Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

A Quick and Dirty CA Hinge Installation

Page 1 of 1

A Quick and Dirty CA Hinge Installation

A Quick and Dirty CA Hinge Installation

Someone emailed and asked me for some help on CA hinges, so I threw together a little video. I started on it after bedtime, so I just shot it, cut it, and uploaded it fast without adding any title page or captions. Gotta get my beauty rest, y’know…

The Dirty Mark

The Dirty Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Thanks for that Dirty Mark. I liked the way you bent them in the middle, I am going to start doing it that way

akjgardner- Diamond Member

Posts : 1602

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Well done.

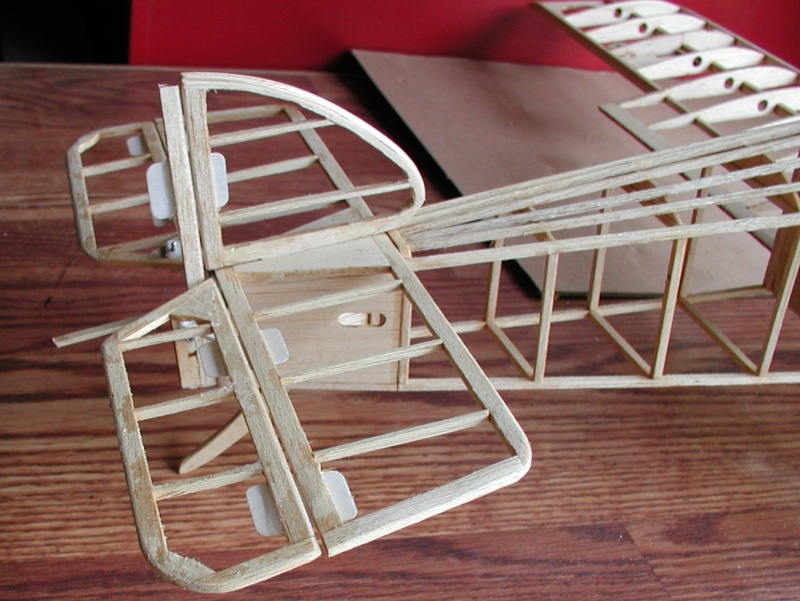

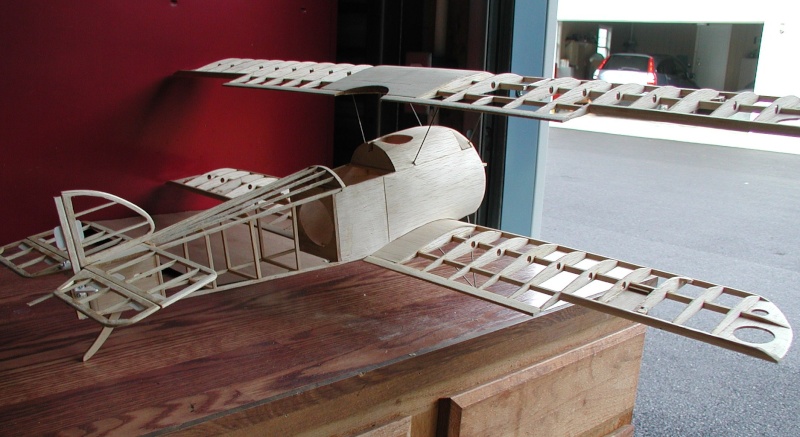

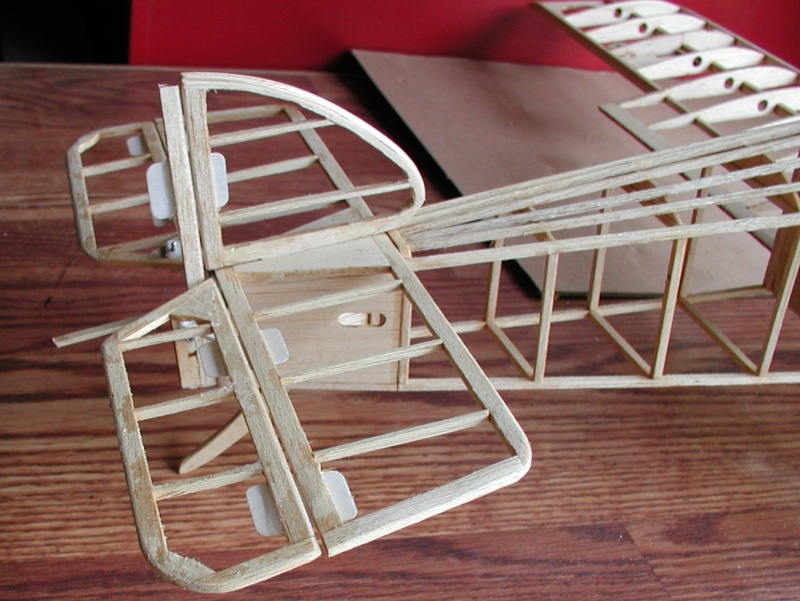

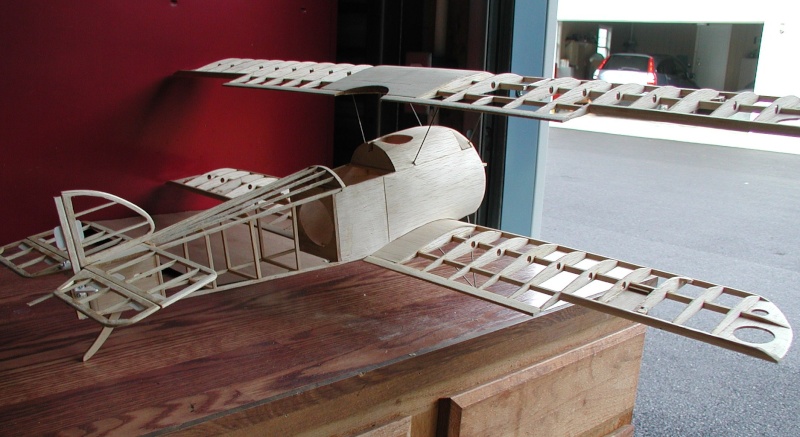

My Camel bought at a flea market has those hinges but are unsecured. I think I will use your system when I get around to finishing it. But, how did you cut the slots?

My Camel bought at a flea market has those hinges but are unsecured. I think I will use your system when I get around to finishing it. But, how did you cut the slots?

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Good video. I like the way you pre - work the hinges.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Ditto that. I've avoided CA hinges like the plague, but I might give them a try now. I think I'll sticky this thread. Ken suggests I use them on the flaps for my current repair. I wish I hadn't already punched holes for stitches. But I may use one at the innermost end of each flap, since there is a wider gap there.akjgardner wrote:Thanks for that Dirty Mark. I liked the way you bent them in the middle, I am going to start doing it that way

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Cutting hinge slots and beveling

Cutting hinge slots and beveling

Thanks for the comments, Guys.

To answer how I cut the slots, I went ahead and did a second vid on slotting and beveling.

Here's a link for the Great Planes tool. The Goldberg tool you'll just have to hope to find on your local hobby shop shelf as NOS.

Hope it helps,

The Dirtier Mark

To answer how I cut the slots, I went ahead and did a second vid on slotting and beveling.

Here's a link for the Great Planes tool. The Goldberg tool you'll just have to hope to find on your local hobby shop shelf as NOS.

Hope it helps,

The Dirtier Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Thanks Mark , That's the way a friend I was building /flying with years ago had showed me and I had forgot how to wick the CA bend and exercise , after I had heard so many on here say that it would stiffing the hinge unusable . I will have to give this a try again // stitched hinges are nice but ... take time and sometimes I just don't have it for building // we never taped over but did mono-cote yes it was larger RC planes 40 size

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Good techniques, thanks for the share.

PeterJGregory- Gold Member

- Posts : 144

Join date : 2014-07-28

Age : 61

Location : Hudson Valley, New York

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

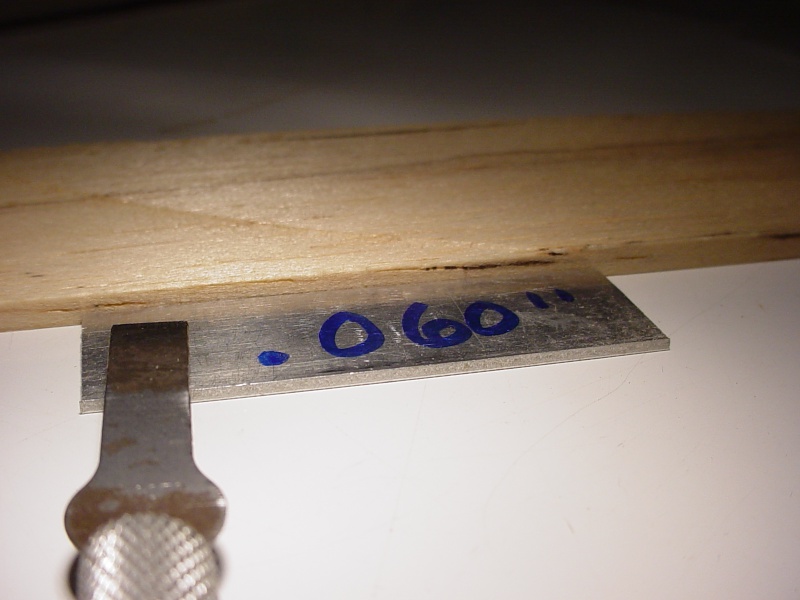

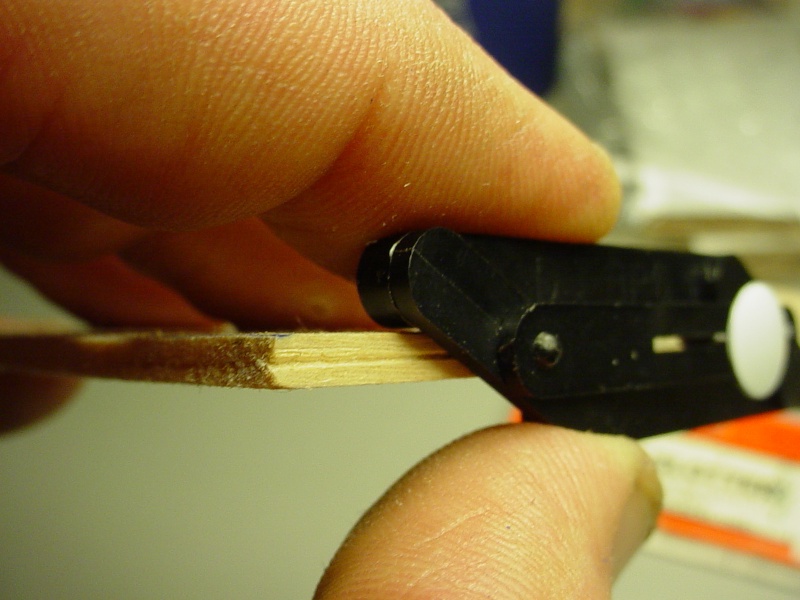

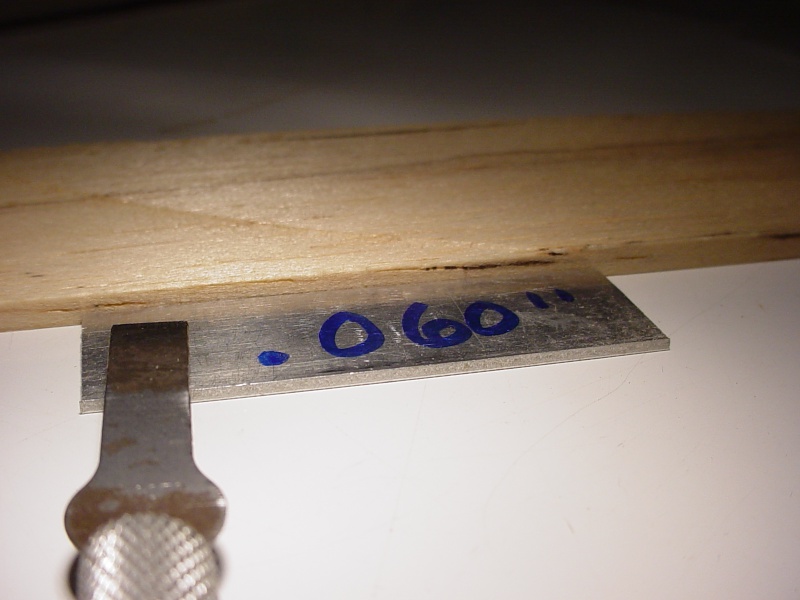

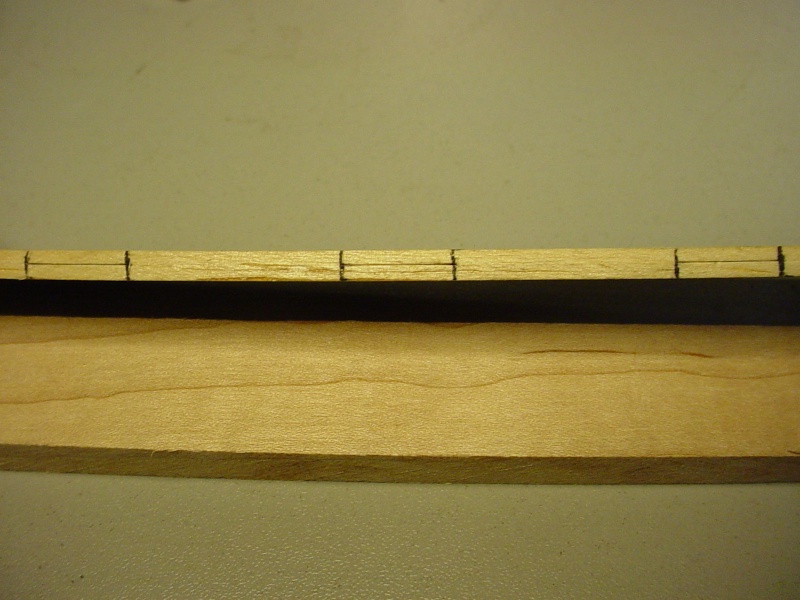

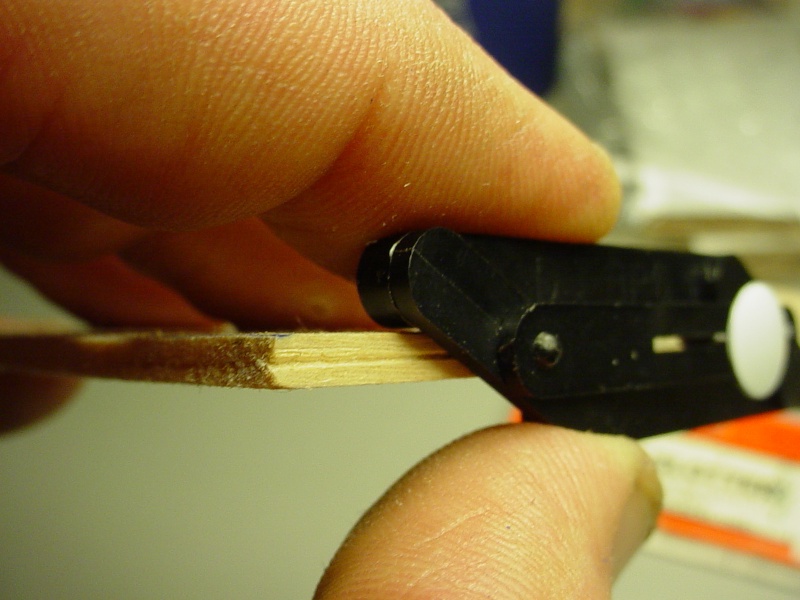

Those are cool tools. I cut my 1/2A hinge slots with an X-acto knife too.. and have been using Sig Easy-Hinges. I use the #17 chisel blade and a "step-plate" at the edge of a table-top. The #17 blade is 1/4"w. This photo shows a piece of 1/8" balsa. I find/make a small rectangular step-plate (approx. 1/2" x 2") from 1/16" thickness stock. Could be plywood, plastic/laminate or in my case I had .060" aluminum handy. I place it at the edge of a tabletop with the balsa behind it and sometimes a fence clamped behind the balsa. It gauges to the center perfectly and guides the blade into the edge squarely. The blade is positioned on the step-plate with the ground bevel on it's end, facing up. Working off the edge of a table keeps the knife's collet/handle from contacting the work. I use my left hand to firmly hold the work-piece down.. and my right hand for exerting firm finger-pressure on the blade, which holds it down and keeps it square. A careful rocking/pushing action into the wood takes just seconds to complete. The #17 blade is long-enough to make a deep slot.. and you can mark the blade for depth of cut too. Marking the "up" side of the blade also helps prevent from using the wrong side. You want to see the chisel's bevel facing up.. or else the slot will be off-center.

For comparison.. the #18 chisel blade is 1/2"w. and fits the larger collets/handles. 1/2" is much wider than I cut my hinges. I typically cut mine 1/4" to 5/16"w. x 1" long and round the edges like Mark does.

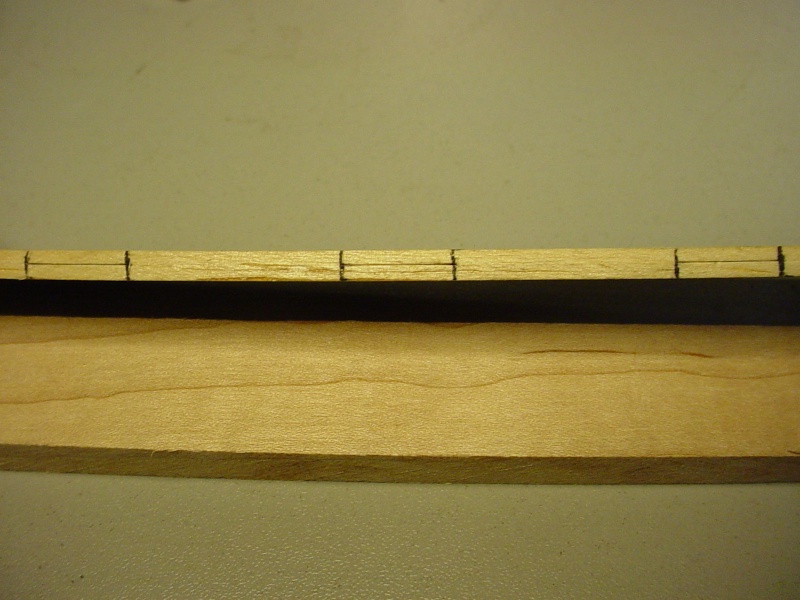

I just made this example with the wider #18 blade this morning. It took longer to post one pic than it did to cut three slots. I used a maple strip for a backing-fence.. C-clamped to the tabletop, which helps keep my concentration more on the hand doing the cutting. I had to shim-up my step-plate with tape on the bottom, to equal 1/2 the thickness of this particular piece of balsa stock. It's well worth the effort to make a good set-up. Most often.. a 1/16" thick plate is going to be perfect for 1/8" balsa.

Just another way to do it.. I like Mark's Goldberg tool for tapering. The Dubro hinge-slotting tool can be used to scribe the center of an edge up to 1/2" thick. A thumbtack fits snug in the slot of either of the two slotted attachments.

This qualifies as "quick and dirty" I think.

I've wanted to make a V-angle sanding block for tapering. My thoughts are using two 36" lengths of 3/4" light-gage aluminum angle-stock with abrasive paper on the outside face(s). The pair would fit (angles facing up) into a 36" long groove/slot cut in a board with end-blocks to keep them from sliding. A slot would support the whole length of the angle-stock. The outside of the angles can be shimmed-up with blocks, to establish the taper you desire.

For comparison.. the #18 chisel blade is 1/2"w. and fits the larger collets/handles. 1/2" is much wider than I cut my hinges. I typically cut mine 1/4" to 5/16"w. x 1" long and round the edges like Mark does.

I just made this example with the wider #18 blade this morning. It took longer to post one pic than it did to cut three slots. I used a maple strip for a backing-fence.. C-clamped to the tabletop, which helps keep my concentration more on the hand doing the cutting. I had to shim-up my step-plate with tape on the bottom, to equal 1/2 the thickness of this particular piece of balsa stock. It's well worth the effort to make a good set-up. Most often.. a 1/16" thick plate is going to be perfect for 1/8" balsa.

Just another way to do it.. I like Mark's Goldberg tool for tapering. The Dubro hinge-slotting tool can be used to scribe the center of an edge up to 1/2" thick. A thumbtack fits snug in the slot of either of the two slotted attachments.

This qualifies as "quick and dirty" I think.

I've wanted to make a V-angle sanding block for tapering. My thoughts are using two 36" lengths of 3/4" light-gage aluminum angle-stock with abrasive paper on the outside face(s). The pair would fit (angles facing up) into a 36" long groove/slot cut in a board with end-blocks to keep them from sliding. A slot would support the whole length of the angle-stock. The outside of the angles can be shimmed-up with blocks, to establish the taper you desire.

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Just a note to say....CA hinges are NOT the best way for Control line models as they are way too stiff

I admit I like them for servo controlled surfaces but prefer MUCH loser hinges for CL models....favoring sewn or pre-made barrel hinges... I even make my own barrel hinges frequently from CF rod and CF tube but it is an acquired technique

and the tried and true method of a brass / aluminium tube with piano wire pin works well with zero stiffness

OTOH this set of posts are excellent ways to locate and use the danged things

again not Poo Pooing the methods of using the CA hinges....just that they are usually too stiff for 1/2a use IMO

I admit I like them for servo controlled surfaces but prefer MUCH loser hinges for CL models....favoring sewn or pre-made barrel hinges... I even make my own barrel hinges frequently from CF rod and CF tube but it is an acquired technique

and the tried and true method of a brass / aluminium tube with piano wire pin works well with zero stiffness

OTOH this set of posts are excellent ways to locate and use the danged things

again not Poo Pooing the methods of using the CA hinges....just that they are usually too stiff for 1/2a use IMO

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

I agree Fred. I used to use the small Dubro pinned-hinges.. but they took a lot of time and care not to break-through a 1/8" thick control surface using their hinge-slotting tool and wood pick. They do however permit the elevator/flap (sans linkage) to deflect downward with gravity alone. A CA hinge is not going to do that. As I mentioned for 1/2A size airplanes.. I cut the CA hinges to about 1/4" width.. and I'm careful not to use more than needed to get the job done. They're QUICK.. when compared to most other methods of hinging. I need all the help I can get when it comes to cutting down on building time!

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Roddie said "I need all the help I can get when it comes to cutting down on building time! Laughing

"

could not agree more...been working off and on with 5 simultaneous builds since last September and just now starting the covering

My production line method did not work out as planned

I must have missed the cut down to smaller (reading too fast some days.) but I can see where that technique would work fine for many 1/2a models with the CA hinges

"

could not agree more...been working off and on with 5 simultaneous builds since last September and just now starting the covering

My production line method did not work out as planned

I must have missed the cut down to smaller (reading too fast some days.) but I can see where that technique would work fine for many 1/2a models with the CA hinges

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

CA Hinges

CA Hinges

Thanks Mark, just in time for the Flite Streak FredVon sold me.

Randy

Randy

musman69- Moderate Poster

- Posts : 19

Join date : 2021-11-17

Age : 70

Location : Rosharon TX

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Thanks Mark.

Excellent Vid!!

We all have our preferences and I fight shy of the CA hinge as they can be a little stiff if the glueing is over done.

For 1/2A control line and similar small models I prefer the very old fashioned method.

In the old kits decades ago we used to get a 1/2" strip of cotton banding which we had to cut to 1" lengths and to use circa three pairs of hinges for each half of the elevator.

The pieces were glued on with balsa cement so one hinge would be made thus......

Cement one half of the hinge to the top of the elevator stab.

Feed it underneath the hinge line and glue the other half to the elevator.

Cement the other half of the hinge to the bottom of the elevator stab, feed it through the hinge line and cement to the top of the elevator and adjacent to the first half of the hinge.

When all hinges are in place, rub balsa cement over them with the finger to seal them.

Wait 5 minutes and enjoy chewing the balsa cement off the fingers and spitting it off!!!

Remember that boys????.......Oh what fun.

I do not think we can get that tape any more so I use 1/4" strips of kite nylon which is super strong.

These hinges allow the elevator to drop by gravity and it will bend 180 degrees back on itself either way.

Super free movement.

But I am an oldie and set in my ways by these old methods.

Excellent Vid!!

We all have our preferences and I fight shy of the CA hinge as they can be a little stiff if the glueing is over done.

For 1/2A control line and similar small models I prefer the very old fashioned method.

In the old kits decades ago we used to get a 1/2" strip of cotton banding which we had to cut to 1" lengths and to use circa three pairs of hinges for each half of the elevator.

The pieces were glued on with balsa cement so one hinge would be made thus......

Cement one half of the hinge to the top of the elevator stab.

Feed it underneath the hinge line and glue the other half to the elevator.

Cement the other half of the hinge to the bottom of the elevator stab, feed it through the hinge line and cement to the top of the elevator and adjacent to the first half of the hinge.

When all hinges are in place, rub balsa cement over them with the finger to seal them.

Wait 5 minutes and enjoy chewing the balsa cement off the fingers and spitting it off!!!

Remember that boys????.......Oh what fun.

I do not think we can get that tape any more so I use 1/4" strips of kite nylon which is super strong.

These hinges allow the elevator to drop by gravity and it will bend 180 degrees back on itself either way.

Super free movement.

But I am an oldie and set in my ways by these old methods.

Woody- Gold Member

- Posts : 133

Join date : 2022-04-20

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

I used CA hinges only once and don't care for them. I prefer pinned hinges and I glue them in place with white glue. Should any glue get into the hinge line it easily breaks away when the hinge is flexed. I've never had one come loose.

I usually remove the factory pin and replace it with a thin piano wire that goes through all of them.

This facilitates repair or recovering should you ever have a crash.

I usually remove the factory pin and replace it with a thin piano wire that goes through all of them.

This facilitates repair or recovering should you ever have a crash.

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Some CA hinges are garbage...the ones that have the fuzzy outer layer seperate from the inner smooth layer delaminate. These are the ones that need to be pinned.

Another problem is using too much CA..then having the hinge material get brittle and fail.

If I'm building a .40 sized rocket...then pinning is a must..but I pin these hinges for 1/2A flight loads mainly due to paranoia and the fact that pinning is easy to do.

I probably pinned these hinges.....but I'm not sure...

https://youtu.be/lcRfpaS7rdE

Another problem is using too much CA..then having the hinge material get brittle and fail.

If I'm building a .40 sized rocket...then pinning is a must..but I pin these hinges for 1/2A flight loads mainly due to paranoia and the fact that pinning is easy to do.

I probably pinned these hinges.....but I'm not sure...

https://youtu.be/lcRfpaS7rdE

TD ABUSER- Gold Member

- Posts : 410

Join date : 2020-11-01

Age : 69

Location : Washington

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

I confess, I like the CA hinges, but have had some break after extensive use.

My approach:

1. Slot the surface and drill a hole centered where the hinge will be inserted.

2. Insert the hinge, but don't drill it. Add CA to the hole; with the hinge intact, CA will wick out from the center to the edges, but not to the hinge line. Add CA to both sides.

3. Once cured, now drill through the hinge and pin. (toothpick or bamboo skewer)

My approach:

1. Slot the surface and drill a hole centered where the hinge will be inserted.

2. Insert the hinge, but don't drill it. Add CA to the hole; with the hinge intact, CA will wick out from the center to the edges, but not to the hinge line. Add CA to both sides.

3. Once cured, now drill through the hinge and pin. (toothpick or bamboo skewer)

Alternate Hinge

Alternate Hinge

I have used house wrap material, often called Tyvek, for hinges. Cheap and easy to get. Usually free at the dumpster of new house builds. They are very flexible. I have had them break when impacting the ground.

I have used them in rudder and elevator applications.

I have used them in rudder and elevator applications.

SABOO- Moderate Poster

- Posts : 10

Join date : 2019-10-03

Location : HALIFAX NS

Re: A Quick and Dirty CA Hinge Installation

Re: A Quick and Dirty CA Hinge Installation

Having tried various hinge material options while sometimes excessively splitting thin control surfaces when tucking in usual hinges, I arrived at my best option, which is hinges cut from large soda bottles aka PET bottles. (Large bottles are preferred whose cylinder shell has large bending radius and the hinge cut from it is practically flat).Thin, strong, durable and flexible, these hinges will slide easily into small slots cut in thin balsa rudders, elevators and ailerons of even my micro RC planes. Even without fixing them with CA glue they will stay put after I add Scotch tape to overlap the edges on both sides of the control surface along the full length, or, only where the hinge sits.

(Skotch tape overlapping the full length of the gap between control surfaces will improve control effect by preventing part of the air from escaping from the surface through the gap, also making vortices on the other side)

Because they flex like flat spring sheets, they help the servo return the control surface into neutral position when the respective joystick on the radio is released.

(Skotch tape overlapping the full length of the gap between control surfaces will improve control effect by preventing part of the air from escaping from the surface through the gap, also making vortices on the other side)

Because they flex like flat spring sheets, they help the servo return the control surface into neutral position when the respective joystick on the radio is released.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Similar topics

Similar topics» The Dirty Duo

» Finally got er' dirty!

» Looking for a dirty old prop rod.

» Canadian Variant P-51 Build

» FF trim tab 'hinge'

» Finally got er' dirty!

» Looking for a dirty old prop rod.

» Canadian Variant P-51 Build

» FF trim tab 'hinge'

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules