply break due to the built in strain and changes in material properties.

This is especially true with the black flexible propellers. They typically have a 10 year shelf life before starting to get brittle and needing to be scrapped. In this case it is the nature of the material. The gray competition series lasts much longer.

On the backplates, initially, a lot of the Estes ones that have the cracking problem was due to improper cleanup of the parts when they came out of the molds and/or the pressing of the spraybar at a bad angle which caused the cracking. The former Estes/Cox did not want to pay any extra to have the spraybar hole properly cleaned of scrap material which may have been sitting in or near the hole. When the spraybar was pressed the ID was essentially a smaller size and caused a small split which increases over time. There was also some poor assembly of the spraybars where they were not fitted at a perpendicular angle and the pressing cased a split. The last run of gray backplates (Star Wars timeframe) were done in Mexico with little quality control.

Cannot tell you how many of these we have trashed due to the splitting issue.

Re: shure start air intake break

Re: shure start air intake break

I guess they figured the shelf life was a year or two, not 40. hehe. I have been contemplating pressing in one of those spraybars into a bee tank. Drill a couple big 3/8" holes in the side of the tank, and the appropriate size hole in the centre of the venturi. You already have the needle assembly from the Surestart. You would need to open up the bore a bit to suit/mimic the plastic one. It is only .250" OD not the .300" that the plastic one is. You do away with the old needle valve on the backplate, as well as the O ring etc. A flying buddy used a TD spray bar inside the tank, as it fit directly over the aluminum tank venturi. Just a thought if you want to experiment and have a bunch of old spare parts with broken needle tips and tanks that you don't mind chopping up. The old flea fright guys would often drill a big hole in the tank of a Bee and run a separate tank or bladder in a similar fashion. I was going to actually drill and tap the venturi in the tank for a 4-40 pressure fitting and use a remote needle just to see how it worked. Just kind of tired of leaky backplates and gaskets. Not that I use the reedy Bees that much. Maybe I might if they worked better.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: shure start air intake break

Re: shure start air intake break

GallopingGhostler wrote:It is interesting that you experienced a break in those Sure Start backs caused by the stresses from the forces of friction fitting undertension by the spray bar inserted into the venturi, Balogh. My 1960's postage stamp backs made of red Delrin nylon still show no signs of any cracking even though they are now easily 50 years old....

.

The same experience here with quite a number of red postage stamp 190-s and red and white horseshoe backplate reedies all dating back to the 60s...80s..no crack anywhere and except for the stiffened NV seals, all parts as new..

When I returned to the hobby 10 years ago and found a bonanza of COX engines on the net I bought some Surestarts and their parts too.in fact I have never used them but preferred old stock COX engines instead, and keep the Surestarts as parts donors if ever needed..their steel and aluminum parts are still good except for some very loose fit cylinder and piston combos.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: shure start air intake break

Re: shure start air intake break

EXModelEngines wrote:On the backplates, initially, a lot of the Estes ones that have the cracking problem was due to improper cleanup of the parts when they came out of the molds and/or the pressing of the spraybar at a bad angle which caused the cracking. The former Estes/Cox did not want to pay any extra to have the spraybar hole properly cleaned of scrap material which may have been sitting in or near the hole. When the spraybar was pressed the ID was essentially a smaller size and caused a small split which increases over time. There was also some poor assembly of the spraybars where they were not fitted at a perpendicular angle and the pressing cased a split. The last run of gray backplates (Star Wars time frame) were done in Mexico with little quality control.

Cannot tell you how many of these we have trashed due to the splitting issue.

Thanks for the practical info from personal observations and experiences. Yes, they were creating what is called concentrated stress by not reaming and deburring the holes clean. That basically pushed the material from the spring range into the plastic deformation area. (Stuff stretches and doesn't return to its original size.) Good to also know so when we get a back that is without the spraybar, to do a little TLC.

Just checking a Sure Start I bought from the Estes engines surplus store prior to them closing forever shortly after, doesn't have the splits in the venturi material, appears very clean and with good compression, may be happen by chance a real Cox engine assembled prior to Estes. The white line reflection is not a break but the steel spring reflecting off the glossy venturi surface.

Of interest too is the choke tube appears to support the venturi edges with a snug fit. Seems worthwhile for a person to remove the choke tube and check venturi area for cracks, may help to explain some of the erratic running conditions described by others in various forums.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: shure start air intake break

Re: shure start air intake break

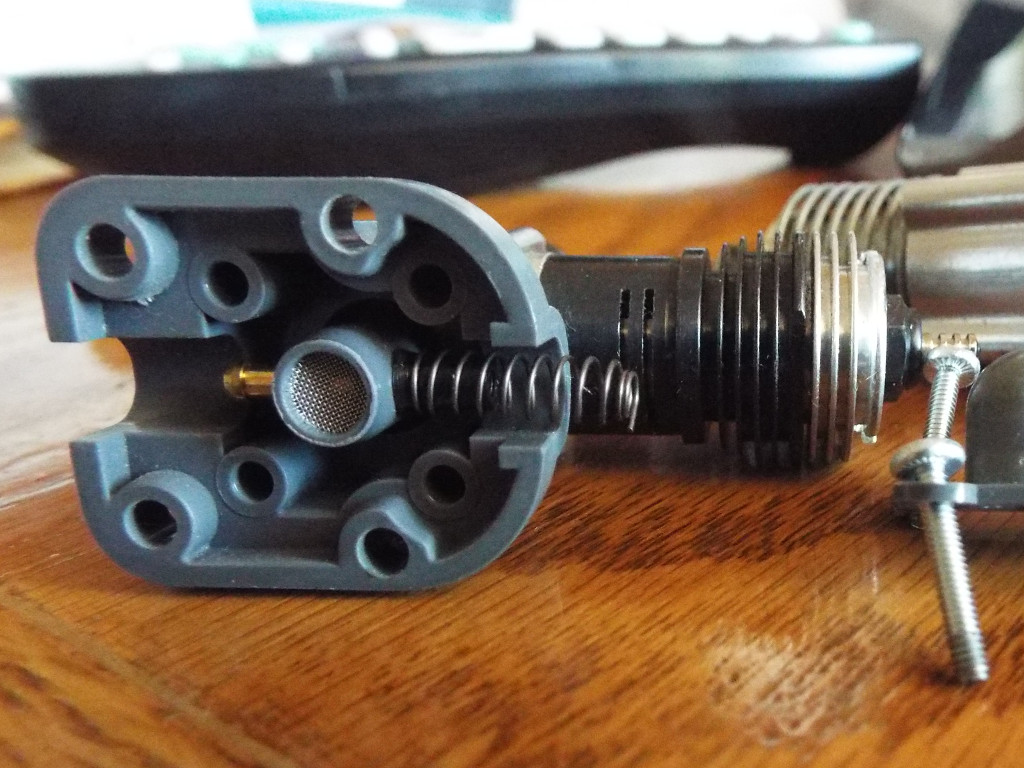

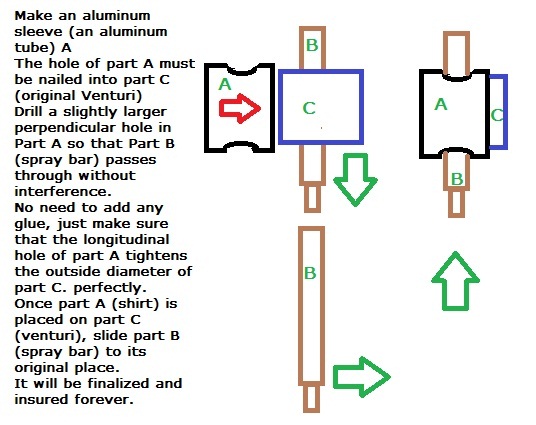

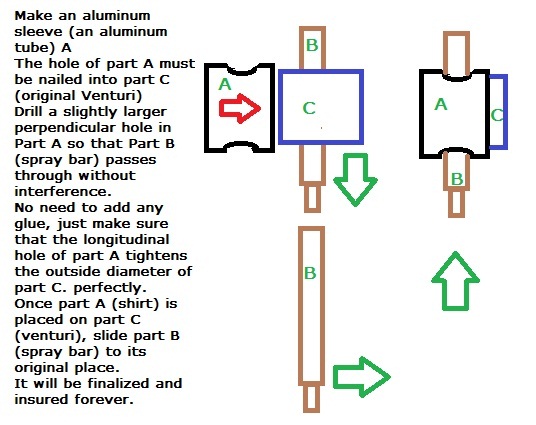

I have done this before and it is final!

I have no photos, the motor was sold!

Make an aluminum sleeve (an aluminum tube) A

The hole of part A must be nailed into part C (original Venturi)

Drill a slightly larger perpendicular hole in Part A so that Part B (spray bar) passes through without interference.

No need to add any glue, just make sure that the longitudinal hole of part A tightens the outside diameter of part C. perfectly.

Once part A (shirt) is placed on part C (venturi), slide part B (spray bar) to its original place.

It will be finalized and insured forever.

I have no photos, the motor was sold!

Make an aluminum sleeve (an aluminum tube) A

The hole of part A must be nailed into part C (original Venturi)

Drill a slightly larger perpendicular hole in Part A so that Part B (spray bar) passes through without interference.

No need to add any glue, just make sure that the longitudinal hole of part A tightens the outside diameter of part C. perfectly.

Once part A (shirt) is placed on part C (venturi), slide part B (spray bar) to its original place.

It will be finalized and insured forever.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: shure start air intake break

Re: shure start air intake break

Great idea and solution Mauricio! Is the piece something you can fond in a hobby shop and cut to length, or did you make it on a lathe?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: shure start air intake break

Re: shure start air intake break

NEW222 wrote:Great idea and solution Mauricio! Is the piece something you can fond in a hobby shop and cut to length, or did you make it on a lathe?

Thanks NEW222, you can use any commercial tube that the internal measurement fits perfectly with the original plastic venturi (in the drawing part C).

Here I leave several tubes as a sample, even the one above is a piece of car radio antenna, the one I hold in my hand is a copper tube.

Based on that, I have also manufactured an air valve to control the rpm of my Pee Wee .020 with a helicopter plate. The way to seal that crack with this system really works and you will forget forever!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: shure start air intake break

Re: shure start air intake break

I have done the sleeve thing on broken TDs for decades, but never thought of it for the reedies. Nice carb idea. Great to see someone is doing the thinking.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: shure start air intake break

Re: shure start air intake break

Good ideas Mauricio  Thanks

Thanks

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: shure start air intake break

Re: shure start air intake break

Earlier engines and RTF planes seemed to have better quality control and better choices in materials.balogh wrote:The same experience here with quite a number of red postage stamp 190-s and red and white horseshoe backplate reedies all dating back to the 60s...80s..no crack anywhere and except for the stiffened NV seals, all parts as new.GallopingGhostler wrote:My 1960's postage stamp backs made of red Delrin nylon still show no signs of any cracking even though they are now easily 50 years old....

Interesting you mention of the poor fitting cylinders and pistons that lack sufficient compression. The Cox that I knew was prior to Estes, had great confidence that when one bought a Cox, one bought a quality engine. It may be in an inexpensive plastic bubble pack on a card, but the engine itself was a jewel of construction.balogh wrote:When I returned to the hobby 10 years ago and found a bonanza of COX engines on the net I bought some Surestarts and their parts too. In fact I have never used them but preferred old stock COX engines instead, and keep the Surestarts as parts donors if ever needed. Their steel and aluminum parts are still good except for some very loose fit cylinder and piston combos.

I was disappointed when I purchased a Cox .074 Queen Bee. Although the muffler assembly appeared to be a quality unit, the plastic carburettor and overall heavier weight akin to my Enya .09-III's (which is a much more powerful engine overall) plus difficulties I had in getting the engine to run at all made me put it aside. Later found I got a bad factory glow plug. This was the downturn of Cox before sale to Estes.

Someone used a .074 to power their Sterling Minnie Mambo, the short coupled nose would allow attaining proper CG. (Mine with a .049 R/C Bee needed a Harry Higley 0.5 oz. brass prop nut as a hub weight for balance.) There's a YouTube video of his Minnie in flight, kudos to him.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: shure start air intake break

Re: shure start air intake break

I was disappointed when I purchased a Cox .074 Queen Bee. Although the muffler assembly appeared to be a quality unit, the plastic carburettor and overall heavier weight akin to my Enya .09-III's (which is a much more powerful engine overall) plus difficulties I had in getting the engine to run at all made me put it aside. Later found I got a bad factory glow plug. This was the downturn of Cox before sale to Estes.

Someone used a .074 to power their Sterling Minnie Mambo, the short coupled nose would allow attaining proper CG. (Mine with a .049 R/C Bee needed a Harry Higley 0.5 oz. brass prop nut as a hub weight for balance.) There's a YouTube video of his Minnie in flight, kudos to him.[/quote] I had a Queen Bee that would not start. Came in a swap meet plane. Took it out and it ran fine out of the plane except the idle with no muffler. There is a carb mod with a small airbleed hole that I did and it runs good now, even fairly good with the muffler. It is still a reedy though. Still have not flown that Jr. Falcon plane for one reason or another. AM radio, not running right ...... Still on the table ready to go really.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: shure start air intake break

Re: shure start air intake break

Mine interestingly enough mine already has a factory bleed hole in the carburettor. Could the one's without be an earlier version, or parts sidelined under Cox before sale to Estes? Yeah, that muffler does seem to be bulkier than it has to be, would have preferred the standard exhaust throttle ring muffler which is considerably lighter yet seems to do a decent job on at least the Cox .09 Medallion R/C.aspeed wrote:GallopingGhostler wrote:Although the muffler assembly appeared to be a quality unit, the plastic carburettor and overall heavier weight akin to my Enya .09-III's (which is a much more powerful engine overall) plus difficulties I had in getting the engine to run at all made me put it aside. Later found I got a bad factory glow plug. This was the downturn of Cox before sale to Estes.

I had a Queen Bee that would not start. Came in a swap meet plane. Took it out and it ran fine out of the plane except the idle with no muffler. There is a carb mod with a small airbleed hole that I did and it runs good now, even fairly good with the muffler. It is still a reedy though. Still have not flown that Jr. Falcon plane for one reason or another. AM radio, not running right ...... Still on the table ready to go really.

Water under the bridge now, but has made me wonder at times why Cox didn't simply come up with a larger scale .09 Sure Start with an exhaust throttle muffler. It would have been a little less powerful of course than a Medallion but still reasonably lighter in weight, easy starting, easy running, definitely more power than a Gilbert .11 Thunderhead.

I guess toward the end that the company was grasping for straws, as the bottom was slowly dropping out of the glow engine market.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: shure start air intake break

Re: shure start air intake break

Hello everyone..

First of all I want to apologize for the delay in answering the questions. I have been away from home for work reasons and it is impossible for me to answer if I am not on my computer.

Regarding the antiquity of the engine, I bought it from a person in my city who sells hobby items, I do not know the origin, if it came from America or China. What I know is that it came wrapped in a clear bubble bag.

The engine where this backplate came from is not this one in the photo, originally it was a die cast, which I could not use since the piston cylinder assembly had no compression.

What I did was get a new piston assembly and put the backplate on it that we are talking about, for which I had to adapt the reed valve since the die cast insert is different, but that's another matter.

Speaking with Mauricio, he told me about the repair that he made with the method that he explained previously.

These days when I have some time I will dedicate myself to the task of getting the tube that fits in the air inlet.

I want to take advantage of this time that I have to tell you an interesting story. Along with the motor that I bought (which had no compression), a friend of mine bought a shure start from those that come with an RC carburetor with the idea of placing it in a QTee.

To install the engine in the plane I had to make a supplement that would allow me to move the F1's away from air tube

To do this, make a template with the shape that i had to cut the wood to make the spacer.

During this process I removed the back plate from the engine and to my surprise I found a pile of metal shavings inside the cylinder.

if for those things I had run the engine it would surely destroy it at the first second of run.

with these two things (the lack of compression in the motor and the metal shavings) convinced me that these engines are no longer what they once were

now I find myself in the task of repairing my engine (or trying to do it). I will keep you updated on progress.

I again apologize for the delay in reply.

a big greeting to all

First of all I want to apologize for the delay in answering the questions. I have been away from home for work reasons and it is impossible for me to answer if I am not on my computer.

Regarding the antiquity of the engine, I bought it from a person in my city who sells hobby items, I do not know the origin, if it came from America or China. What I know is that it came wrapped in a clear bubble bag.

The engine where this backplate came from is not this one in the photo, originally it was a die cast, which I could not use since the piston cylinder assembly had no compression.

What I did was get a new piston assembly and put the backplate on it that we are talking about, for which I had to adapt the reed valve since the die cast insert is different, but that's another matter.

Speaking with Mauricio, he told me about the repair that he made with the method that he explained previously.

These days when I have some time I will dedicate myself to the task of getting the tube that fits in the air inlet.

I want to take advantage of this time that I have to tell you an interesting story. Along with the motor that I bought (which had no compression), a friend of mine bought a shure start from those that come with an RC carburetor with the idea of placing it in a QTee.

To install the engine in the plane I had to make a supplement that would allow me to move the F1's away from air tube

To do this, make a template with the shape that i had to cut the wood to make the spacer.

During this process I removed the back plate from the engine and to my surprise I found a pile of metal shavings inside the cylinder.

if for those things I had run the engine it would surely destroy it at the first second of run.

with these two things (the lack of compression in the motor and the metal shavings) convinced me that these engines are no longer what they once were

now I find myself in the task of repairing my engine (or trying to do it). I will keep you updated on progress.

I again apologize for the delay in reply.

a big greeting to all

nico010- Bronze Member

- Posts : 53

Join date : 2019-04-15

Re: shure start air intake break

Re: shure start air intake break

Nico the part you made as a spacer for the Surestart choke tube is also sold by COX International.

https://coxengines.ca/cox-.049-engine-firewall-helicopter-mount.html

https://coxengines.ca/cox-.049-engine-firewall-helicopter-mount.html

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: shure start air intake break

Re: shure start air intake break

Another solution if one's installation does not permit use of the helicopter mount is nylon spacers. I bought these from the hardware section of a home improvement centre:balogh wrote:nico010 wrote:I want to take advantage of this time that I have to tell you an interesting story. Along with the motor that I bought (which had no compression), a friend of mine bought a shure start from those that come with an RC carburetor with the idea of placing it in a QTee. To install the engine in the plane I had to make a supplement that would allow me to move the F1's away from air tube. To do this, make a template with the shape that i had to cut the wood to make the spacer.

Nico the part you made as a spacer for the Surestart choke tube is also sold by COX International.

https://coxengines.ca/cox-.049-engine-firewall-helicopter-mount.html

It appears that you may have acquired an engine that may have been assembled by Estes, the US model rocket company, who bought the Cox company. From what I have heard, quality control was problematic. The Cox company had a couple ladies who knew quickly how to match pistons with cylinders for proper fit. Estes lacked these workers.nico010 wrote:During this process I removed the back plate from the engine and to my surprise I found a pile of metal shavings inside the cylinder. if for those things I had run the engine it would surely destroy it at the first second of run. With these two things (the lack of compression in the motor and the metal shavings) convinced me that these engines are no longer what they once were.

Back in the 1980's, I bought 2 Fuji .099S-II R/C engines from Hobbyshack in California. They were on clearance sale. (I guess it was to make room for their Magnum series of engines.) Upon removing the backplates, I found both engines had a pile of aluminum shavings. I carefully disassembled them and flushed out the crankcases. Later, I read in one of the model airplane magazines that others were experiencing similar occurrences with engines coming from Asia. Since, I have purposely pulled off the backs of all my engines regardless of where made.

People tell me that I should never disassemble a new engine, but I know what I am doing and found it to help me more than once.

About your experience with unexpected surprises when opening an engine, a K&B .35 Stallion I bought from E-Bay 2 years ago, I found the exterior had been sand blasted to hide its history. This is what I found when I opened it up:

This was the crankcase after cleaning and polishing off the bead blasting:

Rest of my engine restoration is in:

https://www.coxengineforum.com/t12115-kb-35-stallion-acquisition

Yes, you were wise to pull off the back of that engine.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: shure start air intake break

Re: shure start air intake break

The idea of the plastic supplement (GallopingGhostler) to separate the F1 engine is good.

Where I live (balogh), buying anything from another country is a problem due to government restrictions, that is why almost all the time we are looking to solve problems with the things that we have within our reach.

Many times it is not a money problem but the whole process that we have to go through in order for things to arrive.

That is why we take care of everything, since even a burned glowhead can mean many months without being able to fly.

lately the economic situation of the country is making it increasingly difficult to get the elements to prepare fuel (not to mention nitromethane, which is extremely difficult to acquire).

Anyway ... all the time we are fighting against these setbacks.

Greetings already

nico

Where I live (balogh), buying anything from another country is a problem due to government restrictions, that is why almost all the time we are looking to solve problems with the things that we have within our reach.

Many times it is not a money problem but the whole process that we have to go through in order for things to arrive.

That is why we take care of everything, since even a burned glowhead can mean many months without being able to fly.

lately the economic situation of the country is making it increasingly difficult to get the elements to prepare fuel (not to mention nitromethane, which is extremely difficult to acquire).

Anyway ... all the time we are fighting against these setbacks.

Greetings already

nico

nico010- Bronze Member

- Posts : 53

Join date : 2019-04-15

Similar topics

Similar topics» Does Old Fuel Work? Because my NEW .49 with spring start won't start.

» Spacebug fuel intake issue?

» TD 051 Aluminum Intake

» Med .09 Intake Throttle

» Cox Tee Dee.049/.051: Front Intake Position

» Spacebug fuel intake issue?

» TD 051 Aluminum Intake

» Med .09 Intake Throttle

» Cox Tee Dee.049/.051: Front Intake Position

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules