Log in

Search

Latest topics

» Duende V model from RC Model magazine 1983.by TD ABUSER Today at 7:20 pm

» Roger Harris revisited

by rsv1cox Today at 10:46 am

» A Little 400 Mile Hop for Some Memory Lane Stuff, and to Hit a Swap Meet.

by getback Today at 7:48 am

» Free Flight Radio Assist

by getback Today at 6:39 am

» Happy 77th birthday Andrew!

by Kim Yesterday at 9:18 am

» Promote the forum with flyers!

by Admin Yesterday at 1:35 am

» Engine choice

by GallopingGhostler Mon Nov 25, 2024 4:03 pm

» My N-1R build log

by roddie Mon Nov 25, 2024 9:19 am

» Night flying at Walters RC park

by 1975 control line guy Sun Nov 24, 2024 7:29 pm

» Cox films/videos...

by GallopingGhostler Sun Nov 24, 2024 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Sun Nov 24, 2024 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Sun Nov 24, 2024 5:08 pm

Cox Engine of The Month

flat framed construction

Page 1 of 2

Page 1 of 2 • 1, 2

flat framed construction

flat framed construction

This thread I've created as a topic for Cox International's "Quarterly Newsletter". I'm also saving as I write; to an MS Word doc. for Bernie to use if needed. The closing paragraphs are not really relevant to the actual "construction" methods.. but rather outline the configuration of the Cox Bee engines that I used on the models.

This method of construction is something I've experimented with on several 1/2A sized profile models of my own design. If you don't.. or have no desire to scratch-build, then this probably wouldn't interest you. The flight characteristics will be like any sheet-wing.. except there is a weight-savings over a solid-sheet design.. as well as some other benefits.

This method uses CA glue (thick or thin) exclusively.. and Top-Flite's Mono-Kote iron-on covering (or similar-type/weight product)

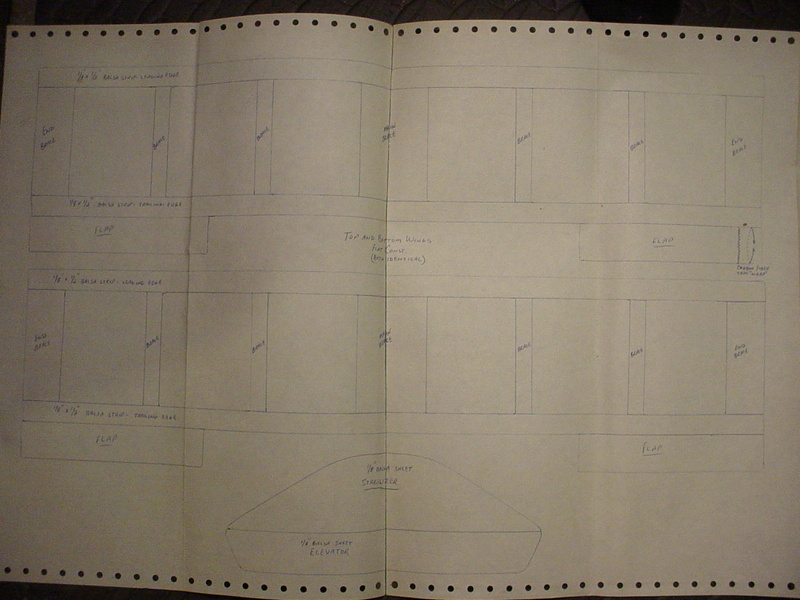

It's basically the same as a solid balsa sheet-wing (flat.. ) as supplied with many kits, except I build a balsa perimeter-framework consisting of a leading-edge, trailing edge, and wingtips, with perpendicular bracing in between. Depending on the design.. I may include a spar made of hardwood, and glue it to the rear of the leading-edge for rigidity. the open structure is then covered with Mono-Kote iron-on film.

) as supplied with many kits, except I build a balsa perimeter-framework consisting of a leading-edge, trailing edge, and wingtips, with perpendicular bracing in between. Depending on the design.. I may include a spar made of hardwood, and glue it to the rear of the leading-edge for rigidity. the open structure is then covered with Mono-Kote iron-on film.

In my experience; building a sheet-wing "framed-up" has had some advantages over a solid structure. They're lighter in weight.. and I haven't experienced any warping in the wings that I've built.. I believe it's because of the multiple grain patterns/directions and joints. The balsa pieces can all be made from 1" (or even less) width; 1/8" sheet. One piece of 1/8" x 1" x 36" will supply the stock the L/E and T/E for an 18" span model. The chord-wise bracing/gussets are made from scrap that many people would throw away. The braces only need to be as long as needed to arrive at the wing's chord; less the two inches of the L/E and T/E. You can use 1/2" width stock for the bracing if you want. If you buy two pieces of 1" x 36".. you can increase the span.. and rip one of the cut-offs in half to make 1/2" width braces.. and triangular gussets for even more support.

All the pieces need to be cut accurately. The braces should be cut with nice square edges.. because the pieces will all be butt-jointed together using the CA glue. It's easier to cut all the braces exactly the same length. I like to use a razor-saw set-up in in a miter-box with a stop-block clamped to set the brace-length. You can build a tapered T/E by adding it afterward if desired. Plan for it when laying out the frame's chord. It's easiest to keep the inner perimeter of the frame symmetrically rectangular. This allows for simple 90 degree joints.

Assemble the wing on as flat a surface as possible. Plate-glass would be ideal.. but I use a piece of 3/4" particle-board smooth-faced with melamine. The replacement closet-shelves you see at the home-improvement stores would work fine.. and a 12" x 36" one is all you need for a wing this size.

The building-surface must be clean and flat. Run a straight-edge over it (on-edge..) to make sure it doesn't drag on any scale or glue-drops. Cover the surface with wax-paper and tape it so it doesn't move. I like to trial-fit the perimeter pieces first.. and check for overall "squareness" using a framing square. Glue this outer perimeter "box-frame" together first. Apply CA to one edge and assemble the two pieces together by pressing them both down firmly on the building board and pressed firmly "together" for at least 10 seconds. Once the perimeter is built, install the remaining internal bracing in the same way. Braces should fit snugly.. but shouldn't need to be forced between the L/E and T/E. If they're too tight.. swipe one edge across a fine sanding block once.. and check the fit again. If there's a gap.. cut a new longer brace.

A 1/8" plywood bellcrank platform can be installed in a few different ways. It takes the place of a balsa brace. The better way to install it is to cut the plate 1/4" longer than a brace.. and cut notches 1/8" deep, into the L/E and T/E on their inside edges.. for the plate to sit "into" as opposed to a butt-joint. (see the tri-plane photos below) A butt-joint can be used.. but should have gussets installed at all 4 corners where the plate meets the frame. If your skeptical about either of these methods, you can opt to install a plywood-plate that extends through the wing-root.. with the wing-slot joint in the fuse for extra security.. but at the expense of added weight. If the iron-on covering is applied properly.. it's going to assist in locking-in a plate that's reinforced with triangular balsa gussets at the corners.

That's really all there is to it.. for building a wing.. Think about trying some framed (or cored) construction with a profile fuse too! If your using conventional ply nose-doublers.. the balsa between them can be cored using a hole-saw of the appropriate diameter, with a series of holes that can remove a significant amount of material. It will be just as strong with the doublers.. with less weight in both balsa "and" glue. The tail-section might have enough area to be cored as well, depending on the taper back from the wing's T/E. You can build your stabilizer as a flat-frame. With small models; the stab is generally flat-construction anyway.. why not save some weight?

Think about trying some framed (or cored) construction with a profile fuse too! If your using conventional ply nose-doublers.. the balsa between them can be cored using a hole-saw of the appropriate diameter, with a series of holes that can remove a significant amount of material. It will be just as strong with the doublers.. with less weight in both balsa "and" glue. The tail-section might have enough area to be cored as well, depending on the taper back from the wing's T/E. You can build your stabilizer as a flat-frame. With small models; the stab is generally flat-construction anyway.. why not save some weight?

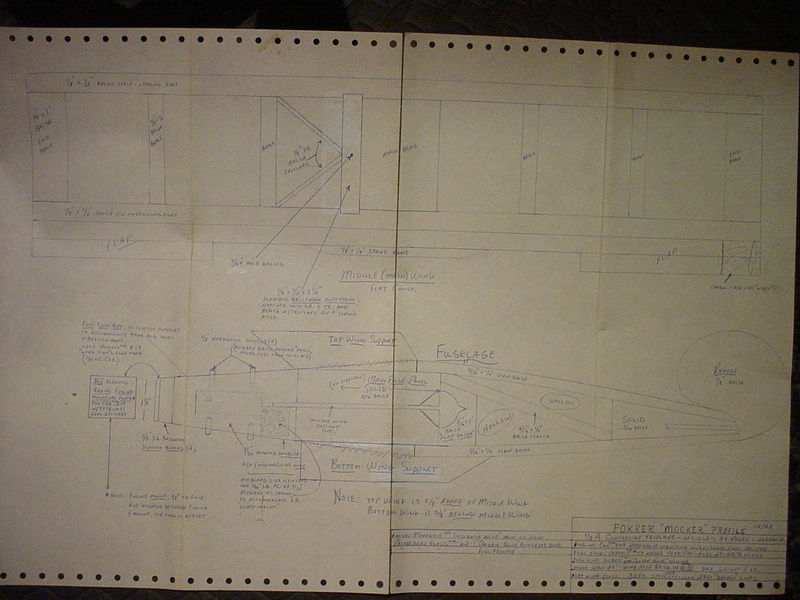

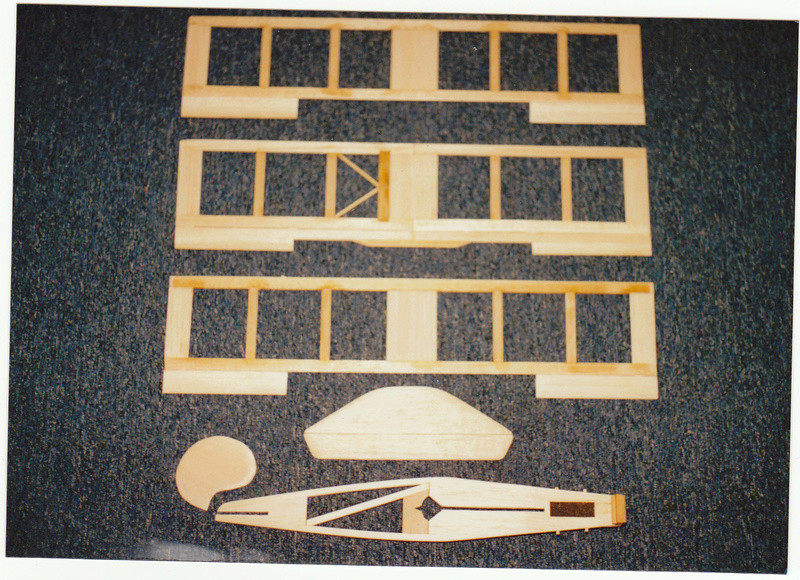

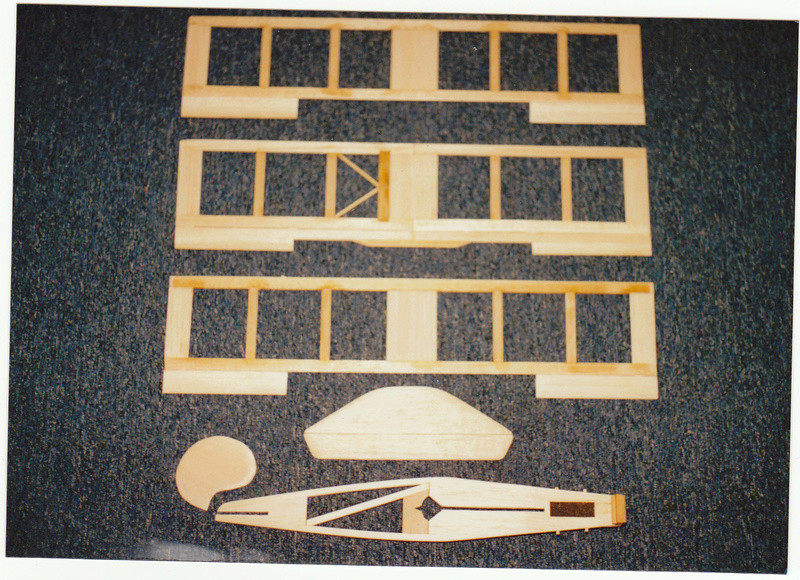

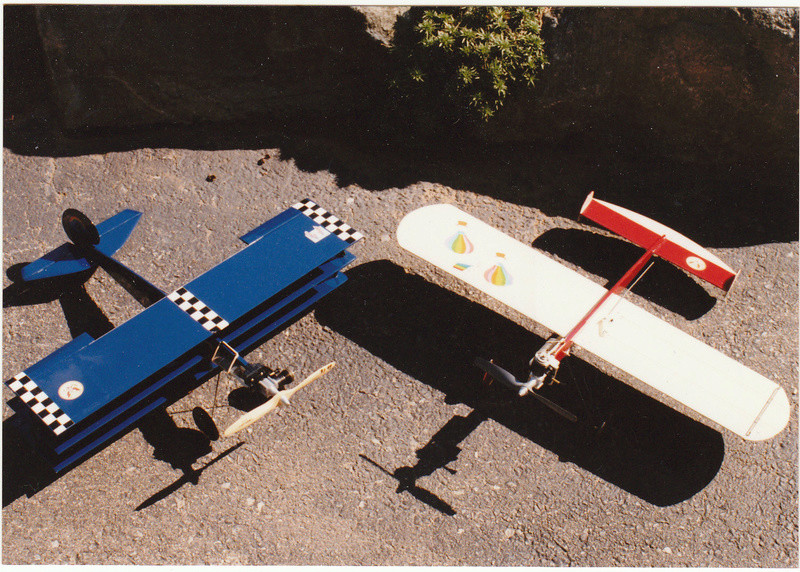

Here are some examples of models I've built, using this type of construction.

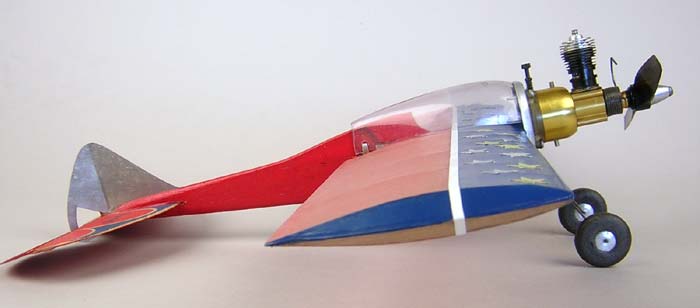

My "Custom-Stunter".. (wishful thinking..)

(wishful thinking..)

This model has a 24" wingspan 5.5" constant-chord for 132 sq. in. yet it weighs-in (less it's Bee engine) at just over 5 oz. and would be well under 5.. if not for the experimental/adjustable lead-out guide.. and tip-weight to compensate for it.

This model incorporates a "total" framed-up construction throughout, with Top-Flite Mono-Kote covering of the early 90's. The fuse consists of top/bottom 1/4" sq. Spruce rails nose to tail.. with 1/4" balsa between for the wing-slot and extending "solidly" all the way forward with 1/32" ply nose-doublers extending back 1.5" rearward of the wing's L/E. The fuse is only 1.625" in height, but unlike most of my designs; I didn't draw the fuse-detail on the plans unfortunately. The stab is flat-framed as well.

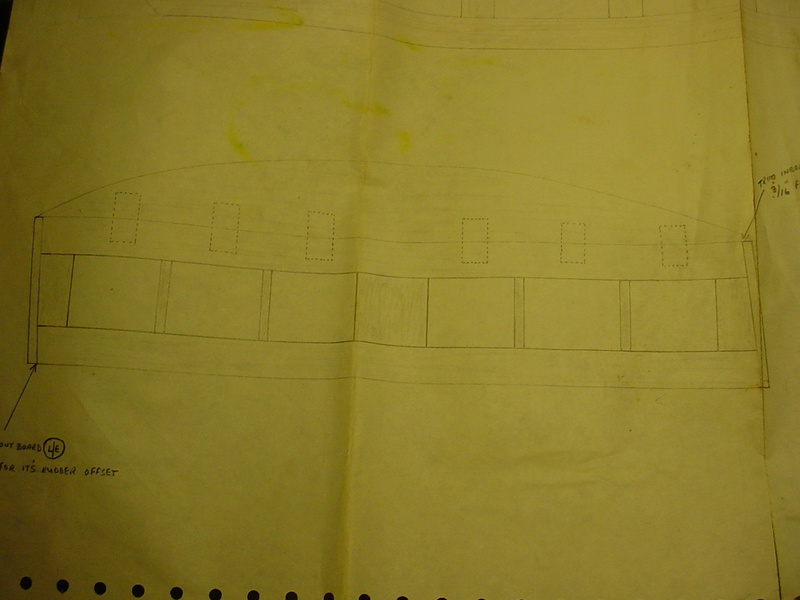

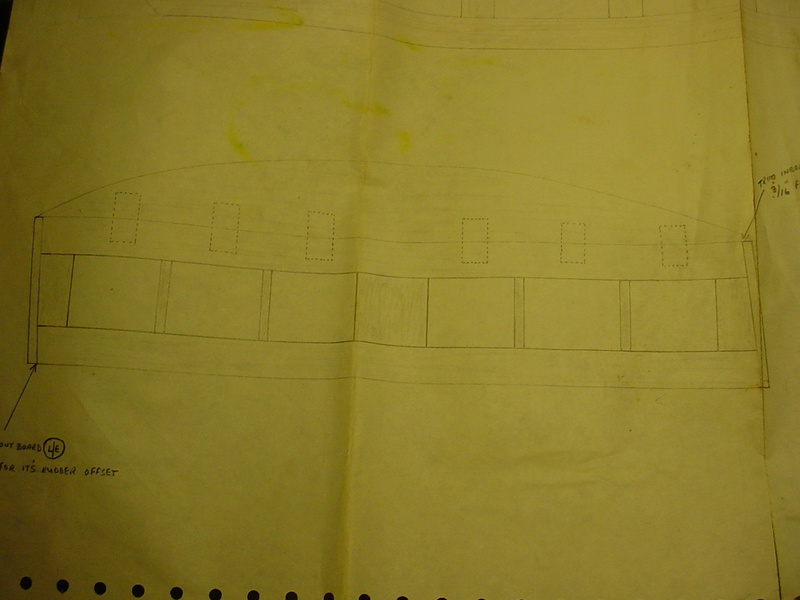

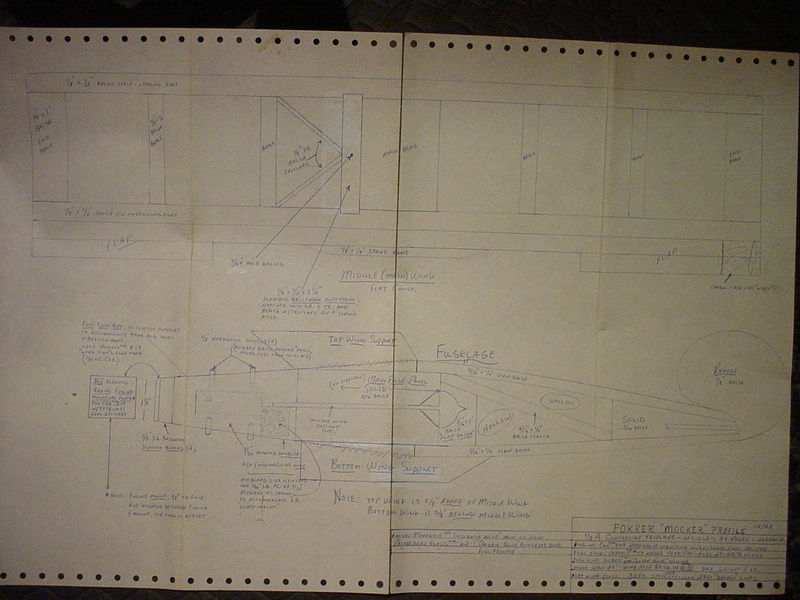

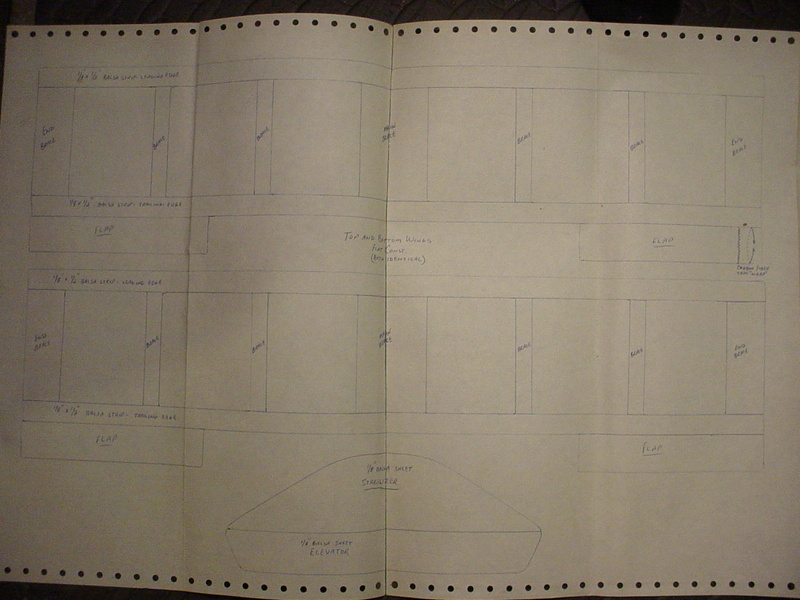

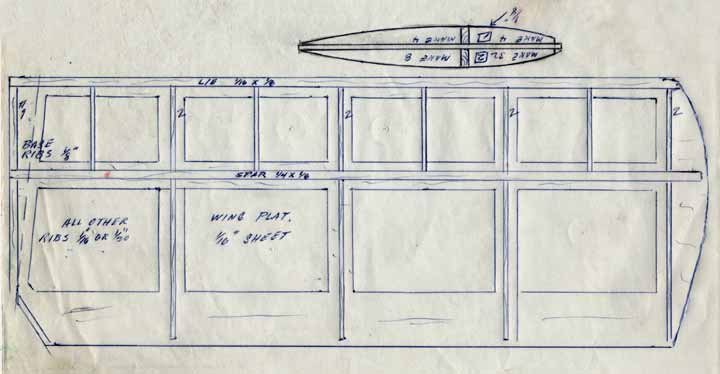

I apologize for the lousy quality of these drawings.. they were never completed or inked.

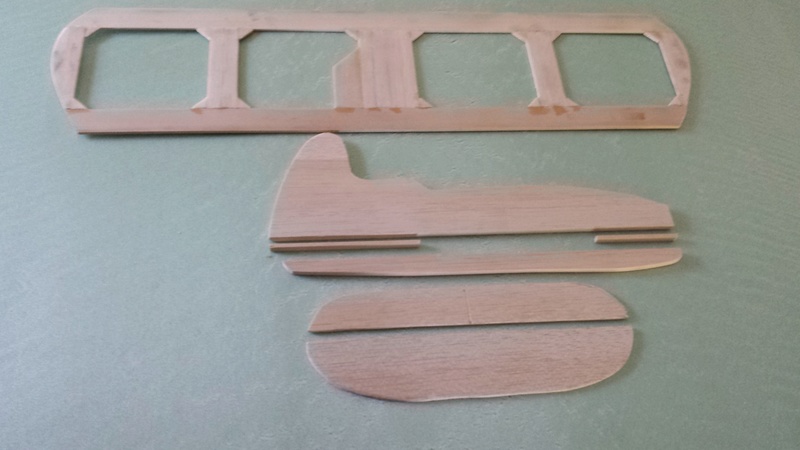

The Custom Stunter's.. built-up stabilizer.. and the second photo shows the plywood bellcrank-mount; a large plate extending into the fuse's wing-slot

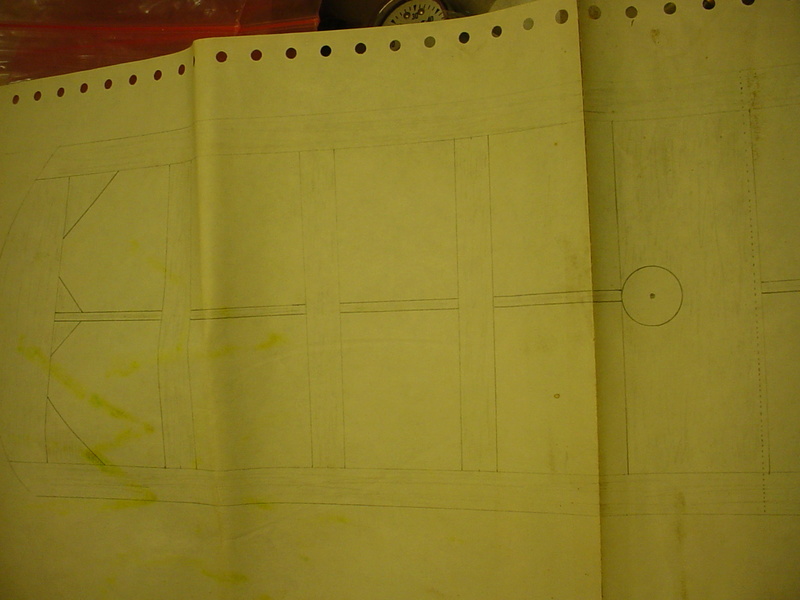

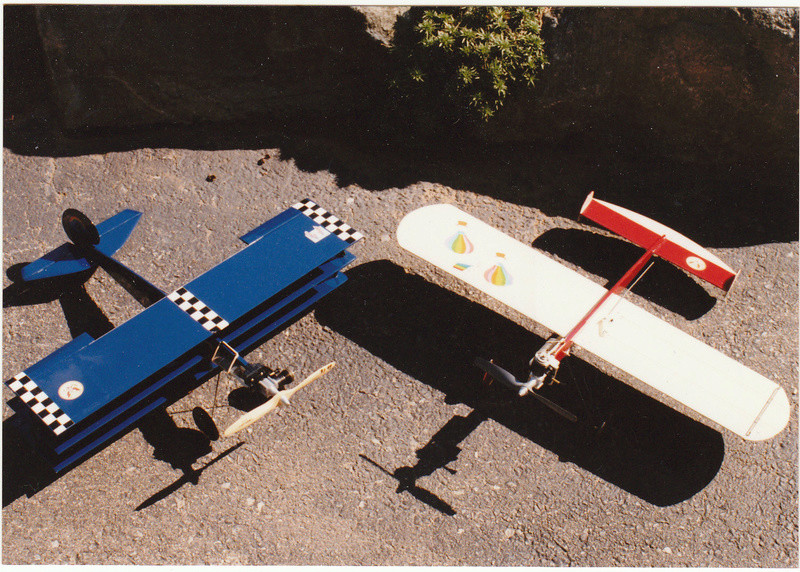

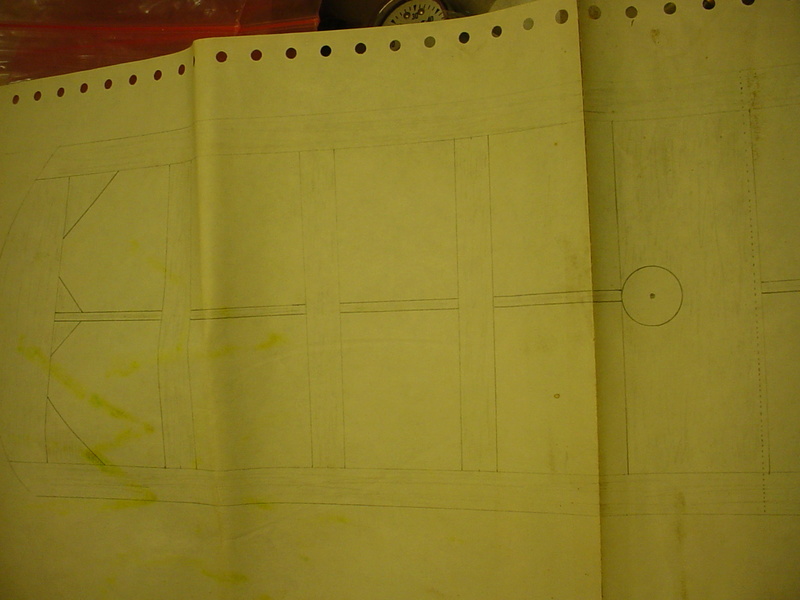

The photos below of my "Custom Tri-Plane" drawings are a bit better.

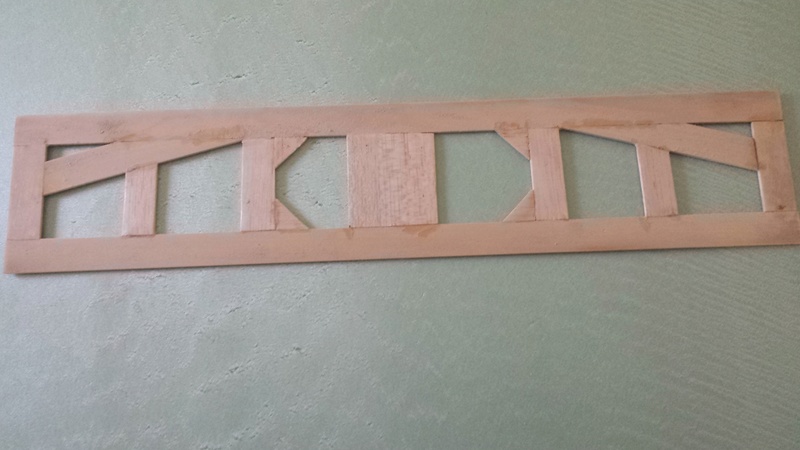

The first photo shows a bellcrank-mount consisting of a 1/2" wide piece of 1/8" birch-ply.. set into notches cut into the main-frame. All three wings have 2" wide 1/8" sheet balsa braces at the root.. and not shown are outer wing-struts, consisting of 3/16" hardwood dowels. The fuse has chord-length pieces of 1/4" balsa supporting the top and bottom wings.

The tri-plane has recently been modified to remove the non-functional flaps from the top/bottom wings.. reducing it's weight (less Bee engine) to under 6oz.

These two models were built months apart in the early 90's..

Both models were a bit of a challenge for a reed-valve Cox Bee engine to pull around.. but they did fly pretty good. I should add that I flew them on 25 foot lines.. which was all the flight area that I had at the time. Both models utilized identical engine/tank configurations. I used standard "horseshoe" backplates.. and small Perfect wedge-tanks in the 8-10cc range of capacity. The engine-cylinders were of the standard "product-engine" type of the early 90's.. (non-sub-port induction slit exhaust-port no-frills cylinders..) running standard glow-heads on Cox Super-Fuel, Cox Racing-Fuel, or Sig "Champion "25" or "35". Propellers were generally two-blade 6" diameter. I preferred the 6" x 3" "Zinger" wood prop. I had several 3-blade 5" x 3" Cox "black" props.. which likely would have run better.. but I didn't have the knowledge at the time. In "general".. props that were sold as ".049" size props.. often assumed that a Cox rotary-valve Tee Dee or Medallion would be used.. rather than the reed-valve engines that I had.

Try adopting a framed-up construction to one of your next builds. A stabilizer would be a cool "ice-breaker".. as they're usually flat-sheet construction anyway.

This method of construction is something I've experimented with on several 1/2A sized profile models of my own design. If you don't.. or have no desire to scratch-build, then this probably wouldn't interest you. The flight characteristics will be like any sheet-wing.. except there is a weight-savings over a solid-sheet design.. as well as some other benefits.

This method uses CA glue (thick or thin) exclusively.. and Top-Flite's Mono-Kote iron-on covering (or similar-type/weight product)

It's basically the same as a solid balsa sheet-wing (flat..

In my experience; building a sheet-wing "framed-up" has had some advantages over a solid structure. They're lighter in weight.. and I haven't experienced any warping in the wings that I've built.. I believe it's because of the multiple grain patterns/directions and joints. The balsa pieces can all be made from 1" (or even less) width; 1/8" sheet. One piece of 1/8" x 1" x 36" will supply the stock the L/E and T/E for an 18" span model. The chord-wise bracing/gussets are made from scrap that many people would throw away. The braces only need to be as long as needed to arrive at the wing's chord; less the two inches of the L/E and T/E. You can use 1/2" width stock for the bracing if you want. If you buy two pieces of 1" x 36".. you can increase the span.. and rip one of the cut-offs in half to make 1/2" width braces.. and triangular gussets for even more support.

All the pieces need to be cut accurately. The braces should be cut with nice square edges.. because the pieces will all be butt-jointed together using the CA glue. It's easier to cut all the braces exactly the same length. I like to use a razor-saw set-up in in a miter-box with a stop-block clamped to set the brace-length. You can build a tapered T/E by adding it afterward if desired. Plan for it when laying out the frame's chord. It's easiest to keep the inner perimeter of the frame symmetrically rectangular. This allows for simple 90 degree joints.

Assemble the wing on as flat a surface as possible. Plate-glass would be ideal.. but I use a piece of 3/4" particle-board smooth-faced with melamine. The replacement closet-shelves you see at the home-improvement stores would work fine.. and a 12" x 36" one is all you need for a wing this size.

The building-surface must be clean and flat. Run a straight-edge over it (on-edge..) to make sure it doesn't drag on any scale or glue-drops. Cover the surface with wax-paper and tape it so it doesn't move. I like to trial-fit the perimeter pieces first.. and check for overall "squareness" using a framing square. Glue this outer perimeter "box-frame" together first. Apply CA to one edge and assemble the two pieces together by pressing them both down firmly on the building board and pressed firmly "together" for at least 10 seconds. Once the perimeter is built, install the remaining internal bracing in the same way. Braces should fit snugly.. but shouldn't need to be forced between the L/E and T/E. If they're too tight.. swipe one edge across a fine sanding block once.. and check the fit again. If there's a gap.. cut a new longer brace.

A 1/8" plywood bellcrank platform can be installed in a few different ways. It takes the place of a balsa brace. The better way to install it is to cut the plate 1/4" longer than a brace.. and cut notches 1/8" deep, into the L/E and T/E on their inside edges.. for the plate to sit "into" as opposed to a butt-joint. (see the tri-plane photos below) A butt-joint can be used.. but should have gussets installed at all 4 corners where the plate meets the frame. If your skeptical about either of these methods, you can opt to install a plywood-plate that extends through the wing-root.. with the wing-slot joint in the fuse for extra security.. but at the expense of added weight. If the iron-on covering is applied properly.. it's going to assist in locking-in a plate that's reinforced with triangular balsa gussets at the corners.

That's really all there is to it.. for building a wing..

Here are some examples of models I've built, using this type of construction.

My "Custom-Stunter"..

This model has a 24" wingspan 5.5" constant-chord for 132 sq. in. yet it weighs-in (less it's Bee engine) at just over 5 oz. and would be well under 5.. if not for the experimental/adjustable lead-out guide.. and tip-weight to compensate for it.

This model incorporates a "total" framed-up construction throughout, with Top-Flite Mono-Kote covering of the early 90's. The fuse consists of top/bottom 1/4" sq. Spruce rails nose to tail.. with 1/4" balsa between for the wing-slot and extending "solidly" all the way forward with 1/32" ply nose-doublers extending back 1.5" rearward of the wing's L/E. The fuse is only 1.625" in height, but unlike most of my designs; I didn't draw the fuse-detail on the plans unfortunately. The stab is flat-framed as well.

I apologize for the lousy quality of these drawings.. they were never completed or inked.

The Custom Stunter's.. built-up stabilizer.. and the second photo shows the plywood bellcrank-mount; a large plate extending into the fuse's wing-slot

The photos below of my "Custom Tri-Plane" drawings are a bit better.

The first photo shows a bellcrank-mount consisting of a 1/2" wide piece of 1/8" birch-ply.. set into notches cut into the main-frame. All three wings have 2" wide 1/8" sheet balsa braces at the root.. and not shown are outer wing-struts, consisting of 3/16" hardwood dowels. The fuse has chord-length pieces of 1/4" balsa supporting the top and bottom wings.

The tri-plane has recently been modified to remove the non-functional flaps from the top/bottom wings.. reducing it's weight (less Bee engine) to under 6oz.

These two models were built months apart in the early 90's..

Both models were a bit of a challenge for a reed-valve Cox Bee engine to pull around.. but they did fly pretty good. I should add that I flew them on 25 foot lines.. which was all the flight area that I had at the time. Both models utilized identical engine/tank configurations. I used standard "horseshoe" backplates.. and small Perfect wedge-tanks in the 8-10cc range of capacity. The engine-cylinders were of the standard "product-engine" type of the early 90's.. (non-sub-port induction slit exhaust-port no-frills cylinders..) running standard glow-heads on Cox Super-Fuel, Cox Racing-Fuel, or Sig "Champion "25" or "35". Propellers were generally two-blade 6" diameter. I preferred the 6" x 3" "Zinger" wood prop. I had several 3-blade 5" x 3" Cox "black" props.. which likely would have run better.. but I didn't have the knowledge at the time. In "general".. props that were sold as ".049" size props.. often assumed that a Cox rotary-valve Tee Dee or Medallion would be used.. rather than the reed-valve engines that I had.

Try adopting a framed-up construction to one of your next builds. A stabilizer would be a cool "ice-breaker".. as they're usually flat-sheet construction anyway.

Last edited by roddie on Mon Sep 19, 2016 12:41 pm; edited 4 times in total (Reason for editing : grammar)

Re: flat framed construction

Re: flat framed construction

Thanks for the share, seems like a good building technique, and why shouldn't it produce less warp than a solid sheet wing, right?

Question - how does one sign up for or otherwise get acccess to the Cox International Quarterly Newsletter?

Cheers,

Poughkeepsie Pete

Question - how does one sign up for or otherwise get acccess to the Cox International Quarterly Newsletter?

Cheers,

Poughkeepsie Pete

PeterJGregory- Gold Member

- Posts : 144

Join date : 2014-07-28

Age : 61

Location : Hudson Valley, New York

Re: flat framed construction

Re: flat framed construction

Pete, just click here Cox International and view/scroll-down the L/H side of their page. the text is in "red".

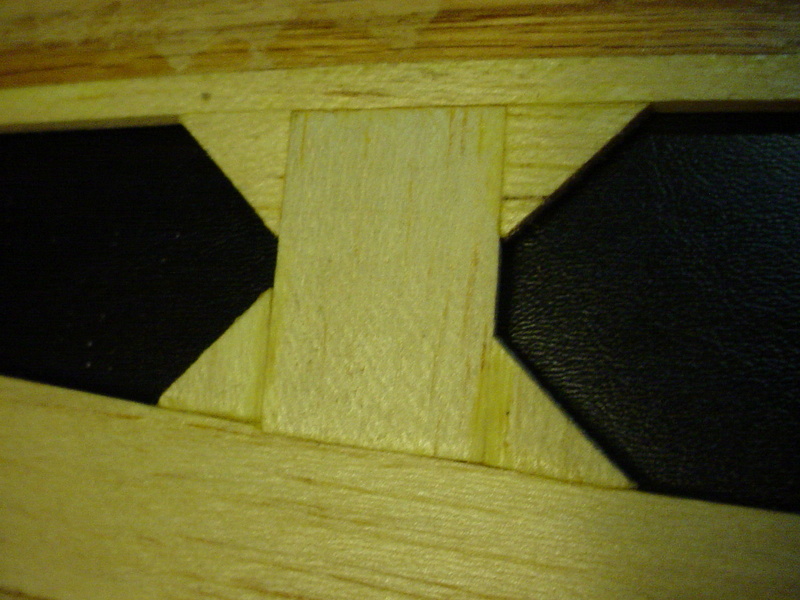

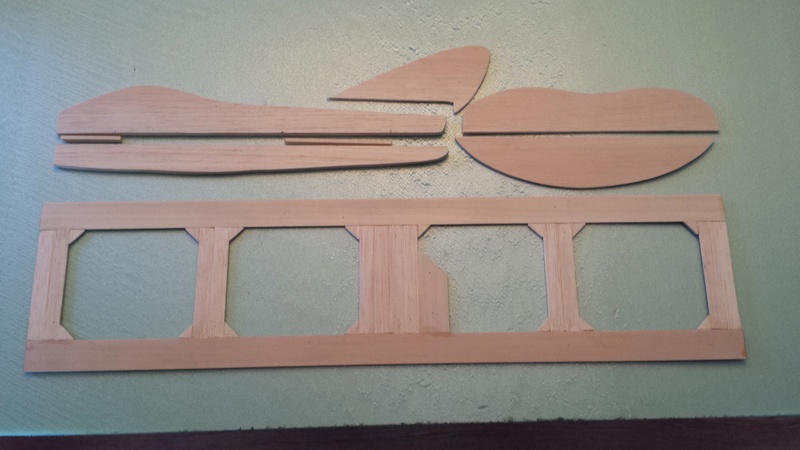

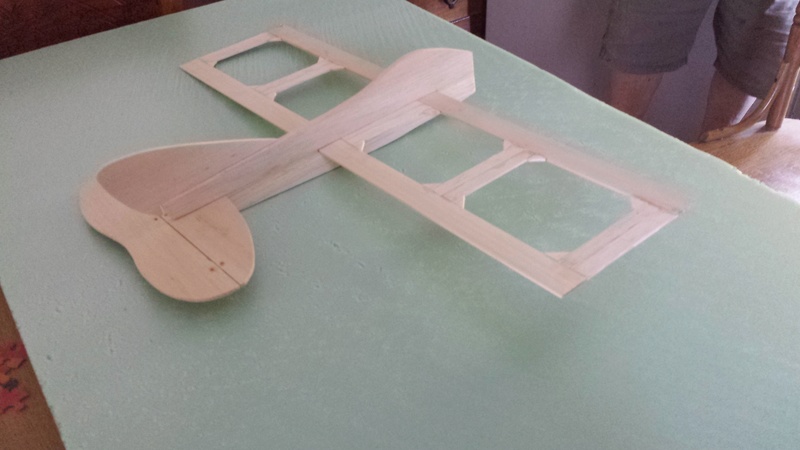

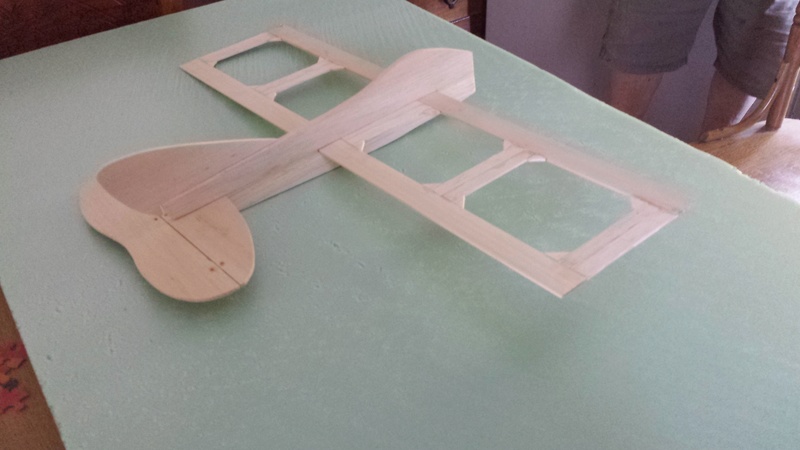

Here's an old project using the flat-framed sheet balsa construction. All I have is this wing so far.. which was built several years ago. This was to be an RC 3-D sort of wing.. with mondo ailerons..

with mondo ailerons..

It's 24" span.. and has been floating around my shop for years, from one spot to another. I show it here; because it's still dead-straight.. no warping. The framework/bracing-angles are a little more intricate.. but the same basic construction principles apply.

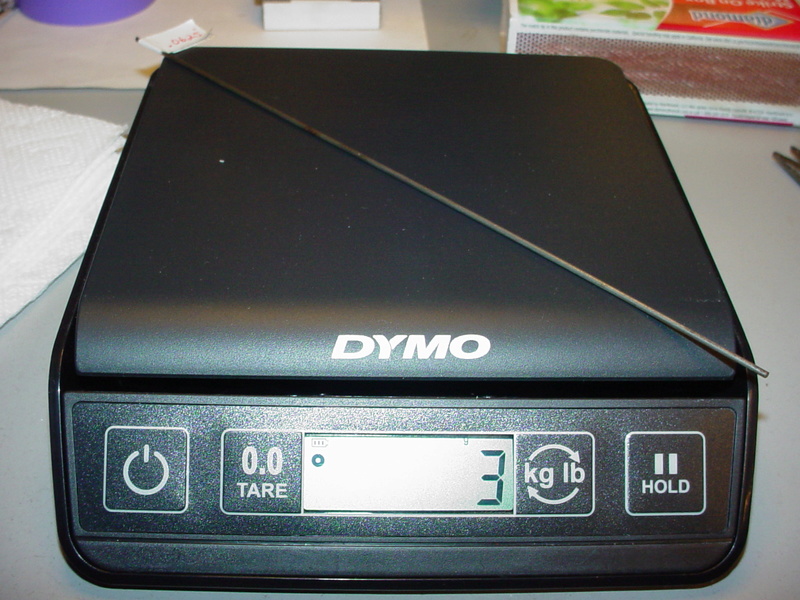

Note the hardwood strip-spar behind the L/E. (it's Oak..) This panel uncovered weighs 1.95oz./56gr. The ailerons are hinged using Sig CA EZ-Hinges

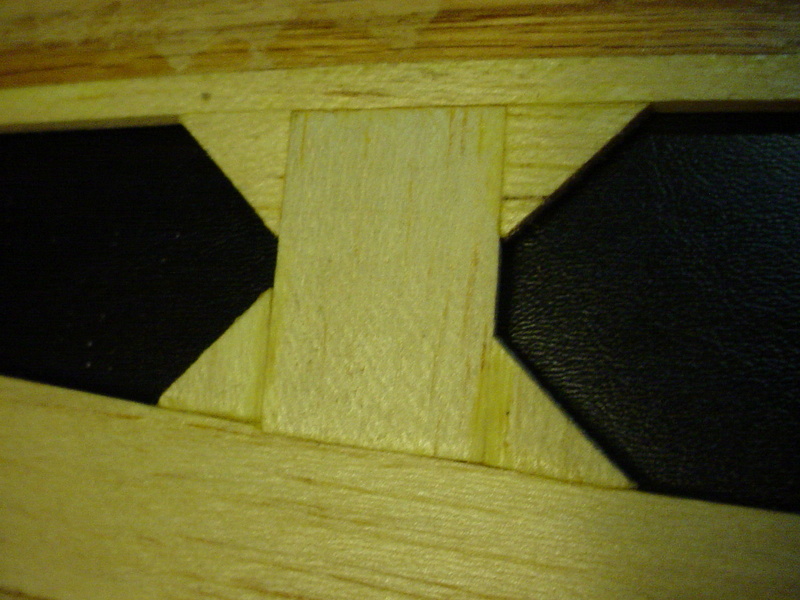

Gusset-detail around the bracing..

It's flat....... no warps or twists.

Here's an old project using the flat-framed sheet balsa construction. All I have is this wing so far.. which was built several years ago. This was to be an RC 3-D sort of wing..

with mondo ailerons..

with mondo ailerons.. It's 24" span.. and has been floating around my shop for years, from one spot to another. I show it here; because it's still dead-straight.. no warping. The framework/bracing-angles are a little more intricate.. but the same basic construction principles apply.

Note the hardwood strip-spar behind the L/E. (it's Oak..) This panel uncovered weighs 1.95oz./56gr. The ailerons are hinged using Sig CA EZ-Hinges

Gusset-detail around the bracing..

It's flat....... no warps or twists.

Re: flat framed construction

Re: flat framed construction

That's Cool looking Roddie , the weight is not that bad for the strength you get from the construction . You keep showing these built up straight wings and I am going to have to try one out , don't know about the flaps I am a little flappy when I fly anyway

getback- Top Poster

Posts : 10448

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: flat framed construction

Re: flat framed construction

getback wrote:That's Cool looking Roddie , the weight is not that bad for the strength you get from the construction . You keep showing these built up straight wings and I am going to have to try one out , don't know about the flaps I am a little flappy when I fly anyway

The way I see it Eric, if you're planning on scratch-building a small sheet-wing design, then this alternate method is something to consider. Whether you have balsa on-hand or not.. it will take a lot less wood to build this wing. I've built 1/2A profile models on less than $5 in the cost of balsa (including the fuse..) with enough wood leftover to build another. Of course.. it's been a while since I've bought any balsa..

A "mono-plane" wing should have some sort of hard(er)-wood strip-spar. A strip of 1/8" x 1/2" Spruce or Bass.. at least 2/3 the span of the wing to stiffen it a little. Depending on where you locate it on the chord.. it could serve as a bellcrank mount too.

You need to be mindful that the original design's balance-point will likely change. Depending on how you frame-up the wing; it's final covered weight might be a lot less than a painted solid-sheets' would be. An "as-designed" tail-section/moment could wind up tail-heavy. If you plan-ahead while building, you can shorten the tail-moment before it's assembled. You just might end up with a better flying airplane than the original.

Re: flat framed construction

Re: flat framed construction

Thanks for the reply man , I think with a see through monakote cover would really stand out with out having to go to the trouble of making the ribs and all. I got wood I just need to do something with it as in build another plane . Just about the right weather for going to the field and do some round D rounds . LOL

getback- Top Poster

Posts : 10448

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: flat framed construction

Re: flat framed construction

getback wrote:Thanks for the reply man , I think with a see through monakote cover would really stand out with out having to go to the trouble of making the ribs and all. I got wood I just need to do something with it as in build another plane . Just about the right weather for going to the field and do some round D rounds . LOL

Eric, I had some correspondence with Richard (RK flyer) recently, and he said that he'd liked the design.. and built a wing a while back when he first saw one of my old threads. He hadn't done anything with it yet.. but since seeing my recent thread on the tri-plane; it encouraged him to build a fuse for it. I hope he does! I forgot to ask him details on how he framed it; the span/chord/area.. and whether he'd tied-in a bell-crank platform.

Scratch-building a conventional wing having airfoiled-ribs is a task.. alignment, jigging etc.. and if it's a "tapered" chord.. even more so. This method of flat-framing is for fun. You can build a wing in an evening easily.. on pennies worth of stock. Most modelers would already have the stock on-hand.. as you do.

Try something small.. maybe 18" span, 4" constant-chord using 1/8" med./hard balsa with 1/2" width frame-pieces throughout. Mount a Pee Wee .020 on it for trials. Back-up the L/E with a piece of 1/8" x 1/2" Basswood or Spruce. Your braces would only need to be 2-1/2" inches long. Make a single root-brace from 1" wide balsa.. which will provide additional clearance and a nice glue-edge to tie-in a plywood bellcrank plate/brace.

Fuse-construction is as easy as you make it. Cutting the slots for the wing and stab "perpendicular" is naturally important. After I mark the locations.. I cut the slots with a #11 blade, pressed firmly up-against a piece of 1/2" square hardwood.. or something that will guide the blade at right-angles to the wood.. and a straight-edge. Cut the slot(s) "tight". Thin CA will wick-into the joint and lock it. If the slots end-up "too tight" to insert the pieces.. you can make a simple sanding tool from an emery-board (lady's manicure supply.. left from an old girlfriend..

There probably aren't too many 1/4A size airplanes using iron-on covering..

Experimenting is fun when you build small models. If something doesn't work.. you're not out a lot of $$. It may take more "time" to build an unorthodox assembly.. but it can pay-off in terms of durability.

My mono-plane's fuse is slender.. at only 1/4" x 1-5/8".. and only uses 1/4" X 1-1/8" balsa from the nose to about 1" rearward of the wing's T/E. It's "capped" top/bottom with 1/4" sq. Spruce that tapers toward the tail. There's another slotted 1/4" balsa piece that encapsulates the stab, with an angle to which the 1/4" sq. spruce "rails" are bent to intercept. This is done by separately gluing one rail at a time.. then bending the other on a flat surface.. (everything is done flat..) to form a "bow". The slot for the stab was then cut.. parallel with the wing-slot. A 1/4 sq. balsa stick was glued-in diagonally to bridge the gap of the void behind the T/E for support.

You can "sort of" see it in this photo.

This airplane could have been a LOT lighter in weight. There's an experimental/adjustable lead-out guide that I made.. which was too much weight vs. the benefit.

That's a 90% tip-chord .062" music-wire "rail". The .025" solid lead-outs pass through a pair of spring-style wheel collars that can be positioned fore/aft on the rail. The counter/tip-weight is significant. Still.. the model with engine weighs in at 7.25 oz. (with my homemade muffler).. not bad for a 130 sq. in. wing.

The lighter a model is.. the better it's going to fly.. sheet-wing or otherwise.

Re: flat framed construction

Re: flat framed construction

Hello Roddie!

Since we "Talked" last I've been back to the bench to finish up a couple of planes that I had set aside. I've been thinking about building a "Fire Baby II" for your flat wing design so I''ll get started soon. The wing that I had built is 24"x 6" but after seeing the pictures, I am going to build another like like the one in this thread. I didn't use a hard wood strip in the first one and since the fuselage of the F.B. has a hard wood strip that runs thru the entire length it will be a good match.

I'll try & post some pictures of the build.

RK Flyer

Since we "Talked" last I've been back to the bench to finish up a couple of planes that I had set aside. I've been thinking about building a "Fire Baby II" for your flat wing design so I''ll get started soon. The wing that I had built is 24"x 6" but after seeing the pictures, I am going to build another like like the one in this thread. I didn't use a hard wood strip in the first one and since the fuselage of the F.B. has a hard wood strip that runs thru the entire length it will be a good match.

I'll try & post some pictures of the build.

RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: flat framed construction

Re: flat framed construction

RK Flyer wrote:Hello Roddie!

Since we "Talked" last I've been back to the bench to finish up a couple of planes that I had set aside. I've been thinking about building a "Fire Baby II" for your flat wing design so I''ll get started soon. The wing that I had built is 24"x 6" but after seeing the pictures, I am going to build another like like the one in this thread. I didn't use a hard wood strip in the first one and since the fuselage of the F.B. has a hard wood strip that runs thru the entire length it will be a good match.

I'll try & post some pictures of the build.

RK Flyer

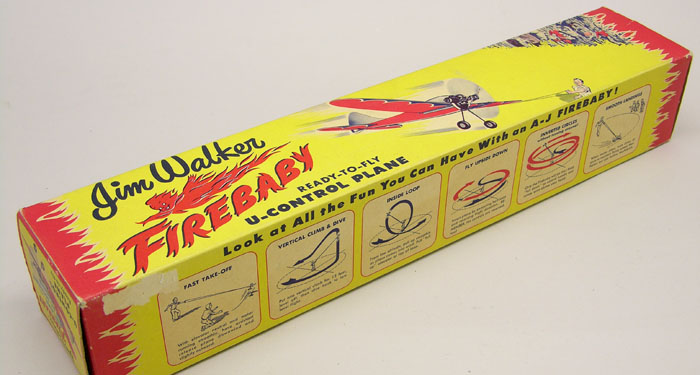

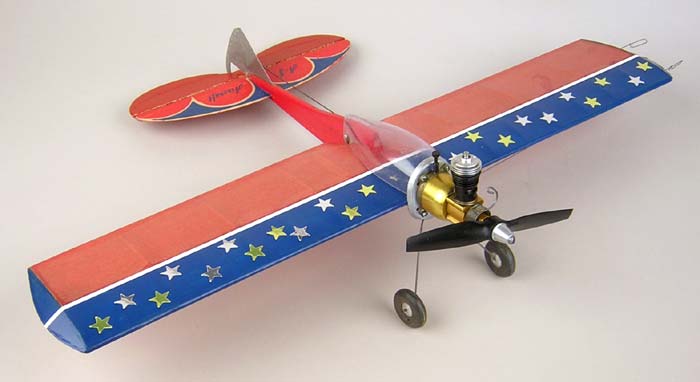

Hi Richard! That's a large flat wing! Just a few squares larger than my mono-plane. The smaller (19" span) Walker Firebaby would be a cool candidate for this construction! I don't have plans for the model. What does the mean-chord measure?

Some Jim Walker/Firebaby images from my archives..

Below; Billy McDow's "Super-Stunter" version. (never kitted)

Re: flat framed construction

Re: flat framed construction

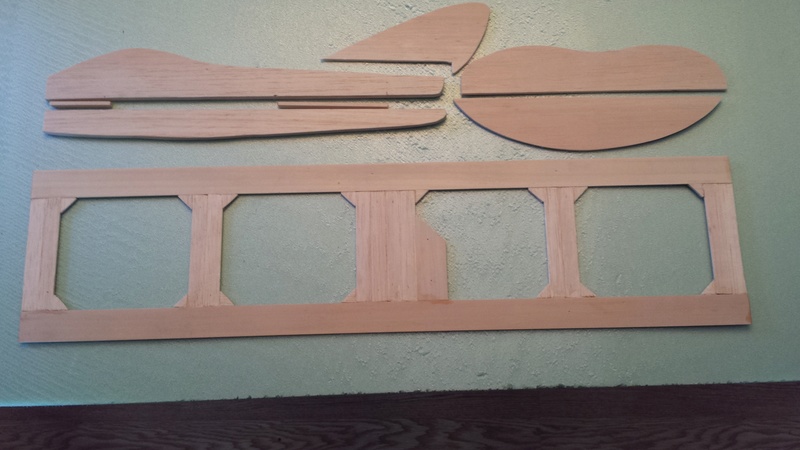

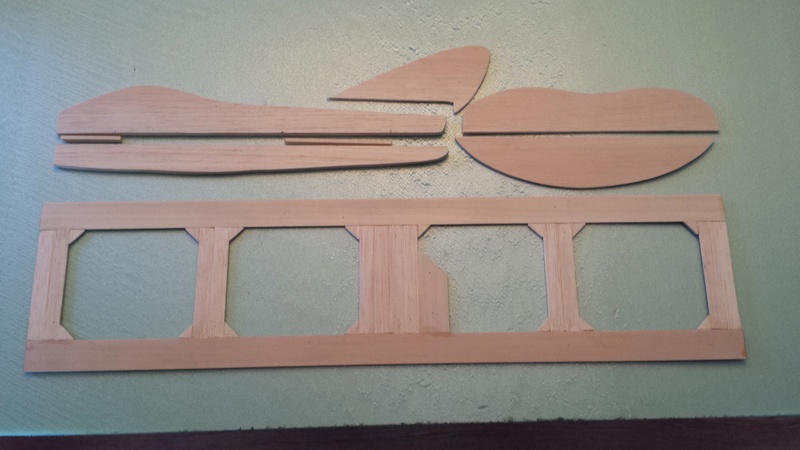

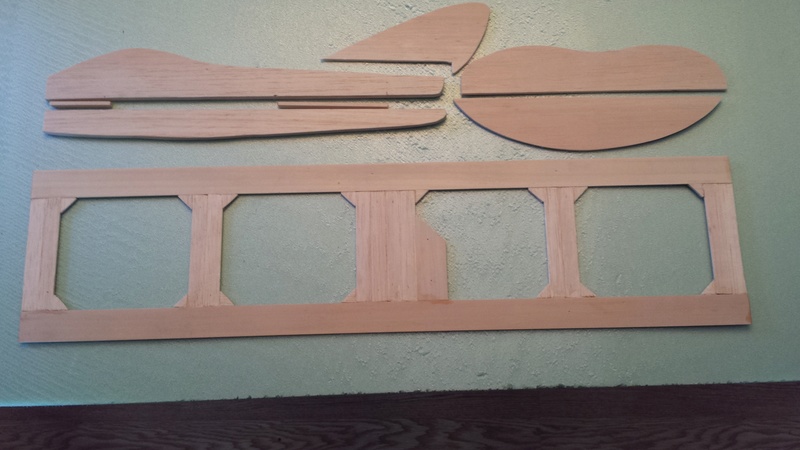

I made a 24" x 6" wing today so I increased the the fuselage 10% to 14" instead of the original 12". I also made up the elevator & rudder so I'll assemble it all tomorrow.

But I am not sure if I like the looks of the rectangle shape of the wing with the Jet type fuselage so I might cut a new fuselage from the "All American" plans that I have. It has a rectangle wing about the same size (26 x 6). The wing of the F. B. has a nice shape to it which would make it much harder to make.

I will try to post pictures tomorrow, also I have extra plans for the Fire Baby II if you want them just send me a PM. These plans were made by Frank Macy & Jim Cameron and the plane is real close to the original but made with a 1/8" flat wing with a hard wood piece in the center & a 1/8" x 1/4" hard wood strip in the 1/4" fuselage. My old club in Portland Or. made several of these planes and they fly very well, I still have the one I made a few years ago.

RK Flyer

But I am not sure if I like the looks of the rectangle shape of the wing with the Jet type fuselage so I might cut a new fuselage from the "All American" plans that I have. It has a rectangle wing about the same size (26 x 6). The wing of the F. B. has a nice shape to it which would make it much harder to make.

I will try to post pictures tomorrow, also I have extra plans for the Fire Baby II if you want them just send me a PM. These plans were made by Frank Macy & Jim Cameron and the plane is real close to the original but made with a 1/8" flat wing with a hard wood piece in the center & a 1/8" x 1/4" hard wood strip in the 1/4" fuselage. My old club in Portland Or. made several of these planes and they fly very well, I still have the one I made a few years ago.

RK Flyer

Last edited by RK Flyer on Thu Sep 22, 2016 1:23 pm; edited 2 times in total (Reason for editing : adding pictures)

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

More flat wing construction

More flat wing construction

My original Fire Baby II built a few years ago. It fly's very well and will do all the stunts with a golden bee or black widow. With the Baby Bee it great for kids to learn on.

Why not build 2 ? This is my version of the DE Marco "All American" from 1950. It has a built up wing (26") & fuse with an 09 engine. I'll use the flat wing design for this one.

RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: flat framed construction

Re: flat framed construction

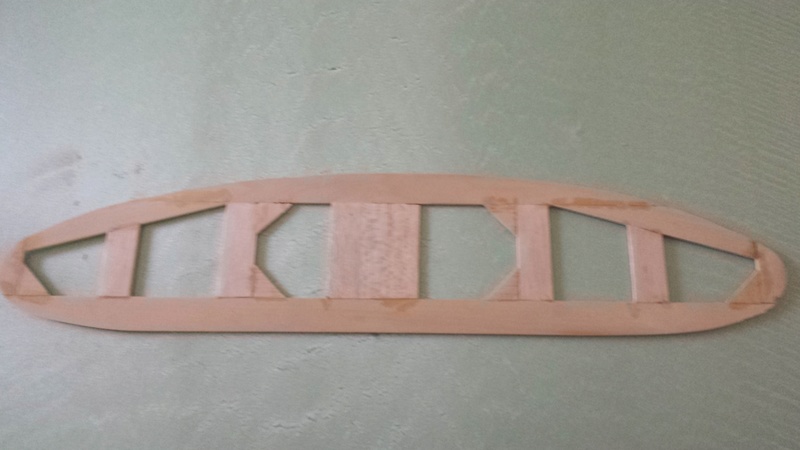

Hi Richard, Your frames look GREAT! You mentioned wanting to capture the nice elliptical wing-profile of the Firebaby.. rather than a constant-chord rectangular profile. You can easily accomplish this by building a shorter-chord and span "inner" frame. Make your two outer tip-braces of wider stock for the taper.. then cut and edge-glue elliptical-profile L/E and T/E pieces to the existing "short-chord" frame. You can still save some weight in the wing.. depending on how you frame it. I don't know the what the Firebaby's mean-chord measurement is.. but try building the "inner-frame" from narrower stock to allow for the elliptical L/E and T/E pieces to make-up the finish-chord. The wider "tips" will provide the extra "meat" where the ellipses taper-down for strength/support.

I like the brace-gussets! They're beneficial.. definitely!

I like the brace-gussets! They're beneficial.. definitely!

Re: flat framed construction

Re: flat framed construction

roddie wrote: I like the brace-gussets! They're beneficial.. definitely!

For maximum strength, gussets should be cut so the grain runs the direction of the long edge.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: flat framed construction

Re: flat framed construction

Looking Good Richard !! My son has the Fire Baby Kit form Duke if he ever gets his head on straight enough we are going to build and fly it ! And the All American is on my bucket list when time permits ( trying to run a small business at home now) taking a lot of time up that would bee building and fling  Eric

Eric  So you lived in Oregon at one time ?

So you lived in Oregon at one time ?

Eric

Eric  So you lived in Oregon at one time ?

So you lived in Oregon at one time ?

getback- Top Poster

Posts : 10448

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: flat framed construction

Re: flat framed construction

gcb wrote:roddie wrote: I like the brace-gussets! They're beneficial.. definitely!

For maximum strength, gussets should be cut so the grain runs the direction of the long edge.

George

Good point George. Gussets in this type of flat-construction eliminate most; if not all of the 90 degree angles where the chord-braces meet the L/E-T/E. I believe that it also maximizes the strength that the covering provides.

I mentioned earlier in the thread.. that having a multiple-piece flat-structure, helps to avoid warping.. as compared to solid-sheet construction. The bracings' wood-grain runs perpendicular to the span-wise pieces' grain. The bracing-joints are all independent of each other. A hardwood strip-spar (if used..) accentuates this effect even further.. and can really stiffen the wing from flexing during flight.

I have an old Sterling 1/2A "Shoestring".. that apparently was kitted with a one-piece wing; of 1/8" x 4" sheet-balsa. It's wing is noticeably cupped/curled now. My Goldberg kits; "Swordsman 18" and "Stuntman 23" were kitted with two-piece (chord-wise) panels that used "tab-joints" for assembly. Goldberg could have chose to simply furnish wing-halves with a full-length butt-joint.. but adding the tab-detail helped to assemble the wing "tip to tip" quickly and accurately. I believe that this also helped avoid warping. Sure it was cheaper to source and kit narrower-width balsa.. but the tab-joints had twofold benefits. My Goldberg models' wings have been broken over the course of time/flying.. but in my case, their "Ambroid" construction yielded separation (for the most part) along the joint.. which helped to salvage a broken panel.

Re: flat framed construction

Re: flat framed construction

getback wrote:Looking Good Richard !! My son has the Fire Baby Kit form Duke if he ever gets his head on straight enough we are going to build and fly it ! And the All American is on my bucket list when time permits ( trying to run a small business at home now) taking a lot of time up that would bee building and flingEric

So you lived in Oregon at one time ?

Hey Eric, You're an inspiration to me brother! You incorporate the "spirit" that we all strive toward. Your boy is so young.. but you often write of your spending quality-time with him.. and mentoring him. He'll surely never forget that. Whether he continues in the hobby or not. Exposing him to the intricacies of Aero-modeling is kind of a subtle lesson in discipline.. and consequences. Some of life's most important lessons.

Even More Flat Wing Construction

Even More Flat Wing Construction

Roddie, Thanks for your ideas on this wing, I think it came out pretty good! I used the same 1" x 1/8" bass wood for the leading edge and trailing edge then framed inside for the curve. It is 24" x 5". Now I can work on the finish for the All American & Fire Baby II along with 3-4 others that have been sitting too long!!

Eric, I did live in Portland Or. and met Duke there along with Mark H. & Jim C., all of them helped me build & fly a lot!

RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: flat framed construction

Re: flat framed construction

That looks terrific Richard! WOW.. you've obviously been busy working on it! Do you have any comments to add.. as far as how the framing-up of the wing went for you? I've found this type of construction to be quite enjoyable.. without the worry of fragile pieces breaking. Alignment is easy.. as long as you measure and cut accurately. Your example looks REALLY GOOD!

Almost finished!

Almost finished!

[

Roddie.....Its almost finished! This is the first time I've used any type of film to cover a plane and it took a lot of work but turned out nice! The plane weighs 3.5 oz. & I am not sure if that's heavy without the engine & controls or not. Anyway it will be some time before I try to fly it, I just can't fly very well these days but I do have a lot of fun building!!

RK Flyer

url=https://servimg.com/view/18617937/56] [/url]

[/url]

Roddie.....Its almost finished! This is the first time I've used any type of film to cover a plane and it took a lot of work but turned out nice! The plane weighs 3.5 oz. & I am not sure if that's heavy without the engine & controls or not. Anyway it will be some time before I try to fly it, I just can't fly very well these days but I do have a lot of fun building!!

RK Flyer

url=https://servimg.com/view/18617937/56]

[/url]

[/url]

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: flat framed construction

Re: flat framed construction

Looks great so far.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: flat framed construction

Re: flat framed construction

RK Flyer wrote:[

Roddie.....Its almost finished! This is the first time I've used any type of film to cover a plane and it took a lot of work but turned out nice! The plane weighs 3.5 oz. & I am not sure if that's heavy without the engine & controls or not. Anyway it will be some time before I try to fly it, I just can't fly very well these days but I do have a lot of fun building!!

RK Flyer

url=https://servimg.com/view/18617937/56][/url]

Looks good from here. MonoKote is all I use anymore, haven't used silk and dope since the 1970s that's what my dad started us kids on. May have to try silk and dope again.

bamboozler- Bronze Member

- Posts : 44

Join date : 2016-09-12

Age : 66

Location : WA

Re: flat framed construction

Re: flat framed construction

Thanks Roddie , all you can do is keep on keeping on with them , can try your patients for sure . Richard that's cool you have hooked up with some of our other brother here . The plane is turning out really NICE !! You can see the panels pretty good but some transparent covering would really make it shine  You did a good job non the less .

You did a good job non the less .  A lot of my models are displays now but got plans for them soooon !!

A lot of my models are displays now but got plans for them soooon !!

A lot of my models are displays now but got plans for them soooon !!

A lot of my models are displays now but got plans for them soooon !!

getback- Top Poster

Posts : 10448

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: flat framed construction

Re: flat framed construction

RK Flyer wrote:[

Roddie.....Its almost finished! This is the first time I've used any type of film to cover a plane and it took a lot of work but turned out nice! The plane weighs 3.5 oz. & I am not sure if that's heavy without the engine & controls or not. Anyway it will be some time before I try to fly it, I just can't fly very well these days but I do have a lot of fun building!!

RK Flyer

url=https://servimg.com/view/18617937/56][/url]

Hi Richard. Bravo on your first iron-on covering job!

That's pretty lightweight for a model with a 156 square-inch wing-area! I realize that "flying" is secondary to building for you.. but I'd really love to see you fly either of these models. Your DeMarco "All-American" is begging for a fresh .09 to be mounted and flown! You could keep the weight down even more if you opt for a carbon-fiber pushrod.. BUT, you may need the weight of music-wire to get the balance-point to where it should be.. considering the weight of many .09 class engines available. I see a radial-mount firewall there. What engine configuration do you have in mind? Your framed-wing.. even with covering; likely weighs less than a solid-sheet sealed/painted wing would. The nose-moment looks fairly short in the photo. Had you trial-fit a subject-engine to arrive at the length of the nose? It's a very cool-looking airplane! "Racey".. but nimble-looking with the short-tail and ample elevator-area! Is this model built "as-per-plan"? I'd love to see the original plan. I think you included the Walker "Firebaby II" in the four full-size plans that you so graciously mailed to me, a few years ago! Yes.. I just checked!

That's pretty lightweight for a model with a 156 square-inch wing-area! I realize that "flying" is secondary to building for you.. but I'd really love to see you fly either of these models. Your DeMarco "All-American" is begging for a fresh .09 to be mounted and flown! You could keep the weight down even more if you opt for a carbon-fiber pushrod.. BUT, you may need the weight of music-wire to get the balance-point to where it should be.. considering the weight of many .09 class engines available. I see a radial-mount firewall there. What engine configuration do you have in mind? Your framed-wing.. even with covering; likely weighs less than a solid-sheet sealed/painted wing would. The nose-moment looks fairly short in the photo. Had you trial-fit a subject-engine to arrive at the length of the nose? It's a very cool-looking airplane! "Racey".. but nimble-looking with the short-tail and ample elevator-area! Is this model built "as-per-plan"? I'd love to see the original plan. I think you included the Walker "Firebaby II" in the four full-size plans that you so graciously mailed to me, a few years ago! Yes.. I just checked! More flat wing construction

More flat wing construction

Roddie......

I have the plans for the 09 size "All American" so I just used the profile for the fuselage and made it the same length also the wing & elevator are pretty close to the plans. The mount that's on it now is for the Golden Bee but I guess there is enough room to mount an 09 but that would be way to much for me to handle. Anyway I really like the look of the plane in either way, I do know that the All American with an 09 is a great flyer & will do all the stunts with a good pilot! Part of the problem I have with flying is not having someone that fly's UC around here my club is all RC. Thanks for your input on this one!

RK Flyer

I have the plans for the 09 size "All American" so I just used the profile for the fuselage and made it the same length also the wing & elevator are pretty close to the plans. The mount that's on it now is for the Golden Bee but I guess there is enough room to mount an 09 but that would be way to much for me to handle. Anyway I really like the look of the plane in either way, I do know that the All American with an 09 is a great flyer & will do all the stunts with a good pilot! Part of the problem I have with flying is not having someone that fly's UC around here my club is all RC. Thanks for your input on this one!

RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: flat framed construction

Re: flat framed construction

RK Flyer wrote:Roddie......

I have the plans for the 09 size "All American" so I just used the profile for the fuselage and made it the same length also the wing & elevator are pretty close to the plans. The mount that's on it now is for the Golden Bee but I guess there is enough room to mount an 09 but that would be way to much for me to handle. Anyway I really like the look of the plane in either way, I do know that the All American with an 09 is a great flyer & will do all the stunts with a good pilot! Part of the problem I have with flying is not having someone that fly's UC around here my club is all RC. Thanks for your input on this one!

RK Flyer

Richard, I know what it's like to not have any C/L people around. That's what led me to build launching devices. I see that your All-American has no landing-gear yet. It's probably best to keep it that way.. unless you need to add some nose-weight. If it comes to that (after mounting the controls and the Golden Bee) I would bend-up an inverted "V" gear from 1/16" music-wire.. and cut a triangular piece of 1/16" plywood to fit inside the wire's angle as a spacer for mounting the gear to that firewall, just behind the engine. This gives you a wide-variety of different size/weight wheels to dial-in the best balance-point.

Alternately... are you familiar with the "wing-stooge"? I've never used one, but I plan on trying it. "Rusty" uses one when he flies his Baby Flite-Streak.. and Lil' Satan models which have no landing-gear. It's basically made by using an elevated platform to support the models' outboard-wing with a "weighted" rubber-mat wrapped around the wing which holds the running-model until you walk to the handle. A card-table would be easy to transport.. and the smooth-side of a rubber bathmat won't snag on a tip-weight when the model is gradually pulled out of the mat. A weight could consist of a one-gallon size zipper-seal plastic bag filled with sand, which would conform to distribute the weight evenly on top of the mat.

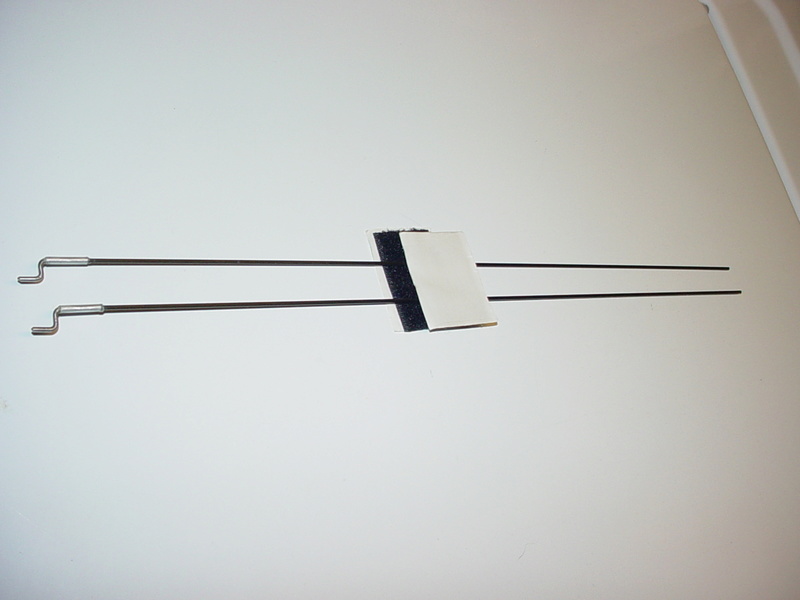

Your All-American less engine/tip-weight/controls weighs in thus far at 3.5oz. Figure on at least an additional ounce (less engine) once you install the controls, depending on what you use for materials. The elevator pushrod has the most effect on balance; being rearward of the CG. If you opt to omit landing-gear and end-up tail-heavy with a music-wire pushrod.. you can make an .060" (1.5mm) carbon-fiber pushrod that will weigh 75% less than one made from .062" music-wire. That's a significant difference.

This "pair" of pushrods are made from .060" carbon-fiber. I made the ends using aluminum tubing sleeves and 3/4" lengths of "Z"-bent 1/16" music-wire. They're quite rigid.. and weigh next to nothing as compared to a full "shorter and single" length of 1/16" music wire.

Note that the pushrod/wire weights are in "grams".

Below photo is of a shorter single piece of 1/16" music-wire.

My Golden Bee weighs 2.4oz. with an APC 4.75 x 4 prop and Tee Dee-style spinner.

It's always better to be able to add or subtract weight "functionally" to balance your model.

Either way, you'll likely still be less than 7oz. RTF.. which is pretty darn lightweight for a 26" span 156" square model.. and the Golden bee should be up to that task! It might be "floaty" though.. and I wouldn't fly it on a breezy day.. or with lines of the length that you'd ordinarily use for a wing of that size. I'd actually start with 30' lines on a calm day. Do you have any L/H props to fit the Golden Bee? If so.. I'd use one. Doing so will help with line-tension.

Please keep us informed on how you proceed!

Page 1 of 2 • 1, 2

Similar topics

Similar topics» *SOLD* Walt Musciano Scientific "Red Tiger P-40" kit

» My N-1R build log

» tank construction

» Multi cylinder Valentines

» Space Bug Jr. box construction

» My N-1R build log

» tank construction

» Multi cylinder Valentines

» Space Bug Jr. box construction

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules