Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Schnürle Tee Dee 049

Page 1 of 2

Page 1 of 2 • 1, 2

Schnürle Tee Dee 049

Schnürle Tee Dee 049

Somewhere on this Forum I saw mention of incorporating schnürle porting into a Cox engine. I did this in 1973. The Tee Dee 049 engine design had proven to have great longevity from its introduction in ‘63. 1/2 A Speed was one of my flying partner Dub Jett’s favorite events. He had long ago reached the structural limits of the Tee Dee. However, our success with our DJS 29 design reinforced the belief that a tuned pipe applied to a 1/2 A could produce increased power at an RPM just below the structural limit of the Tee Dee 049 (about 30,000). Dub was sure he could design a tuned pipe with the correct tuning RPM and volumetric characteristics for a 1/2 A engine. He was right! His first design was perfect. I obtained some blank (unported) Tee Dee 049 pistons and sleeves from Dale Kirn. I ported the sleeves with a single exhaust and three bypass ports. These sleeves were fabricated in two different designs. Both had a relative small single exhaust port. The boost port was the same in both designs with an up angle of 50 degrees. This was accomplished by using an end mill with a 100 degree included angle conical tip. The difference in design was in the main transfer ports. One design had the mains angled up at 50 degrees just like the boost using the same special end mill. The other design had the main ports 90 degrees at the top accomplished with a standard flat end mill. To obtain the fit we were looking for we chrome plated these tiny jewels.

Fabrication was challenging. Or I should say it was challenging for me. The sleeves were first test fitted to the case to determine the rear location and the TDC dimension. A simple permanent marker line was good enough. This established the exhaust port location. The exhaust port was cut by visually aligning the mark straight up and using the TDC dimension for the position from the top. The bypass ports were a more difficult task. The sleeve was mounted on a stud that threaded into the glow plug hole. This was held vertically exposing the lower end of the sleeve in a rotary table. Angular position was established by dial indicating the already cut exhaust port. The end mills used were touched off on the bottom of the sleeve and then the mill bed was raised to get the port top at the correct dimension. Cutting the ports involved side cutting with the end mill to a length of about ??? inches with a ?? inch diameter mill. That is a 4:1 ratio. It is easy to break the end mill. The trick was to take very small cuts at very slow feeds. Essentially “worrying the port in place”. First the end mill was x-y moved to clear out material to the end position, then the rotary table was used to remove the material between the ends of the port. Going very slowly produced a really nice part, but took a very long time!

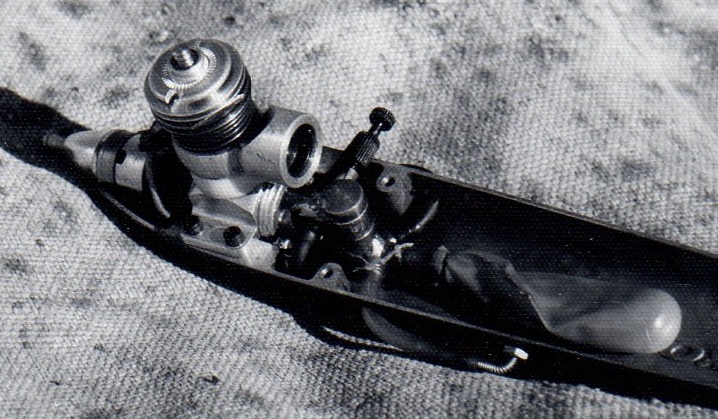

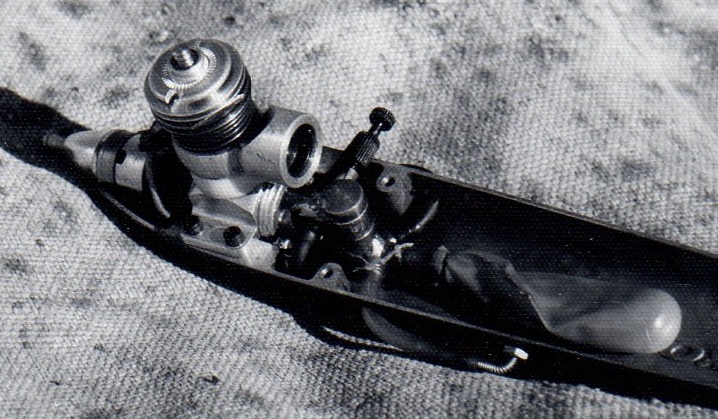

I built headers to adapt to the pipe. This can be seen in the grainy, but only, photo of the actual engine mounted in the pan. A couple of other interesting things can be seen, or not seen because of the quality of the photo. The header is all lathe turned with a bunch of facets at 10 degree increments. Just filing it to shape wound would have been faster! The other is the fuel piping. WHAT A MESS! You will notice an external fueler going to the centerpost where a glob job solder joint hooks together the fueler, pen bladder and exit line. Does this go to the NVA. OH NO! It goes out the right side of the model then back inside to the input to the NVA. The output of the NVA connects to a brass tube that goes to a hole drilled in the plastic front intake housing. What about a venturi you might ask. This is a glow plug drilled out to the max. Why might this be you should ask. Really simple the 1/4-32 thread matched the front end plastic housing. And why was all this Rube Goldberg used. The NV was preset at a position that would let the engine run rich, but on the pipe. This setting is, of course, way too rich for the engine running off the pipe. With the fuel line running outside the model the fuel could be regulated by simply squeezing on the fuel line after the engine was running to “put it on the pipe”. As the engine piped up it needs much more fuel and this is supplied by simply fully releasing the squeezed fuel line. Sounds very complicated, but with a little practice the procedure was mastered by even a couple of dunces.

The real success of this project is not just Dub’s pipe design, but its fabrication. Dub has many things at which he is a wizard. His wizardry is never any greater than aluminum brazing of these thin wall tuned pipes! All I ever managed to obtain while attempting this task was a blob of melted aluminum on the work bench!

Using these engines I won the 1973 Nationals with a speed of 111 MPH.

This is an interesting story. Dub and I both flew identical models at the Nats. Or, more correctly, we both attempted to fly. The flying surface had very large humps at the expansion joints. Between the two of us we had six (6) attempts for a flight. The expansion joints had caused our light weight 1/2 As to release and clip the prop on the first 5 attempts. We were down to our last chance which just by luck was mine. Our procedure was, at best, less than desirable for flying this piped 1/2 A. Part is due to the fact that we did our test flying alone (so, a two person operation was required) and part due to stupidity. We were releasing these airplanes on the pipe close to peak RPM. The fragility of the Tee Dee crankshaft dictated hand cranking to start. I am not the best at this. So, Dub would hand start the engine. I would get it running rich, but on the pipe. Dub would run around and take over the airplane and take off dolly. I would run to the flying handle while Dub set the needle valve. He releases the airplane and off we go! A Keystone Cops’ routine at best! This last attempt I got the airplane safely off the ground and started my timed run. Now comes a critical decision. Bill Wisniewski (event director and good friend) had already disqualified other 1/2 A contestants for “whipping”. I was not taking any chance on our only (and winning) flight. So, after I got the airplane leveled off and in the pylon I simply lifted my hand off the monoline control button to eliminate any question! Many years later Mike Langlois viewed this action in a bit of a different light. He described my flight as running around the pylon waving to the crowd and “rubbing-it-in” at the spanking we were giving everyone. Now, for the stupid part? We should have hand launched the airplanes! These were airplanes with generous wing area and could have easily been hand launched and Dub and I finish 1st and 2nd!

Johnny

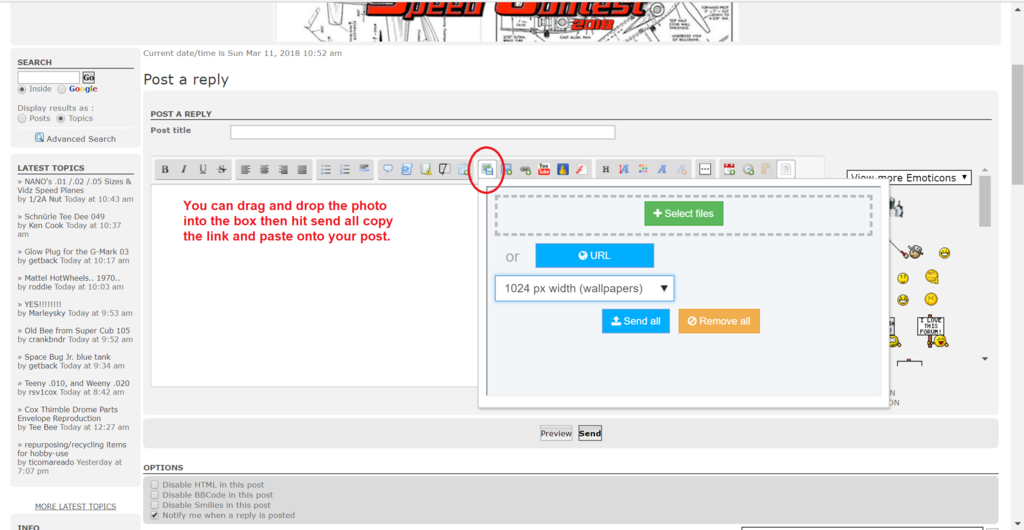

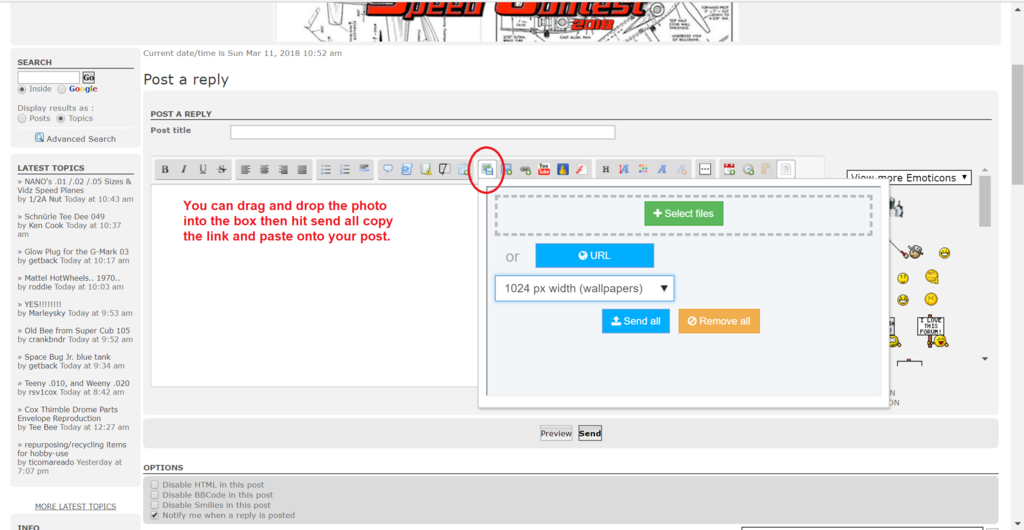

I guess I am the stupidest person in the world. I simply want to insert a picture below its description. The picture is on my computer. The picture does not have an http://. This is my first attempted post.

OK, I did not know there was a waiting period to upload images. Hopefully I have been successful.

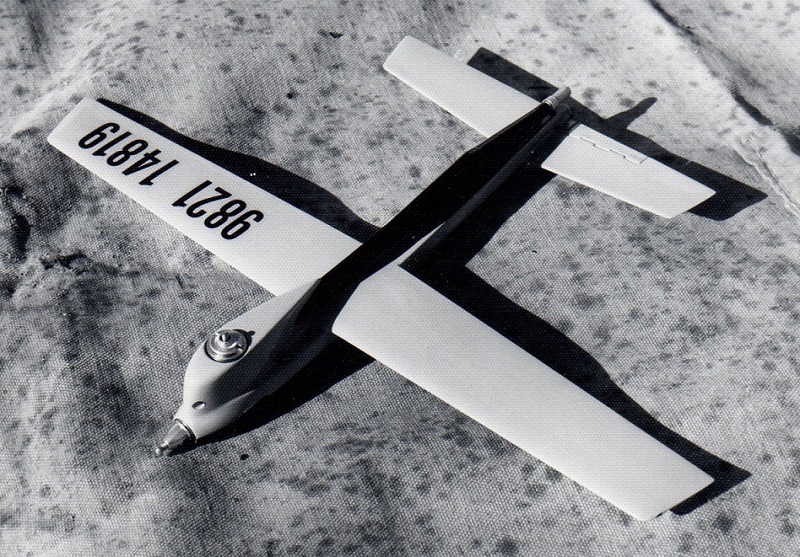

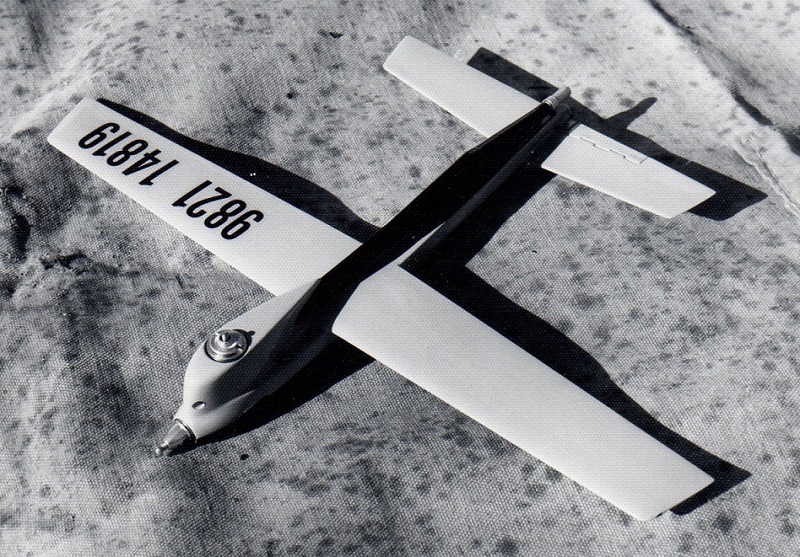

1973 AMA 1/2 A Nationals Winner

Actual Engine with plumbing

Dub and John with their 1973 AMA Nationals Winners (in their 1973 costumes)

1/2 A Tuned Pipe

Fabrication was challenging. Or I should say it was challenging for me. The sleeves were first test fitted to the case to determine the rear location and the TDC dimension. A simple permanent marker line was good enough. This established the exhaust port location. The exhaust port was cut by visually aligning the mark straight up and using the TDC dimension for the position from the top. The bypass ports were a more difficult task. The sleeve was mounted on a stud that threaded into the glow plug hole. This was held vertically exposing the lower end of the sleeve in a rotary table. Angular position was established by dial indicating the already cut exhaust port. The end mills used were touched off on the bottom of the sleeve and then the mill bed was raised to get the port top at the correct dimension. Cutting the ports involved side cutting with the end mill to a length of about ??? inches with a ?? inch diameter mill. That is a 4:1 ratio. It is easy to break the end mill. The trick was to take very small cuts at very slow feeds. Essentially “worrying the port in place”. First the end mill was x-y moved to clear out material to the end position, then the rotary table was used to remove the material between the ends of the port. Going very slowly produced a really nice part, but took a very long time!

I built headers to adapt to the pipe. This can be seen in the grainy, but only, photo of the actual engine mounted in the pan. A couple of other interesting things can be seen, or not seen because of the quality of the photo. The header is all lathe turned with a bunch of facets at 10 degree increments. Just filing it to shape wound would have been faster! The other is the fuel piping. WHAT A MESS! You will notice an external fueler going to the centerpost where a glob job solder joint hooks together the fueler, pen bladder and exit line. Does this go to the NVA. OH NO! It goes out the right side of the model then back inside to the input to the NVA. The output of the NVA connects to a brass tube that goes to a hole drilled in the plastic front intake housing. What about a venturi you might ask. This is a glow plug drilled out to the max. Why might this be you should ask. Really simple the 1/4-32 thread matched the front end plastic housing. And why was all this Rube Goldberg used. The NV was preset at a position that would let the engine run rich, but on the pipe. This setting is, of course, way too rich for the engine running off the pipe. With the fuel line running outside the model the fuel could be regulated by simply squeezing on the fuel line after the engine was running to “put it on the pipe”. As the engine piped up it needs much more fuel and this is supplied by simply fully releasing the squeezed fuel line. Sounds very complicated, but with a little practice the procedure was mastered by even a couple of dunces.

The real success of this project is not just Dub’s pipe design, but its fabrication. Dub has many things at which he is a wizard. His wizardry is never any greater than aluminum brazing of these thin wall tuned pipes! All I ever managed to obtain while attempting this task was a blob of melted aluminum on the work bench!

Using these engines I won the 1973 Nationals with a speed of 111 MPH.

This is an interesting story. Dub and I both flew identical models at the Nats. Or, more correctly, we both attempted to fly. The flying surface had very large humps at the expansion joints. Between the two of us we had six (6) attempts for a flight. The expansion joints had caused our light weight 1/2 As to release and clip the prop on the first 5 attempts. We were down to our last chance which just by luck was mine. Our procedure was, at best, less than desirable for flying this piped 1/2 A. Part is due to the fact that we did our test flying alone (so, a two person operation was required) and part due to stupidity. We were releasing these airplanes on the pipe close to peak RPM. The fragility of the Tee Dee crankshaft dictated hand cranking to start. I am not the best at this. So, Dub would hand start the engine. I would get it running rich, but on the pipe. Dub would run around and take over the airplane and take off dolly. I would run to the flying handle while Dub set the needle valve. He releases the airplane and off we go! A Keystone Cops’ routine at best! This last attempt I got the airplane safely off the ground and started my timed run. Now comes a critical decision. Bill Wisniewski (event director and good friend) had already disqualified other 1/2 A contestants for “whipping”. I was not taking any chance on our only (and winning) flight. So, after I got the airplane leveled off and in the pylon I simply lifted my hand off the monoline control button to eliminate any question! Many years later Mike Langlois viewed this action in a bit of a different light. He described my flight as running around the pylon waving to the crowd and “rubbing-it-in” at the spanking we were giving everyone. Now, for the stupid part? We should have hand launched the airplanes! These were airplanes with generous wing area and could have easily been hand launched and Dub and I finish 1st and 2nd!

Johnny

I guess I am the stupidest person in the world. I simply want to insert a picture below its description. The picture is on my computer. The picture does not have an http://. This is my first attempted post.

OK, I did not know there was a waiting period to upload images. Hopefully I have been successful.

1973 AMA 1/2 A Nationals Winner

Actual Engine with plumbing

Dub and John with their 1973 AMA Nationals Winners (in their 1973 costumes)

1/2 A Tuned Pipe

Last edited by johnshannon on Sun Mar 11, 2018 3:25 pm; edited 1 time in total

johnshannon- New Member

- Posts : 4

Join date : 2018-03-10

Location : Houston, TX

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Great story!! Thanks for sharing, welcome to CEF!! You will be able to post photos shortly, there is a short wait for new members.

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

I own a TD which matches your description to the letter. A rear exhaust which has a header that entire surrounds the cylinder in which the tuned pipe plugs into the rear of it and it's indeed chrome plated. Your description of the venturi is also spot on with mine. I will locate it and take a picture of it. My engine was made from cylinder blanks as it has if memory serves me, 3 ports not to mention the rear exhaust window. One day amidst all of my other projects I will use it to complete a 1/2A speed plane. Archaic by design and certainly by no means a competition engine as I have many other variants of .049's that would blow the doors off of it. I just like to fiddle I suppose.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Thank you for sharing please review photo to show how to post photos.

I have used a tune pipe on a Cox TD see my results per the video.

I am trying to encourage a machinist to make me some cylinder manifolds

with a header pipes using CNC machining for the TD .020 it would be more

so for goo control at this stage till I can make a carbon tuned pipe for it.

Published on Aug 3, 2016

Cox TD .050 / Profi Tuned Pipe / 25,193 rpm Static - HQ Prop 4 x 4.5

Without the pipe the engine would spin up to 23,821 rpm

Static 7.3 oz thrust / .132 hp / 99w / 107.3 mph /

9.3in MRP / 140 deg timing / Pipe set for 25,215 rpm!

Fuel line was a bit big for 1/2A use / pressure line was correct.

For flight prop HQ Prop 5x4.5 will unload near MRP and produce

est. 11 oz thrust. Non SPI / 20% castor oil / 30% nitro.

I have busted 130+ mph with a TD RC per vid here:

Published on Feb 10, 2018

NANO III / 9oz / 28" span / APC 4.22x5.5

Best pass 26,647 rpm / 139 mph prop speed

Static 20,370 rpm / 1oz fuel / 25% nitro / 20 castor

With speed the sound follows behind the plane in the vid.

Checked all passes found the best per posted vid:

Per Audio RPM Gauge 26,647

Per Prop Calc 139 mph

Per Doppler Wav. Scope software 136 mph / 219 Kp/h

Here was a flight with a modified 4.1x4.1 prop with back cut

Lil Speedy - Cox TD .049 / 118 MPH / 30,492 RPM throttle sleeve.

Published on May 7, 2016

TD .049 /SPI / Throttle Sleeve Ports Allow SPI function / Prop 4.1 x 4.1N / 30% Nitro

Static 24,790 rpm / 7.4oz thrust / .127hp / 94.74w / 96.2 mph / 6.19oz RTF

Unloaded 30,492 best on Vid 1 / 118.4 mph per prop calc.

Doppler reading has it at 118mph per pass at 1:47mins into the vid.

Hard tank no pressure tap. 3.7g servos. Cox low compression plug

3mins 20sec of run time on 15cc tank. 16.5"x4" span wing 66sq. in.

Here is the highest static reading obtained with a stock engine / nelson head / pressure tap on the stock muffler.

Published on Oct 22, 2017

Tee Dee RC .050 - All Carbon 4 x 4.5 speed prop.

Best static peak 27,051 / .164hp / 122w / 8.5oz thrust / 115 mph

Nelson plug / aluminum carb body / pressure tap on muffler.

I have used a tune pipe on a Cox TD see my results per the video.

I am trying to encourage a machinist to make me some cylinder manifolds

with a header pipes using CNC machining for the TD .020 it would be more

so for goo control at this stage till I can make a carbon tuned pipe for it.

Published on Aug 3, 2016

Cox TD .050 / Profi Tuned Pipe / 25,193 rpm Static - HQ Prop 4 x 4.5

Without the pipe the engine would spin up to 23,821 rpm

Static 7.3 oz thrust / .132 hp / 99w / 107.3 mph /

9.3in MRP / 140 deg timing / Pipe set for 25,215 rpm!

Fuel line was a bit big for 1/2A use / pressure line was correct.

For flight prop HQ Prop 5x4.5 will unload near MRP and produce

est. 11 oz thrust. Non SPI / 20% castor oil / 30% nitro.

I have busted 130+ mph with a TD RC per vid here:

Published on Feb 10, 2018

NANO III / 9oz / 28" span / APC 4.22x5.5

Best pass 26,647 rpm / 139 mph prop speed

Static 20,370 rpm / 1oz fuel / 25% nitro / 20 castor

With speed the sound follows behind the plane in the vid.

Checked all passes found the best per posted vid:

Per Audio RPM Gauge 26,647

Per Prop Calc 139 mph

Per Doppler Wav. Scope software 136 mph / 219 Kp/h

Here was a flight with a modified 4.1x4.1 prop with back cut

Lil Speedy - Cox TD .049 / 118 MPH / 30,492 RPM throttle sleeve.

Published on May 7, 2016

TD .049 /SPI / Throttle Sleeve Ports Allow SPI function / Prop 4.1 x 4.1N / 30% Nitro

Static 24,790 rpm / 7.4oz thrust / .127hp / 94.74w / 96.2 mph / 6.19oz RTF

Unloaded 30,492 best on Vid 1 / 118.4 mph per prop calc.

Doppler reading has it at 118mph per pass at 1:47mins into the vid.

Hard tank no pressure tap. 3.7g servos. Cox low compression plug

3mins 20sec of run time on 15cc tank. 16.5"x4" span wing 66sq. in.

Here is the highest static reading obtained with a stock engine / nelson head / pressure tap on the stock muffler.

Published on Oct 22, 2017

Tee Dee RC .050 - All Carbon 4 x 4.5 speed prop.

Best static peak 27,051 / .164hp / 122w / 8.5oz thrust / 115 mph

Nelson plug / aluminum carb body / pressure tap on muffler.

Last edited by 1/2A Nut on Sun Mar 11, 2018 3:26 pm; edited 2 times in total

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

crankbndr wrote:Great story!! Thanks for sharing, welcome to CEF!! You will be able to post photos shortly, there is a short wait for new members.

Thanks,

I knew there had to be something going on. Will try to post the pictures after a wait.

Johnny

johnshannon- New Member

- Posts : 4

Join date : 2018-03-10

Location : Houston, TX

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Hi Johnny, So glad to see that you made it over.

If your first post is an indicator, you have a lot to offer.

Bob

If your first post is an indicator, you have a lot to offer.

Bob

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

crankbndr wrote:Great story!! Thanks for sharing, welcome to CEF!! You will be able to post photos shortly, there is a short wait for new members.

Images added. Johnny

johnshannon- New Member

- Posts : 4

Join date : 2018-03-10

Location : Houston, TX

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

rsv1cox wrote:Hi Johnny, So glad to see that you made it over.

If your first post is an indicator, you have a lot to offer.

Bob

Thanks Bob,

Hopefully I can add my experience to help others from making the mistakes I have made!

Johnny

johnshannon- New Member

- Posts : 4

Join date : 2018-03-10

Location : Houston, TX

Schnürle Tee Dee 049

Schnürle Tee Dee 049

Dear John,

What a fabulous story! Thank you for sharing with us, what really went down. Way more interesting than the results sheet! Yeah, hand launching sure would have

looked neat. I certainly like your approach to things as I can really relate to it. I would so much like to have the machining skills necessary to turn my ideas into reality.

Currently though, I often turn otherwise nice metal into junk & broken tools...AAARG! yet I persist...

Way back I was able to acquire a piped Schnurle ported Cox .049 speed model after the original owner had given up on it. Even though the 27,000+ RPM made my hair stand on end, it was a failure as the engine ( w/ a Gerry Bradshaw designed pipe) could never hold that setting for more than a few seconds. The worst problem was that while HOT on the pipe, the cylinder would start to unscrew! I never did solve that problem, so I gave the model away to yet another speed flier who couldn't get it to work either!

Fast forward some 25 years or so, I took up International F2A speed flying using alcohol fed piped .15 engines. There were many years & thousands of lost flights trying to figure out how to get a front induction engine to feed properly in the air and on the pipe without going overlean. The American way was to use some type of pressure feed system. (Centrifugal Fuel Switch CFS, or bladder fed pressure regulator). Those systems were better than nothing, but inevitably were quite unreliable ESPECIALLY when one needed a good flight the most (like at a world championship)! Casting a specially designed pan that allowed a further than normal inboard tank placement was the Australian "secret" to getting a front induction engine to run in an upright model. But in the end, these were all band-aid / partial fixes that never properly addressed the real issue of just not enough fuel being fed to the engine whilst still being able to manage to take off safely.

Around the 1984 world championship in Chicopee, Mass. the Hungarian national team showed everybody how it was done by placing 1,2,3 with what many thought were sub standard built models. They all used the Rossi .15 MK III engine that most teams couldn't get to work reliably. Speeds were ~ 280 KPH. Although that result made Bill Wisniewski sick to his stomach, apparently not enough for him to do anything about it... But, team race flier John McCollum did notice that and on his next trip to an East Block world championships, traded a video camera for a Kalmykov front induction FAI speed model system. John replicated the prop and spinner ass'y so as not to risk damaging the originals. Once done, he arranged for a get together of several of the USA speed team members to do a test flight as John wasn't a speed flier. I guess Carl Dodge did the test flight with Bill Hughes performing the ground tuning (as he had seen the Russian do previously). The exact speed of that test flight varied depending on who I talked to & at what point in the flight it was timed. But ALL agreed it was the easiest & fastest flight they had ever seen relative to their own models.

From that point on, (& previously in Europe) most F2A fliers threw away their pressure fed models & went to the reliable cylinder head outboard suction models. There were a few hold outs who persisted with their pressure fed engines like Carl Dodge who placed as high as 4th at one world champs. But as John pointed out, Carl never had a rich run. I guess he was right because the first year that Carl flew a head outboard suction fed model that fed his homemade engine properly, he won 5 national Championships in a row (in different countries) as well as the world championships at 302 KPH (on his first flight) in 1994 in China. A steady 42,000 RPM is a sound you don't easily forget!

So, what has this trivia got to do with you? Well running an upright model with a front intake engine has been a problem that the entire C/L speed world never solved completely, UNTIL they changed their model layouts to the current norm. That goes DOUBLY when using a pen bladder fuel system. Nobody was able to get a .15 FAI engine to work in the air without using some form of pressure regulator (or pressure bleeder). Like the CFS, it worked but was not optimal.

What you and Dub were trying to do at the time was to overcome what turned out to be an incredibly complex engineering problem. It is truly a tribute to you two that you were able to get that combination to work when you needed it. Congratulations for sticking with it to finally snare a Nats win!

p.s. Now you know an easier way to realize your DJS engines potential should you ever want to fly it again in C/L speed....

and now you know the rest of the story....

Cheers, Paul

What a fabulous story! Thank you for sharing with us, what really went down. Way more interesting than the results sheet! Yeah, hand launching sure would have

looked neat. I certainly like your approach to things as I can really relate to it. I would so much like to have the machining skills necessary to turn my ideas into reality.

Currently though, I often turn otherwise nice metal into junk & broken tools...AAARG! yet I persist...

Way back I was able to acquire a piped Schnurle ported Cox .049 speed model after the original owner had given up on it. Even though the 27,000+ RPM made my hair stand on end, it was a failure as the engine ( w/ a Gerry Bradshaw designed pipe) could never hold that setting for more than a few seconds. The worst problem was that while HOT on the pipe, the cylinder would start to unscrew! I never did solve that problem, so I gave the model away to yet another speed flier who couldn't get it to work either!

Fast forward some 25 years or so, I took up International F2A speed flying using alcohol fed piped .15 engines. There were many years & thousands of lost flights trying to figure out how to get a front induction engine to feed properly in the air and on the pipe without going overlean. The American way was to use some type of pressure feed system. (Centrifugal Fuel Switch CFS, or bladder fed pressure regulator). Those systems were better than nothing, but inevitably were quite unreliable ESPECIALLY when one needed a good flight the most (like at a world championship)! Casting a specially designed pan that allowed a further than normal inboard tank placement was the Australian "secret" to getting a front induction engine to run in an upright model. But in the end, these were all band-aid / partial fixes that never properly addressed the real issue of just not enough fuel being fed to the engine whilst still being able to manage to take off safely.

Around the 1984 world championship in Chicopee, Mass. the Hungarian national team showed everybody how it was done by placing 1,2,3 with what many thought were sub standard built models. They all used the Rossi .15 MK III engine that most teams couldn't get to work reliably. Speeds were ~ 280 KPH. Although that result made Bill Wisniewski sick to his stomach, apparently not enough for him to do anything about it... But, team race flier John McCollum did notice that and on his next trip to an East Block world championships, traded a video camera for a Kalmykov front induction FAI speed model system. John replicated the prop and spinner ass'y so as not to risk damaging the originals. Once done, he arranged for a get together of several of the USA speed team members to do a test flight as John wasn't a speed flier. I guess Carl Dodge did the test flight with Bill Hughes performing the ground tuning (as he had seen the Russian do previously). The exact speed of that test flight varied depending on who I talked to & at what point in the flight it was timed. But ALL agreed it was the easiest & fastest flight they had ever seen relative to their own models.

From that point on, (& previously in Europe) most F2A fliers threw away their pressure fed models & went to the reliable cylinder head outboard suction models. There were a few hold outs who persisted with their pressure fed engines like Carl Dodge who placed as high as 4th at one world champs. But as John pointed out, Carl never had a rich run. I guess he was right because the first year that Carl flew a head outboard suction fed model that fed his homemade engine properly, he won 5 national Championships in a row (in different countries) as well as the world championships at 302 KPH (on his first flight) in 1994 in China. A steady 42,000 RPM is a sound you don't easily forget!

So, what has this trivia got to do with you? Well running an upright model with a front intake engine has been a problem that the entire C/L speed world never solved completely, UNTIL they changed their model layouts to the current norm. That goes DOUBLY when using a pen bladder fuel system. Nobody was able to get a .15 FAI engine to work in the air without using some form of pressure regulator (or pressure bleeder). Like the CFS, it worked but was not optimal.

What you and Dub were trying to do at the time was to overcome what turned out to be an incredibly complex engineering problem. It is truly a tribute to you two that you were able to get that combination to work when you needed it. Congratulations for sticking with it to finally snare a Nats win!

p.s. Now you know an easier way to realize your DJS engines potential should you ever want to fly it again in C/L speed....

and now you know the rest of the story....

Cheers, Paul

Last edited by Paulgibeault on Fri Apr 05, 2019 3:13 pm; edited 1 time in total

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Hi Paul. I had problems being too rich on the ground to take off with pipe pressure in about 1978. Went to the World champs in England and got the CFS from Emil Rumpel and they worked quite well on backplate pressure once you figured them out. The next year I wemt way better, but found out I couldn't run fast enough (in the pylon) That was it for me and the FAI stuff. Sammy had one of those Schneurle TDs We / he got it going pretty good. Over 100 anyway. He had the Canadian record for a while IIRC. The header was brazed on. Can't remember who did it for him. Anyway, the cylinder would wear, being softer. He tried different pistons and they helped for a while, but that was it really. John did the right thing with the plating. Then the Russian stuff came out. Sammy got one of the Stels,(I got a hold of it, and got it working pretty good, but lost the flying circle.) and then the Norvels, and CS stuff took over..... Wow lots of famous guys here eh.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Here is my update contribution to the thread:

Published on Dec 21, 2018

TD .051 / HQ carbon 4x4.5 / Profi 1/2A Tuned Pipe / MRP 30.8K rpm

Pipe's MRP is 7.5" set for unloaded state 132 mph pitch speed

Best peak static 27,051 rpm / 115 mph / .164hp - 122w / 8.5oz thrust

CNC manifold with crank case backplate pressure tap and custom

spun 13mm bullet spinner. Total system weight as shown 74.3g

25% Nitro / 20% Castor / 72F

This plane awaits a good sunny dry ground day with low winds:

Published on Jan 12, 2019

Piped TD .05 / set up on new Nano-X RC Plane

4 x 4.5 Static Peak 26,086 rpm / 111 mph pitch speed

.147hp / 110w / 7.8oz thrust

Published on Dec 21, 2018

TD .051 / HQ carbon 4x4.5 / Profi 1/2A Tuned Pipe / MRP 30.8K rpm

Pipe's MRP is 7.5" set for unloaded state 132 mph pitch speed

Best peak static 27,051 rpm / 115 mph / .164hp - 122w / 8.5oz thrust

CNC manifold with crank case backplate pressure tap and custom

spun 13mm bullet spinner. Total system weight as shown 74.3g

25% Nitro / 20% Castor / 72F

This plane awaits a good sunny dry ground day with low winds:

Published on Jan 12, 2019

Piped TD .05 / set up on new Nano-X RC Plane

4 x 4.5 Static Peak 26,086 rpm / 111 mph pitch speed

.147hp / 110w / 7.8oz thrust

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

I wonder how these cylinders would work on a reedie. I love how easy they make goo control and surely they have to breathe better than the stock setup does.

JennyC6- Bronze Member

- Posts : 46

Join date : 2019-03-04

Location : Mid TN

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

In think having such a cylinder on a reedie would be like carrying nuclear warheads on a bicycle...The lower efficiency of the reed valve than front rotary valve (friction loss of air-fuel mix while inhaled into the crankcase, then sealing of the pressurized crankcase) as well as the engine speed limit imposed by the reed-float -some say around 20k, though I have a reedie that unloads at higher rpm in the air - all would render those TD cylinder strengths largely un-utilized.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Likely be good. I doubt that a pipe would have the desired effect though. Could be more stress on the reed and force it to be closed longer or ? maybe swallow the reed. Bikes and snowmobiles are often schnuerle with reeds.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

I have ran up my Killer Bee with a 4x4.5 carbon mixed prop:

Published on Oct 1, 2017

Real Cox Killer Bee Carbon 4x4.5 / 1.8g prop - Cox Made Date: May 31st 1995

High rpm reed function check mylar reed.

Best peak 25,516

Best steady static: 25,193 / 107 mph pitch speed / 7.1oz thrust / .132hp / 98.47W

- glow plug adapter came loose hence short clip but was able to reach peak NV setting.

For a 4D x 4.5P this could be the highest static rpm recorded of a Cox reed valve engine

5x4.5 Test:

Published on Oct 14, 2017

Killer Bee .049 / HQ 5x4.5 / 19,379 rpm

Static 10.6oz thrust / 83mph / .147hp / 110w

Est. unload in the air at 22.7k rpm 97 mph

Duel mics on the vid camera distorted sound

Made date May 31st 1995 all correct parts less the

Nelson plug and Galbreath adapter head / 25% nitro.

Published on Oct 1, 2017

Real Cox Killer Bee Carbon 4x4.5 / 1.8g prop - Cox Made Date: May 31st 1995

High rpm reed function check mylar reed.

Best peak 25,516

Best steady static: 25,193 / 107 mph pitch speed / 7.1oz thrust / .132hp / 98.47W

- glow plug adapter came loose hence short clip but was able to reach peak NV setting.

For a 4D x 4.5P this could be the highest static rpm recorded of a Cox reed valve engine

5x4.5 Test:

Published on Oct 14, 2017

Killer Bee .049 / HQ 5x4.5 / 19,379 rpm

Static 10.6oz thrust / 83mph / .147hp / 110w

Est. unload in the air at 22.7k rpm 97 mph

Duel mics on the vid camera distorted sound

Made date May 31st 1995 all correct parts less the

Nelson plug and Galbreath adapter head / 25% nitro.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Brad, have you tried a Killer Bee with a pipe yet? I know you will want to.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Schnurle ported reed valve.

Schnurle ported reed valve.

I have a schnurle (3 port) cylinder on a mouse racer. Although I only had 3 races with it, it appeared to go OK but not as fast as my better standard Venom & TeeDee cylinder engines. I also got disqualified when it flew the entire 50 lap race on one tank of fuel! Even with a huge .093" venturi hole. I don't know quite what to make of it. Certainly it's running more fuel efficient...but not as fast speed wise. I much prefer speed over efficiency in mouse racing.

My previous testing with the mylar reed showed 25,500 steady state running. So, the 3 port engine I have only turns a bit over 20,000 with a standard APC 4.5'D X 4"P prop. This is 1/4" less dia. than I normally run, but this particular engine does not like a "full load" prop for some reason. Perhaps due to a "looser" piston fit, I don't really know.

I have also had other K/K schnerle port cylinders on my TeeDee .049 that did not perform near as well as the standard cylinder! Rather disappointing, but really it is quite possible the piston to cylinder fit was not optimal. This fit can result in thousands of RPM difference with no porting change whatsoever. Sadly, I do not know for sure EXACTLY why some cylinders are noticeably faster than others that appear to look identical. I suspect it has to do with the roundness & especially amount of cylinder taper, (as well as piston taper) but I do not have a good way of consistently measuring these parameters.

I have also had superior running piston / cylinder assemblies that run noticeably faster on a TeeDee, run only mediocre when transferred to a reed engine. I keep the piston TDC the same with shims if necessary, but it does not seem to help.

So the BOTTOM LINE is schnurle ported cylinders can run quite OK, but in my experience have not shown to be any better than a good running standard assembly.

Cheers,

Paul (aka Mr. Mouse)

My previous testing with the mylar reed showed 25,500 steady state running. So, the 3 port engine I have only turns a bit over 20,000 with a standard APC 4.5'D X 4"P prop. This is 1/4" less dia. than I normally run, but this particular engine does not like a "full load" prop for some reason. Perhaps due to a "looser" piston fit, I don't really know.

I have also had other K/K schnerle port cylinders on my TeeDee .049 that did not perform near as well as the standard cylinder! Rather disappointing, but really it is quite possible the piston to cylinder fit was not optimal. This fit can result in thousands of RPM difference with no porting change whatsoever. Sadly, I do not know for sure EXACTLY why some cylinders are noticeably faster than others that appear to look identical. I suspect it has to do with the roundness & especially amount of cylinder taper, (as well as piston taper) but I do not have a good way of consistently measuring these parameters.

I have also had superior running piston / cylinder assemblies that run noticeably faster on a TeeDee, run only mediocre when transferred to a reed engine. I keep the piston TDC the same with shims if necessary, but it does not seem to help.

So the BOTTOM LINE is schnurle ported cylinders can run quite OK, but in my experience have not shown to be any better than a good running standard assembly.

Cheers,

Paul (aka Mr. Mouse)

JennyC6 wrote:I wonder how these cylinders would work on a reedie. I love how easy they make goo control and surely they have to breathe better than the stock setup does.

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

HI Al,

Indeed the German (Emil Rumpel) designed CFS was a break though at the time. It allowed front induction engines a way to take off without being too rich, then

richen up in the air for the "on pipe" phase of flight. I used one for many years and even won the Cdn Nats in Ontario with it one year. What I didn't know then is although the engine seemed to pipe up well, it STILL was not running STEADY throughout the run. Often the engine would run rich to lean or some combination throughout the run. With the 17 metre lines & 9 lap timing, it became VERY OBVIOUS that with 3 separate three lap clockings, the run (although on the pipe) was unstable. If you thought Rossi's were unstable, try a Profi! Horrendously powerful, but a great deal of work is involved in stabilizing that beast for consistent results.

My hat goes off to Sam Burke to have the patience to deal with a piped Cox .049 with the limited information available at the time. Of course Sam's marvelous

1/2A speed record fell to a ball bearing ABC (non piped) schnurle ported Shuriken which retailed for only $200+ at the time compared to the $35 Cox TeeDee!

Then as you say, with ball bearing C.S., Cyclon, G-Z & Picco engines, they left the plain bearing piped engines in the dust. I had the good fortune to pick up a C.S. .049 speed engine right at the C.S. factory in 1994. They ran it up in the test room moments before while I was having a bowl of noodles with the Director of C.S. engines Mr. Gou Gojun. It was still warm from the test run. When I asked why he had it run up. Mr. Gou replied, " Ahh Mr. Gibeault, you are Canadian F2A speed pilot. If engine not run well, I know you will send it right back..." !! YES, lots of famous guys here. Sadly many of the famous Cox guys have passed away...

Cheers,

Paul (aka Mr. Mouse)

Indeed the German (Emil Rumpel) designed CFS was a break though at the time. It allowed front induction engines a way to take off without being too rich, then

richen up in the air for the "on pipe" phase of flight. I used one for many years and even won the Cdn Nats in Ontario with it one year. What I didn't know then is although the engine seemed to pipe up well, it STILL was not running STEADY throughout the run. Often the engine would run rich to lean or some combination throughout the run. With the 17 metre lines & 9 lap timing, it became VERY OBVIOUS that with 3 separate three lap clockings, the run (although on the pipe) was unstable. If you thought Rossi's were unstable, try a Profi! Horrendously powerful, but a great deal of work is involved in stabilizing that beast for consistent results.

My hat goes off to Sam Burke to have the patience to deal with a piped Cox .049 with the limited information available at the time. Of course Sam's marvelous

1/2A speed record fell to a ball bearing ABC (non piped) schnurle ported Shuriken which retailed for only $200+ at the time compared to the $35 Cox TeeDee!

Then as you say, with ball bearing C.S., Cyclon, G-Z & Picco engines, they left the plain bearing piped engines in the dust. I had the good fortune to pick up a C.S. .049 speed engine right at the C.S. factory in 1994. They ran it up in the test room moments before while I was having a bowl of noodles with the Director of C.S. engines Mr. Gou Gojun. It was still warm from the test run. When I asked why he had it run up. Mr. Gou replied, " Ahh Mr. Gibeault, you are Canadian F2A speed pilot. If engine not run well, I know you will send it right back..." !! YES, lots of famous guys here. Sadly many of the famous Cox guys have passed away...

Cheers,

Paul (aka Mr. Mouse)

aspeed wrote:Hi Paul. I had problems being too rich on the ground to take off with pipe pressure in about 1978. Went to the World champs in England and got the CFS from Emil Rumpel and they worked quite well on backplate pressure once you figured them out. The next year I wemt way better, but found out I couldn't run fast enough (in the pylon) That was it for me and the FAI stuff. Sammy had one of those Schneurle TDs We / he got it going pretty good. Over 100 anyway. He had the Canadian record for a while IIRC. The header was brazed on. Can't remember who did it for him. Anyway, the cylinder would wear, being softer. He tried different pistons and they helped for a while, but that was it really. John did the right thing with the plating. Then the Russian stuff came out. Sammy got one of the Stels,(I got a hold of it, and got it working pretty good, but lost the flying circle.) and then the Norvels, and CS stuff took over..... Wow lots of famous guys here eh.

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

I have a GZ .049 which seems slow, a CS piped and a non piped one. They are ok, but the piped one I got off someone in the Toronto club that couldn't get it going. I guess he should have stopped in at the factory too. It was very tight. If the F2A was at 17 meters then, I would likely have kept flying for a couple more years.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

HI Al,

Truth be told, the "quality" of the C.S. engine product varied greatly. There were articles in the SPEED TIMES newsletter about the many modifications required to get this engine up to "real competitive" standards. It was referred to as a "kit engine" as the basics were there but much fitting work was still needed. Fortunately, most important clearances were too tight and therefore careful machining could bring them back into the ideal tolerance range. I also believe Doug Galbreath out of California published similar information on the subject. Further work with properly fitted ceramic bearings done by the late Greg Settles also increased performance.

As well, a properly fitted (and designed) head button using Nelson type glow plugs yielded another major performance boost.

Regarding Control Line FAI rotational speeds, yeah it's FAST, always was fast & will remain fast until this last generation can no longer keep interested. Many European fliers are in their late 60's and even 70's now.

I was most impressed at the Muncie World Speed Championships where 73 year old Jean Mange from France was able to fly (left handed yet!) and tie the winning 295.9 KPH flight. Jean was often found NAPPING between rounds & had to be woken up for his flights! What a man, he ended up with the silver medal that year...

Cheers,

Paul (aka Mr. Mouse)

Truth be told, the "quality" of the C.S. engine product varied greatly. There were articles in the SPEED TIMES newsletter about the many modifications required to get this engine up to "real competitive" standards. It was referred to as a "kit engine" as the basics were there but much fitting work was still needed. Fortunately, most important clearances were too tight and therefore careful machining could bring them back into the ideal tolerance range. I also believe Doug Galbreath out of California published similar information on the subject. Further work with properly fitted ceramic bearings done by the late Greg Settles also increased performance.

As well, a properly fitted (and designed) head button using Nelson type glow plugs yielded another major performance boost.

Regarding Control Line FAI rotational speeds, yeah it's FAST, always was fast & will remain fast until this last generation can no longer keep interested. Many European fliers are in their late 60's and even 70's now.

I was most impressed at the Muncie World Speed Championships where 73 year old Jean Mange from France was able to fly (left handed yet!) and tie the winning 295.9 KPH flight. Jean was often found NAPPING between rounds & had to be woken up for his flights! What a man, he ended up with the silver medal that year...

Cheers,

Paul (aka Mr. Mouse)

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Here is my CS bone stock first run up after some break in.

Published on Nov 24, 2017

CS .061 / Nelson Plug Med. / Profi .8cc Tuned Pipe / APC 4.5x4

Best Peak 25,193 rpm / .188hp / 140.3w / 12oz thrust / 96 mph

Hold peak 25,052 rpm / 25% nitro / 20% oil blend

8.75" Mean Reflective Point / "center of piston to 2" from end of stinger.

Needle Valve 3.75 turns out due to no pressure tap.

105.7g as shown with pipe

4.75 x 4 would make a good sport / speed prop in the air.

I should have propped down to get it solid on the pipe but did

not want to push it with such low run time needs a pressure tap.

Published on Nov 24, 2017

CS .061 / Nelson Plug Med. / Profi .8cc Tuned Pipe / APC 4.5x4

Best Peak 25,193 rpm / .188hp / 140.3w / 12oz thrust / 96 mph

Hold peak 25,052 rpm / 25% nitro / 20% oil blend

8.75" Mean Reflective Point / "center of piston to 2" from end of stinger.

Needle Valve 3.75 turns out due to no pressure tap.

105.7g as shown with pipe

4.75 x 4 would make a good sport / speed prop in the air.

I should have propped down to get it solid on the pipe but did

not want to push it with such low run time needs a pressure tap.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

Paulgibeault wrote:I have a schnurle (3 port) cylinder on a mouse racer. Although I only had 3 races with it, it appeared to go OK but not as fast as my better standard Venom & TeeDee cylinder engines. I also got disqualified when it flew the entire 50 lap race on one tank of fuel! Even with a huge .093" venturi hole. I don't know quite what to make of it. Certainly it's running more fuel efficient...but not as fast speed wise. I much prefer speed over efficiency in mouse racing.

My previous testing with the mylar reed showed 25,500 steady state running. So, the 3 port engine I have only turns a bit over 20,000 with a standard APC 4.5'D X 4"P prop. This is 1/4" less dia. than I normally run, but this particular engine does not like a "full load" prop for some reason. Perhaps due to a "looser" piston fit, I don't really know.

I have also had other K/K schnerle port cylinders on my TeeDee .049 that did not perform near as well as the standard cylinder! Rather disappointing, but really it is quite possible the piston to cylinder fit was not optimal. This fit can result in thousands of RPM difference with no porting change whatsoever. Sadly, I do not know for sure EXACTLY why some cylinders are noticeably faster than others that appear to look identical. I suspect it has to do with the roundness & especially amount of cylinder taper, (as well as piston taper) but I do not have a good way of consistently measuring these parameters.

I have also had superior running piston / cylinder assemblies that run noticeably faster on a TeeDee, run only mediocre when transferred to a reed engine. I keep the piston TDC the same with shims if necessary, but it does not seem to help.

So the BOTTOM LINE is schnurle ported cylinders can run quite OK, but in my experience have not shown to be any better than a good running standard assembly.

Cheers,

Paul (aka Mr. Mouse)JennyC6 wrote:I wonder how these cylinders would work on a reedie. I love how easy they make goo control and surely they have to breathe better than the stock setup does.

....your anecdote of getting DQ'd from a comp because you had better fuel economy than you should have actually makes me want a Schnuerle ported cylinder more. Same performance more or less, but less fuel used? For the flying I do that's a win win.

JennyC6- Bronze Member

- Posts : 46

Join date : 2019-03-04

Location : Mid TN

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

The mileage thing goes against all common knowledge. The old Fox and K&B type motors were thought to sip fuel compared to the "new" schnurles. Funny how rules are made to be bent, and that is ok until someone loses and changes the rules. The .049 mileage isn't such a big deal, I spill more than I use, but those little tanks sure don't last long.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Schnürle Tee Dee 049

Re: Schnürle Tee Dee 049

[quote="Paulgibeault"]

I have also had other K/K schnerle port cylinders on my TeeDee .049 that did not perform near as well as the standard cylinder! Rather disappointing, but really it is quite possible the piston to cylinder fit was not optimal. This fit can result in thousands of RPM difference with no porting change whatsoever. Sadly, I do not know for sure EXACTLY why some cylinders are noticeably faster than others that appear to look identical. I suspect it has to do with the roundness & especially amount of cylinder taper, (as well as piston taper) but I do not have a good way of consistently measuring these parameters.

I have also had superior running piston / cylinder assemblies that run noticeably faster on a TeeDee, run only mediocre when transferred to a reed engine. I keep the piston TDC the same with shims if necessary, but it does not seem to help.

So the BOTTOM LINE is schnurle ported cylinders can run quite OK, but in my experience have not shown to be any better than a good running standard assembly.

Cheers,

Paul (aka Mr. Mouse)

About a decade ago I interviewed NZ's top engine man Harvey Westland for the UK publication 'Model Engine World'-we covered a great deal in terms of background, history material selection as well as design-one of the points he was most emphatic on was roundness-and he states "as little as 2 microns out of round (barely detectable with routine engineering equipment) has a detectable effect on engine performance"...he was quite thorough in his engineering-even making his shafts with negative tapered crankpins (ie narrower at the shaft crankweb end) so they would flex on the power stroke and remain 'square' and aligned for the power stroke...

In a production environment it is inevitable that some engines will come out 'bang on' with the correct fits and tolerances, whereas others will be out a bit-whether in clearances or roundness. Johnny S has a few tales he's posted in other forums about some of the mysteries about 'good uns' and 'not so good uns'-where there was no obvious engineering explanation for the differences observed in actual running.

My own example is somewhat more mundane-in the early 90s here in NZ we used the Russian Typhoon combat 'practice' motors for F1C....they were cheap-ridiculously so, and readily available-unlike the Rossis (which non one was using at that stage) while the Conquest was out of production, and Nelsons both in short supply and expensive. My particular Typhoon-which came from 'Engines from Russia' in the UK-was a good 2000 rpm up on any of the other ones in NZ-and this was on straight 80:20 FAI fuel-and a 7mm venturi. Eventually I was persuaded to part with it-and the guy I swapped it with-who'd been privy to much of the comparative testing anyway-tore it down and thoroughly analysed it to see if he could work out why it was so much better. His verdict: "the liner chroming was rubbish.....but the piston and liner were absolutely round....I could not detect any out of roundness-right down to less than a micron.."

So I guess this was one of the magic 1 in a hundred or 1 in a thousand engines where everything was 'just right' from the production line....

ChrisM

'ffkiwi'

I have also had other K/K schnerle port cylinders on my TeeDee .049 that did not perform near as well as the standard cylinder! Rather disappointing, but really it is quite possible the piston to cylinder fit was not optimal. This fit can result in thousands of RPM difference with no porting change whatsoever. Sadly, I do not know for sure EXACTLY why some cylinders are noticeably faster than others that appear to look identical. I suspect it has to do with the roundness & especially amount of cylinder taper, (as well as piston taper) but I do not have a good way of consistently measuring these parameters.

I have also had superior running piston / cylinder assemblies that run noticeably faster on a TeeDee, run only mediocre when transferred to a reed engine. I keep the piston TDC the same with shims if necessary, but it does not seem to help.

So the BOTTOM LINE is schnurle ported cylinders can run quite OK, but in my experience have not shown to be any better than a good running standard assembly.

Cheers,

Paul (aka Mr. Mouse)

About a decade ago I interviewed NZ's top engine man Harvey Westland for the UK publication 'Model Engine World'-we covered a great deal in terms of background, history material selection as well as design-one of the points he was most emphatic on was roundness-and he states "as little as 2 microns out of round (barely detectable with routine engineering equipment) has a detectable effect on engine performance"...he was quite thorough in his engineering-even making his shafts with negative tapered crankpins (ie narrower at the shaft crankweb end) so they would flex on the power stroke and remain 'square' and aligned for the power stroke...

In a production environment it is inevitable that some engines will come out 'bang on' with the correct fits and tolerances, whereas others will be out a bit-whether in clearances or roundness. Johnny S has a few tales he's posted in other forums about some of the mysteries about 'good uns' and 'not so good uns'-where there was no obvious engineering explanation for the differences observed in actual running.

My own example is somewhat more mundane-in the early 90s here in NZ we used the Russian Typhoon combat 'practice' motors for F1C....they were cheap-ridiculously so, and readily available-unlike the Rossis (which non one was using at that stage) while the Conquest was out of production, and Nelsons both in short supply and expensive. My particular Typhoon-which came from 'Engines from Russia' in the UK-was a good 2000 rpm up on any of the other ones in NZ-and this was on straight 80:20 FAI fuel-and a 7mm venturi. Eventually I was persuaded to part with it-and the guy I swapped it with-who'd been privy to much of the comparative testing anyway-tore it down and thoroughly analysed it to see if he could work out why it was so much better. His verdict: "the liner chroming was rubbish.....but the piston and liner were absolutely round....I could not detect any out of roundness-right down to less than a micron.."

So I guess this was one of the magic 1 in a hundred or 1 in a thousand engines where everything was 'just right' from the production line....

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Schnurle TeeDee 049

Schnurle TeeDee 049

Hi Chris,

Indeed the cylinder /piston tolerances on Cox .049's are a magnificent 50 millionths of an inch (just a shade over your metric micron).

As a training exercise, I once showed a group of aircraft maintenance engineers/mechanics that they could indeed easily feel with their own fingers tolerances of one tenth thousandth of an inch (.0001").

My example was a Cox .049 cylinder with assorted loose - medium - tight fitting pistons. My .00005" snap gauge micrometer was having a hard time even measuring the differences, they were so small. So my hat's off to those very few people who can get these tiny engines to "GO".

I was very lucky to have been a guest of your late Allen (Barney / Granddad) Barnes while attending C/L Speed competitions on the North Island one year. Allen designed & built his own competitive FAI speed motor which was a real jewel.

* Fascinating note on Harvey's crank pin design too! *

Funny how when I teamed up with Peter Tilley of Australia, we blew away the Canadian Open Goodyear records using a magnificent (and very expensive many thought) George Aldrich prepared Rossi .15. Canada's (then) top F1C F/F power flier asked to "borrow" the motor for inspection. He measured it up & concluded there was nothing particularly special about it. What a comment!! GMA had perfected a way of making perfect piston/cylinder fits that produced enormous power while still being able to be hand started very easily hot or cold. It was a rare pit stop that took me more than 2 flips to re-start. We can only suspect our "evaluator" did not have the precision measuring tools necessary to measure the cylinder properly. Although most top engines seem to have shiny chrome bores, I suspect that dull chrome can be equally effective IF it's round enough along the cylinder bore.

You can't believe the angst I felt when I accidentally ruined my record holding Cox piston by incorrect disassembly! ARG! Since then, my performance has not returned

to the high level that it once was...

So as top engine men know .... You can CNC make all the precision parts you like, but that last 5% power boost ends up being.. "All in the hand fit "

Cheers,

Paul (aka Mr. Mouse)

About a decade ago I interviewed NZ's top engine man Harvey Westland for the UK publication 'Model Engine World'-we covered a great deal in terms of background, history material selection as well as design-one of the points he was most emphatic on was roundness-and he states "as little as 2 microns out of round (barely detectable with routine engineering equipment) has a detectable effect on engine performance"...he was quite thorough in his engineering-even making his shafts with negative tapered crankpins (ie narrower at the shaft crankweb end) so they would flex on the power stroke and remain 'square' and aligned for the power stroke...

In a production environment it is inevitable that some engines will come out 'bang on' with the correct fits and tolerances, whereas others will be out a bit-whether in clearances or roundness. Johnny S has a few tales he's posted in other forums about some of the mysteries about 'good uns' and 'not so good uns'-where there was no obvious engineering explanation for the differences observed in actual running.

My own example is somewhat more mundane-in the early 90s here in NZ we used the Russian Typhoon combat 'practice' motors for F1C....they were cheap-ridiculously so, and readily available-unlike the Rossis (which non one was using at that stage) while the Conquest was out of production, and Nelsons both in short supply and expensive. My particular Typhoon-which came from 'Engines from Russia' in the UK-was a good 2000 rpm up on any of the other ones in NZ-and this was on straight 80:20 FAI fuel-and a 7mm venturi. Eventually I was persuaded to part with it-and the guy I swapped it with-who'd been privy to much of the comparative testing anyway-tore it down and thoroughly analysed it to see if he could work out why it was so much better. His verdict: "the liner chroming was rubbish.....but the piston and liner were absolutely round....I could not detect any out of roundness-right down to less than a micron.."

So I guess this was one of the magic 1 in a hundred or 1 in a thousand engines where everything was 'just right' from the production line....

ChrisM

'ffkiwi'[/quote]

[/quote]

Indeed the cylinder /piston tolerances on Cox .049's are a magnificent 50 millionths of an inch (just a shade over your metric micron).

As a training exercise, I once showed a group of aircraft maintenance engineers/mechanics that they could indeed easily feel with their own fingers tolerances of one tenth thousandth of an inch (.0001").

My example was a Cox .049 cylinder with assorted loose - medium - tight fitting pistons. My .00005" snap gauge micrometer was having a hard time even measuring the differences, they were so small. So my hat's off to those very few people who can get these tiny engines to "GO".

I was very lucky to have been a guest of your late Allen (Barney / Granddad) Barnes while attending C/L Speed competitions on the North Island one year. Allen designed & built his own competitive FAI speed motor which was a real jewel.

* Fascinating note on Harvey's crank pin design too! *

Funny how when I teamed up with Peter Tilley of Australia, we blew away the Canadian Open Goodyear records using a magnificent (and very expensive many thought) George Aldrich prepared Rossi .15. Canada's (then) top F1C F/F power flier asked to "borrow" the motor for inspection. He measured it up & concluded there was nothing particularly special about it. What a comment!! GMA had perfected a way of making perfect piston/cylinder fits that produced enormous power while still being able to be hand started very easily hot or cold. It was a rare pit stop that took me more than 2 flips to re-start. We can only suspect our "evaluator" did not have the precision measuring tools necessary to measure the cylinder properly. Although most top engines seem to have shiny chrome bores, I suspect that dull chrome can be equally effective IF it's round enough along the cylinder bore.

You can't believe the angst I felt when I accidentally ruined my record holding Cox piston by incorrect disassembly! ARG! Since then, my performance has not returned

to the high level that it once was...

So as top engine men know .... You can CNC make all the precision parts you like, but that last 5% power boost ends up being.. "All in the hand fit "

Cheers,

Paul (aka Mr. Mouse)

About a decade ago I interviewed NZ's top engine man Harvey Westland for the UK publication 'Model Engine World'-we covered a great deal in terms of background, history material selection as well as design-one of the points he was most emphatic on was roundness-and he states "as little as 2 microns out of round (barely detectable with routine engineering equipment) has a detectable effect on engine performance"...he was quite thorough in his engineering-even making his shafts with negative tapered crankpins (ie narrower at the shaft crankweb end) so they would flex on the power stroke and remain 'square' and aligned for the power stroke...

In a production environment it is inevitable that some engines will come out 'bang on' with the correct fits and tolerances, whereas others will be out a bit-whether in clearances or roundness. Johnny S has a few tales he's posted in other forums about some of the mysteries about 'good uns' and 'not so good uns'-where there was no obvious engineering explanation for the differences observed in actual running.

My own example is somewhat more mundane-in the early 90s here in NZ we used the Russian Typhoon combat 'practice' motors for F1C....they were cheap-ridiculously so, and readily available-unlike the Rossis (which non one was using at that stage) while the Conquest was out of production, and Nelsons both in short supply and expensive. My particular Typhoon-which came from 'Engines from Russia' in the UK-was a good 2000 rpm up on any of the other ones in NZ-and this was on straight 80:20 FAI fuel-and a 7mm venturi. Eventually I was persuaded to part with it-and the guy I swapped it with-who'd been privy to much of the comparative testing anyway-tore it down and thoroughly analysed it to see if he could work out why it was so much better. His verdict: "the liner chroming was rubbish.....but the piston and liner were absolutely round....I could not detect any out of roundness-right down to less than a micron.."

So I guess this was one of the magic 1 in a hundred or 1 in a thousand engines where everything was 'just right' from the production line....

ChrisM

'ffkiwi'[/quote]

[/quote]

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules