Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Scorpion - Simple trainer build

Page 1 of 2

Page 1 of 2 • 1, 2

Scorpion - Simple trainer build

Scorpion - Simple trainer build

OK, here is my first ever C/L build project

It all begun about 6 months ago when I stumbled upon my old Babe Bee engine from the early '80s. Back then I did not have much success getting it to run, so it has very little run time on it. A few minutes in total maybe. Now, some 30 years later, RC planes run on batteries, but I thought I should finally get my old Babe Bee up in the air and so I figured, why not try control line in true Cox tradition. Shortly after that I found this forum, got really into Cox engines and now I am a proud owner of a bunch of them. Here is my current fleet, minus my original Babe.

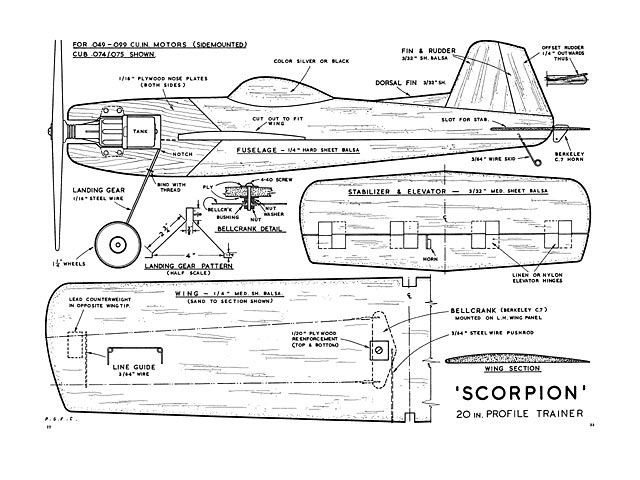

The model I have selected is "Scorpion", an all-sheet design from mid '50s. I modified the plan a little, as the original is for a beam-mount engine and the Babe Bee obviously has the back plate mount. I was looking for an "easy to build, hard to break" design since I have never flown a C/L and I most likely won't have an instructor available for the first flights (I am an optimist,hence the plural on the flightS ). For the first flight(s) I will equip the Babe Bee with a muffler and a left-hand 6x2 prop to reduce the power a little.

). For the first flight(s) I will equip the Babe Bee with a muffler and a left-hand 6x2 prop to reduce the power a little.

Here's a link to the original plan and instructions:

http://www.outerzone.co.uk/plan_details.asp?ID=5973

Right now my garage/shop is a mess and there is no heat either so all the gluing will need to happen inside the house. Any major sanding work needs to happen outside, no problem, it's not TOO cold to do that, but fuelproofing and painting will be a challenge.

Anyway, last Saturday I finally got my rear in gear and got to work. My older son and I first "warmed up" by building new winglets and tail feathers for his "Eka" glider to replace the original cardboard ones, and also did some other minor repairs:

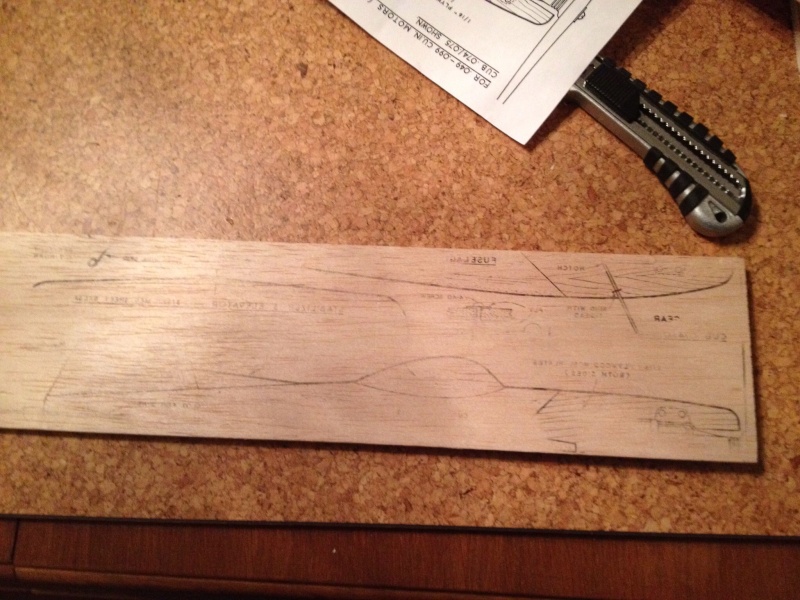

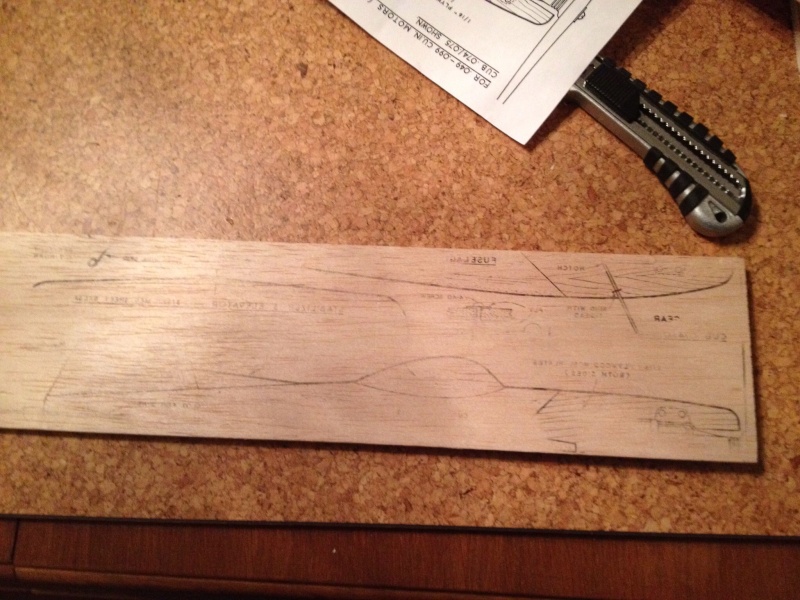

It felt good to actually cut and glue some balsa after many years, so on with the Scorpion. First I ironed the patterns from the plan to balsa. It was a new method to me, but it works on laser prints and photocopies. Just put the plan face down on the balsa and iron on high setting to move the print to balsa. It only works once per print. Here's the result:

After cutting out the halves I made some room for the Babe Bee, and cut the reinforcement pieces from thin plywood:

I won't bore you with the details about cutting the tail feathers or sanding the wing into shape, but here it is propped up with no glue:

I made the landing gear a bit taller and wider than what was in the original plan, maybe it is a little too tall. I am going to mount it a little higher and more forward-pointing, maybe I'll also bend it a little wider still. I hate bending the landing gear, never seem to get them the way I want, or symmetrical I have a pair of perfect NOS Graupner aluminum hub wheels for it already, a flea market purchase for 90 cents

I have a pair of perfect NOS Graupner aluminum hub wheels for it already, a flea market purchase for 90 cents

Weight-wise we are at 122 grams (4.3 oz), roughly half of which is the engine.

The landing gear and wheels are about 18 grams total so there won't be much trouble getting the CG were it belongs. I don't have the engine mount, bellcrank, pushrod, hinges etc yet, and of course glue and paint will add some weight too but I think we'll stay under 200 grams.

So this is where I am now Next step is to build the engine mount and glue everything together. And order the missing parts of course.

Next step is to build the engine mount and glue everything together. And order the missing parts of course.

It all begun about 6 months ago when I stumbled upon my old Babe Bee engine from the early '80s. Back then I did not have much success getting it to run, so it has very little run time on it. A few minutes in total maybe. Now, some 30 years later, RC planes run on batteries, but I thought I should finally get my old Babe Bee up in the air and so I figured, why not try control line in true Cox tradition. Shortly after that I found this forum, got really into Cox engines and now I am a proud owner of a bunch of them. Here is my current fleet, minus my original Babe.

The model I have selected is "Scorpion", an all-sheet design from mid '50s. I modified the plan a little, as the original is for a beam-mount engine and the Babe Bee obviously has the back plate mount. I was looking for an "easy to build, hard to break" design since I have never flown a C/L and I most likely won't have an instructor available for the first flights (I am an optimist,hence the plural on the flightS

). For the first flight(s) I will equip the Babe Bee with a muffler and a left-hand 6x2 prop to reduce the power a little.

). For the first flight(s) I will equip the Babe Bee with a muffler and a left-hand 6x2 prop to reduce the power a little.Here's a link to the original plan and instructions:

http://www.outerzone.co.uk/plan_details.asp?ID=5973

Right now my garage/shop is a mess and there is no heat either so all the gluing will need to happen inside the house. Any major sanding work needs to happen outside, no problem, it's not TOO cold to do that, but fuelproofing and painting will be a challenge.

Anyway, last Saturday I finally got my rear in gear and got to work. My older son and I first "warmed up" by building new winglets and tail feathers for his "Eka" glider to replace the original cardboard ones, and also did some other minor repairs:

It felt good to actually cut and glue some balsa after many years, so on with the Scorpion. First I ironed the patterns from the plan to balsa. It was a new method to me, but it works on laser prints and photocopies. Just put the plan face down on the balsa and iron on high setting to move the print to balsa. It only works once per print. Here's the result:

After cutting out the halves I made some room for the Babe Bee, and cut the reinforcement pieces from thin plywood:

I won't bore you with the details about cutting the tail feathers or sanding the wing into shape, but here it is propped up with no glue:

I made the landing gear a bit taller and wider than what was in the original plan, maybe it is a little too tall. I am going to mount it a little higher and more forward-pointing, maybe I'll also bend it a little wider still. I hate bending the landing gear, never seem to get them the way I want, or symmetrical

I have a pair of perfect NOS Graupner aluminum hub wheels for it already, a flea market purchase for 90 cents

I have a pair of perfect NOS Graupner aluminum hub wheels for it already, a flea market purchase for 90 cents Weight-wise we are at 122 grams (4.3 oz), roughly half of which is the engine.

The landing gear and wheels are about 18 grams total so there won't be much trouble getting the CG were it belongs. I don't have the engine mount, bellcrank, pushrod, hinges etc yet, and of course glue and paint will add some weight too but I think we'll stay under 200 grams.

So this is where I am now

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Well, you have been busy on both fronts, buying and building. These little Cox engines are like pototo chips, as they say - you can't have just one.

Good looking little model.

Good looking little model.

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

That should be a nice looking model when it is done. A good beginner ship. But, I just looked at the Outerzone plans and the article and there is an error in the article. At the end of the article it states that the front line should go to the top of your handle, and the rear line to the bottom. Since the bellcrank and control horn are both on the bottom of the wing and elevator, that would give you the opposite input that you want. The rear leadout is the one you want attached to the "Up" side of your handle. You'll see when you get it finished.

The Proof Reader Mark

The Proof Reader Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

batjac wrote:That should be a nice looking model when it is done. A good beginner ship. But, I just looked at the Outerzone plans and the article and there is an error in the article. At the end of the article it states that the front line should go to the top of your handle, and the rear line to the bottom. Since the bellcrank and control horn are both on the bottom of the wing and elevator, that would give you the opposite input that you want. The rear leadout is the one you want attached to the "Up" side of your handle. You'll see when you get it finished.

The Proof Reader Mark

Good catch Mark.. Kari probably would have figured it out.. but it's good to mention these things since it "is" his first c/l experience. I think he's chosen a great little model for his engine!

Kari, I see by your engine collection; that you have several tank adapters for increasing the Babe Bee's capacity to 8cc's. Did those engines come this way.. or did you source the tank kits? That's a nice all-around 1/2A engine collection you have there!! Lots of room to grow with various model airplanes to suit them!

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

KariFS , Looking Good man its good to see some building going on and did you laser cut that or just nice straight pencil lines?  good to see some one else flying Babe Bees they can bee a lot of fun and not too fast. Nice Engines Too!! I like the medallion , they are good starters and run out decent , I think those tank extensions are cool also . Eric

good to see some one else flying Babe Bees they can bee a lot of fun and not too fast. Nice Engines Too!! I like the medallion , they are good starters and run out decent , I think those tank extensions are cool also . Eric

good to see some one else flying Babe Bees they can bee a lot of fun and not too fast. Nice Engines Too!! I like the medallion , they are good starters and run out decent , I think those tank extensions are cool also . Eric

good to see some one else flying Babe Bees they can bee a lot of fun and not too fast. Nice Engines Too!! I like the medallion , they are good starters and run out decent , I think those tank extensions are cool also . Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Nice plane you got started there. I thank you for sharing this, as I have seen a few beam mounted engine plans that I liked, but was unsure of how to mount a Bee type engine, and here you showed me just what I needed to know. Thank you. I will Bee waiting for the finished product.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Thanks for all the feedback  I can't seem to do multiple quotes for some reason but I'll reply to all in this single post anyway.

I can't seem to do multiple quotes for some reason but I'll reply to all in this single post anyway.

Ain't that the truth I think I have enough engines, now it is time to get them running and build some models. And fly them of course.

I think I have enough engines, now it is time to get them running and build some models. And fly them of course.

@Mark: Good point. It pays to always check and double-check and then re-check the controls before the flight. I had my "electrified" Riser almost fly away over a lake on my first flight, and finally it ended up nose about 6" deep in the soil because of a panic landing. I had the rudder reversed And I did check the controls before the flight. And while setting the rudder movement, I also accidentally reversed the elevator, and failed to check that before the next flight. Fortunately the hay on the field was tall and strong

And I did check the controls before the flight. And while setting the rudder movement, I also accidentally reversed the elevator, and failed to check that before the next flight. Fortunately the hay on the field was tall and strong  Again, no other damage than a hurt pride and a prop hub full of soil.

Again, no other damage than a hurt pride and a prop hub full of soil.

@Roddie: i think the tank kits are made by Kavan. It was a very common accessory back then, I also installed one before I even ran my first Babe bee the first time. All these engines came with the kits installed. Lot of the engines in the picture are from the bottoms of people's junk boxes, the only ones that seem to be in running condition are the PeeWee, BW, RR1, QRC and one of the product engines. I messed up the cylinder on the TeeDee, and the rest of them are more or less stuck because of the castor oil gunk.

@Eric: No, no laser I just ironed the fuselage shape to the sheet and used a carpet knife to cut the balsa. 3 or 4 passes is better for 6mm (~1/4") balsa sheet than trying to cut it with a single pass. I laid the parts out like I did to get the "factory made" edges against each other in the fuselage to make sure the fit is best possible. For the straight cuts like the wing trailing edge I used a steel ruler for support.

I just ironed the fuselage shape to the sheet and used a carpet knife to cut the balsa. 3 or 4 passes is better for 6mm (~1/4") balsa sheet than trying to cut it with a single pass. I laid the parts out like I did to get the "factory made" edges against each other in the fuselage to make sure the fit is best possible. For the straight cuts like the wing trailing edge I used a steel ruler for support.

@New: I have some 3mm (~1/8") birch plywood that I'm going to use for the mounting plate, and for some triangular supports behind it. I think Brodak sells or at least used to sell a plastic mount to install a Cox tanked engine to a profile fuselage, but the plywood version is a widely used alternative.

rsv1cox wrote:Well, you have been busy on both fronts, buying and building. These little Cox engines are like pototo chips, as they say - you can't have just one.

Ain't that the truth

@Mark: Good point. It pays to always check and double-check and then re-check the controls before the flight. I had my "electrified" Riser almost fly away over a lake on my first flight, and finally it ended up nose about 6" deep in the soil because of a panic landing. I had the rudder reversed

@Roddie: i think the tank kits are made by Kavan. It was a very common accessory back then, I also installed one before I even ran my first Babe bee the first time. All these engines came with the kits installed. Lot of the engines in the picture are from the bottoms of people's junk boxes, the only ones that seem to be in running condition are the PeeWee, BW, RR1, QRC and one of the product engines. I messed up the cylinder on the TeeDee, and the rest of them are more or less stuck because of the castor oil gunk.

@Eric: No, no laser

@New: I have some 3mm (~1/8") birch plywood that I'm going to use for the mounting plate, and for some triangular supports behind it. I think Brodak sells or at least used to sell a plastic mount to install a Cox tanked engine to a profile fuselage, but the plywood version is a widely used alternative.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Good job on your plane Kari. That are Kavan tank extensions indeed. It's an outer ring and an inner venturi extension. The kit came with 4 longer bolts and an extra venturi gasket.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

OK then, yesterday evening I spent a couple of hours with the Scorpion again.

I used quick epoxy to put the airframe together. Epoxy is considered heavy, which it is of course as there is no evaporating component in it. The amount you lay on a model stays on it. But I wanted to use the strongest glue possible as the surfaces of the joins are small and glue has a major part in making the structure rigid.

I used the epoxy sparingly, and after the main airframe was together my low-precision kitchen scale showed total weight of 128 grams, an increase of 6 grams. Second weighing showed 126 grams, so I suppose the actual increase is around 5 grams. I don't think it's too bad.

I am going to weigh the model after every major phase. This is the first time I use a scale on a model plane project and I want to see and learn how much weight each phase adds. I am especially curious about the weight of the paintjob.

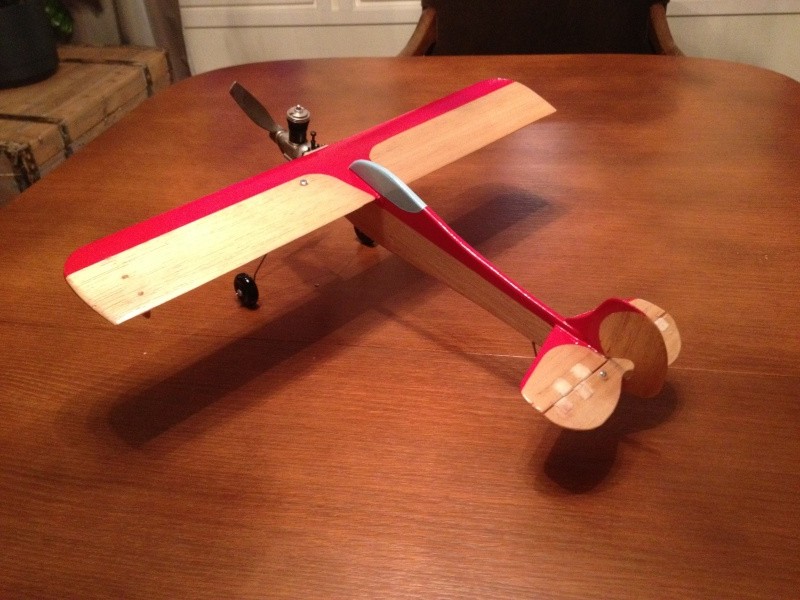

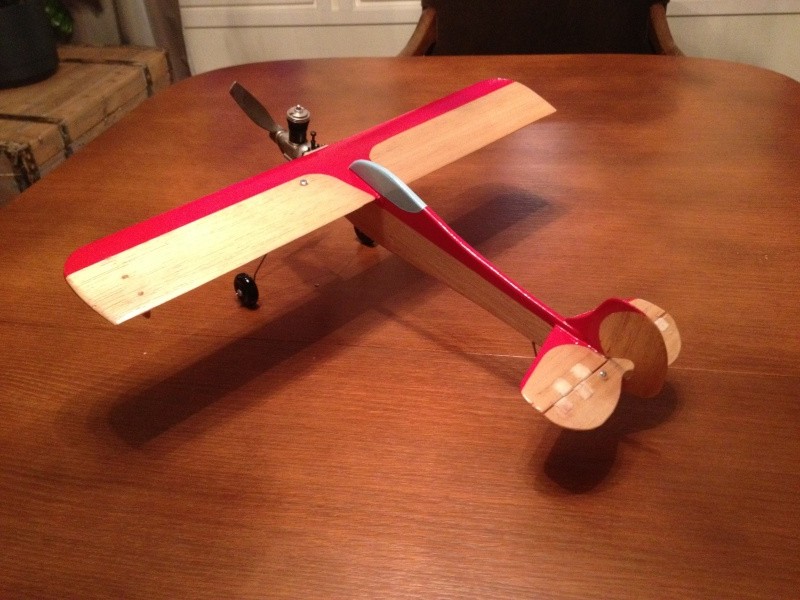

After the weighing of the parts I couldn't resist propping the rest of the parts on it to see how it looks:

I like the vintage look and proportions, the designer certainly did a nice job. The model feels really nose heavy, of course the paint will move the CG back a little but I am considering a plywood rudder to add weight to the tail and it'll also be stonger "if" I happen to get the plane to tip over while landing or take off.

I am glad I made the landing gear taller after all, now the tip of the propeller is about 1 1/2" from the ground:

That's all for tonight, next up is the motor mount and its supports

PS: I do have a question: do you usually build the outward-angle into the motor mount or do you add washers between the engine and the mount to create the angle? I am thinking a 2 or 3 degree outward angle built in the engine mount would be a good solution.

I used quick epoxy to put the airframe together. Epoxy is considered heavy, which it is of course as there is no evaporating component in it. The amount you lay on a model stays on it. But I wanted to use the strongest glue possible as the surfaces of the joins are small and glue has a major part in making the structure rigid.

I used the epoxy sparingly, and after the main airframe was together my low-precision kitchen scale showed total weight of 128 grams, an increase of 6 grams. Second weighing showed 126 grams, so I suppose the actual increase is around 5 grams. I don't think it's too bad.

I am going to weigh the model after every major phase. This is the first time I use a scale on a model plane project and I want to see and learn how much weight each phase adds. I am especially curious about the weight of the paintjob.

After the weighing of the parts I couldn't resist propping the rest of the parts on it to see how it looks:

I like the vintage look and proportions, the designer certainly did a nice job. The model feels really nose heavy, of course the paint will move the CG back a little but I am considering a plywood rudder to add weight to the tail and it'll also be stonger "if" I happen to get the plane to tip over while landing or take off.

I am glad I made the landing gear taller after all, now the tip of the propeller is about 1 1/2" from the ground:

That's all for tonight, next up is the motor mount and its supports

PS: I do have a question: do you usually build the outward-angle into the motor mount or do you add washers between the engine and the mount to create the angle? I am thinking a 2 or 3 degree outward angle built in the engine mount would be a good solution.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

That's a sweeeet looking little airplane!! I agree; it's hard to resist fitting the parts to see how it will look. Paint will add some tail-weight for sure.. but you still need to install a pushrod. A 1.1mm music-wire pushrod would add some weight.

You can forego any engine offset if you place the lead-out wing-tip-guide(s) slightly rearward. Leave that step for when near finished.. at which point you would "hang" the model 90 degrees by it's lead-outs while holding them against the wing. You can then mark the guide(s) position on the wing where the nose of the model drops slightly lower than the tail. (just a few degrees nose-down should be enough for adequate line-tension)

You can of course build-in offset to the firewall or install washers.. but this lowers the efficiency of the engine a bit.. because you've altered the thrust-line in relation to the airframe. Installing washers can create vibration.. because there's less "contact-area" for the engine's back-plate mounting to bear-on.

You can forego any engine offset if you place the lead-out wing-tip-guide(s) slightly rearward. Leave that step for when near finished.. at which point you would "hang" the model 90 degrees by it's lead-outs while holding them against the wing. You can then mark the guide(s) position on the wing where the nose of the model drops slightly lower than the tail. (just a few degrees nose-down should be enough for adequate line-tension)

You can of course build-in offset to the firewall or install washers.. but this lowers the efficiency of the engine a bit.. because you've altered the thrust-line in relation to the airframe. Installing washers can create vibration.. because there's less "contact-area" for the engine's back-plate mounting to bear-on.

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Thanks Roddie

I'll go with no outward angle on the engine then, and just glue the mount as straight as I can. IF there is any offset or misalignment, I'll make sure it is not inward. Don't want to lose any power since there's not that much horsepower to begin with. I believe that the lead-out support positioned as you described, the opposite wing weight and rudder offset should be enough to keep the lines tight.

I'll go with no outward angle on the engine then, and just glue the mount as straight as I can. IF there is any offset or misalignment, I'll make sure it is not inward. Don't want to lose any power since there's not that much horsepower to begin with. I believe that the lead-out support positioned as you described, the opposite wing weight and rudder offset should be enough to keep the lines tight.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

KariFS wrote:Thanks Roddie

I'll go with no outward angle on the engine then, and just glue the mount as straight as I can. IF there is any offset or misalignment, I'll make sure it is not inward. Don't want to lose any power since there's not that much horsepower to begin with. I believe that the lead-out support positioned as you described, the opposite wing weight and rudder offset should be enough to keep the lines tight.

You're welcome Kari! Years ago I went "overkill" building both; engine "and" rudder offset into my scratch-built designs. I only learned about the "raking the lead-outs rearward".. a year or so ago, since being a member here on the forum. Some C/L modelers would say that neither engine/rudder offset is needed.. but on a little airplane that will be sensitive to the inevitable wind-gust; better to be safe by providing slight rudder offset.. than sorry!

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Good job Roddie Greenie for U !! I am still a little for get full when I build as I tend to put to much offset at both ends , The good thing about washers are you can take some out if you need , I really don't like models coming in on me or slack lines , I guess it takes practice and where you stand with the model as far as flying it , the 2 degrees at the engine would be my fairing to go on . Eric  Nice Looking AIRPLANE !!! KariFS

Nice Looking AIRPLANE !!! KariFS

Nice Looking AIRPLANE !!! KariFS

Nice Looking AIRPLANE !!! KariFS

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Hi Kari, Note the position of the lead-outs.. The original "beam" engine mounting doesn't specify any offset. There is a note for 1/4" of rudder offset though. Another way to add functional weight to the tail (if you need it..) is to add a music-wire tailskid (shown) and maybe a tail-wheel. If by chance you "do" end up tail-heavy after installing a music-wire pushrod, you can swap it out for a carbon fiber one. You won't know for sure until it's finish painted and ready to fly.

The engines recommended seem a bit BIG for a 20" span model! I think you'll do well with the Babe Bee.

The engines recommended seem a bit BIG for a 20" span model! I think you'll do well with the Babe Bee.

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

roddie wrote:Hi Kari, Note the position of the lead-outs.. The original "beam" engine mounting doesn't specify any offset. There is a note for 1/4" of rudder offset though. Another way to add functional weight to the tail (if you need it..) is to add a music-wire tailskid (shown) and maybe a tail-wheel. If by chance you "do" end up tail-heavy after installing a music-wire pushrod, you can swap it out for a carbon fiber one. You won't know for sure until it's finish painted and ready to fly.

The engines recommended seem a bit BIG for a 20" span model! I think you'll do well with the Babe Bee.

I've been thinking about the dynamics of C/L flying and it starts to make sense now. The axle or pivot point of the bellcrank is located aft of the CG. The vector of the (much argued) centrifugal force goes through the CG, and the vector of the control line force that keeps the plane on track goes through the bellcrank pivot point. These two vectors create a "moment" that tries to turn the nose outward. This creates an outward offset for the engine. And also if the plane flies with its nose pointing slightly out of the circle, the lead-out guides should be moved back to prevent them from bending and/or binding. Makes sense to me, not sure if it's the truth though

And yes, an .099 engine would look scary on a plane this little. But the design pre-dates the Babe Bee by couple of years, and the Cub engines were probably a little less powerful. I'll still start slow, with my non-SPI engine, with a muffler and maybe even a 6x2 prop... I get dizzy easily

Last edited by KariFS on Fri Feb 20, 2015 2:36 pm; edited 2 times in total

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Last Sunday was a great day for flying, temperatures were around -10C, sunny, no wind. My son and I took our gliders out, and after a few hours out at my parents' cabin, on the frozen lake we were a bit cold, hungry and ready for sauna, so no energy to build planes. I am glad we had that day out, it's been raining pretty much since, so it's foggy, cloudy and there's water on the ice too.

Here's a picture of our fleet My SIG Riser with a nose mounted brushless motor, and the son's Eka. Note my ancient, second-hand Futaba transmitter

My SIG Riser with a nose mounted brushless motor, and the son's Eka. Note my ancient, second-hand Futaba transmitter

But on the other night, some progress was made with the Scorpion too.

I took an outrageously expensive (€7.50) piece of 3mm aircraft plywood and sawed off a piece for the motor mount. The price of the plywood doesn't seem too bad now that I figured I can make about 59 more similar mounts out of that piece

For the reinforcement parts I used pieces of some paint mixing sticks, I think they are basswood. As the position of the lower pieces was at about the same height as the wing, I decided to notch the wing and extend the pieces accordingly. This may give some extra support.

Dang I always make a mess when I use epoxy

I made the top pieces pretty long and rounded them at the ends. The bolt holes of the engine mounts dictated the position of these too.

Another pic of the mount.

I had to modify the "chin" of the plane by making it about 3mm or 1/8" shorter. I was looking at my engines and realized that the engine with the Kavan tank kit was about 1/8" longer than the ones with the original 8cc tank. I made this mod in case I want to run this model with one of my stunt tanked engines.

And finally, the obligatory weighing.

The scale shows 132 grams so again a relatively small increase of about 5 grams. Almost makes me suspicious about the accuracy of the scale I can shed some weight by cleaning off some of the epoxy mess and of course the final sanding will take off a marginal amount too.

I can shed some weight by cleaning off some of the epoxy mess and of course the final sanding will take off a marginal amount too.

Next up, the hunt for some hinge fabric. Stay tuned

Here's a picture of our fleet

But on the other night, some progress was made with the Scorpion too.

I took an outrageously expensive (€7.50) piece of 3mm aircraft plywood and sawed off a piece for the motor mount. The price of the plywood doesn't seem too bad now that I figured I can make about 59 more similar mounts out of that piece

For the reinforcement parts I used pieces of some paint mixing sticks, I think they are basswood. As the position of the lower pieces was at about the same height as the wing, I decided to notch the wing and extend the pieces accordingly. This may give some extra support.

Dang I always make a mess when I use epoxy

I made the top pieces pretty long and rounded them at the ends. The bolt holes of the engine mounts dictated the position of these too.

Another pic of the mount.

I had to modify the "chin" of the plane by making it about 3mm or 1/8" shorter. I was looking at my engines and realized that the engine with the Kavan tank kit was about 1/8" longer than the ones with the original 8cc tank. I made this mod in case I want to run this model with one of my stunt tanked engines.

And finally, the obligatory weighing.

The scale shows 132 grams so again a relatively small increase of about 5 grams. Almost makes me suspicious about the accuracy of the scale

I can shed some weight by cleaning off some of the epoxy mess and of course the final sanding will take off a marginal amount too.

I can shed some weight by cleaning off some of the epoxy mess and of course the final sanding will take off a marginal amount too.Next up, the hunt for some hinge fabric. Stay tuned

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Nice work. Keep it up. I am sorry I cannot help with the hinge material, as I am not 100% sure what I use. All I know is that I purchased it in the clearance bin while at the fabric store.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Coming along nicely KariFS , Your elect. gliders look really good I like the finishes , I have old radios myself so you are not alone

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Coming along nicely Kari! These are my favorite type of models.. and the Scorpion is one I'd never seen before.

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Oops, over 2 months without updates

Well, the progress has been slow but unsteady... Lot of other stuff going on. During the past two months I have sanded the plane, covered the front end with a light coat of epoxy to help fuel proofing and also made a notch to the front under the fuel tank to make room for the lower breather pipe of a stunt tank. I am glad I tried my QRC on it and noticed the interference. The whole plane has got two coats of urethane clearcoat too, the first was 50% thinned to help it to absorb.

Yesterday evening I also glued the tail feathers on and again mocked-up the whole plane. Here's how it looks now, sorry about the quality of the pic, but if you look closely you can see the notch for the breather.

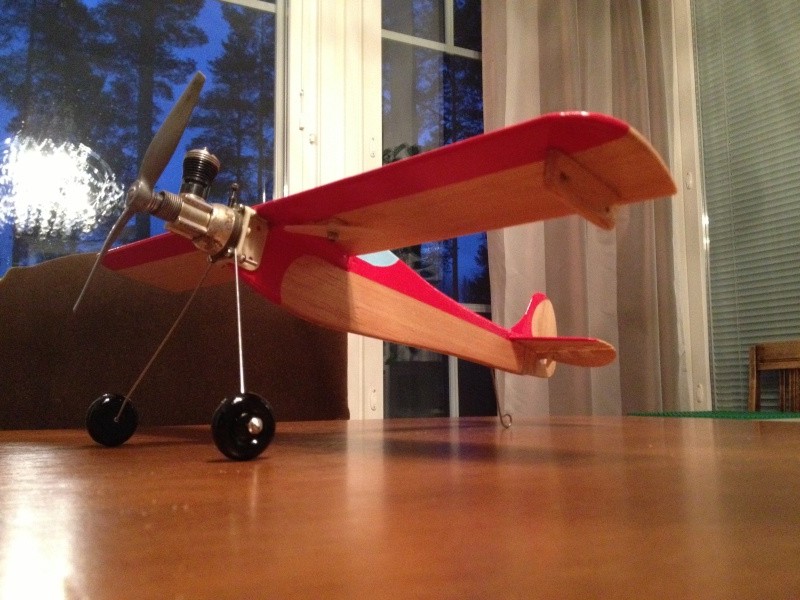

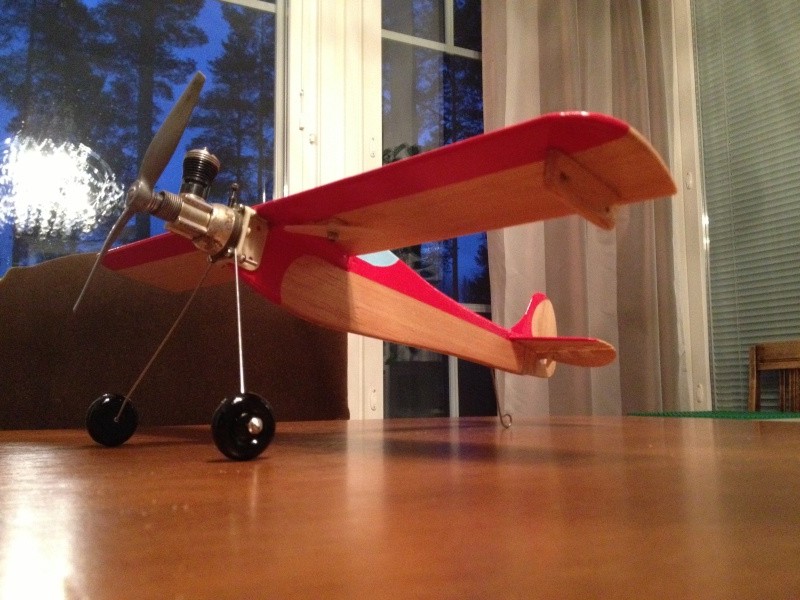

A lot of my plane-building time is consumed by getting the stuff out, waiting for the glue to dry and especially cleaning up afterwards. As you can see from the pics, it all happens on the dining table late at night. So, I figured I might as well start a side project, and did too. For the simple side job I chose "American Boy", inspired by "batjac" Mark's nice example. The plan on outerzone.com was not in scale and for some reason I could not print out the part patterns as 100% either so I pretty much just took the main dimensions and eyeballed the shape. Like Mark I also used a Brodak engine/landing gear mount. The wheels are 1-1/4" wooden toy wheels. Sig wing profile is not available in Finland so I just sanded mine from plain 6mm balsa. I also practiced making fabric hinges Did not find it convenient so I'll try dyneema hinging for the Scorpion. Here's a pic of both of my planes:

Did not find it convenient so I'll try dyneema hinging for the Scorpion. Here's a pic of both of my planes:

So, both of them are now pretty much missing just lead-out guides and control linkage, the Scorpion also needs hinges, right now the elevator is held on only by masking tape.

Of course I forgot to weigh the Scorpion after each phase, but right now it weighs 162 grams with that engine, engine bolts, wheels, prop, spinner etc. Not too bad I hope. The CG is right at the leading edge, I hope the final paint helps to move it a little further back. The "Boy" weighs 132 as pictured, CG just about right.

Couple more pics of the two:

Until next time

EDIT: dang, most of the pics are upside down, I'll try to figure out how to fix them.

EDIT2: Eric fixed them for me, thank you, and I posted them above

Well, the progress has been slow but unsteady... Lot of other stuff going on. During the past two months I have sanded the plane, covered the front end with a light coat of epoxy to help fuel proofing and also made a notch to the front under the fuel tank to make room for the lower breather pipe of a stunt tank. I am glad I tried my QRC on it and noticed the interference. The whole plane has got two coats of urethane clearcoat too, the first was 50% thinned to help it to absorb.

Yesterday evening I also glued the tail feathers on and again mocked-up the whole plane. Here's how it looks now, sorry about the quality of the pic, but if you look closely you can see the notch for the breather.

A lot of my plane-building time is consumed by getting the stuff out, waiting for the glue to dry and especially cleaning up afterwards. As you can see from the pics, it all happens on the dining table late at night. So, I figured I might as well start a side project, and did too. For the simple side job I chose "American Boy", inspired by "batjac" Mark's nice example. The plan on outerzone.com was not in scale and for some reason I could not print out the part patterns as 100% either so I pretty much just took the main dimensions and eyeballed the shape. Like Mark I also used a Brodak engine/landing gear mount. The wheels are 1-1/4" wooden toy wheels. Sig wing profile is not available in Finland so I just sanded mine from plain 6mm balsa. I also practiced making fabric hinges

So, both of them are now pretty much missing just lead-out guides and control linkage, the Scorpion also needs hinges, right now the elevator is held on only by masking tape.

Of course I forgot to weigh the Scorpion after each phase, but right now it weighs 162 grams with that engine, engine bolts, wheels, prop, spinner etc. Not too bad I hope. The CG is right at the leading edge, I hope the final paint helps to move it a little further back. The "Boy" weighs 132 as pictured, CG just about right.

Couple more pics of the two:

Until next time

EDIT: dang, most of the pics are upside down, I'll try to figure out how to fix them.

EDIT2: Eric fixed them for me, thank you, and I posted them above

Last edited by KariFS on Sun Apr 26, 2015 2:03 pm; edited 2 times in total

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Here you goo

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Thanks Eric! That Bruce Lee fellow may be on to something

The pics showed the right side up on my iPad, but after hosting&posting they were upside down. Did you just download, flip and host them (that was what I was about to do) or was there magic involved?

I'll just steal those pics and attach them to my previous post.

Thanks again.

The pics showed the right side up on my iPad, but after hosting&posting they were upside down. Did you just download, flip and host them (that was what I was about to do) or was there magic involved?

I'll just steal those pics and attach them to my previous post.

Thanks again.

Last edited by KariFS on Sun Apr 26, 2015 2:00 pm; edited 1 time in total

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Yes no Magic and they look really good man my computer is running so slow took a while and forgot to say something  Looks like your about to go Flying

Looks like your about to go Flying

Looks like your about to go Flying

Looks like your about to go Flying

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

Some progress with "the Boy": I decided to paint only some red trim and leave most of it to wood colour. I was too lazy to do the scallops to the wings as per original kit and took some artistic liberties with tail feathers and cabin design too.

The wheels are held on with soldered washers, still have to dremel off some excess wire. Control linkage needs to be built too, and the motor mount is not yet attached properly. But other than that, it's pretty much done. Right now it weighs 150g or 5.3oz. CG is a little too far aft, it is right at the edge of the red area on the wing. I'll see if an extended-tank Bee with a muffler is enough to move the CG sufficiently.

I have a question: Should I add wingtip weight and if so, how much? I have a small jar of U.S. pennies, should I add one or two?

Here's a couple of pics:

The wheels are held on with soldered washers, still have to dremel off some excess wire. Control linkage needs to be built too, and the motor mount is not yet attached properly. But other than that, it's pretty much done. Right now it weighs 150g or 5.3oz. CG is a little too far aft, it is right at the edge of the red area on the wing. I'll see if an extended-tank Bee with a muffler is enough to move the CG sufficiently.

I have a question: Should I add wingtip weight and if so, how much? I have a small jar of U.S. pennies, should I add one or two?

Here's a couple of pics:

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Scorpion - Simple trainer build

Re: Scorpion - Simple trainer build

KariFS wrote:

I have a question: Should I add wingtip weight and if so, how much? I have a small jar of U.S. pennies, should I add one or two?

Hard to say how much outboard tip-weight would be adequate. Once your lead-outs are installed, you'll have a better idea. Are you planning on running your main-lines through the guide and attaching directly to the bellcrank? That would be the lightest weight to offset on the outboard wing-tip.

You could make a simple adjustable lead-out guide.. not necessary, but convenient. I've built "comb" type guides which are fairly simple and lightweight. It can help with flight-trimming.

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Guillows Cessna 150 build circa 1970 (Build Log)

» Cox scorpion ARF build!

» Simple Sabar Trainer ?

» Simple Baby Ringmaster build

» Cox Scorpion ARF

» Cox scorpion ARF build!

» Simple Sabar Trainer ?

» Simple Baby Ringmaster build

» Cox Scorpion ARF

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules