Log in

Search

Latest topics

» Tee Dee .020 combat modelby Ken Cook Today at 3:23 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

3D printed PeeWee .020 tank backplate

Page 1 of 2

Page 1 of 2 • 1, 2

3D printed PeeWee .020 tank backplate

3D printed PeeWee .020 tank backplate

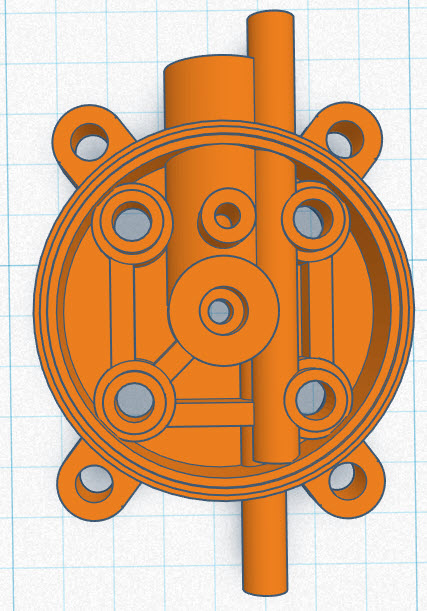

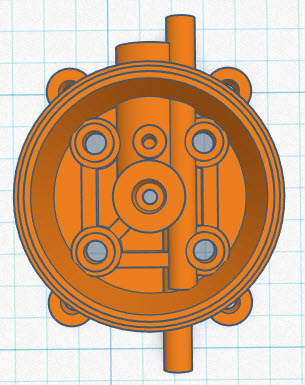

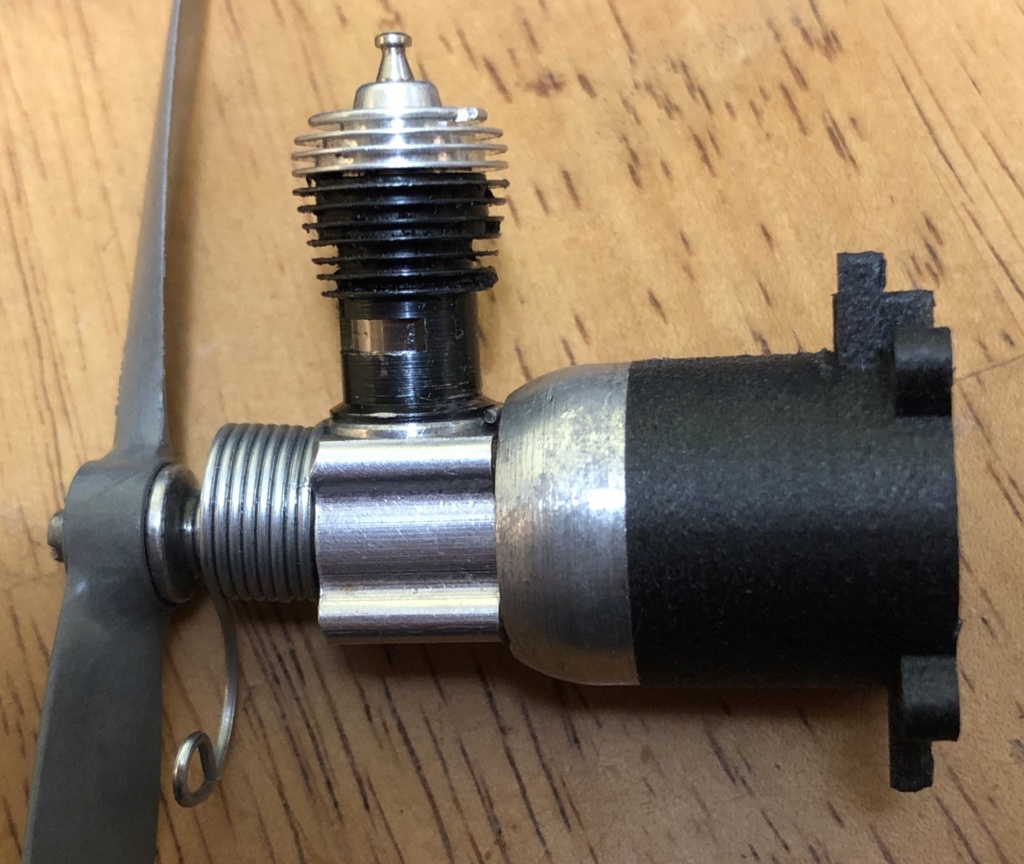

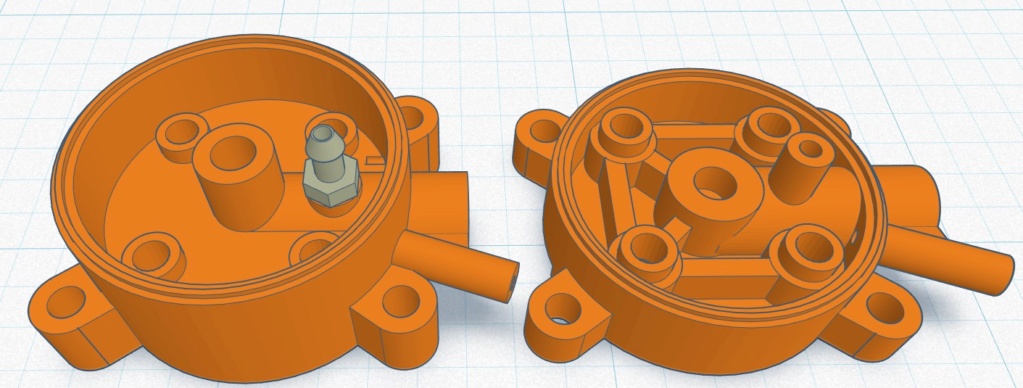

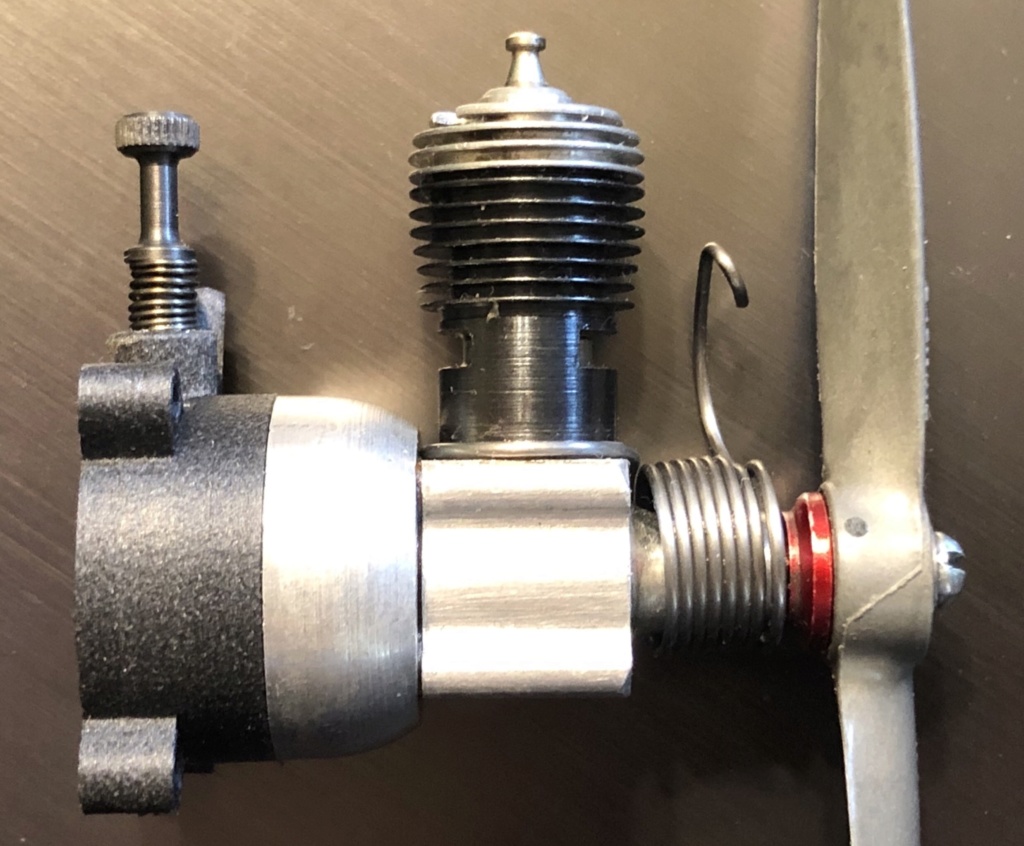

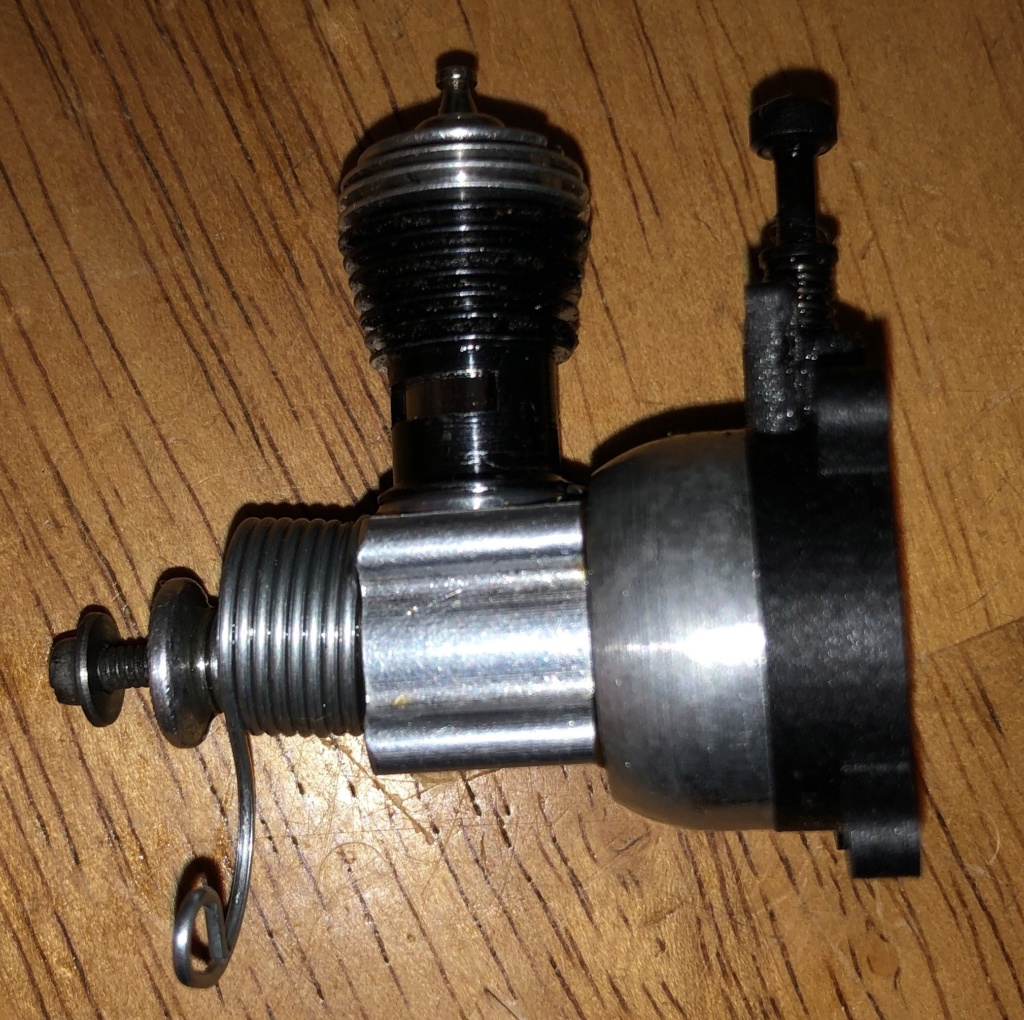

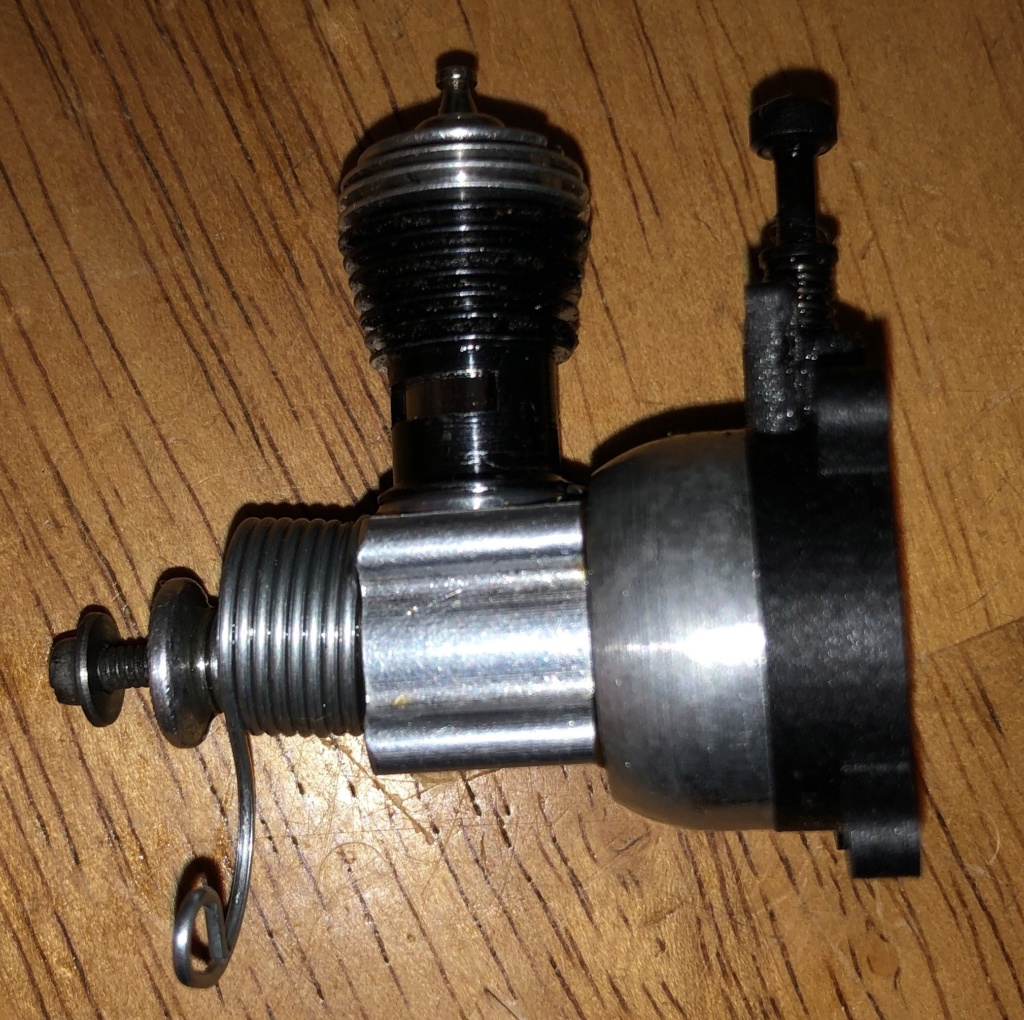

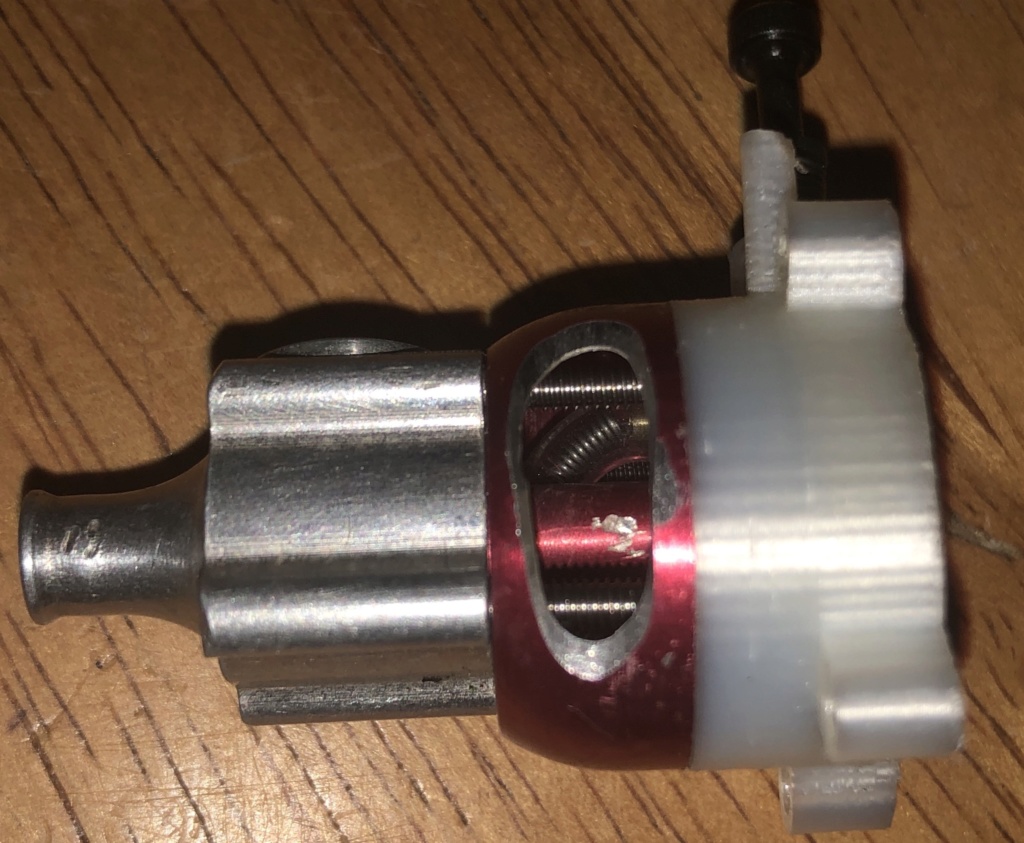

Had some time this weekend and drew up the PeeWee .020 tank backplate. This utilizes the spraybar and needle valve from a babe bee plastic backplate. I had one that was broken and extracted the spraybar from it.

It is thicker to support the larger spraybar. I also angled the tank fill port for easier access. Small vent hole on the other side of the needle valve for filling.

It needs a few changes. I need to increase the size of the fuel tube nipple inside the backplate. I suspect air leaks there as the fit is loose. I also need to reduce the diameter of the spraybar hole for a better pressfit and sealing. The first plate I drilled too big and fuel escaped past the spraybar and the engine ran with the needle valve all the way closed. The only issue was I had to retighten the backplate screws after a few runs. The heat and vibration probably settled in the backplate. More run time needed.

The good think is the tank didn’t leak where it meets up with the backplate.

Probably not too hard to find a couple of beta testers.

Other features that could be added are using an extended fuel inlet top and bottom to make a stunt PeeWee tank backplate. Also can extend the side wall to use black widow screws and make an extended run tank.

Here are a few pictures and a run video.

It is thicker to support the larger spraybar. I also angled the tank fill port for easier access. Small vent hole on the other side of the needle valve for filling.

It needs a few changes. I need to increase the size of the fuel tube nipple inside the backplate. I suspect air leaks there as the fit is loose. I also need to reduce the diameter of the spraybar hole for a better pressfit and sealing. The first plate I drilled too big and fuel escaped past the spraybar and the engine ran with the needle valve all the way closed. The only issue was I had to retighten the backplate screws after a few runs. The heat and vibration probably settled in the backplate. More run time needed.

The good think is the tank didn’t leak where it meets up with the backplate.

Probably not too hard to find a couple of beta testers.

Other features that could be added are using an extended fuel inlet top and bottom to make a stunt PeeWee tank backplate. Also can extend the side wall to use black widow screws and make an extended run tank.

Here are a few pictures and a run video.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

Looks good. Will be good solution for all those broken off mounting tabs on PeeWees. But something you said gives me an idea. I know you're busy with new things, but how about a printed tank extender for the PeeWees like the Kavan tank extender for the Bee engines?

The Pondersome Mark

The Pondersome Mark

batjac- Diamond Member

Posts : 2374

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

It lives!

LOL, I thought the same thing. This backplate is like a much improved version of the Kavan tank extender (I don't believe they even made a .020 extender). Could make the backplate as deep as screws are available. Extending runtime.

batjac wrote:but how about a printed tank extender for the PeeWees like the Kavan tank extender for the Bee engines?

LOL, I thought the same thing. This backplate is like a much improved version of the Kavan tank extender (I don't believe they even made a .020 extender). Could make the backplate as deep as screws are available. Extending runtime.

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

You guys! Jason was all ready thinking of that!! Re read his last comment:

“Probably not too hard to find a couple of beta testers. Smile

Other features that could be added are using an extended fuel inlet top and bottom to make a stunt PeeWee tank backplate. Also can extend the side wall to use black widow screws and make an extended run tank.

Here are a few pictures and a run video. “

Oh yeah......I volunteer to be a Beta testors!!

“Probably not too hard to find a couple of beta testers. Smile

Other features that could be added are using an extended fuel inlet top and bottom to make a stunt PeeWee tank backplate. Also can extend the side wall to use black widow screws and make an extended run tank.

Here are a few pictures and a run video. “

Oh yeah......I volunteer to be a Beta testors!!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

Now if it would just rain .020 pistons and cylinders.

Oops, still dreaming. This is great, Jason. Can't wait.

Bob

Oops, still dreaming. This is great, Jason. Can't wait.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

Jason_WI wrote:Not sure if a stunt peewee would be useful but now its an option.

If you're going to stunt a PeeWee, it's gotta have an extended tank. Who wants to stunt for only two minutes? And if you're going to run an extended PeeWee, no sense getting bored going roundy-roundy for six minutes.

The Greedy Mark

batjac- Diamond Member

Posts : 2374

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

I bought some of these small barb fittings as I’m not sure how reliable the printed one will be inside the backplate. Also have some 3-56 bottom taps on the way.

https://www.clippard.com/part/11750-2-PKG

https://www.clippard.com/part/11750-2-PKG

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

SuperTanker! Love it!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

Very Nice Jason !! that is one long (looking tank) !! How much does she weight ?

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

So I ran the super tanker pee wee last night. I didn't get a chance to get a video as I was constantly messing with the needle valve.

With the long tank and engine vibrations I'm thinking the fuel was foaming inside the tank. It would run great for 10 seconds then lean out. I would open the needle till it ran rich then close it up and it would run great for 10 seconds then repeat the cycle. I can thicken the side wall on the inside, add cross supports inside the tank area, or shorten to use babe bee screws vs the stunt tank screws that are 1" long.

My .25 mm hardened tool steel nozzle is worn out from the abrasive carbon fiber filament. I have new ones coming tomorrow and can resume printing tanks with the changes mentioned above.

I'm already using a nickle plated hardened tool steel nozzle but after all the horseshoe back plates I printed its worn out to the point where the print quality is poor.

Nozzle I'm using now:

https://e3d-online.com/nozzlex-v6

Might have to go to a ruby nozzle instead but they are pricey.

https://olssonruby.com/the-olsson-ruby/#high-temp

With the long tank and engine vibrations I'm thinking the fuel was foaming inside the tank. It would run great for 10 seconds then lean out. I would open the needle till it ran rich then close it up and it would run great for 10 seconds then repeat the cycle. I can thicken the side wall on the inside, add cross supports inside the tank area, or shorten to use babe bee screws vs the stunt tank screws that are 1" long.

My .25 mm hardened tool steel nozzle is worn out from the abrasive carbon fiber filament. I have new ones coming tomorrow and can resume printing tanks with the changes mentioned above.

I'm already using a nickle plated hardened tool steel nozzle but after all the horseshoe back plates I printed its worn out to the point where the print quality is poor.

Nozzle I'm using now:

https://e3d-online.com/nozzlex-v6

Might have to go to a ruby nozzle instead but they are pricey.

https://olssonruby.com/the-olsson-ruby/#high-temp

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

What filament material do you use for these parts?

Many Thanks,

=Adrian=

Many Thanks,

=Adrian=

Ada99- Moderate Poster

- Posts : 28

Join date : 2018-07-18

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

DuPont carbon fiber reinforced Zytel.

https://coexllc.com/product/3d-filaments/dupont-filament/zytel-carbon/zytel-3d10c20fl-bk544-1-75mm

In addition to zytel I’m going to try this with POM (delrin) which is what the original .049 horseshoe backplates were made of. The issue with delrin is getting it to stick to the build plate.

https://coexllc.com/product/3d-filaments/dupont-filament/zytel-carbon/zytel-3d10c20fl-bk544-1-75mm

In addition to zytel I’m going to try this with POM (delrin) which is what the original .049 horseshoe backplates were made of. The issue with delrin is getting it to stick to the build plate.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

Here are the brass fuel inlet nipples I bought to use instead of the fragile printed one on the inside of the tank.

Uses a 3-56 thread. Bottom tap hasn’t arrived yet from Amazon.

I’m going to have to beef up the back where the screws enter as I have cracked a few of them tightening the screws. I’m thinking of using babe bee screws and making the back solid instead of having the open voids where the screws are. With the slightly longer screws I can lengthen the tank area to still give more run time than a standard PeeWee tank.

Uses a 3-56 thread. Bottom tap hasn’t arrived yet from Amazon.

I’m going to have to beef up the back where the screws enter as I have cracked a few of them tightening the screws. I’m thinking of using babe bee screws and making the back solid instead of having the open voids where the screws are. With the slightly longer screws I can lengthen the tank area to still give more run time than a standard PeeWee tank.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

That sounds like a plan Jason , and that ruby tip looks really nice and so is the price lol . I would bee interested in 10 of the horse shoe back plate mounts if you would like to perform that task ? if so PM me a price / and for rules here i will bee selling some on the bay with some engines i have

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

Wow. Just simply amazing work.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

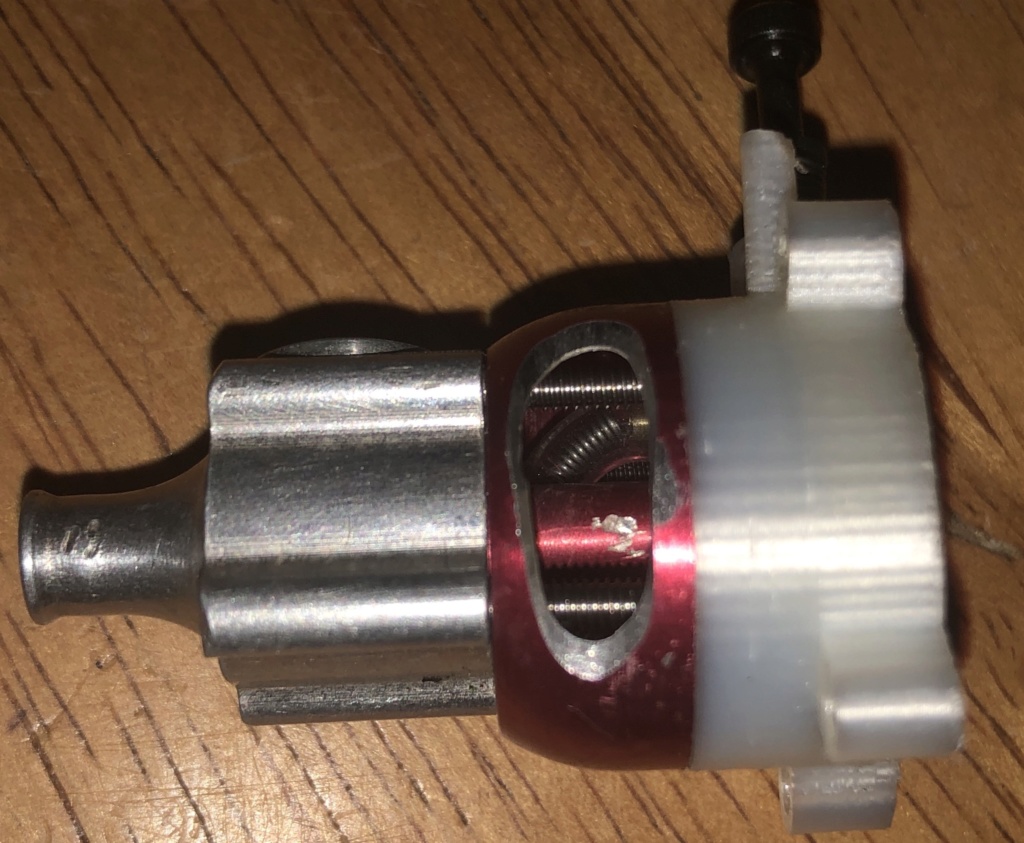

Still no luck getting these to run consistently. I took a tank with a hole drilled in it and filed the side out to see what was going on inside. Looks like I have a good seal. I even tried two venturi seals. Same result. Engine never comes up to speed and needle setting has little effect which would point to it leaking in the tank.

I will add a few thousands to the backplate venturi tube to add a bit more squish to the venturi seal and increase the diameter 10 to 15 thousands. This way there will be margin for a nice flat area before it meets the edge.

I will add a few thousands to the backplate venturi tube to add a bit more squish to the venturi seal and increase the diameter 10 to 15 thousands. This way there will be margin for a nice flat area before it meets the edge.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

The print quality of your black unit looks as if it could be porous, maybe allowing air to be drawn through the material. Your white test unit certainly looks smoother in the finish.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: 3D printed PeeWee .020 tank backplate

Re: 3D printed PeeWee .020 tank backplate

OER beat me too my question...porosity of final part?

need some fixture to above atmosphere under water and look for bubbles

need some fixture to above atmosphere under water and look for bubbles

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Page 1 of 2 • 1, 2

Similar topics

Similar topics» 3D printed R/C Pee Wee backplate

» 3D printed beam mount .049 backplate

» PeeWee .020 Silver Tank

» Separate tank for peewee 0.020

» 3D printed Pee Wee 0.020 tank extension?

» 3D printed beam mount .049 backplate

» PeeWee .020 Silver Tank

» Separate tank for peewee 0.020

» 3D printed Pee Wee 0.020 tank extension?

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules