Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Phred's Foam adventure

Page 1 of 1

Phred's Foam adventure

Phred's Foam adventure

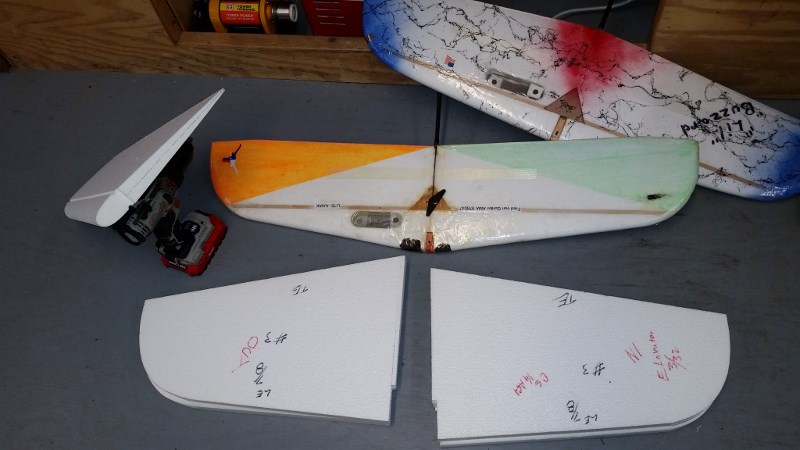

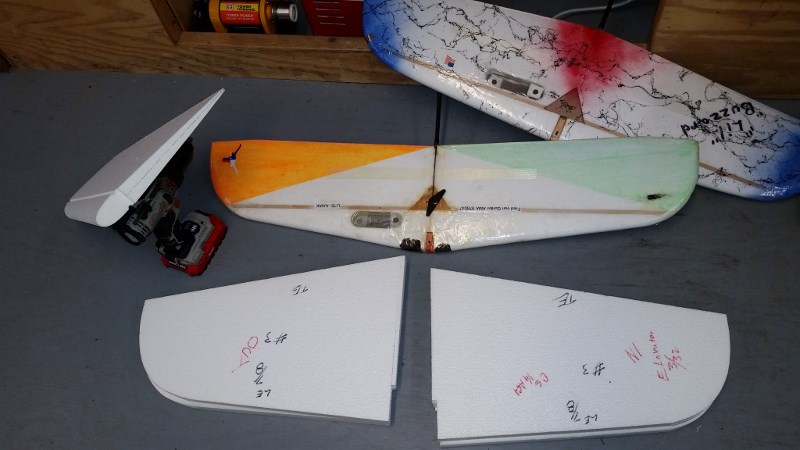

I lost my foam cutting hardware years ago in a Army move. My buddy Jeff Dawson cuts his own cores for all the combat planes he sells. I have helped him a bunch so he will cut just about any wing profile for me.

I want to set my airplane shop up so I can do my own. My original set up was simple but dangerous. A 30" bow of spring tension Ni-chrome wire, connected to the output of a 110 VAC Variac. Worked well but I did not have any safety switches, fuses, or a positive stop on the Variac preventing VAC above 24 ( the starting point of lethal AC voltage).

I have a few items here for a good DC setup at 13.6VDC up to 45 Amp. The original 1997 power supply in the RV is/was old skool transformer iron core heat and humm monster with no real battery management other then constant 13.6Vdc.

I replaced it with a more intelligent 90 Amp version that senses battery bank conditions and adjust from recharge, float, and every 90 day sulfite bust mode.

I ordered a Harbor Freight Router speed control.

I ordered some Iconel and Rene' wire (have Ni-Chrome on hand from Sig)

Fairly simple using the router speed control to adjust the 110 VAC into the Ac to Dc power supply (because it is a dumb supply it will not care) to adjust wire temp. Bows from 20 to 30 inches and small diameter high resistance wire should draw between 3 to 6 amps to get into the 600F range. The PS has 45 Amp max 40 amp continuous spec so it has PLENTY of overhead

A 30" bow is plenty to cut 20-29" wing cores any thickness and width. For the larger wingspans we just use two or more cores.

I cut these last year with Jeff's bow:

I want to set my airplane shop up so I can do my own. My original set up was simple but dangerous. A 30" bow of spring tension Ni-chrome wire, connected to the output of a 110 VAC Variac. Worked well but I did not have any safety switches, fuses, or a positive stop on the Variac preventing VAC above 24 ( the starting point of lethal AC voltage).

I have a few items here for a good DC setup at 13.6VDC up to 45 Amp. The original 1997 power supply in the RV is/was old skool transformer iron core heat and humm monster with no real battery management other then constant 13.6Vdc.

I replaced it with a more intelligent 90 Amp version that senses battery bank conditions and adjust from recharge, float, and every 90 day sulfite bust mode.

I ordered a Harbor Freight Router speed control.

I ordered some Iconel and Rene' wire (have Ni-Chrome on hand from Sig)

Fairly simple using the router speed control to adjust the 110 VAC into the Ac to Dc power supply (because it is a dumb supply it will not care) to adjust wire temp. Bows from 20 to 30 inches and small diameter high resistance wire should draw between 3 to 6 amps to get into the 600F range. The PS has 45 Amp max 40 amp continuous spec so it has PLENTY of overhead

A 30" bow is plenty to cut 20-29" wing cores any thickness and width. For the larger wingspans we just use two or more cores.

I cut these last year with Jeff's bow:

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Phred's Foam adventure

Re: Phred's Foam adventure

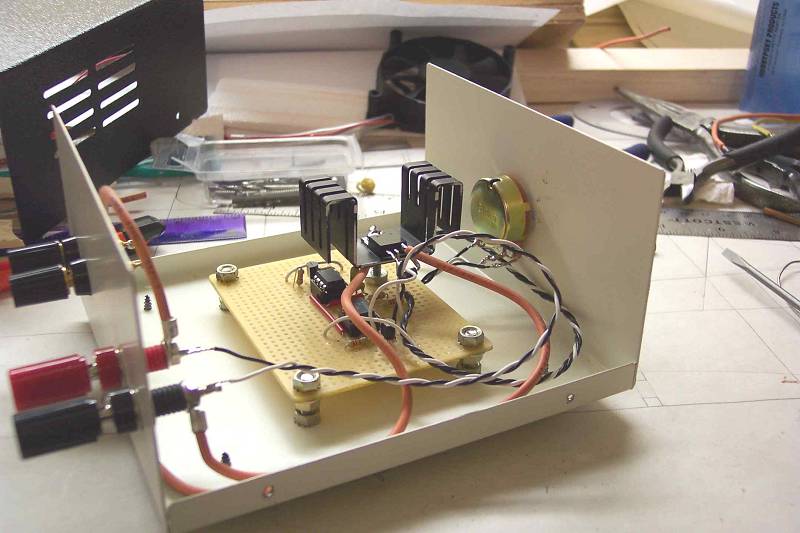

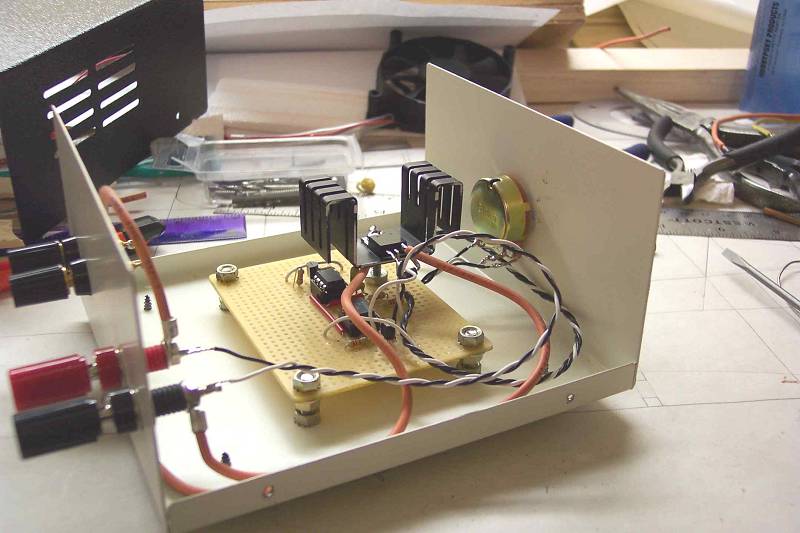

I've built several power supplies, both in DC and in AC. The AC output supplies sometimes have a tendency to develop some harmonics and cause the surface of the foam to be wavy. Here are a couple of pics of my DC heat controller and a 12v power supply converted from a salvaged PC power supply. If I need a long bow, I'll use a Pyramid 13.8v supply to drive the heat controller. I generally use .018 bright stainless steel wire (spring steel) from McMaster-Carr (285' for $10.80).

Re: Phred's Foam adventure

Re: Phred's Foam adventure

Well done Andrew. Good safe design and very neat engineering of layout and box.

As a Ham Radio operator I have several AC to DC power supplies but all are either store bought or purpose built (by me) to maintain constant current to keep the transmitter finals happy.

I fondly remember building several Heath Kit projects in the 60s with my dad and he stressed to me the importance of "neat" and efficient construction/layout.

As a Ham Radio operator I have several AC to DC power supplies but all are either store bought or purpose built (by me) to maintain constant current to keep the transmitter finals happy.

I fondly remember building several Heath Kit projects in the 60s with my dad and he stressed to me the importance of "neat" and efficient construction/layout.

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Similar topics

Similar topics» My newest adventure...

» A Gilbert adventure

» On the Ramp Right Now!

» W/M SNJ - Hopeless adventure or worthwhile project

» Foam safe CA?

» A Gilbert adventure

» On the Ramp Right Now!

» W/M SNJ - Hopeless adventure or worthwhile project

» Foam safe CA?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules