Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Avoiding my chores.

Page 1 of 1

Avoiding my chores.

Avoiding my chores.

As my vacation is over, I looked around my desk and started cleaning. Well, pushing things around from place to place really. But, one thing I’ve been pushing around for months is the test fixture I made for THIS thread on my pipe bomb engines. As I’ve finished that test, I have no further use for a Testors test stand. Get it? Testors Test stand? Ahhh-ha-ha-ha.

But, it seemed a shame to toss out a perfectly usable item, so I got “distracted” from my cleaning to do something with this. I needed something quick and dirty for this, so I cast about in my mind for something to do with it. Since it is for Testors pipe bomb engines, I thought of Riley Wooten’s L’il Bomb. That plane is pretty simple, so I decided to cut down the test fixture and graft it into the plane and call it….

Wait for it….

A L’il Pipe Bomb!!!

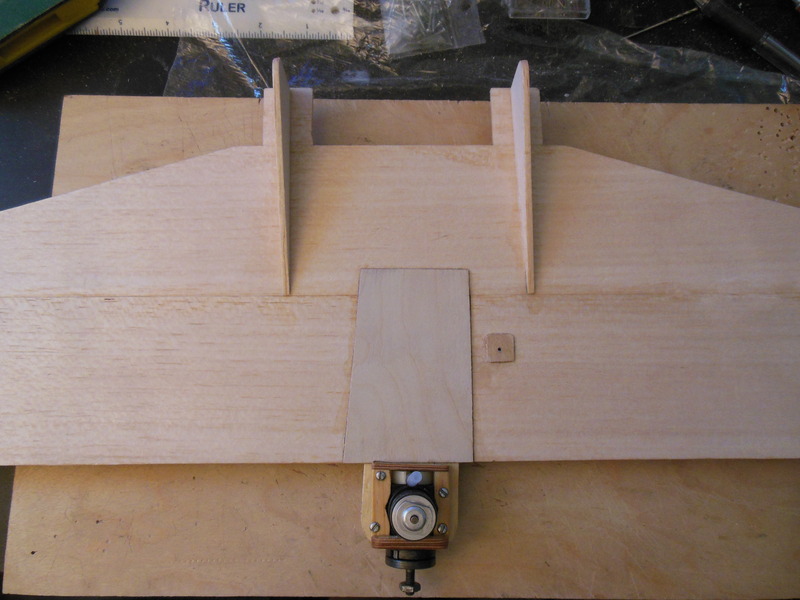

As usual, I started building before I thought to start taking pictures. Here’s the plane with the basic frame. I took a 1/8x3x36’ stick of balsa and cut it into two 18” pieces. I butt-joined the two pieces to make a 6x18” slab. I cut a couple of 1” end cross pieces from a scrap 1/8” balsa. Then cut the wing to shape and cut out two pieces for the elevator to attach to. All glued together:

Then I made a cutout for the section of engine mount made from the test fixture. No, I didn’t cut the angle for in-thrust. This is the bottom of the plane. The angle is not as extreme as the crappy camera makes it look.

I then cut and glued on the fins.

Afterwards, I glued in the engine mount. The burnt patches were from about 22 years ago when I used the ply as a fixture to solder up the cabanes on an ACE 4-120 Bipe kit.

Taping the elevator in place to mark up the pushrod, and the pushrod cut to length.

Next I glued in ply doublers for the bellcrank mount and a 1/32” doubler to cover the engine mount and secure it to the wing.

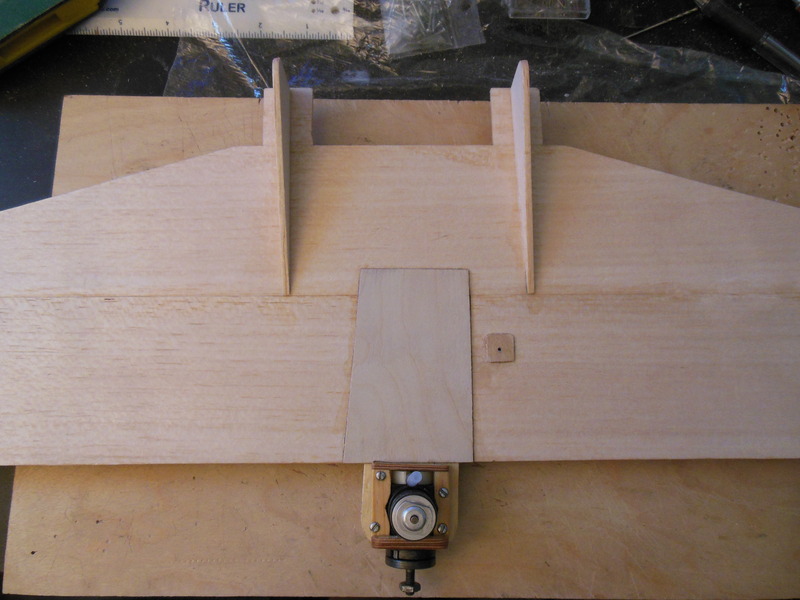

Test fitting the engine. I decided to use the engine clamp that I used for my Pipe Bomb Special, as I was a little lazy tonight. I might make up a better clamp that matches the bottom of the mount, but the plane currently balances about 3/8" behind the leading edge of the plane, so I don’t want to add more weight to the front. We’ll see how it balances after I paint it.

I made up and glued in the leadout guide, but then looking at it I decided I had glued it in too far back, especially since I’m putting out-thrust in the engine. So, I made a poor man’s adjustable leadout guide and glued another guide ahead of the first one. Now I have four holes spaced ½” apart that I can adjust the guide in.

And here it is assembled to check final layout and rough balance before I take it apart for painting. This is two evenings’ work. Not fancy, but it looks functional. I’ll wait until after I paint it to decide the exact placement of the fuel tank.

Now to put aside the L’il Pipe Bomb until we have a non-rainy/non-humid day so I can paint it.

The Soggy Mark

But, it seemed a shame to toss out a perfectly usable item, so I got “distracted” from my cleaning to do something with this. I needed something quick and dirty for this, so I cast about in my mind for something to do with it. Since it is for Testors pipe bomb engines, I thought of Riley Wooten’s L’il Bomb. That plane is pretty simple, so I decided to cut down the test fixture and graft it into the plane and call it….

Wait for it….

A L’il Pipe Bomb!!!

As usual, I started building before I thought to start taking pictures. Here’s the plane with the basic frame. I took a 1/8x3x36’ stick of balsa and cut it into two 18” pieces. I butt-joined the two pieces to make a 6x18” slab. I cut a couple of 1” end cross pieces from a scrap 1/8” balsa. Then cut the wing to shape and cut out two pieces for the elevator to attach to. All glued together:

Then I made a cutout for the section of engine mount made from the test fixture. No, I didn’t cut the angle for in-thrust. This is the bottom of the plane. The angle is not as extreme as the crappy camera makes it look.

I then cut and glued on the fins.

Afterwards, I glued in the engine mount. The burnt patches were from about 22 years ago when I used the ply as a fixture to solder up the cabanes on an ACE 4-120 Bipe kit.

Taping the elevator in place to mark up the pushrod, and the pushrod cut to length.

Next I glued in ply doublers for the bellcrank mount and a 1/32” doubler to cover the engine mount and secure it to the wing.

Test fitting the engine. I decided to use the engine clamp that I used for my Pipe Bomb Special, as I was a little lazy tonight. I might make up a better clamp that matches the bottom of the mount, but the plane currently balances about 3/8" behind the leading edge of the plane, so I don’t want to add more weight to the front. We’ll see how it balances after I paint it.

I made up and glued in the leadout guide, but then looking at it I decided I had glued it in too far back, especially since I’m putting out-thrust in the engine. So, I made a poor man’s adjustable leadout guide and glued another guide ahead of the first one. Now I have four holes spaced ½” apart that I can adjust the guide in.

And here it is assembled to check final layout and rough balance before I take it apart for painting. This is two evenings’ work. Not fancy, but it looks functional. I’ll wait until after I paint it to decide the exact placement of the fuel tank.

Now to put aside the L’il Pipe Bomb until we have a non-rainy/non-humid day so I can paint it.

The Soggy Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Avoiding my chores.

Re: Avoiding my chores.

Nicely done! And I like how you built the motor mount. Looks great!

larrys4227- Gold Member

- Posts : 338

Join date : 2015-07-23

Location : Lakeland, FL

Re: Avoiding my chores.

Re: Avoiding my chores.

Yes, looks great. I may have to copy-cat it this winter and make use of one of my unusable "pipe-bombs."

Bob

Bob

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: Avoiding my chores.

Re: Avoiding my chores.

That's Da Bomb!

Mark, your ingenuity is inspiring. Well thought out and executed. I like the skids on the belly.

I hate to suggest anything, because you probably already processed it. But, maybe a scuff plate or additional skid under the nacelle?

Rusty

Mark, your ingenuity is inspiring. Well thought out and executed. I like the skids on the belly.

I hate to suggest anything, because you probably already processed it. But, maybe a scuff plate or additional skid under the nacelle?

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Avoiding my chores.

Re: Avoiding my chores.

Looks Good Mark , just wondering is there going to be enough air for the engine to breath there in the nice mount you have made ? I didn't see a hole in the bottom of the mount plate for an interance . Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Avoiding my chores.

Re: Avoiding my chores.

"Wicked" as usual Mark! Will the Testors' needle handle a bladder? It would look trick having a bladder mounted on stand-offs atop that ply plate behind the engine. I think "Foremost" used to make a small size fuel-fittings set that contained a 90 degree elbow for a low straight-shot from the backplate to a bladder or balloon tank capsule.

You get Kudos for again.. resurrecting the pipe-bomb retro fit. I needed a 3/4" (19mm) hole-saw (which I bought a while ago..) for boring through the side of 3/4" PVC pipe for the engine-cylinder to fit through. I shelved the project shortly after I bought the tool.. but I should tinker with that mount some more. Your back-end trimming idea.. allows the whole lower-end to fit inside the pipe with some strategic slotting.

allows the whole lower-end to fit inside the pipe with some strategic slotting.

I'm hoping to redesign my mount so that the cylinder is installed after the crankcase snaps into the pipe from the front. The pipe acts as a c-clamp when slit all the way down one side.

The pipe forms a nice streamlined profile that's barely visible behind the wind-up starter.

A short piece of 3/4" hardwood dowel "halved" lengthwise and glued top/bottom to the leading-edge of a sheet-wing would form a good foundation for the rear-slotted pipe to fit over. The ID of my PVC pipe is actually .800".. so halving the dowel will provide for the proper snug fit. Secure the pipe to the dowel-piece with a wood screw.

You get Kudos for again.. resurrecting the pipe-bomb retro fit. I needed a 3/4" (19mm) hole-saw (which I bought a while ago..) for boring through the side of 3/4" PVC pipe for the engine-cylinder to fit through. I shelved the project shortly after I bought the tool.. but I should tinker with that mount some more. Your back-end trimming idea..

allows the whole lower-end to fit inside the pipe with some strategic slotting.

allows the whole lower-end to fit inside the pipe with some strategic slotting.

I'm hoping to redesign my mount so that the cylinder is installed after the crankcase snaps into the pipe from the front. The pipe acts as a c-clamp when slit all the way down one side.

The pipe forms a nice streamlined profile that's barely visible behind the wind-up starter.

A short piece of 3/4" hardwood dowel "halved" lengthwise and glued top/bottom to the leading-edge of a sheet-wing would form a good foundation for the rear-slotted pipe to fit over. The ID of my PVC pipe is actually .800".. so halving the dowel will provide for the proper snug fit. Secure the pipe to the dowel-piece with a wood screw.

Re: Avoiding my chores.

Re: Avoiding my chores.

getback wrote:Looks Good Mark , just wondering is there going to be enough air for the engine to breath there in the nice mount you have made ? I didn't see a hole in the bottom of the mount plate for an interance . Eric

Eric, There's plenty of room for air to get in. The air inlet is in the center of the plastic back piece just like a product engine. Lots of free space around it in the mount I have. But, looking at the pictures, I'll have to do some trimming to make the wood behind the inlet parallel with he plastic piece. Not that it'd make any difference, but looking at it in the picture, the way its angled just bothers me. I didn't bother with making anything straight or neat when I slapped the test fixture together, as it was temporary and I figured I'd just toss it when I was done. Foolish me.

The Crooked Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Avoiding my chores.

Re: Avoiding my chores.

roddie wrote:"Wicked" as usual Mark! Will the Testors' needle handle a bladder? It would look trick having a bladder mounted on stand-offs atop that ply plate behind the engine. I think "Foremost" used to make a small size fuel-fittings set that contained a 90 degree elbow for a low straight-shot from the backplate to a bladder or balloon tank capsule.

Roddie, no luck on the bladder. The needle is finicky just on atmospheric. It's just too coarse for a bladder. Although a balloon would probably work. But I'm just going to go with a wedge tank, as I've a couple in my goodie box. I have a few of the 90° elbows in my other goodie box, and I might use one. I don't know yet.

The Rough Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Avoiding my chores.

Re: Avoiding my chores.

RknRusty wrote:That's Da Bomb!

Mark, your ingenuity is inspiring. Well thought out and executed. I like the skids on the belly.

I hate to suggest anything, because you probably already processed it. But, maybe a scuff plate or additional skid under the nacelle?

Rusty

Suggest away Rusty. If it's a good suggestion, I'll just use it and claim credit for it, "forgetting" that someone else suggested it first...

Just kidding. I'll take any suggestions I can get. I was thinking of just using a small wire bow under the bottom of the mount to protect the fuel line going into the fuel nipple. But I need to see how the tank mounts first.

The Borrower Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Avoiding my chores.

Re: Avoiding my chores.

larrys4227 wrote:Nicely done! And I like how you built the motor mount. Looks great!

Larry,

I kind of like that design myself. Initially, I thought to make a mount by stacking light ply strips cut out and beveled for the bottom of the engine until the engine was enclosed as a quick and easy way for a temporary fixture. But after getting done, I thought that it might just be a good way to make a permanent one, doing a little more careful job of it and coating the entire thing with epoxy. I still may do another one like that to try on other planes if I acquire any more pipe bomb engines.

The Planning Mark

edit: Now that I think about it, it'd be a good way to mount a TD engine in a streamlined nose for a 1/2A speed plane or racer, so long as the first ply layer was 5-ply....

The Big Plans Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Avoiding my chores.

Re: Avoiding my chores.

Hey Mark, I wonder if you'd be willing to try Minwax polyurethane instead of epoxy. Since I first used it on the Osprey, I've painted it onto a lot of stuff, the entire Ukey nose being the best example, and I've found it to be incredibly bulletproof to anything our hobby might spill on it or soak it in. It's lighter and it sands nicer, easy to fuelproof screw-holes with a toothpick, and hardly slow down to wait for it. Wipe it on with a t-shirt rag and a pint lasts a long time. I'm a recent convert at the fuelproofaholic meetings.batjac wrote:...it might just be a good way to make a permanent one, doing a little more careful job of it and coating the entire thing with epoxy....

The Big Plans Mark

And it makes your fingernails beautiful for weeks. I've been meaning to post a thread asking others' opinions on that... urethane, not fingernails.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Avoiding my chores.

Re: Avoiding my chores.

Finger nails  I know what your saying about that , and it is some darn good stuff I have yet to put it on an airplane but , since you are living proof of the resilience of it to fuel and other ill stuff of the fun I want to give it a go . Good deal Mark just wondering the way it was closed in around the bottom half of the engine in the pic . Eric

I know what your saying about that , and it is some darn good stuff I have yet to put it on an airplane but , since you are living proof of the resilience of it to fuel and other ill stuff of the fun I want to give it a go . Good deal Mark just wondering the way it was closed in around the bottom half of the engine in the pic . Eric

I know what your saying about that , and it is some darn good stuff I have yet to put it on an airplane but , since you are living proof of the resilience of it to fuel and other ill stuff of the fun I want to give it a go . Good deal Mark just wondering the way it was closed in around the bottom half of the engine in the pic . Eric

I know what your saying about that , and it is some darn good stuff I have yet to put it on an airplane but , since you are living proof of the resilience of it to fuel and other ill stuff of the fun I want to give it a go . Good deal Mark just wondering the way it was closed in around the bottom half of the engine in the pic . Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Avoiding my chores.

Re: Avoiding my chores.

batjac wrote:roddie wrote:"Wicked" as usual Mark! Will the Testors' needle handle a bladder? It would look trick having a bladder mounted on stand-offs atop that ply plate behind the engine. I think "Foremost" used to make a small size fuel-fittings set that contained a 90 degree elbow for a low straight-shot from the backplate to a bladder or balloon tank capsule.

Roddie, no luck on the bladder. The needle is finicky just on atmospheric. It's just too coarse for a bladder. Although a balloon would probably work. But I'm just going to go with a wedge tank, as I've a couple in my goodie box. I have a few of the 90° elbows in my other goodie box, and I might use one. I don't know yet.

The Rough Mark

Yes, I was afraid of that (coarse-thread needle..) I still want to experiment with putting a restrictor in the fuel line for that issue. The concept was used (and works) on crankcase-pressure systems. Would need to use a fuel filter upstream of it though. I bought a couple bags (Tower Hobbies) of K & S assorted size alloy tubing/rod cut-offs. Wicked handy to have.. cost only a couple bucks.

Here's an example of a restricted-flow using a couple pieces. It could be restricted further by crimping the smaller tube, which would also hold it in place inside the larger one.

I think this would work.. although I have not tried it yet.

You have more of these Testors engines right? Why not try making an experimental balsa mount for one of them. Laminations w/thin CA glue would harden it.. then try Rusty's suggestion of Minwax Poly to seal it. It would be super light.. and fairly strong.. wouldn't it?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules