Log in

Search

Latest topics

» TEE DEE Having issuesby Ken Cook Today at 7:10 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

slab-wing/built-up construction

Page 1 of 1

slab-wing/built-up construction

slab-wing/built-up construction

Here's a method I have used on a couple of small models. It's unorthodox.. and involves a little work.. but less time than scratch-building an airfoil/ribbed-wing. You can use narrow strips of 1/8" balsa.. preferably span-length. (You probably have enough laying around to try it..)

I lay-out a sheet of wax paper on a good flat surface to work on, and use thin CA which will not stick to it. The frame consists of leading/trailing edge pieces with perpendicular pieces tying the two together to establish the chord. These pieces must be cut squarely. Cut the two tip-braces 1st.. and CA-glue them to the L/E and T/E to form the overall wing perimeter. Then piece-in the remaining ribs to fit snug between the L/E and T/E. You can strengthen the structure with gusseting and also by using span-wise strips of 1/8" x 1/2" Spruce and scrap-wood.. Use your imagination.

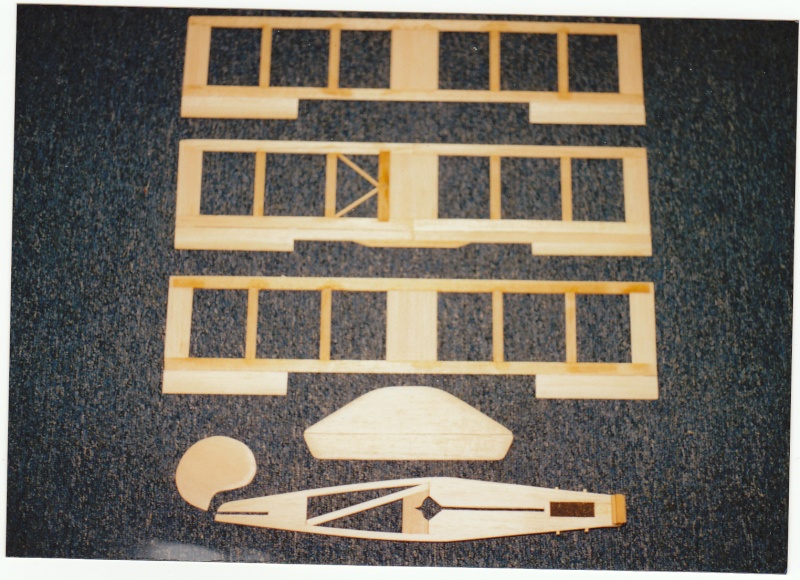

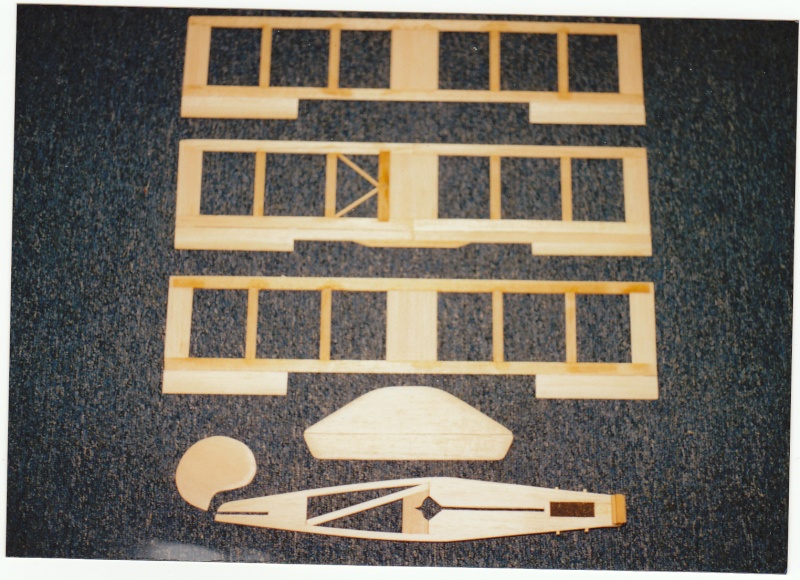

Here's a tri-plane that I designed, which shows this construction.

The fuse also utilized a built-up technique. Cover with iron-on (I used Top-Flite Mono-Kote) and had no issues with warping.. even after 25 years.

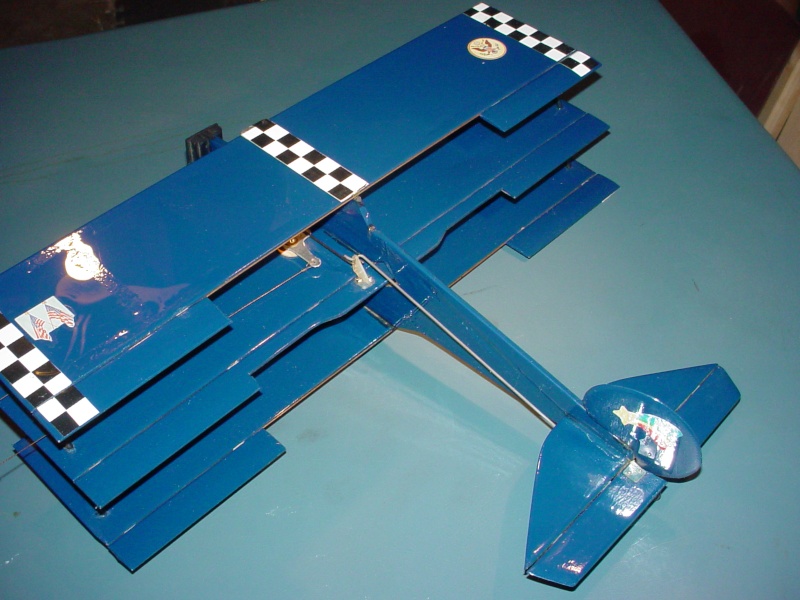

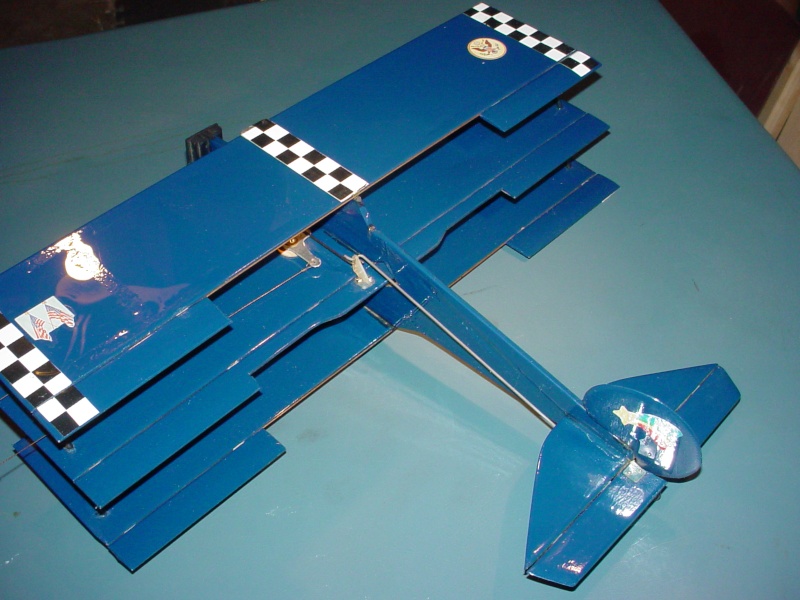

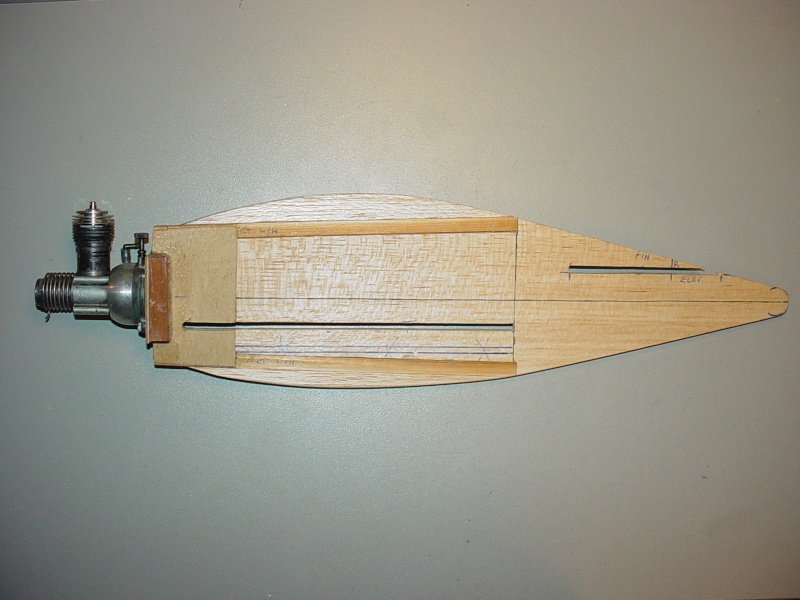

This "Custom Stunter" (below) was built in 1993 and uses the same type of wing/fuse construction. It's a little big for the reed-valve Cox .049 I designed it for.. (24" span/5.5" constant-chord for an approx. 132 square-in. wing) but it's weight is not bad. That's 7.25 oz. dry, with engine, and gear/wheels. This fuse design incorporates 1/4" x 1/4" spruce rails from nose to tail.. which would accommodate beam-mounting a medallion or Tee Dee for extra power. (I have plans drawn for these two models)

Here's a backlit shot, showing the internal framework of the wing.

Below is a shot of the tri-plane's weight without the engine installed. 5.9oz... All three wings are 20" span/4" chord.

These two models have been flown.. but neither have been crashed.. so I can't speak for the integrity of this type of wing construction.. but it is something to try.. and as I stated; is resistant to warping and is lighter than a solid-slab wing. Two strips of 1/8" x 1/2" x 36" balsa would build a 1/2A slab-wing. Your stabilizer could use the same construction too.. if it's area is enough to warrant it.

I lay-out a sheet of wax paper on a good flat surface to work on, and use thin CA which will not stick to it. The frame consists of leading/trailing edge pieces with perpendicular pieces tying the two together to establish the chord. These pieces must be cut squarely. Cut the two tip-braces 1st.. and CA-glue them to the L/E and T/E to form the overall wing perimeter. Then piece-in the remaining ribs to fit snug between the L/E and T/E. You can strengthen the structure with gusseting and also by using span-wise strips of 1/8" x 1/2" Spruce and scrap-wood.. Use your imagination.

Here's a tri-plane that I designed, which shows this construction.

The fuse also utilized a built-up technique. Cover with iron-on (I used Top-Flite Mono-Kote) and had no issues with warping.. even after 25 years.

This "Custom Stunter" (below) was built in 1993 and uses the same type of wing/fuse construction. It's a little big for the reed-valve Cox .049 I designed it for.. (24" span/5.5" constant-chord for an approx. 132 square-in. wing) but it's weight is not bad. That's 7.25 oz. dry, with engine, and gear/wheels. This fuse design incorporates 1/4" x 1/4" spruce rails from nose to tail.. which would accommodate beam-mounting a medallion or Tee Dee for extra power. (I have plans drawn for these two models)

Here's a backlit shot, showing the internal framework of the wing.

Below is a shot of the tri-plane's weight without the engine installed. 5.9oz... All three wings are 20" span/4" chord.

These two models have been flown.. but neither have been crashed.. so I can't speak for the integrity of this type of wing construction.. but it is something to try.. and as I stated; is resistant to warping and is lighter than a solid-slab wing. Two strips of 1/8" x 1/2" x 36" balsa would build a 1/2A slab-wing. Your stabilizer could use the same construction too.. if it's area is enough to warrant it.

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

That is a good idea. I do like it. I really like the looks of the sheet wing stunter you drew up. Have you tried using dope on the wings or other built up structures?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

NEW222 wrote:That is a good idea. I do like it. I really like the looks of the sheet wing stunter you drew up. Have you tried using dope on the wings or other built up structures?

Nope on the dope.. I've only used Mono-Kote. If I were to build the Stunter again for reed-valve, I'd scale the design down some.. probably to 20" span and 5" chord making for a 100 sq. in. wing. Maybe shorten the tail-moment a bit too.

Dumb Question

Dumb Question

What is the main point of dope?

AUjack2003- Silver Member

- Posts : 76

Join date : 2015-07-20

Age : 21

Location : Noosa, Queensland, Australia

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

Usually for applying silk to the rib wings to adhere to surface and tighten , also fuel proofing , Very light weight stuff can bee used for a light weight aircraft .

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

Hi Jack ( and I am briefly going to hijack Roddie's excellent post on his method of built up slab wings)

DOPE is just one of several methods used for covering and finishing a model

There are basically two types, Nitrate and Buyrate Dope (actually there are many other sub classes with different properties but basically we use these two "TYPES")

There are variations but you must remember Butyrate OVER Nitrate never the other way

Of the two, Butyrate dope is referred to a HOT FUEL PROOF and is more or less resistant to deterioration when we get raw fuel and exhaust residue on the model. That said it is still important to clean off any spillage or exhaust as soon after flying as possible because even a dope finish can soften if the fuel is left on the plane

A raw wood model airplane needs to be completely sealed so the oil and fuel does not soak into the wood and make it very heavy, and weaken glue joints

One method is to paint the entire plane with Nitrate dope first and cover it with tissue (a very light paper that is a lot like the wrapping you see on gifts), or real silk, or man made covering like polyspan (there are many others)

When you prep the wood first with Nitrate then when you put on the tissue or silk we use Nitrate OR Butyrate dope to make the covering "glue" down to the wood. The dope on the top of the covering flows into the tissue or silk and softens the dope on the wood and then they both dry and bond.

Some DOPE shrinks a lot and some is designed to not shrink too much but they all SHRINK and we use this property to make the covering say on the wing, tauten, and keep the covering nice and tight

Look around this site and other places like stunthanger, RC groups, RC universe and learn all you can about finishing a model airplane

At your age I would recommend newer easier man made iron on coverings. The learning curve is much easier, they are cheaper, and the smells more agreeable to your parents...dope is bad to to breath, and it smells very bad in a house

DOPE is just one of several methods used for covering and finishing a model

There are basically two types, Nitrate and Buyrate Dope (actually there are many other sub classes with different properties but basically we use these two "TYPES")

There are variations but you must remember Butyrate OVER Nitrate never the other way

Of the two, Butyrate dope is referred to a HOT FUEL PROOF and is more or less resistant to deterioration when we get raw fuel and exhaust residue on the model. That said it is still important to clean off any spillage or exhaust as soon after flying as possible because even a dope finish can soften if the fuel is left on the plane

A raw wood model airplane needs to be completely sealed so the oil and fuel does not soak into the wood and make it very heavy, and weaken glue joints

One method is to paint the entire plane with Nitrate dope first and cover it with tissue (a very light paper that is a lot like the wrapping you see on gifts), or real silk, or man made covering like polyspan (there are many others)

When you prep the wood first with Nitrate then when you put on the tissue or silk we use Nitrate OR Butyrate dope to make the covering "glue" down to the wood. The dope on the top of the covering flows into the tissue or silk and softens the dope on the wood and then they both dry and bond.

Some DOPE shrinks a lot and some is designed to not shrink too much but they all SHRINK and we use this property to make the covering say on the wing, tauten, and keep the covering nice and tight

Look around this site and other places like stunthanger, RC groups, RC universe and learn all you can about finishing a model airplane

At your age I would recommend newer easier man made iron on coverings. The learning curve is much easier, they are cheaper, and the smells more agreeable to your parents...dope is bad to to breath, and it smells very bad in a house

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Slab / Built up wings

Slab / Built up wings

Hi Roddy,

I really like your idea of a built up wing for 1/2A planes, so much that I am going to build my version of the "All American"! Its scaled down a little from the original 09 sized plane. The new wing will be 24" x 5"- 120 sq.in. I 'll also use a profile fuse instead of the built up version. I plan on using a Gold Bee for power.

Thanks again, RK Flyer

I really like your idea of a built up wing for 1/2A planes, so much that I am going to build my version of the "All American"! Its scaled down a little from the original 09 sized plane. The new wing will be 24" x 5"- 120 sq.in. I 'll also use a profile fuse instead of the built up version. I plan on using a Gold Bee for power.

Thanks again, RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

RK Flyer wrote:Hi Roddy,

I really like your idea of a built up wing for 1/2A planes, so much that I am going to build my version of the "All American"! Its scaled down a little from the original 09 sized plane. The new wing will be 24" x 5"- 120 sq.in. I 'll also use a profile fuse instead of the built up version. I plan on using a Gold Bee for power.

Thanks again, RK Flyer

Hi Richard! Good to hear from you! I'm actually surprised that this topic has gotten some interest.. but I'm happy that you're going to give it a try. I plan to try this method on at least one of the four 1/2A plans that you mailed to me last year! I may need to very slightly shorten the tail-moments.. because this method does produce a lighter wing. If you're building a mono-plane.. I would recommend incorporating a spruce spar; butt-jointed behind the leading edge. For example; if you're building a 1/8" slab-wing; you might want to back-up the L/E with a strip of 1/8" x 1/2" spruce, to stiffen it up. You can use a scrap piece of the spruce; chord-wise.. near the inboard root, for a bell-crank mount, supported by gussets.. or construct the center of the wing panel, using 1/8" plywood running through the joint in the fuselage. Either way, it provides a good strong bell-crank mount.

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

That is Sweet Roddie , looks like you monakote the whole thing ? Were the flight charastics in between slab and air foil ?

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

I've used this on empannage parts for RC glider rebuilds. The weight saving is pretty helpful, as is the MATERIAL savings. It is pretty awesome to build a tail assembly from scraps without fuss!

I have never tried it for a slab main wing.

I have never tried it for a slab main wing.

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

as a kid i built quite a few rubber band powered models (mostly peanut scale). every bit of those things was built that way and then tissue covered. i would imagine being covered with monokote creates a stronger, much lighter rigid wing.

very cool!! had to save a lot of weight on that tripe

very cool!! had to save a lot of weight on that tripe

rogermharris- Platinum Member

- Posts : 503

Join date : 2015-03-17

Age : 61

Location : Long Branch, New Jersey

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

getback wrote:That is Sweet Roddie , looks like you monakote the whole thing ? Were the flight charastics in between slab and air foil ?

Hi Eric, It's still a slab-wing.. so it's got that same feel.. except you're saving a little weight. A lighter model is going to respond better to your control inputs. Yes; the wing is all mono-koted with this method. I don't know how other iron-on products would work though. The MOST important thing; is to build accurate, perpendicular joints into the structure.. because they're butt-jointed and they need to fit "nice-nice"..

Roger, the tripe's wings are built entirely of 1/8" balsa sheet.. except for the bell-crank mount on the center-wing; which is 1/8" x 1/2" spruce with gussets running inboard for support. I used 3/16" diameter hardwood dowels for struts, which tie the three wingtips together. A "mono-plane" should incorporate a hardwood strip-spar to stiffen-up the wing. This is very important.. because of the fragile construction. A "hard" landing could snap the wing at it's root without one. You can get creative with your choice of spar materials. Whatever you use, is only going to be a small percentage of the wing's area.. so we're only talking "grams"; as far as weight is concerned. Set your table-saw's ripping-fence to the required thickness.. (1/8" in our case here..) and carefully feed a span-length piece of 1/2" or thicker hardwood through.. and you've made your strip-spar. Remember this when you're throwing away an old piece of hardwood furniture.. like an old bureau. Hardwood panels can be ripped-down on a table-saw to provide all sorts of useful model stock. One single panel from a maple drawer could provide a lifetime of beam-style engine mounts!

Slab wing / Built up

Slab wing / Built up

Roddie,

I am getting ready to build and I was wondering if anyone has tried drilling 2"- 3" holes in a solid wing then covering with Mono Kote or something similar?

RK Flyer

I am getting ready to build and I was wondering if anyone has tried drilling 2"- 3" holes in a solid wing then covering with Mono Kote or something similar?

RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

I think I might try that idea of making a triplane. But first I'd better get my skills up with scratch building.

AUjack2003- Silver Member

- Posts : 76

Join date : 2015-07-20

Age : 21

Location : Noosa, Queensland, Australia

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

RK Flyer wrote:Roddie,

I am getting ready to build and I was wondering if anyone has tried drilling 2"- 3" holes in a solid wing then covering with Mono Kote or something similar?

RK Flyer

Yes. I have done that as a method of making lighter for a plane that built overweight and out of balance. I removed crazy material from behind the CG. I would have been better to custom build a slab wing.

The plane was a white lightening when I started.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: slab-wing/built-up construction

Re: slab-wing/built-up construction

pkrankow wrote:RK Flyer wrote:Roddie,

I am getting ready to build and I was wondering if anyone has tried drilling 2"- 3" holes in a solid wing then covering with Mono Kote or something similar?

RK Flyer

Yes. I have done that as a method of making lighter for a plane that built overweight and out of balance. I removed crazy material from behind the CG. I would have been better to custom build a slab wing.

The plane was a white lightening when I started.

Phil

Interesting! The White Lightning was one of the four plans that Richard mailed to me!

Surely you can drill lightening holes.. anywhere you need to, in order to balance. We often use a different engine for a model that was "optimized" for a certain power-plant of the era that the airframe was designed. Modern engines of the same recommended displacement, tend to be much lighter; creating balance issues with a vintage airplane design. You can easily extend the length of the nose-moment slightly.. during the building of a profile fuse.. and trim it back after finish.. to balance your engine/fuel tank placement.

Scratch-building my own designs is something that I've always enjoyed. They'll always fly and be controllable.. as long as they're not tail-heavy. It all depends on what you want the model to do. If you're looking for aerobatic performance.. then the balance has to be spot-on.

The whole idea of this flat-frame construction is to save on weight.. and materials too. We're talking SMALL airplanes here.. 1/4A to 1/2A size.. 16" to 20" wingspans. There's no sense in using solid 2" to 3" balsa sheet; butt-jointed to build a slab-wing.. only to end up having to core it with lightening holes, in order to balance it.

The profile fuse is another area where you can get really creative. Conventionally; it's usually a solid sheet of 1/4" balsa for your average 1/2A kit. You've probably got lots of 1/4" balsa cut-offs in your balsa scrap-stock box (I do..) Try making a framed-fuse; the same as this wing construction. The fuse is not subjected to the same forces as a wing is. If you're skeptical about this.. then use 1/4" square-spruce/hardwood for the perimeter of your fuse-frame.. and use cored-pieces of 1/4" balsa for filler-pieces. It will require a skin.. but so will the wing. When it's finished, it won't show .. and it will be lightweight and rigid.

Here's a couple photos of how I used hardwood to strengthen the slab-wing and profile fuse on my speed-model. If you're building a scale-design that has wing-mounted gear.. then this really helps to strengthen the wing-root against the shock of a hard landing.

I'm not sure what type of wood I used.. but it's HARD.. and it has some serious load-carrying properties. It's just a "strip" though.. so I'm not adding a lot of weight.

This fuse has 1/4" square spruce rails top and bottom.. from nose to back far beyond where nose-doublers would extend. This is a speed model.. so I wasn't overly concerned with weight.. but it's very strong. If you notice; I built-in the hardwood "rails" first.. (simple parallel beams with conventional plywood nose-doublers) and finished the top/canopy and bottom/belly contours with 1/4" sheet balsa.

Similar topics

Similar topics» balsa slab-wing 1/2A U-Control

» Plans for my latest scratch designed and built half-A profile Slab Plane

» flat framed construction

» Curious Wing Construction - Fairchild 24, Del Gatto on Outerzone

» Carl Goldberg Stuntman

» Plans for my latest scratch designed and built half-A profile Slab Plane

» flat framed construction

» Curious Wing Construction - Fairchild 24, Del Gatto on Outerzone

» Carl Goldberg Stuntman

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules