Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Medallion nozzle assembly: which way?

Page 1 of 2

Page 1 of 2 • 1, 2

Medallion nozzle assembly: which way?

Medallion nozzle assembly: which way?

Hi everybody,

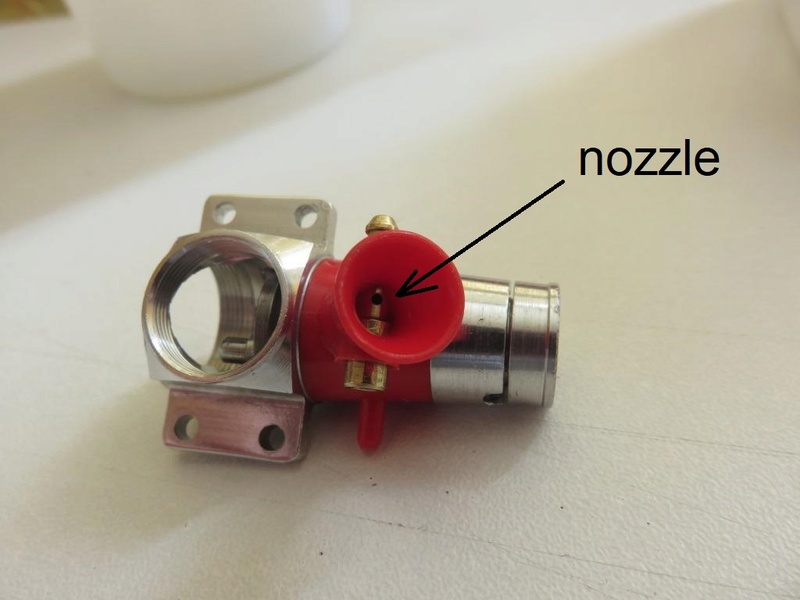

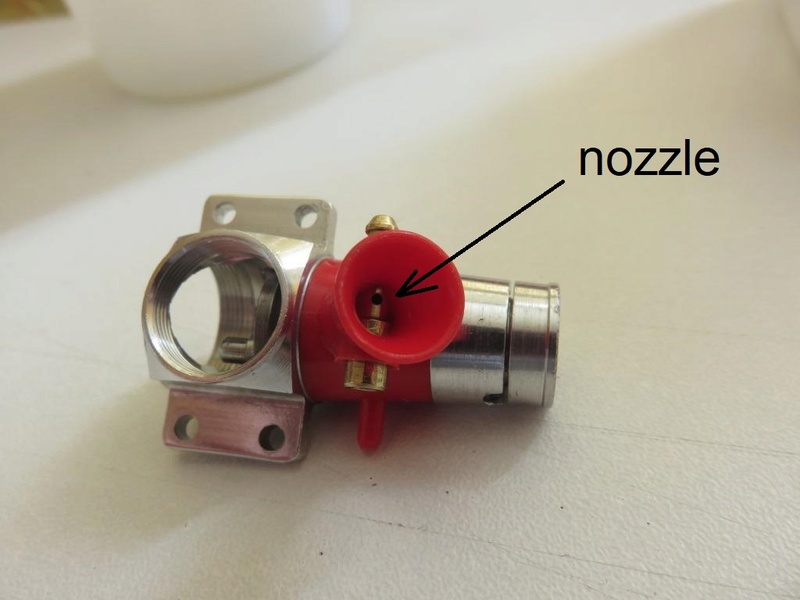

I just bought a .049 Medallion in an almost new condition from a member of my club. I proceeded to clean it up thoroughly, but I forgot to note the position of the spray bar nozzle when I disassembled it. I suppose that the nozzle must be aligned with the direction of the venturi, facing downward (unlike shown in the picture below). Can you confirm it?

Thanks.

I just bought a .049 Medallion in an almost new condition from a member of my club. I proceeded to clean it up thoroughly, but I forgot to note the position of the spray bar nozzle when I disassembled it. I suppose that the nozzle must be aligned with the direction of the venturi, facing downward (unlike shown in the picture below). Can you confirm it?

Thanks.

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Opinions will vary between straight down or slightly behind straight down. Most people, I think, will opt for the latter. Definitely not straight up like yours is. You only have so many choices with the flats of the nut fitting into the receptacle.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Paul, your correct in your assumption. Seeing that the Medallion uses a indexed hex, choose the position that faces it the same angle and down. ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Some claim the spray hole should not point directly down the intake but should be angled just below the "horizontal" (in relation to the direction of airflow).

Personally, I see no real advantage in this. Straight down the hole is how most new engines come from the factory, so that's good enough for me.

Personally, I see no real advantage in this. Straight down the hole is how most new engines come from the factory, so that's good enough for me.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

There is turbulent flow directly behind the spray, so therefore the pressure is not as low there as it will be to either side from that, that's the idea anyway....

On PAW engines you Actually have two holes, such that both holes will be positioned just away from straight behind the spray bar.

On PAW engines you Actually have two holes, such that both holes will be positioned just away from straight behind the spray bar.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

IMHO, because air accelerates around the spraybar and has its highest velocity/lowest static pressure just on the bar diameter perpendicular to the airflow, the best suction will be ensured by the spraybar hole pointing 90 degrees into the airflow.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

This is my opinion:

The position of the fuel outlet hole depends directly on its own diameter.

That is why not all positions are the same for different engines.

When the orifice is smaller, it should be placed at or equal to 90 degrees of airflow. That way suction is produced.

If the orifice is large, it should be placed equally parallel to the air flow as the flow entrains the fuel due to the size of the orifice.

It is true that there is turbulence behind the sprinkler, but this is if the orifice is small. If the fuel outlet port is large, that turbulence does not form and suction.

Each engine has a different position to another.

For example, the Tee Dee, has very small holes, at 90 degrees of airflow.

The Medallion has the hole more than 90 degrees or equal to the air flow, has a much larger fuel outlet.

The plastic rear plates of the Cox 0.049 and Cox 0.020 engines have the fuel outlet parallel to the airflow. On the other hand the Cox Babe Bee or anything with a built-in tank like the Cox Pee Wee 0.020, have a fuel outlet opening at 90 degrees from the airflow.

If you compare the diameter of the fuel outlet hole of a rear plastic plate with the plate of a fuel tank, you will notice that the fuel outlets are large, while the fuel tank plate have the Fuel outlet port, much smaller.

For all this I understand that from the factory have been tested and experienced all situations and therefore, it is best to respect the position that manufactures placed originally.

The position of the fuel outlet hole depends directly on its own diameter.

That is why not all positions are the same for different engines.

When the orifice is smaller, it should be placed at or equal to 90 degrees of airflow. That way suction is produced.

If the orifice is large, it should be placed equally parallel to the air flow as the flow entrains the fuel due to the size of the orifice.

It is true that there is turbulence behind the sprinkler, but this is if the orifice is small. If the fuel outlet port is large, that turbulence does not form and suction.

Each engine has a different position to another.

For example, the Tee Dee, has very small holes, at 90 degrees of airflow.

The Medallion has the hole more than 90 degrees or equal to the air flow, has a much larger fuel outlet.

The plastic rear plates of the Cox 0.049 and Cox 0.020 engines have the fuel outlet parallel to the airflow. On the other hand the Cox Babe Bee or anything with a built-in tank like the Cox Pee Wee 0.020, have a fuel outlet opening at 90 degrees from the airflow.

If you compare the diameter of the fuel outlet hole of a rear plastic plate with the plate of a fuel tank, you will notice that the fuel outlets are large, while the fuel tank plate have the Fuel outlet port, much smaller.

For all this I understand that from the factory have been tested and experienced all situations and therefore, it is best to respect the position that manufactures placed originally.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

So after all the scientific explanations, someone needs to tell me then why the Fox .35 has it's holes perpendicular to the throat of the venturi angle and it's been working fine for years. The Fox has a two hole spraybar and it's holes are not pointed down or towards the rear of the venturi. Based on my experience, no manufacturers of the engines I own offer a placement for the spraybar. In addition, I have found as long as the majority of engines utilize the hole downward it works fine. Many spraybars offer no indexing. Therefore, when placed into the engine during assembly your essentially guessing because we can't see through the spraybar as to where the hole orientation is. I have filed flats on the spraybar parallel to the venturi to insure positive placement.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Ken Cook wrote:Based on my experience, no manufacturers of the engines I own offer a placement for the spraybar.

Hmmm, I guess that you don not have any Super Tigre RC engines?

These have a tuning ability of the midrange, it is adjusted by simply rotating spray and thus altering the position of the spar-bar hole. This is also described in their manual....

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Ken Cook wrote:So after all the scientific explanations, someone needs to tell me then why the Fox .35 has it's holes perpendicular to the throat of the venturi angle and it's been working fine for years. The Fox has a two hole spraybar and it's holes are not pointed down or towards the rear of the venturi. Based on my experience, no manufacturers of the engines I own offer a placement for the spraybar. In addition, I have found as long as the majority of engines utilize the hole downward it works fine. Many spraybars offer no indexing. Therefore, when placed into the engine during assembly your essentially guessing because we can't see through the spraybar as to where the hole orientation is. I have filed flats on the spraybar parallel to the venturi to insure positive placement.

With all due respect, in my case this is not a scientific explanation, but rather work in a workshop, read a few manuals, work on several engines, and take information from people with more experience.

The fact that your engine has two orifices is due to supply the fuel exerting the greatest possible aspercion, because it is a motor already of more cubic centimeters. If it were a single hole, the fuel itself would enter the not so oxygenated engine.

If, in that two-hole arrangement, it is placed parallel to the venturi inlet, buddy, IT DOES NOT WORK, since the air would pass through the orifice directly without suctioning and spreading the fuel.

I think everyone tries to contribute their own experience, I believe in the vanguard will of the people, I do not think anyone wants to feel like a scientist.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Okay, the reality is, it just doesn't matter. They came from Cox with the hole pointing straight down.That's how I have most of them. I did one offset 60 degrees, which is one flat away from straight down. Still worked. So do it whichever way you want. It'll run. Just don't have it pointing up. The bigger concern is not which way the hole points, it's making sure you don't fumble-finger the c-clip that holds the nozzle in. I just lost one somewhere in this room two weeks ago. I had to break into my spare Medallion c-clip stash. I'd say I'll find it someday, but my wife vacuumed my workroom a couple of days ago... I thought I had her trained better than that.

The Lion Tamer Mark

The Lion Tamer Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Hmm somehow this was construed the wrong way and apparently I twisted some nuts here. I don't know where you think I made the claim that you or anyone else here is a scientist. In addition, when I read turbulence, orifices, and parallel air flows, it sounds pretty scientific to me which is why I used that terminology. I'm curious as to why the Fox .35 is that way if it's been claimed that to the rear or to the front is the best possible way.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Ken Cook wrote: Hmm somehow this was construed the wrong way and apparently I twisted some nuts here. I don't know where you think I made the claim that you or anyone else here is a scientist. In addition, when I read turbulence, orifices, and parallel air flows, it sounds pretty scientific to me which is why I used that terminology. I'm curious as to why the Fox .35 is that way if it's been claimed that to the rear or to the front is the best possible way.

Ken, it happens that not to handle English and to have different interpretations by the customs and forms of different places, can be taken of one way or another.

I am very happy to know that your comment was with all good intentions, because that is what it is, and good thing it clarified, because this way I also feel better. Best of all, we can learn from each other and clarify every possible way to communicate in the best way.

Let's continue sharing, which is what makes this forum and friendship grow!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Thanks everybody for your very interesting inputs. I understand now that the position of the nozzle is not the same for all engines.

But I would like to position the nozzle the way it was went the Medallion left the manufacture. So I take it that this original position is downward parallel to the airflow.

But I would like to position the nozzle the way it was went the Medallion left the manufacture. So I take it that this original position is downward parallel to the airflow.

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Paul_BB wrote:Thanks everybody for your very interesting inputs. I understand now that the position of the nozzle is not the same for all engines.

But I would like to position the nozzle the way it was went the Medallion left the manufacture. So I take it that this original position is downward parallel to the airflow.

If Paul, that's how he should put it. For the doubts I leave some photos of reference:

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Thanks for the pictures Mauricio!

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

MauricioB wrote:You're welcome, I hope you enjoy this Medallion! By the way, do you have any projects?

Yes, a French 1/2A trainer named PIAF (sparrow) that I have built when I was 15 years old, and on which I learned how to fly RC. This trainer is not very pretty but this project is pure nostalgia.

It flew at the time with a Babe Bee but I tried once to put on a TD with a Tarno carb I had bought in Canada just before coming to France. But I had to put on a muffler for the idle to be consistent, and even with the muffler the idling speed was too great, the bird just didn't want to come down. I remember I did not use Cox fuel (not available in France) but some German 5% nitro fuel (Graupner I think). So maybe was the fuel responsible for the poor idling speed. I really don't know. So I switched back to the Babe Bee.

This time I will power my trainer with my newly bought RC Medallion and a 15% nitro content fuel. Have you a good (stable) idling speed with your Medallion?

I will build it next winter (northern hemisphere). I am currently flying my new Jr Falcon powered by a Golden Bee Mk II.

Very nice model you have by the way.

Paul

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Mauricio, the Fox .35 you show is a older wide bypass Fox. The spraybar and needle in your engine is a OS engines needle valve. While your needle valve in your engine is far superior to the Fox version it's taking up a lot more throat area in your venturi thus robbing power. The older Fox .35's used a single hole in the spraybar. Your version is from the 50's. I have a 15th anniversary Fox which was in the 60's which still utilized the single hole. Seeing that the 80's 40th anniversary on up to the 60th used the 2 hole spraybar which I mentioned in my prior post, I'm thinking the 2 hole spraybar was introduced somewhere possibly in the mid to late 70's.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Paul_BB wrote:MauricioB wrote:You're welcome, I hope you enjoy this Medallion! By the way, do you have any projects?

Yes, a French 1/2A trainer named PIAF (sparrow) that I have built when I was 15 years old, and on which I learned how to fly RC. This trainer is not very pretty but this project is pure nostalgia.

It flew at the time with a Babe Bee but I tried once to put on a TD with a Tarno carb I had bought in Canada just before coming to France. But I had to put on a muffler for the idle to be consistent, and even with the muffler the idling speed was too great, the bird just didn't want to come down. I remember I did not use Cox fuel (not available in France) but some German 5% nitro fuel (Graupner I think). So maybe was the fuel responsible for the poor idling speed. I really don't know. So I switched back to the Babe Bee.

This time I will power my trainer with my newly bought RC Medallion and a 15% nitro content fuel. Have you a good (stable) idling speed with your Medallion?

I will build it next winter (northern hemisphere). I am currently flying my new Jr Falcon powered by a Golden Bee Mk II.

Very nice model you have by the way.

Paul

Paul, I understand perfectly when we try to build a model that transports us to some time in our lives, I think it is the best flight of our imagination, where there are gathered memories of different moments lived, full of nostalgia.

I am very happy that you undertake this project, surely you will enjoy it very much.

Regarding the idle of these engines (Tee Dee), when you put a carburetor, they become critical when regulating low, regulate but at certain relatively high values, since, ideally when a carburetor is placed, it would pressurize the Tank, that way with carburetor and pressurizing the tank, a more even flow and a more appropriate idle is achieved. You can also experiment with a carburetor and a tank of the bladder type, that way, the fuel is pressed to reach the engine, even when the turns are down and the engine makes less effort to suck, you get equal fuel, maintaining a constant flow And a more even idle.

Another configuration I learned from friend Balogh, is to place a carburetor and simultaneously a regulating ring in the cylinder, this helps a lot to lower the rpm while maintaining a even gear:

I also clarify that, in my experience, motors with flapper valves are much more reliable to regulate low with a regulating ring, than those with rotary valve feed. But precisely, at high rpm, rotary valves like Medallion or Tee Dee, have much more power:

As a personal experience, made a few years ago a model that calls it Cox Vintage, is a model inspired by the lines of those models of racing of the 30's, but with all the possibilities to a good flight stable, for that reason the profile chosen and The wing length, I had built it for a Tee Dee .051, but then a friend fell in love with the model and asked me to sell it, so I put a motor that he had, a Cox Medallion 0.049 with a hoop Acceleration, I made several flights with that configuration, I could land decently on the grass and even take off again, anyway, the idle is always something I worked to try to be the lowest rpm possible, but given the configuration of these Engines I think have an inevitable relatively high level of regulation:

And here is the video with the Cox Medallion 0.049:

In the minute 5:20 I start to land and then I take off again from the grass, very happy indeed!

The key is that the size of the model is large enough so that the engine at idle does not make it fly and small enough (light) for mid-flight to fly normal, in depth can be enjoyed with a plus of power.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Ken Cook wrote: Mauricio, the Fox .35 you show is a older wide bypass Fox. The spraybar and needle in your engine is a OS engines needle valve. While your needle valve in your engine is far superior to the Fox version it's taking up a lot more throat area in your venturi thus robbing power. The older Fox .35's used a single hole in the spraybar. Your version is from the 50's. I have a 15th anniversary Fox which was in the 60's which still utilized the single hole. Seeing that the 80's 40th anniversary on up to the 60th used the 2 hole spraybar which I mentioned in my prior post, I'm thinking the 2 hole spraybar was introduced somewhere possibly in the mid to late 70's.

Ken, I inherited this and other motors from a friend who died a few years ago and his son decided that I would keep them for the great affection that his father had and how I am passionate about this hobby-sport.

I just asked him how his sprinkler was, because I have that one placed there as it was given to me, it's an almost unused motor and I did not see the two holes you mentioned. Obviously it has been changed for some reason.

I started it well to enjoy it in my workshop, it is possible and I agree that it loses power if it is "down" the air intake.

Have a photo of yours, I'll see if in some accessories that I got too, there is the original spray bar there ....

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Ken, I just read your message, I make public my answer because it serves so that we can all understand that the forms of our own languages and traditions can confuse us, but when people have the capacity to reason, then concretely they are people, and you deserve All my respect because it is precisely what you generate, even more with your message.

Thanks for taking the time to write to me. I am sorry for the distance, I am a person that I am very moved, I wish I could shake my hand!

Thanks for taking the time to write to me. I am sorry for the distance, I am a person that I am very moved, I wish I could shake my hand!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Medallion nozzle assembly: which way?

Re: Medallion nozzle assembly: which way?

Mauricio,

Thanks for your comprehensive answer. I've read somewhere that the SPI cylinders (TD case but not Medallion) did not work well with a ring muffler because part of the exhaust gaz is re-injected into the combustion chamber.

I love your Cox Vintage model. Did you draw a plan? If so you should send it to Steve from Outerzone. I could be interested in the future.

Thanks for your comprehensive answer. I've read somewhere that the SPI cylinders (TD case but not Medallion) did not work well with a ring muffler because part of the exhaust gaz is re-injected into the combustion chamber.

I love your Cox Vintage model. Did you draw a plan? If so you should send it to Steve from Outerzone. I could be interested in the future.

Paul_BB- Bronze Member

- Posts : 59

Join date : 2015-03-16

Age : 61

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Medallion 049 & Medallion 049; what is the difference?

» Modeling COX engines with 3D Printer

» Wanted- Medallion .15 Spray Bar & Needle Valve Assembly

» For Sale For those interested in the Cox Medallion Venturi-spray bar-needle assembly

» Crankcase dis-assembly and assembly

» Modeling COX engines with 3D Printer

» Wanted- Medallion .15 Spray Bar & Needle Valve Assembly

» For Sale For those interested in the Cox Medallion Venturi-spray bar-needle assembly

» Crankcase dis-assembly and assembly

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules