Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Now Complete : New Build And New Hinge Technique, Pics Now Added

Page 1 of 1

Now Complete : New Build And New Hinge Technique, Pics Now Added

Now Complete : New Build And New Hinge Technique, Pics Now Added

Hi there. I am in process of building yet again another plank wing profile 1/2a airplane. I will not say what it is until I have pictures. Hopefully this weekend, as I am having camera issues. I had generously received these plans from a member after seeing the plans in another post. I had also mentioned that it was the second in my build queue this winter, but.... Early this week I saw the plans laying there and thought it would be a quick build, so thought why not? But at the time being I have the fuse cut and am working on the cut-outs in it, the wing just needs the bellcrank mount cut and installed, vertical stab is ready, and horizontal stab and elevator are ready for hardware installation. Also, on this build, I had always seen stitched hinges and wanted to try. But after reading about them, I was worried and said I would not do them. So I grabbed some .009 Dacron fishing line, a needle and stitched my hinges anyways. Now the only question I ask is why did nobody ever try stitched hinges years ago?  They went very well in my opinion. I differed a tiny bit from what I had read as to the number of holes, and finishing location. I just wish my stitches looked better, but it was a first, and most definitely will not be a last. Relatively quick, very easy, look alright, line things up great, and offer huge flexibility with no pressure. So thank you to those who have posted about them here, as well as to the others on other sites I have read about them.

They went very well in my opinion. I differed a tiny bit from what I had read as to the number of holes, and finishing location. I just wish my stitches looked better, but it was a first, and most definitely will not be a last. Relatively quick, very easy, look alright, line things up great, and offer huge flexibility with no pressure. So thank you to those who have posted about them here, as well as to the others on other sites I have read about them.

Last edited by NEW222 on Sat Oct 17, 2015 11:09 am; edited 2 times in total

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Ok. Quick question regarding wingtip weight. The plans call for a 1" o.d. washer for wingtip weight. So I Googled washer sizes. There are 2 washers in question. The first is 15/16" o.d., and the second is 1 1/16" o.d.. So, as it is a 1/2 a plane, which would be better to pick up for the weight, assuming they are the same thickness? One site shows them as the same thickness, the other shows the smaller one at a slight bit thinner. Or would this slight difference be negligible? Also included with the plans was a note telling me that it will fly with a Babe Bee, but would haul some rear end with a Black Widow or Golden Bee. I have a Babe Bee, and Black widow that I can use, but I am really hoping that my new parts-built engine will be close to the balance point, as I am loving this engine.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Without the plans it is a little difficult... However typical wingtip weight is 1-2 pennies to a nickle, US currency. A rare number of plans call for more weight up to 1/2 oz (15 g) Coin size fender washers for small screws is a choice instead of actual money.

The washer used is the weight in steel. It isn't a washer in this application, it just happens to look like one. The weight can look like anything you need it to look like.

Phil

The washer used is the weight in steel. It isn't a washer in this application, it just happens to look like one. The weight can look like anything you need it to look like.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

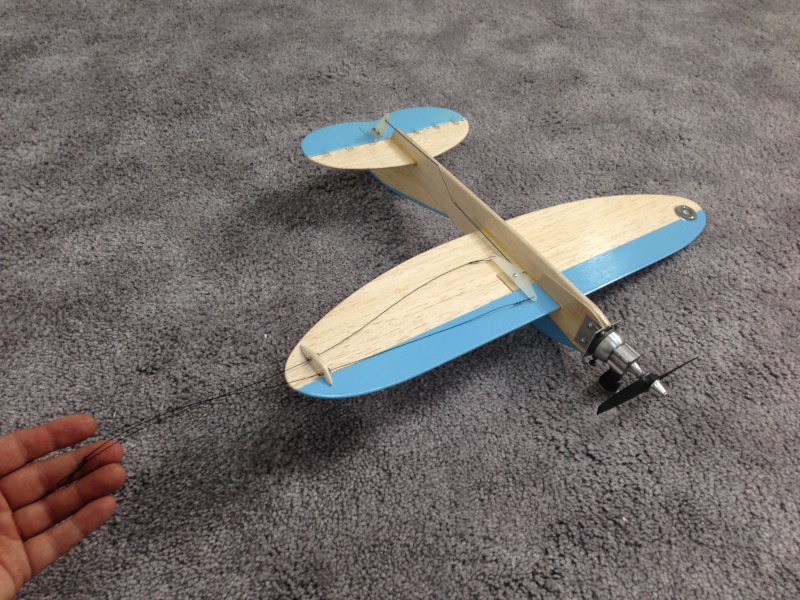

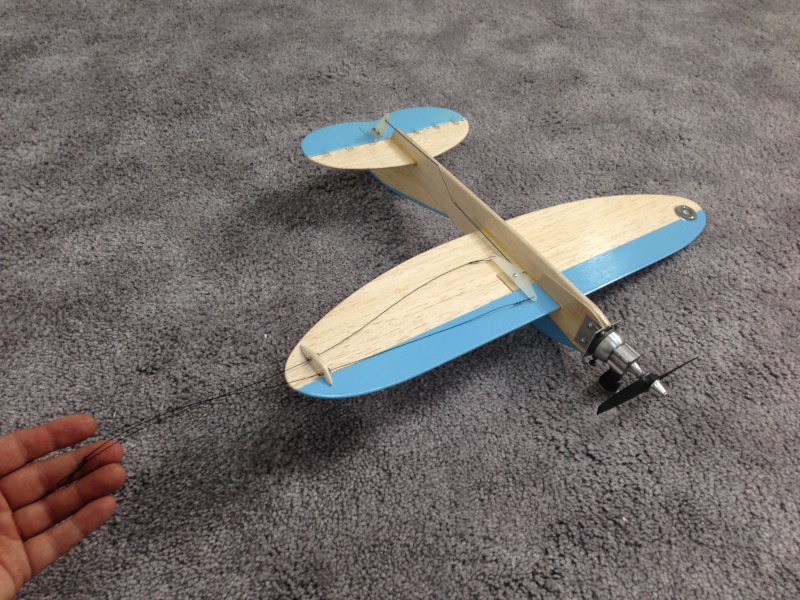

Ok. I just got a couple of pictures of the new bird. And here they are. Also is a picture of my first attempt of figure 8 hinging. This is where it is at currently. My goal is to have the airframe complete with hardware installed, minus the leadouts, by the end of the weekend.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Self-adhesive wheel weights are easy to use and have the weight figures stamped on them

Example:

http://www.amazon.com/Adhesive-Wheel-Balancing-Weights-Strips/dp/B00AKXC54Q

Example:

http://www.amazon.com/Adhesive-Wheel-Balancing-Weights-Strips/dp/B00AKXC54Q

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Don't use the stick on weights by adhesive only. They fly off and can really hurt. True lead weights were to be banned from use in the US. This has been a topic of discussion for several years. If you have them keep them. I prefer them over the ones pictured on the Amazon site as they're not real lead but a coated steel. Real lead weights can be hammered paper thin. One 1/4 oz stick em is 7 grams. 1/2A planes rarely need more than 5 grams of tip weight. Nipping off a portion and hammering the weight paper allows you to mortise out the wing and bury the weight within the planked wing. This can easily be covered with a piece of balsa and sanded flush . This is a very clean install which no one would even know is on the wing. I personally don't like to go through all the work and have a wart like object glued to the wing. Ken

Last edited by Ken Cook on Sat Sep 26, 2015 10:46 am; edited 1 time in total

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Good Looking airplane New222 !! , Keep use updated , I hope you don't have the problem I had with the hinges stiffening up during dope /paint process , your hinges look GOOD , I made the mistake on the Zero (very thin wood) and had to tear it back out . I would have trimmed those platforms for the bellcrank /control horn they look well square ? But that's just me . Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Eric, a simple solution is to edge glue a piece of basswood to the front of the elevator. Not only does this stiffen the elevator it also prevents the thread from tear out as you experienced. In addition, a bowed piece of balsa can be stabilized and straightened by using the piece of bass by opposing bows in both pieces making the elevator serviceable. If your bass is too wide, sanding it down can warp the piece and the use of a razor plane is highly suggested as it makes quick clean work out of stock removal. Edge gluing bass to the leading edge of the wing can also stiffen but most important it prevents hangar rash and dings and dents that balsa can't provide with little weight penalty if a narrow piece is used.This is a common practice I do with hand launch gliders. I glue a piece of 1/16" hardwood around all perimeters. It also adds a very professional look to a clear finish. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Thanks for the compliments. As an update. All hardware is installed for test fitting, and the leadouts are installed on the bellcrank, just not finished on the ends until it is finished. Leadout block is also resting with a clamp on it until dry.

@getback - what did you mean by saying "I would have trimmed those platforms for the bellcrank /control horn they look well square ?" I am curious. Do you mean round them off? If so, yes, I got lazy last night....

@ Ken Cook - I had thought of adding a hardwood LE and TE to the tail surfaces, but since it was my first time I was just happy to try the hinge method. I will definitely think about it on future builds. As this winter, I plan on building a Pinto Stunter, and will most definitely install them on it!

@getback - what did you mean by saying "I would have trimmed those platforms for the bellcrank /control horn they look well square ?" I am curious. Do you mean round them off? If so, yes, I got lazy last night....

@ Ken Cook - I had thought of adding a hardwood LE and TE to the tail surfaces, but since it was my first time I was just happy to try the hinge method. I will definitely think about it on future builds. As this winter, I plan on building a Pinto Stunter, and will most definitely install them on it!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Forgot to add that this is a Fire Baby 2 plane.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Yea that's all just round them or make them that way just to save on a little weight and I think they would look better , but I am not much on one to say I get the same way and don't follow up on what should bee or could be sometime , heck I thought I use to build pretty nice ships but after being on here and seeing what other people do well not so much Blah Blah Fire Baby, cool I new I had seen and remember you talking about it in another thread but couldn't remember the name of the plane .... Thanks Ken I will see if I can find my thin spruce wood and get on with it  Eric

Eric

Eric

Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Ken suggested spruce thin strips and it is great advice

However you can accomplish the same idea with what is on hand or easy to make the size you need

I find that a sheet of 1/64th ply can be used for all sorts of strengthening without a steep weight penalty

I also sand it pretty thin but it still has a harder face than the attached balsa

I also do a lot of wood work with western cedar (a relatively soft wood) and sometimes the table saw gives me a very thin 1"or 2" tall cut off 3 or 4 feet long...I am talking 1/16" or thinner. I have used these strips exactly as Ken suggests and as fuselage rear end quasi doublets. Easy to sand but more dent resistant than the balsa. You could do the same with thin fir and pine strips off a side of a 2X4

However you can accomplish the same idea with what is on hand or easy to make the size you need

I find that a sheet of 1/64th ply can be used for all sorts of strengthening without a steep weight penalty

I also sand it pretty thin but it still has a harder face than the attached balsa

I also do a lot of wood work with western cedar (a relatively soft wood) and sometimes the table saw gives me a very thin 1"or 2" tall cut off 3 or 4 feet long...I am talking 1/16" or thinner. I have used these strips exactly as Ken suggests and as fuselage rear end quasi doublets. Easy to sand but more dent resistant than the balsa. You could do the same with thin fir and pine strips off a side of a 2X4

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Ok. Just as a little update, as I am not sure on how I want to finish this plane, as it sat with all hardware, leadouts, and engine installed, it was right around 4 1/4 oz. I am going to try for a lightweight finish, so again, like my Baby Ringmaster, I am honestly considering a wood finish with a few accent pieces of tissue or marker on it. I like it because it is easy, lighter than my painting talents, as well as I am learning to make nicer builds and like to show them off. As for pictures, not much has changed from the last pictures. I will also only have to glue on my wingtip weight after finishing the model, unless, I do it with some color.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

I had forgotten to ask. What kind of up and down elevator movement should I be looking for on this nice little 1/2a bird? Thank you. I will be able to measure what I am getting tomorrow.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

a aussie 50 cent or 20 cents i used on my plane the same as yours rk flyer sent it to me and it flyes wellNEW222 wrote:Ok. Quick question regarding wingtip weight. The plans call for a 1" o.d. washer for wingtip weight. So I Googled washer sizes. There are 2 washers in question. The first is 15/16" o.d., and the second is 1 1/16" o.d.. So, as it is a 1/2 a plane, which would be better to pick up for the weight, assuming they are the same thickness? One site shows them as the same thickness, the other shows the smaller one at a slight bit thinner. Or would this slight difference be negligible? Also included with the plans was a note telling me that it will fly with a Babe Bee, but would haul some rear end with a Black Widow or Golden Bee. I have a Babe Bee, and Black widow that I can use, but I am really hoping that my new parts-built engine will be close to the balance point, as I am loving this engine.

cox24711- Platinum Member

- Posts : 722

Join date : 2014-01-18

Age : 21

Location : Noosa Queensland Australia

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Thank you cox24711 for that info. I will look up the weight of your currency and work with that, as yours is up and flying.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

The 50c coin Greg spoke about is 0.5 ounces (16 gram) and the 20c is 0.3 ounces (12 gram). I generally use the smaller and it seems adequate. It's around 1 1/8" (28mm) diameter and 3/32" (2mm) thick.

Rod.

Rod.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Thank you, much appreciated. I just have to prep the plane for doping then off to the races we will go, as I do have a washer within the specified weights you mentioned.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

A Little Update

A Little Update

Hi all. I just thought I would give a little update here on the ship. I had put 2 coats of clear dope unthinned on the whole plane and let it dry. I then sanded it with 400 grit dry. I am now at the final stage. I am going to add one color and possibly two. This is where the current problem has rose up. I have never done a dope finish before, with the exception of my Baby Rinmaster which remained all natural woodgrain. Anyways, all dope used on this build is Sig Butyrate Supercoat, clear and color. I am just unsure of which order to apply it to the sanded fuselage. Do I put on my final coat of clear over the whole fuselage first, then my accent and 'artwork' overtop, OR, do my color coats then clear over the whole thing as a final coat? Also, is unthinned better, or would 50/50 be alright? Thanks.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Typically I brush on my initial coats which are thinned out . Reason I do this is that it soaks in and strengthens the balsa. It also raises the grain a bit as well. After the 1st coat, I leave a few hours and try to expedite things and coat again. I leave the plane sit for a day and I use 240 wet dry paper and I use it dry to knock down the plane as it will feel very coarse and sandpaper like. Once the plane is sanded, I wipe off the dust as best as possible with a soft cloth. I coat the plane again with the same thinned material. Brushing fast and continuous strokes not back and forth. Remember to brush off of the work and not into it. Don't puddle dope as this will blister and cause a lot of problems and some that don't make themselves present until you start into the color. Keep it thing building the coats. This can take anywhere from 3-5 coats sanded in between. Once the fuse and or wing appears to be uniform and continuously shiny begin with your color. Use clear as many times as it takes prior to color. It's far lighter than color dope. If you want, I never had great success doing it, but you can add unperfumed talc to your clear constantly stirring it while applying. Once dry and sanded, the smoothness is quickly recognizeable. Sig makes a similar product which they refer to as sanding sealer. It works well but it takes a bit of thinning and a lot of stirring. I typically thin to what I feel is roughly 60/40 for brushing. I keep things a bit thinner 50/50 when spraying.

Any trim should be masked off and the trim side of the tape should be painted down with an additional coat of clear prior to color. If the color is already on and your going to another color, that transition should be masked and once again the side of the tape receiving the new color should be brushed down with a line of clear to prevent bleed under the tape and it also makes a crisp line when the tape is removed. Color can be completed.

Depending on your initial prep, and the continuous sanding that you should've been doing the color coat at this point should look very smooth and shiny. Humidity has a lot to do with the overall shine but as I mentioned Sig dries the slowest and it generally doesn't blush. You can offer more fuel proof qualities and also shine to the finish if you give the model a top coat of clear. Brushing this on however doesn't always offer good results as dope instantly attacks the underlying coats. Spraying it on is the way to go. I have brushed it on, but I only thin the material enough so that when I go back into the work the brush doesn't drag. If you brush the opposing way it will remove the paint you just cleared over. It can be brushed on though but you always need to keep an extremely wet edge and your brush should be loaded with material. You can puddle the dope and brush it out, just not back and forth strokes. having a squirrel hair brush about 1" wide can yield good results. Ken

Any trim should be masked off and the trim side of the tape should be painted down with an additional coat of clear prior to color. If the color is already on and your going to another color, that transition should be masked and once again the side of the tape receiving the new color should be brushed down with a line of clear to prevent bleed under the tape and it also makes a crisp line when the tape is removed. Color can be completed.

Depending on your initial prep, and the continuous sanding that you should've been doing the color coat at this point should look very smooth and shiny. Humidity has a lot to do with the overall shine but as I mentioned Sig dries the slowest and it generally doesn't blush. You can offer more fuel proof qualities and also shine to the finish if you give the model a top coat of clear. Brushing this on however doesn't always offer good results as dope instantly attacks the underlying coats. Spraying it on is the way to go. I have brushed it on, but I only thin the material enough so that when I go back into the work the brush doesn't drag. If you brush the opposing way it will remove the paint you just cleared over. It can be brushed on though but you always need to keep an extremely wet edge and your brush should be loaded with material. You can puddle the dope and brush it out, just not back and forth strokes. having a squirrel hair brush about 1" wide can yield good results. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

15-10-2015 : Ok. Final coat of dope and color were added this evening. Now I just have to wait until Saturday evening to get my hands on a can of clear spray. I will then hopefully spray that Sunday morning. AUW till this evening is at 4 3/4 oz, that is all hardware, motor mount, engine and prop. I hope the Babe Bee will do alright. I just want a nice little relaxing flier.

16-10-2015 : Ok. Well back from outside yet again. I took the advice of a local modeler and went out and bought a can of Minwax Polyurethane Clear today and just sprayed on a coat. I will have to let it sit and dry a bit before assembling the plane. I cannot wait to take a few pictures when it is completed. Anyways, just a little progress update.

16-10-2015 : Ok. Well back from outside yet again. I took the advice of a local modeler and went out and bought a can of Minwax Polyurethane Clear today and just sprayed on a coat. I will have to let it sit and dry a bit before assembling the plane. I cannot wait to take a few pictures when it is completed. Anyways, just a little progress update.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Minwax , weight check and see what it gained after putting that /those coats on I would be curious to see what it is , Cant wait to see her in her finished stage  getback

getback

getback

getback

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Done, finally!

Done, finally!

I am sorry, I did not mark the weight down before completing the finishing. I can now tell you the AUW ready to fly. The final AUW ready to fly is at 4.7 oz. This includes the following. Complete build using carpenters glue, epoxy for the bellcrank and control horn mounting plates, washer wingtip weight is epoxied on, aluminum engine mount with screws, Babe Bee engine with propeller and solid aluminum spinner, control rod, 2 unthinned coats of clear dope, 1 thinned coat of clear dope, 2 coats of colored dope in areas, and one full wet coat of Minwax Polyurethane ClearCoat spray paint, and wire leadouts with brass tubes on wingtip. Overall, I was and am very happy with the Minwax product, although not yet flown. The last weight given was a give or take as it was not fully assembled and included an estimate of the finish, in turn which was lower than my estimate. Here are the final pictures of it. Enjoy.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

Re: Now Complete : New Build And New Hinge Technique, Pics Now Added

SWEET I like the wood finish and the trim just stands out really nice , with that weight you should have enough power with the bee to make some good laps . Hope it flys as well as it looks Thanks , getback

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules