Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

My Southridge CNC Hyper Viper build

Page 1 of 2

Page 1 of 2 • 1, 2

My Southridge CNC Hyper Viper build

My Southridge CNC Hyper Viper build

Okay, I can't believe I'm the first one posting a build thread on the Southridge CNC Hyper Viper.

Mine is a quick kit, as you may know, since y'all bought it for me. I took it as a get well present and it worked... I'm pretty damn well! The first thing I needed to do was address the grooves scribed by the CNC tool. I used 60 grit paper and carefully went over the whole fuselage. That and become reacquainted with my shop, which has been mostly inactive for 2 years now. Wow, time passes fast when you're not having fun. It's a lot of work removing the grooves and making sure not to re-shape anything by accident. I still keep finding some, but I think some of it must be pressure indentations. I lightly spritzed it today from 3 feet away with Windex to see if some of it would swell out. The jury's still out on that. I've rounded the 4 corners of the wing slightly, as well as the flat edges of the wingtips and put more of a radius on the top of the rear fuselage, following up with 220 and 320 paper. This picture still shows some of the scribing that has now been smoothed out. I've also removed 4 grams of wood from inside the fuselage. It's all about 3/16" thick, and I took some more wood out where I thought it was structurally safe.

Next are the hardwood motor mounts. I took the option of running them full length and, for the sake of reducing stress risers, rounded the ends to match the existing radius of the CNCd shelves they sit upon.

Here it is with a Tee Dee perched on the crutch. You can see I have removed some thickness from the inside top of the cowl. It had ridges that could have abraded the bladder, plus it makes more room for it to expand with a full load of fuel too. I also made a breather hole for the venturi. The Norvel may not need it, but this will aid in future engine swapping. I think there is enough room for enough fuel. There certainly is enough for the more efficient Big Mig or AME. The Tee Dee might be close if I want 6-1/2 minutes for a Stunt run. It will be flying PAMPA at 1/2A day in September.

As for cooling and exhaust evacuation... I'm still imagining ways to handle that. The muffler for the Norvel wont fit without butchery that I'm not likely to do. Some sort of deflector and side vents are likely.

Plenty of room for cooling intake, but not the prettiest thing. I'll probably add another vent on the bottom, because the rule of thumb for heat removal is twice as much exit as intake. Texaco heads are no longer available. I do have a scruffy red one on the old Paul G. Mouse Racer Black Widow. Cooling the Norvel is more critical than the Tee Dee.

The inside of the nose will be coated with fiberglass and epoxy finishing resin. Where I've thinned the wood in the fuse could be covered with resin and carbon veil, but I didn't really take that much wood out, and it should still be plenty strong. I've never seen a plane break there. The wing will be covered with doctor paper, and I've stocked up on enough dope for a similar scheme as the Cox model.

So, thar she blows.

Rusty

Mine is a quick kit, as you may know, since y'all bought it for me. I took it as a get well present and it worked... I'm pretty damn well! The first thing I needed to do was address the grooves scribed by the CNC tool. I used 60 grit paper and carefully went over the whole fuselage. That and become reacquainted with my shop, which has been mostly inactive for 2 years now. Wow, time passes fast when you're not having fun. It's a lot of work removing the grooves and making sure not to re-shape anything by accident. I still keep finding some, but I think some of it must be pressure indentations. I lightly spritzed it today from 3 feet away with Windex to see if some of it would swell out. The jury's still out on that. I've rounded the 4 corners of the wing slightly, as well as the flat edges of the wingtips and put more of a radius on the top of the rear fuselage, following up with 220 and 320 paper. This picture still shows some of the scribing that has now been smoothed out. I've also removed 4 grams of wood from inside the fuselage. It's all about 3/16" thick, and I took some more wood out where I thought it was structurally safe.

Next are the hardwood motor mounts. I took the option of running them full length and, for the sake of reducing stress risers, rounded the ends to match the existing radius of the CNCd shelves they sit upon.

Here it is with a Tee Dee perched on the crutch. You can see I have removed some thickness from the inside top of the cowl. It had ridges that could have abraded the bladder, plus it makes more room for it to expand with a full load of fuel too. I also made a breather hole for the venturi. The Norvel may not need it, but this will aid in future engine swapping. I think there is enough room for enough fuel. There certainly is enough for the more efficient Big Mig or AME. The Tee Dee might be close if I want 6-1/2 minutes for a Stunt run. It will be flying PAMPA at 1/2A day in September.

As for cooling and exhaust evacuation... I'm still imagining ways to handle that. The muffler for the Norvel wont fit without butchery that I'm not likely to do. Some sort of deflector and side vents are likely.

Plenty of room for cooling intake, but not the prettiest thing. I'll probably add another vent on the bottom, because the rule of thumb for heat removal is twice as much exit as intake. Texaco heads are no longer available. I do have a scruffy red one on the old Paul G. Mouse Racer Black Widow. Cooling the Norvel is more critical than the Tee Dee.

The inside of the nose will be coated with fiberglass and epoxy finishing resin. Where I've thinned the wood in the fuse could be covered with resin and carbon veil, but I didn't really take that much wood out, and it should still be plenty strong. I've never seen a plane break there. The wing will be covered with doctor paper, and I've stocked up on enough dope for a similar scheme as the Cox model.

So, thar she blows.

Rusty

Last edited by RknRusty on Wed Mar 27, 2019 11:53 pm; edited 1 time in total

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

That's a very nice model coming along very well. Keep up teh good work!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Bravo !!!!!!!!!!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Good to see you in the shop Rusty !! The plane looks Great maiking me think more about getting myself one

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

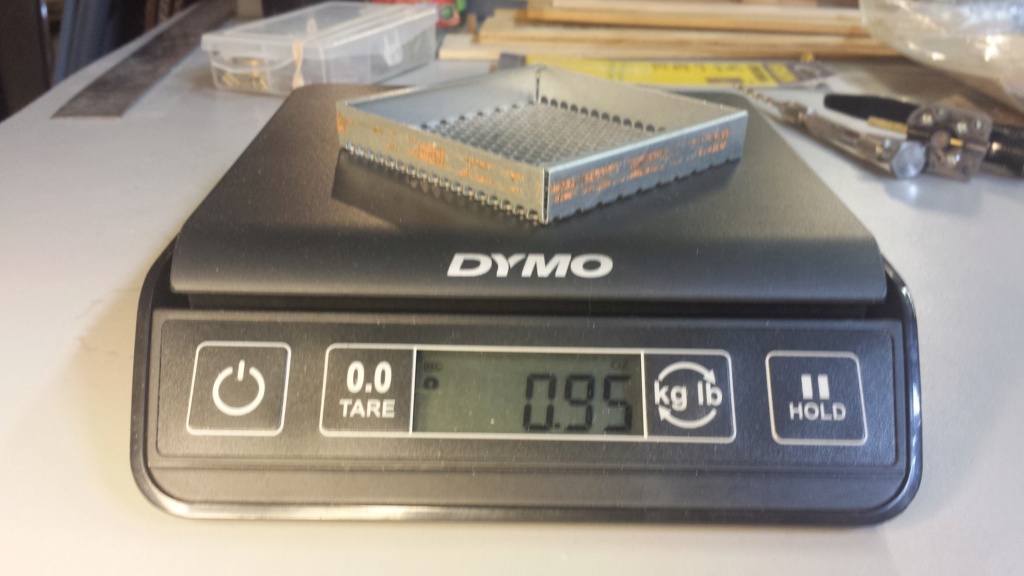

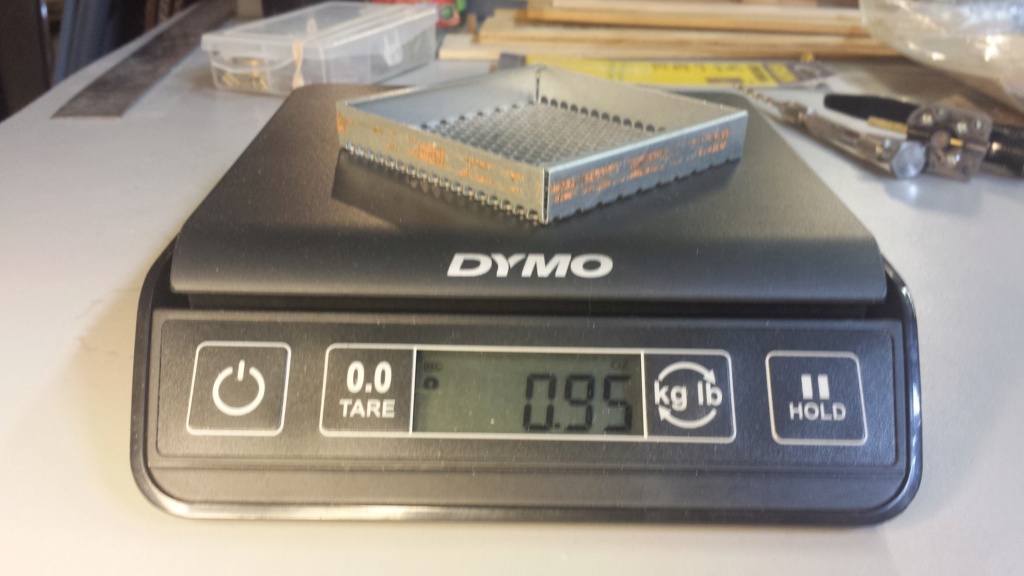

Hey Rus! Great to see you getting busy building again man! That's a cool-looking kit. You mentioned concerns with engine-cooling.. so I thought I'd throw this out there. I have some grill material that may interest you.

It's light-gage steel.. and you'd need to cut it to shape. Being steel.. a panel made from it would be structural.. if epoxied into place. A piece cut to fit a rectangular-opening in the bottom of the cowl, would vent heat.. as well as provide fuel-oil drainage. I was originally thinking that you could attach it directly across the bottom of the engine-beams.. but you mentioned the beams being contoured into the surrounding cowl.

Being perforated; this grill-material would anchor solidly, using an epoxy glue.

Here's a couple of photos showing some weight comparisons.

The perforations cut easily with tin-shears. As you can see by the 2nd photo; 2/3rds of the panel-weight was in the "solid" angle-pieces which I cut off.

Just say the word, and I'll stuff the flat-panel in a bubble-mailer.. and send it your way.

It's light-gage steel.. and you'd need to cut it to shape. Being steel.. a panel made from it would be structural.. if epoxied into place. A piece cut to fit a rectangular-opening in the bottom of the cowl, would vent heat.. as well as provide fuel-oil drainage. I was originally thinking that you could attach it directly across the bottom of the engine-beams.. but you mentioned the beams being contoured into the surrounding cowl.

Being perforated; this grill-material would anchor solidly, using an epoxy glue.

Here's a couple of photos showing some weight comparisons.

The perforations cut easily with tin-shears. As you can see by the 2nd photo; 2/3rds of the panel-weight was in the "solid" angle-pieces which I cut off.

Just say the word, and I'll stuff the flat-panel in a bubble-mailer.. and send it your way.

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Thanks, Roddie, I'll let you know. I'm still in the head scratching mode now. I'll try to get some useful work done on it today.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

If your running bladder, cooling is a non -issue for the most part. The engine runs cooler due to having a constant fuel supply. I never had a Rev-Lite Norvel overheat in fact it's just the opposite. They rarely get hot enough. When the model lands, the engine is barely warm to the touch. The TD gets much hotter, seeing that much cylinder sticking out of the model, I highly doubt cooling will be a issue. What would concern me though is keeping the model flying at speeds conducive to stunt. Your not going to achieve that using bladder easily. The other problem I see is that when using a tank, the engine leans throughout the flight. A bladder goes richer therefore when you need the most power in the overheads in this could be a issue unless your carrying a large enough bladder. Cramming a lot of fuel into a small bladder tube can create false pressure offering a rich run then going over lean.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Roddie, where did you score the grill? Is it a PC fan vent?

TIA!

TIA!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Here's today's build installment:

I didn't like the way the nose of the TD was rubbing the starter spring, so I removed it. Without it, I was able to mount the engine with a degree or so of outboard thrust offset. Ity took some more sanding the holes, but it still looks neat.

And this will be the very first time I have ever EVER bored perfect holes in the beams. I got the tabs exactly where I wanted them and put a tiny drop of thin CA in each screw hole. Double checked and trimmed the cowl holes to fit perfectly, and with the engine glued in place, I bored the pilot holes. I'm not going to unglue the engine, just gonna screw it down. Only thing is I didn't add aluminum bearers... I forgot about those, but it'll work. If I decide it needs them, I'll put them in. I already have several sets drilled and ready. I don't care for the screws, so a trip to Lowes may be in my near future. I cannot locate a source for 2-56 threaded inserts, or I would have used them

Okay, a good weekend. Next weekend I will be occupied with birthday related stuff, so no shop time for the old man. But it looks like good WX on Tuesday and Thursday. And Daylight Savings time is forecast for the foreseeable future too. Yaaaazoo!!

Rusty

Ken, thanks for kicking me right in the... brain cells. I knew that. I always tell people how bladder fed engines are self protecting and cannot overheat. DUH!

In my experience my planes only change to a rich run 3 laps before the shutoff. The cowl has a very roomy diameter so it won't be squeezing the sides of the bladder. I haven't measured its length yet(should have) but I think I can fit 3-1/2 inches of fuel in it. This 4 minute flight is on 2-1/2 inches of fuel and I think another 1/2 - 1 inch will work on the new 1/2A Pattern rules where we only have to fly one lap between stunts. We'll be following the 2019 Brodak rules.

Please understand I'm not arguing. If it won'r run well, then I'll relegate it to sport flying and enter one of my BFS, because I've put as much as 5 inches of fuel in those bad boys with good steady runs. Oh, and another fuel economy fix is that I could change to the Big Mig, because it'll fly another minute on the same volume of fuel as the Tee Dee will. You're possibly right about being too fast too. But I have 6 months till our 1/2A day contest. In any case I'm sure the little Bugger will be fun to fly. I started turning circles in the house. And I got tired and dizzy, Lol.

Rusty

I didn't like the way the nose of the TD was rubbing the starter spring, so I removed it. Without it, I was able to mount the engine with a degree or so of outboard thrust offset. Ity took some more sanding the holes, but it still looks neat.

And this will be the very first time I have ever EVER bored perfect holes in the beams. I got the tabs exactly where I wanted them and put a tiny drop of thin CA in each screw hole. Double checked and trimmed the cowl holes to fit perfectly, and with the engine glued in place, I bored the pilot holes. I'm not going to unglue the engine, just gonna screw it down. Only thing is I didn't add aluminum bearers... I forgot about those, but it'll work. If I decide it needs them, I'll put them in. I already have several sets drilled and ready. I don't care for the screws, so a trip to Lowes may be in my near future. I cannot locate a source for 2-56 threaded inserts, or I would have used them

Okay, a good weekend. Next weekend I will be occupied with birthday related stuff, so no shop time for the old man. But it looks like good WX on Tuesday and Thursday. And Daylight Savings time is forecast for the foreseeable future too. Yaaaazoo!!

Rusty

____________________________

Ken Cook wrote:If your running bladder, cooling is a non -issue for the most part. The engine runs cooler due to having a constant fuel supply. I never had a Rev-Lite Norvel overheat in fact it's just the opposite. They rarely get hot enough... What would concern me though is keeping the model flying at speeds conducive to stunt. Your not going to achieve that using bladder easily... A bladder goes richer therefore when you need the most power in the overheads in this could be a issue... Cramming a lot of fuel into a small bladder tube can create false pressure offering a rich run then going over lean.

Ken, thanks for kicking me right in the... brain cells. I knew that. I always tell people how bladder fed engines are self protecting and cannot overheat. DUH!

In my experience my planes only change to a rich run 3 laps before the shutoff. The cowl has a very roomy diameter so it won't be squeezing the sides of the bladder. I haven't measured its length yet(should have) but I think I can fit 3-1/2 inches of fuel in it. This 4 minute flight is on 2-1/2 inches of fuel and I think another 1/2 - 1 inch will work on the new 1/2A Pattern rules where we only have to fly one lap between stunts. We'll be following the 2019 Brodak rules.

Please understand I'm not arguing. If it won'r run well, then I'll relegate it to sport flying and enter one of my BFS, because I've put as much as 5 inches of fuel in those bad boys with good steady runs. Oh, and another fuel economy fix is that I could change to the Big Mig, because it'll fly another minute on the same volume of fuel as the Tee Dee will. You're possibly right about being too fast too. But I have 6 months till our 1/2A day contest. In any case I'm sure the little Bugger will be fun to fly. I started turning circles in the house. And I got tired and dizzy, Lol.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

That's pretty cool gluing the engine in to drill the pilot holes , i started using the auto-matic punch but it has to bee adjusted because of being aggressive . Also drill one hole to bolt engine down , and set for the others for reedies works good for me . I didn't know the Texaco Hd adpt. was no longer available / did you miss dy light saving time day ??

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

I've been busy with non-modeling adventures, so progress has slowed for the past week. But I had to put it all together for a Stunthangar Hangouts Calendar picture, and had Holley take a photo of me with it outside the shop yesterday. I figured I'd use it to bump my thread to keep it alive, so here's what it looks like.

Damn, I think I need a haircut!

Still got the Tee Dee on it, but if I have a fuel economy problem, I may still go with the Big Mig. I measured the bladder compartment and it's only 2-1/2" long. I can make an alternate bladder holder if needed for a 7 minute contest run(which includes the time to walk out to the handle). That would be a sling underneath the belly. Not too aerodynamic, but none of my other planes seem to suffer from it. I bought one of those exhaust pipes for it that Matt sells so I can pipe it out the side... iif it doesn''t rob too much power. I also got a fist-full of 5.5 and 6x2 APC props I can cut up to tune it.

I'll be painting it soon. Some pretty blue present wrapping tissue gave me a nice color if I want use that instead of the purple(sorry, Doug, Lol). Then there's the elongated checkerboard pattern to figure out. I've never masked and painted such detail. The clamshell fuse design lends itself to a great two-tone divider. The wing is still slated for doctor paper. I've bought some various shades of dope; Miami blue and Piper blue, as well as black, white and red, so I can mix and match for a similar Viper scheme.

Of course I'm sure I'm getting ahead of myself, as usual for me, but it's moving along. I'll be in the shop tomorrow. I may go to harbor Freight for my airbrush too, because I need to practice with it before botching the Viper. I finally bought my 2" chop saw from ebay. It's the same one HF sells, but I had a coupon and it was on sale, so for $30 bucks it was delivered two weeks ago. I gave it a run-in for a couple of minutes and then test cut some brass 1/8" tube. Very nice cuts. Then the motor burned up before I could use it. Bob Z has one just like it and his has worked for years. He even cuts bolts with it. I may get a 6" one if the kerf isn't too wide.

Anyway, see y'all next time I make some progress.

Rusty

P.S. that pic should be right side up now.

Damn, I think I need a haircut!

Still got the Tee Dee on it, but if I have a fuel economy problem, I may still go with the Big Mig. I measured the bladder compartment and it's only 2-1/2" long. I can make an alternate bladder holder if needed for a 7 minute contest run(which includes the time to walk out to the handle). That would be a sling underneath the belly. Not too aerodynamic, but none of my other planes seem to suffer from it. I bought one of those exhaust pipes for it that Matt sells so I can pipe it out the side... iif it doesn''t rob too much power. I also got a fist-full of 5.5 and 6x2 APC props I can cut up to tune it.

I'll be painting it soon. Some pretty blue present wrapping tissue gave me a nice color if I want use that instead of the purple(sorry, Doug, Lol). Then there's the elongated checkerboard pattern to figure out. I've never masked and painted such detail. The clamshell fuse design lends itself to a great two-tone divider. The wing is still slated for doctor paper. I've bought some various shades of dope; Miami blue and Piper blue, as well as black, white and red, so I can mix and match for a similar Viper scheme.

Of course I'm sure I'm getting ahead of myself, as usual for me, but it's moving along. I'll be in the shop tomorrow. I may go to harbor Freight for my airbrush too, because I need to practice with it before botching the Viper. I finally bought my 2" chop saw from ebay. It's the same one HF sells, but I had a coupon and it was on sale, so for $30 bucks it was delivered two weeks ago. I gave it a run-in for a couple of minutes and then test cut some brass 1/8" tube. Very nice cuts. Then the motor burned up before I could use it. Bob Z has one just like it and his has worked for years. He even cuts bolts with it. I may get a 6" one if the kerf isn't too wide.

Anyway, see y'all next time I make some progress.

Rusty

P.S. that pic should be right side up now.

Last edited by RknRusty on Thu Mar 28, 2019 11:29 pm; edited 2 times in total

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

That's a beautiful plane, I like it.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Hello Rusty, what a good model you have there! I like it.

Also the message of your flag on the doors of the workshop ...

That photo has a very good climate and your hair is matched with the adventure! ... enjoy the moment friend!

I'll be attentive to news!

Also the message of your flag on the doors of the workshop ...

That photo has a very good climate and your hair is matched with the adventure! ... enjoy the moment friend!

I'll be attentive to news!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Excellent Dude !!!!!!!!!!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Lieven, Mauricio, and Big Red, thanks guys! It's good to be easing back into the game.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Looking Good Rusty !! Sounds like your working up a nice paint and cover jog for the bird

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Yup, Eric. Thanks. I'm watching airbrushing for dummies videos now. I'm going to try using my 5 gallon air tank, keeping it topped off with my 1 gallon compressor. I'm told my small compressor tank won't work well. Besides it's earsplitting loud.getback wrote:Looking Good Rusty !! Sounds like your working up a nice paint and cover jog for the bird

On my way to Harbor Freight for some cheap tools.

Later,

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Hi Rusty ,

I like your picture and the plane is looking super slick ! Don't worry about your hair , least you have some . I have a landing strip for flys on my head . Good luck with your new plane .

Mike1484

I like your picture and the plane is looking super slick ! Don't worry about your hair , least you have some . I have a landing strip for flys on my head . Good luck with your new plane .

Mike1484

Mike1484- Gold Member

- Posts : 303

Join date : 2011-10-28

Age : 76

Location : Northern Ohio

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Dang Rusty, I like that a lot. Is it a kit of from plans ?

akjgardner- Diamond Member

Posts : 1602

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Thanks Ron, i like the picture much better right side up!

Great to see you smiling Rusty!

Great to see you smiling Rusty!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

It shows rightside up on my computer. But the folder thumbnail is upside down... Whatever. I'll copy Rons and edit my post so mine will be right too.

I got my airbrush equipment today, hose, regulator, water filter, and all that rot. For once it looks like it'll all hook up without another trip to the hardware store. And before I went to HF, I looked closer at my compressor. It's a Coleman with a 4 gallon tank. I had thought it was only 1 gallon and I'd need my holding tank as a reserve, but no, I'm all set. I have plenty of Brodak dope to go to town on it.

I also got another chop saw. It looks just like the burnt up ebay one, but... get this... It's heavier! I knew it as soon as I picked the box up. And reading the box, the motor turns 10,600 RPMs. The eBay one was 7,800 RPMs... for 5 minutes. It was a counterfeit knockoff. This one seems strong, but I did spot one problem. When I shut it off, it stops instantly. I think it should coast at least one turn. I took the belt cover off and it's extremely tight. Too tight in my opinion. And when I touched the drive sprocket it burned my finger. I'll try the belt off the dead one. If it's still tight, I'll loosen the bolts and try to adjust it.

I'd planned on upping to the 6" saw, but it's too big. And I was hanging out jabbering with Bob Z Monday. He said his 2" HF chop saw has lasted for years. So I decided to try it again. If I didn't hurt it by overheating it, I think it's fine. These come with a steel toothed blade, and Bob runs friction blades. I don't see 2" versions of those, so I bought some 3" x 3/64" kerf cutoff wheels with the same 3/8" arbor hole and can make it fit. That will allow me to cut bolts and music wire. I might try to burn one down to 2" with the drill press and a file. I don't think it'll cut the file, but even if it does, I know it'll take some blade off.

So maybe I can get some work done on the Viper this weekend, The wx is going to be beautiful.

Rusty

I got my airbrush equipment today, hose, regulator, water filter, and all that rot. For once it looks like it'll all hook up without another trip to the hardware store. And before I went to HF, I looked closer at my compressor. It's a Coleman with a 4 gallon tank. I had thought it was only 1 gallon and I'd need my holding tank as a reserve, but no, I'm all set. I have plenty of Brodak dope to go to town on it.

I also got another chop saw. It looks just like the burnt up ebay one, but... get this... It's heavier! I knew it as soon as I picked the box up. And reading the box, the motor turns 10,600 RPMs. The eBay one was 7,800 RPMs... for 5 minutes. It was a counterfeit knockoff. This one seems strong, but I did spot one problem. When I shut it off, it stops instantly. I think it should coast at least one turn. I took the belt cover off and it's extremely tight. Too tight in my opinion. And when I touched the drive sprocket it burned my finger. I'll try the belt off the dead one. If it's still tight, I'll loosen the bolts and try to adjust it.

I'd planned on upping to the 6" saw, but it's too big. And I was hanging out jabbering with Bob Z Monday. He said his 2" HF chop saw has lasted for years. So I decided to try it again. If I didn't hurt it by overheating it, I think it's fine. These come with a steel toothed blade, and Bob runs friction blades. I don't see 2" versions of those, so I bought some 3" x 3/64" kerf cutoff wheels with the same 3/8" arbor hole and can make it fit. That will allow me to cut bolts and music wire. I might try to burn one down to 2" with the drill press and a file. I don't think it'll cut the file, but even if it does, I know it'll take some blade off.

So maybe I can get some work done on the Viper this weekend, The wx is going to be beautiful.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Gloves and goggles if you are going to do that!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

Safety First, Safety Last! I am guessing that the “Instant Off” is a safety feature to prevent the user from chopping off fingers? My full size chop saw stops quite quickly when the trigger is released, almost like it has disc brakes!

If the saw arbor is getting to hot to touch, there may be a tight bearing or something, i’m guessing, once again, that the motor is not intended for constant use, without a cooling off between uses, consumer quality, not contractor grade?

I’m also glad to see you bought a water separator for the compressor air line. Nothing worse than having a spray of water blast thru and ruin a newly painted plane. Iam amazed at the quanity of water that Drains out of my compressor tank when I used it in the hot humid summer months.

Let the painting begin!

If the saw arbor is getting to hot to touch, there may be a tight bearing or something, i’m guessing, once again, that the motor is not intended for constant use, without a cooling off between uses, consumer quality, not contractor grade?

I’m also glad to see you bought a water separator for the compressor air line. Nothing worse than having a spray of water blast thru and ruin a newly painted plane. Iam amazed at the quanity of water that Drains out of my compressor tank when I used it in the hot humid summer months.

Let the painting begin!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: My Southridge CNC Hyper Viper build

Re: My Southridge CNC Hyper Viper build

I am going to try airbrushing also for the first time. What gun do you have, most online warned to stay away from the cheap chicom brushes.

I need to get hoses and filters also for a large air tank I already have.

This brush seems to be well liked for the money

https://www.ebay.com/itm/NEW-Iwata-Neo-Gravity-Feed-Dual-Action-Airbrush-N4500-NIB-IWAN4500-1-/372107706683?hash=item56a359013b

I need to get hoses and filters also for a large air tank I already have.

This brush seems to be well liked for the money

https://www.ebay.com/itm/NEW-Iwata-Neo-Gravity-Feed-Dual-Action-Airbrush-N4500-NIB-IWAN4500-1-/372107706683?hash=item56a359013b

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Southridge CNC Hyper Viper

» Hybrid-Profile Flite Streak/Cox Hyper Viper scratch build

» Cox me-109 stunt measures - for a friend - he wants to build one again !

» Hyper Viper #3

» Cox Hyper Viper *** And Chipmunk, now

» Hybrid-Profile Flite Streak/Cox Hyper Viper scratch build

» Cox me-109 stunt measures - for a friend - he wants to build one again !

» Hyper Viper #3

» Cox Hyper Viper *** And Chipmunk, now

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules