Log in

Search

Latest topics

» Tee Dee .020 combat modelby TD ABUSER Today at 12:38 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

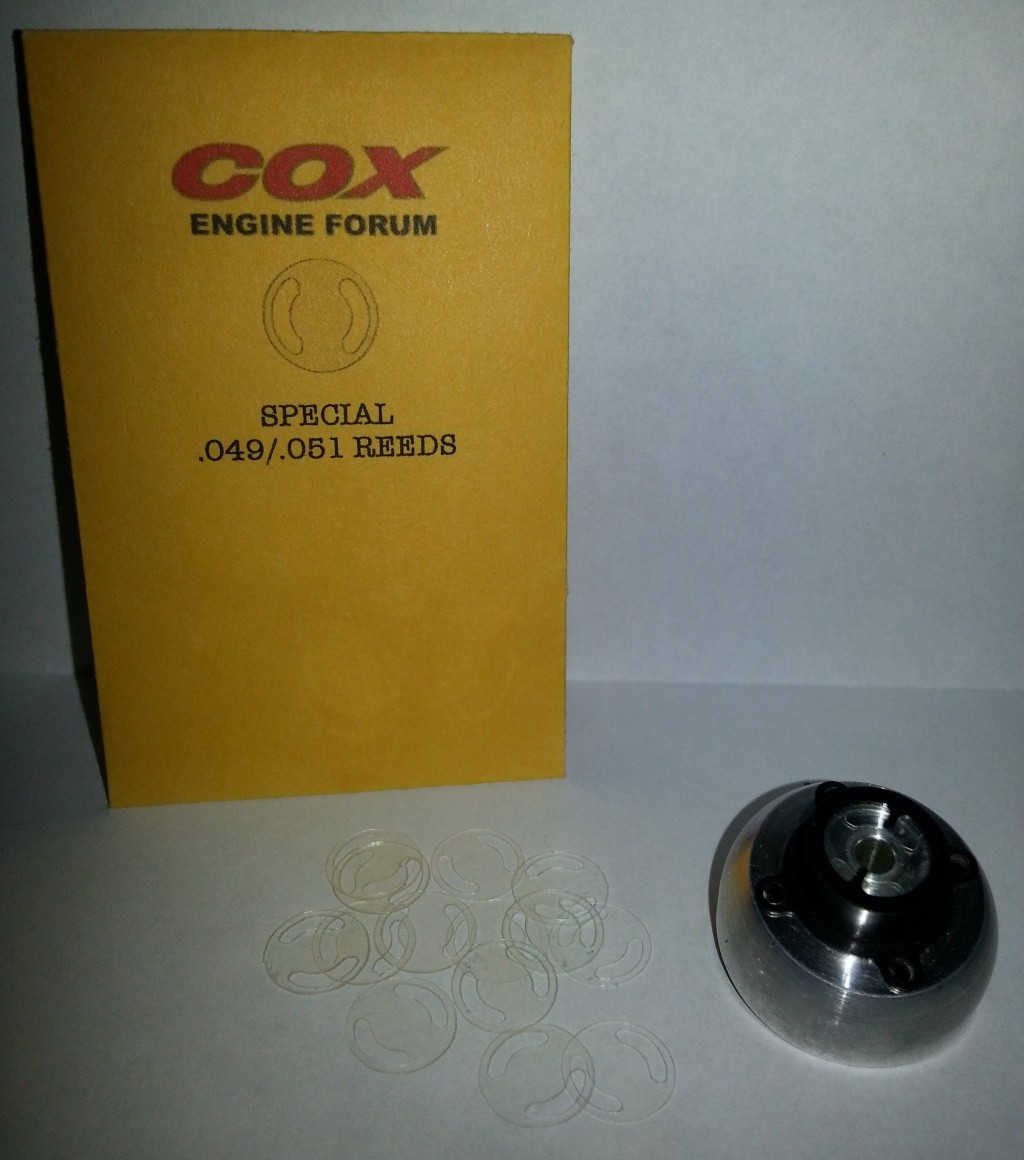

Special reeds

Page 1 of 1

Special reeds

Special reeds

I was just browsing and had a look in the CEF Store. I don't recall hearing about these "special" mylar reeds before.  Has anyone done any testing that they'd like to report on?

Has anyone done any testing that they'd like to report on?

Has anyone done any testing that they'd like to report on?

Has anyone done any testing that they'd like to report on?

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Special reeds

Re: Special reeds

The "crystal" clear reeds? They run nicely. I don't have numbers though. The clear Mylar is harder and/or stiffer than the opaque/translucent reed that is new production. There is a definite "feel" difference if you have one of each in your hands.

I have some star reeds from the same material, and it was always a major hop up from a brass star reed. They came in the rebuild kits in the late 80's.

I have some oblong clear reeds too, bought them from Bernie, but as I said I haven't done numbers on the same engine to compare.

Phil

I have some star reeds from the same material, and it was always a major hop up from a brass star reed. They came in the rebuild kits in the late 80's.

I have some oblong clear reeds too, bought them from Bernie, but as I said I haven't done numbers on the same engine to compare.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Special reeds

Re: Special reeds

I used to look for those rebuild pacs Phil speaks of, those clear reeds in my opinion are best. They could be a little thinner also. Teflon are garbage reeds

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: Special reeds

Re: Special reeds

Those are some reeds that I designed years ago while playing around with cutting my own reeds from floppy disks. The first ones were hand cut in a similar (more crude) design. It could've been just me and my engine but I thought it ran pretty smooth and gained some RPMs with the reed.

A few years ago, Jason and I were discussing the reed design and he sent me a few he cut out of a floppy disk using his Cricut machine. Those seemed to work pretty good, as good as a factory reed at least.

Many things have come up since I last put a lot of "research and development" into the reeds. My grandparents were failing in health and required a lot more care, I've been taking classes at a local university for electrical engineering...

I planned on running tests on those reeds this summer to see if they would be ready to offer to members on here. I haven't yet tried them using the material I cut them with. With the surprise terminal cancer my grandma got and dealing with probate and all that kind of stuff, that threw a wrench into my summer plans.

Anyone want to try some of those reeds and let me know how they work?

Last edited by Admin on Fri Sep 02, 2016 4:09 am; edited 1 time in total

Re: Special reeds

Re: Special reeds

This is an interesting thread. I'd like to add my  The reed and it's "retainer".. are the heart of the reed-valve engine.. and should be considered as so. It doesn't matter much; what your engine has for high-performance parts down-stream of the reed.. if the reed is not functioning properly. I'm partial to the original-style "star-shaped" Copper-Beryllium reed and e-clip retainer for use in the old "Bee-style" tanked engines. I feel that they run reliably as designed. I save these reeds where I can.. and have many of them in my parts-stock. As fragile as they are.. they can be re-used if handled carefully.. even if stuck with castor in an old forgotten engine. As long as they're not bent or creased.. they'll almost always work beautifully in a freshly rebuilt engine. It's worth the time, to soak the reed/seat with solvent.. until you can gently lift a corner and "peel" it off the seat using a sharp... preferably a scalpel.

The reed and it's "retainer".. are the heart of the reed-valve engine.. and should be considered as so. It doesn't matter much; what your engine has for high-performance parts down-stream of the reed.. if the reed is not functioning properly. I'm partial to the original-style "star-shaped" Copper-Beryllium reed and e-clip retainer for use in the old "Bee-style" tanked engines. I feel that they run reliably as designed. I save these reeds where I can.. and have many of them in my parts-stock. As fragile as they are.. they can be re-used if handled carefully.. even if stuck with castor in an old forgotten engine. As long as they're not bent or creased.. they'll almost always work beautifully in a freshly rebuilt engine. It's worth the time, to soak the reed/seat with solvent.. until you can gently lift a corner and "peel" it off the seat using a sharp... preferably a scalpel.

Some of you "hot-rod" guys may have had the pleasure of using a penetrant the was available as a "General Motors" part known as "Heat-Valve Lubricant". It was a super-penetrant comprised of colloidal-graphite.. formulated for freeing-up a stuck "heat-riser valve" between the exhaust manifold.. and carburetor. No longer produced; if you happen to find an aerosol can of this product anywhere... scoop it up. Don't worry if there's no pressure left in the can. Puncture it.. and drain it into another vessel. It's absolutely the best penetrant you'll ever find.

Back to the Cox reeds.. The "Copper-Star" is .001" thick. The Cox Mylar reeds (star or oval-shaped) are all .005" thick. This may not "seem" like much.. but the Mylar is .004" thicker. The Mylar has different "flex" properties than the alloy reed does. The Mylar reed works well.. but it needs allowance for comparable flexing off the valve-seat.. without being "bound" by it's retainer. I'm not sure how Cox overcame this in the early years with the "horseshoe" backplate.. (which to my knowledge; is when they first started using the Mylar reed..) but they continued with the e-clip style retainer. Possibly; the e-clip wire was of a lesser wire-diameter.. so as not to bind the thicker Mylar in the groove where the clip seats?

Call me anal.. but my research supports that the e-clip wire diameter varies by as much as .005"..

Maybe a coincidence.. but not by a company known for keeping tolerances to the 4th decimal point..

The reed and it's "retainer".. are the heart of the reed-valve engine.. and should be considered as so. It doesn't matter much; what your engine has for high-performance parts down-stream of the reed.. if the reed is not functioning properly. I'm partial to the original-style "star-shaped" Copper-Beryllium reed and e-clip retainer for use in the old "Bee-style" tanked engines. I feel that they run reliably as designed. I save these reeds where I can.. and have many of them in my parts-stock. As fragile as they are.. they can be re-used if handled carefully.. even if stuck with castor in an old forgotten engine. As long as they're not bent or creased.. they'll almost always work beautifully in a freshly rebuilt engine. It's worth the time, to soak the reed/seat with solvent.. until you can gently lift a corner and "peel" it off the seat using a sharp... preferably a scalpel.

The reed and it's "retainer".. are the heart of the reed-valve engine.. and should be considered as so. It doesn't matter much; what your engine has for high-performance parts down-stream of the reed.. if the reed is not functioning properly. I'm partial to the original-style "star-shaped" Copper-Beryllium reed and e-clip retainer for use in the old "Bee-style" tanked engines. I feel that they run reliably as designed. I save these reeds where I can.. and have many of them in my parts-stock. As fragile as they are.. they can be re-used if handled carefully.. even if stuck with castor in an old forgotten engine. As long as they're not bent or creased.. they'll almost always work beautifully in a freshly rebuilt engine. It's worth the time, to soak the reed/seat with solvent.. until you can gently lift a corner and "peel" it off the seat using a sharp... preferably a scalpel. Some of you "hot-rod" guys may have had the pleasure of using a penetrant the was available as a "General Motors" part known as "Heat-Valve Lubricant". It was a super-penetrant comprised of colloidal-graphite.. formulated for freeing-up a stuck "heat-riser valve" between the exhaust manifold.. and carburetor. No longer produced; if you happen to find an aerosol can of this product anywhere... scoop it up. Don't worry if there's no pressure left in the can. Puncture it.. and drain it into another vessel. It's absolutely the best penetrant you'll ever find.

Back to the Cox reeds.. The "Copper-Star" is .001" thick. The Cox Mylar reeds (star or oval-shaped) are all .005" thick. This may not "seem" like much.. but the Mylar is .004" thicker. The Mylar has different "flex" properties than the alloy reed does. The Mylar reed works well.. but it needs allowance for comparable flexing off the valve-seat.. without being "bound" by it's retainer. I'm not sure how Cox overcame this in the early years with the "horseshoe" backplate.. (which to my knowledge; is when they first started using the Mylar reed..) but they continued with the e-clip style retainer. Possibly; the e-clip wire was of a lesser wire-diameter.. so as not to bind the thicker Mylar in the groove where the clip seats?

Call me anal.. but my research supports that the e-clip wire diameter varies by as much as .005"..

Maybe a coincidence.. but not by a company known for keeping tolerances to the 4th decimal point..

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules