Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Fitting Cox .049 pistons to cylinders..

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Fitting Cox .049 pistons to cylinders..

Re: Fitting Cox .049 pistons to cylinders..

Roddie. I know you said the screws tightened up ok, but I've found when removing the choke tube from a Surestart backplate that my screrws bottomed & needed shortening, or a washer under the head.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Fitting Cox .049 pistons to cylinders..

Re: Fitting Cox .049 pistons to cylinders..

Thanks fella's.. good tips! I like the servo-mount inserts Mauricio!  My airplanes almost all have firewalls drilled for mounting the backplate for the fuel-line to be on the R/H side where I usually have a wedge-tank. This keeps the fuel-line as short as possible.

My airplanes almost all have firewalls drilled for mounting the backplate for the fuel-line to be on the R/H side where I usually have a wedge-tank. This keeps the fuel-line as short as possible.

I really don't know why I chose to orient the cylinders "upright" on all six engines.. and I'm going to re-orient them all to run outboard. I honestly don't want to remove the cylinder to mount an engine.. plus; orienting it horizontally helps to protect it in a crash.

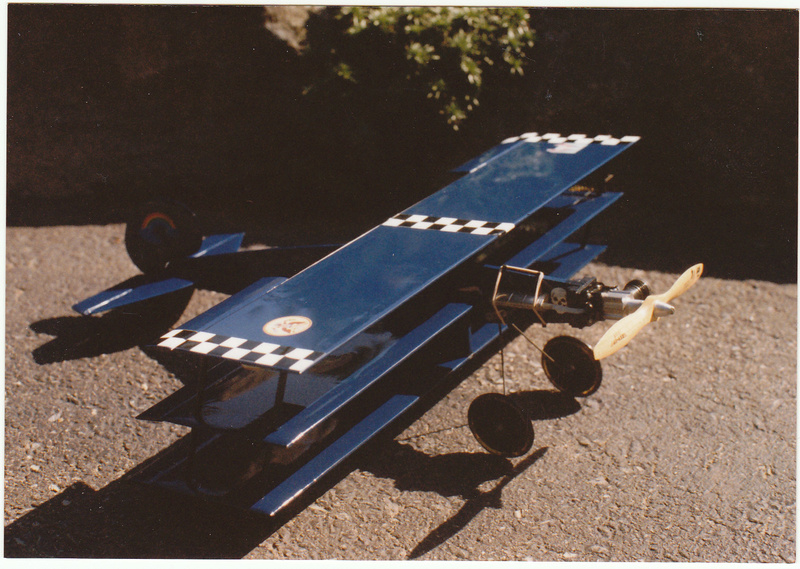

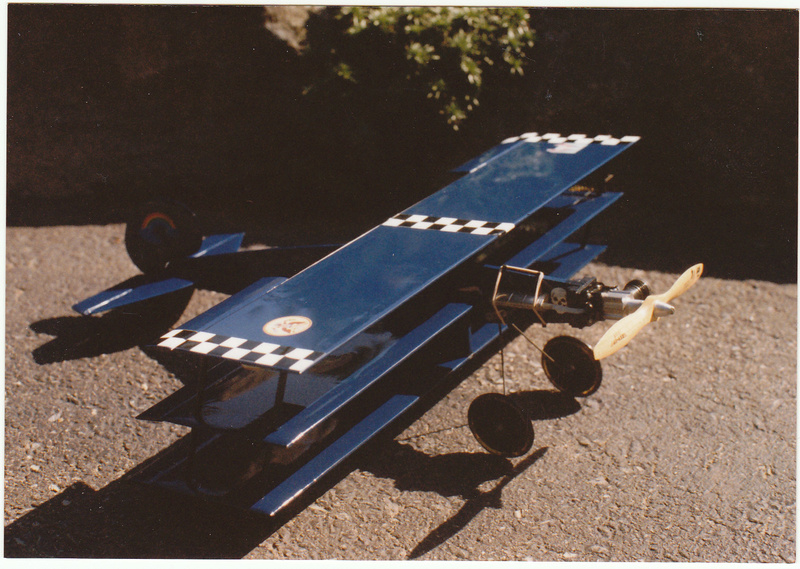

This triplane had its cylinder mounted "inboard".. when I flew it 25 years ago. It had balance issues (tail-heavy.. ) so it only flew once.. and crashed.

) so it only flew once.. and crashed.

The damage was minor and I've made some modifications.. but haven't flown it since.

Those top/bottom wing-flaps have been removed, saving .4oz. of weight behind the C of G.

I'll orient the cylinder outboard this time when I try to fly it. Those were the early days when I knew even less than I do now..

My airplanes almost all have firewalls drilled for mounting the backplate for the fuel-line to be on the R/H side where I usually have a wedge-tank. This keeps the fuel-line as short as possible.

My airplanes almost all have firewalls drilled for mounting the backplate for the fuel-line to be on the R/H side where I usually have a wedge-tank. This keeps the fuel-line as short as possible. I really don't know why I chose to orient the cylinders "upright" on all six engines.. and I'm going to re-orient them all to run outboard. I honestly don't want to remove the cylinder to mount an engine.. plus; orienting it horizontally helps to protect it in a crash.

This triplane had its cylinder mounted "inboard".. when I flew it 25 years ago. It had balance issues (tail-heavy..

) so it only flew once.. and crashed.

) so it only flew once.. and crashed.

The damage was minor and I've made some modifications.. but haven't flown it since.

Those top/bottom wing-flaps have been removed, saving .4oz. of weight behind the C of G.

I'll orient the cylinder outboard this time when I try to fly it. Those were the early days when I knew even less than I do now..

Re: Fitting Cox .049 pistons to cylinders..

Re: Fitting Cox .049 pistons to cylinders..

One more time..  (humor me please..) Back-plates have been re-oriented for mounting all-four screws to the firewall with a horizontal outboard cylinder configuration. (What a maroon.... Bugs Bunny..)

(humor me please..) Back-plates have been re-oriented for mounting all-four screws to the firewall with a horizontal outboard cylinder configuration. (What a maroon.... Bugs Bunny..)

See that stubby screwdriver? OCD Roddie likes its' ratcheting function. I start each screw by turning it "out" until I feel the screw-threads engage with a "click".. then I tighten each a few turns. I do this to all four screws until they're close to seating. Then I set the ratchet-driver in reverse to act as a "clutch". When the ratchet clicks while tightening.. I switch to a diagonal screw in the pattern. When they all "click".. I switch-off the ratchet and tighten gradually in the same alternating sequence.. (the way I was taught to change a car tire..) without being too heavy-handed.. After all they're only 2-56 size screws.. The PH1 insert-bit fits these screw-heads nicely. The case-screws were sourced from Cox International (Bernie).. as were the back-plates.

The short-style needles and Mylar reeds were sourced from ExModel engines (Matt). I have a few long-style needles.. in the event that I want to try a choke-tube. The short needles are too short to work with them.

See that stubby screwdriver? OCD Roddie likes its' ratcheting function. I start each screw by turning it "out" until I feel the screw-threads engage with a "click".. then I tighten each a few turns. I do this to all four screws until they're close to seating. Then I set the ratchet-driver in reverse to act as a "clutch". When the ratchet clicks while tightening.. I switch to a diagonal screw in the pattern. When they all "click".. I switch-off the ratchet and tighten gradually in the same alternating sequence.. (the way I was taught to change a car tire..) without being too heavy-handed.. After all they're only 2-56 size screws.. The PH1 insert-bit fits these screw-heads nicely. The case-screws were sourced from Cox International (Bernie).. as were the back-plates.

The short-style needles and Mylar reeds were sourced from ExModel engines (Matt). I have a few long-style needles.. in the event that I want to try a choke-tube. The short needles are too short to work with them.

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» What are the differences (if any) between Cox .09 TD and Medallion pistons/cylinders?

» Fitting a .051 piston to a worn .049 cylinder?

» ISO plans for a V Twin glow engine using Cox 049 cylinders, pistons, glowplugs

» Tips and tricks for getting that tinyt fuel line on the tiny fitting on the back of all.049s HELP!

» Workshop safety

» Fitting a .051 piston to a worn .049 cylinder?

» ISO plans for a V Twin glow engine using Cox 049 cylinders, pistons, glowplugs

» Tips and tricks for getting that tinyt fuel line on the tiny fitting on the back of all.049s HELP!

» Workshop safety

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules