Log in

Search

Latest topics

» Landing-gear tipsby roddie Today at 6:17 pm

» Roger Harris revisited

by TD ABUSER Today at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Today at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 1:37 pm

» Happy 77th birthday Andrew!

by getback Today at 11:52 am

» My latest doodle...

by roddie Today at 10:43 am

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

messing around with flywheels

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

flywheels as rev-limiters...

flywheels as rev-limiters...

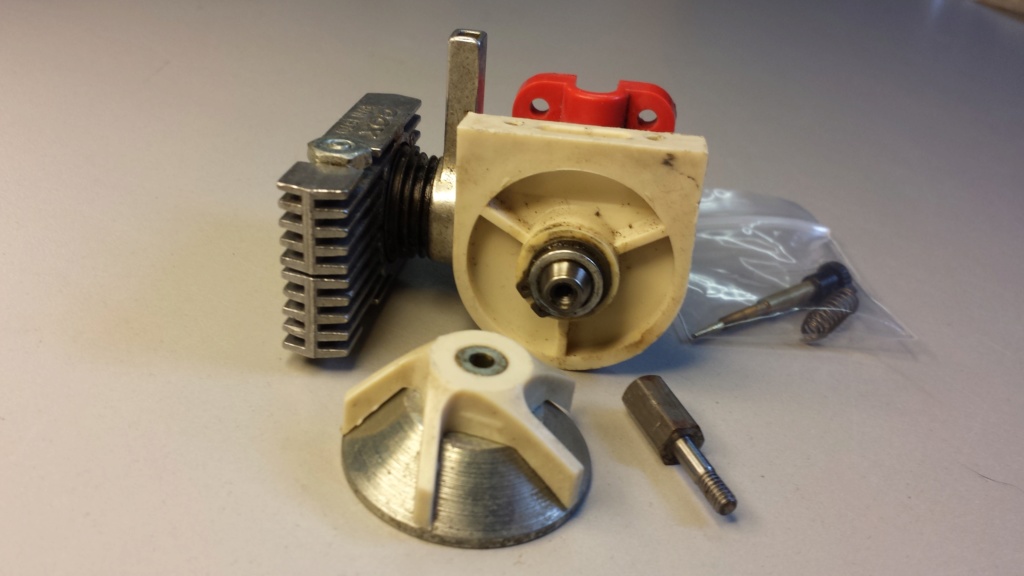

I discovered something interesting about two different flywheels that were both designed for the Cox .049 engine. One is a Cox part.. and the other was made by "Dumas" for use in their Cox .049 powered model boats.

A while back, I received some engines from "Bob" (rsv1cox) and amongst them was a Cox .049 reed-valve engine with a flywheel which we would classify as a car or buggy engine.

I hadn't paid much attention to that engine until yesterday. Because of a recent thread on Cox engine performance; I became curious about the weight of that flywheel.. in comparison to the Dumas flywheel. It turns-out that they're exactly the same in weight.

The Cox flywheel weight..

The Dumas flywheel weight..

The Cox flywheel was not difficult to remove from the engine. Note that the buggy/car engines' crankshaft is different than that of an aero-engine. This was something "new to me".. as I never owned a Cox model that used this type of engine.

I suspect that this engine is original.. but as I mentioned; I don't know much about them.

We can talk more about my engine later in another thread. For now.. I'd like to discuss the flywheels' role in our Cox engines' performance.

There's been some forum-interest in building/running some unlimited tether-cars. Many tether-cars that I have seen (previously..) don't utilize a flywheel. Some have their drive-axle/wheel geared-down to suit a ratio which suits a certain "class" of race-car.

This fascinates me.. .. and I'd like to know more about how the final-drive ratio was calculated.

.. and I'd like to know more about how the final-drive ratio was calculated.

Until then... if we reduce the weight/mass of the Cox-class of .049 flywheels for a no-load/test-run of an engine with a lightened flywheel installed; what sort of RPM#'s might we be looking at? How much would cylinder-porting, SPI, compression, timing, fuel-blend/induction play a role in the results?

A while back, I received some engines from "Bob" (rsv1cox) and amongst them was a Cox .049 reed-valve engine with a flywheel which we would classify as a car or buggy engine.

I hadn't paid much attention to that engine until yesterday. Because of a recent thread on Cox engine performance; I became curious about the weight of that flywheel.. in comparison to the Dumas flywheel. It turns-out that they're exactly the same in weight.

The Cox flywheel weight..

The Dumas flywheel weight..

The Cox flywheel was not difficult to remove from the engine. Note that the buggy/car engines' crankshaft is different than that of an aero-engine. This was something "new to me".. as I never owned a Cox model that used this type of engine.

I suspect that this engine is original.. but as I mentioned; I don't know much about them.

We can talk more about my engine later in another thread. For now.. I'd like to discuss the flywheels' role in our Cox engines' performance.

There's been some forum-interest in building/running some unlimited tether-cars. Many tether-cars that I have seen (previously..) don't utilize a flywheel. Some have their drive-axle/wheel geared-down to suit a ratio which suits a certain "class" of race-car.

This fascinates me..

Until then... if we reduce the weight/mass of the Cox-class of .049 flywheels for a no-load/test-run of an engine with a lightened flywheel installed; what sort of RPM#'s might we be looking at? How much would cylinder-porting, SPI, compression, timing, fuel-blend/induction play a role in the results?

Re: messing around with flywheels

Re: messing around with flywheels

It looks like it could be a boat engine . Just the way the heat sink is mounted and the little fan blades and prop nut .

Mike 1484

Mike 1484

Mike1484- Gold Member

- Posts : 303

Join date : 2011-10-28

Age : 76

Location : Northern Ohio

Re: messing around with flywheels

Re: messing around with flywheels

Mike1484 wrote:It looks like it could be a boat engine . Just the way the heat sink is mounted and the little fan blades and prop nut .

Mike 1484

Hi Mike, I don't think that my engine came from a boat.. not a "Cox" boat anyway. The Cox "Sea Bee" ski boat did use a similar flywheel.. but it didn't use a heat-sink. (page 1 of this thread has some photos of the Cox Sea Bee engine) Its' engine may have used a "cylinder-shim".. to apparently "detune" the engine to aid in cooling.. and also had an exhaust-throttle tab/speed-control. The Sea Bee engine also had a "pin" protruding from the front of the flywheel, for a spring to attach as a flex-coupling for its drive. My engine doesn't have any of these features.

Re: messing around with flywheels

Re: messing around with flywheels

Roddie, that's the engine used in the Cox Action Van minus the thumbwheel to start it. The Seabee used a integral type tank ( Babe Bee) but it did use a similar flywheel with the vanes usually black in color. The van used the heatsink and exhaust deflector with the horseshoe backplate.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: messing around with flywheels

Re: messing around with flywheels

Roddie, now that you have disassembled the front end of your engine you can remove that spring clip holding the plastic mount assembly and install a adapter/prop driver from Ex Engines. This will alow you to use the engine as a “standard “ airplane engine. http://www.exmodelengines.com/product.php?productid=18246&cat=266&page=2

Well, you’d have to remove the heatsink and install a standard glow head too.

Well, you’d have to remove the heatsink and install a standard glow head too.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: messing around with flywheels

Re: messing around with flywheels

Ken Cook wrote: Roddie, that's the engine used in the Cox Action Van minus the thumbwheel to start it. The Seabee used a integral type tank ( Babe Bee) but it did use a similar flywheel with the vanes usually black in color. The van used the heatsink and exhaust deflector with the horseshoe backplate.

Thanks for identifying my engine Ken.

Re: messing around with flywheels

Re: messing around with flywheels

Marleysky wrote:Roddie, now that you have disassembled the front end of your engine you can remove that spring clip holding the plastic mount assembly and install a adapter/prop driver from Ex Engines. This will alow you to use the engine as a “standard “ airplane engine. http://www.exmodelengines.com/product.php?productid=18246&cat=266&page=2

Well, you’d have to remove the heatsink and install a standard glow head too.

Hi Rene, It figures; I recently (last week) placed and received an order from EX Model Engines..

but that's ok. I'll put one of those adapters on the order-list for next time.

but that's ok. I'll put one of those adapters on the order-list for next time. The glowhead on this engine is a standard one. It's a bonus to have another Cox heatsink though. I now have four of them.

This engine may actually be just what I need to perform some high-rpm tests. From what I understand; the crankshaft is stronger than a standard aero-engines'. I would need that adapter/drive-plate for using my lighter-weight flywheels though..

Another option would be to use a standard crankcase with a diesel crankshaft, which I do have.

Re: messing around with flywheels

Re: messing around with flywheels

roddie wrote:

This engine may actually be just what I need to perform some high-rpm tests. From what I understand; the crankshaft is stronger than a standard aero-engines'. I would need that adapter/drive-plate for using my lighter-weight flywheels though..

They may be slightly stronger but the crank pin can still break off. The NMMTPA guys can break these crankshafts running modified 1702 heads and 60% nitro.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: messing around with flywheels

Re: messing around with flywheels

Jason_WI wrote:The NMMTPA guys can break these crankshafts running modified 1702 heads and 60% nitro.

Have you been to any pulls? I learned of this many years ago and it looks interesting.

gkamysz- Gold Member

- Posts : 416

Join date : 2018-02-22

Location : Chicagoland

Re: messing around with flywheels

Re: messing around with flywheels

No I haven’t but I bought a lot of parts from a NMMTPA competor had on eBay. I should say a lot of carnage. 1/2 the 1702 glow heads looked brand new but the filament was melted out. Couple of .051 cylinders with the piston wedged tight and the con rod broken off at the ball socket. Broken cranks, holes in crankcases. Looked like good fun.

Every once an a while a NMMTPA modified Ertl dicast tractor shows up on eBay. They still bring good money. I’ll have to throw a bid at one sometime.

Every once an a while a NMMTPA modified Ertl dicast tractor shows up on eBay. They still bring good money. I’ll have to throw a bid at one sometime.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: messing around with flywheels

Re: messing around with flywheels

Roddie , do plan to run a engine with just the flywheel ? it would bee interesting to see if it will overspeed or just run like a prop installed .

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: messing around with flywheels

Re: messing around with flywheels

getback wrote:Roddie , do plan to run a engine with just the flywheel ? it would bee interesting to see if it will overspeed or just run like a prop installed .

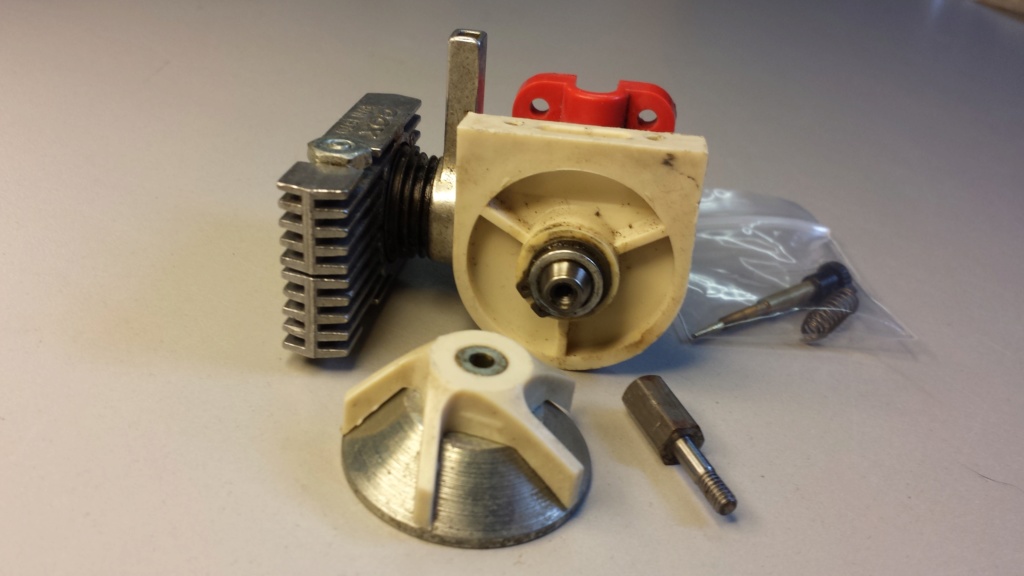

Hi Eric, Yes.. I do intend to bench-run a Cox reed-valve .049 engine with only a flywheel. As an over-speed precaution; I intend to integrate a throttle. The easiest way for me to achieve this, is to use the "Ace/Ralph Cooney" venturi-throttle.. designed for the Babe Bee. (you've seen my vid..

Another aspect of bench-running a "flywheel-only" air-cooled engine is providing sufficient cooling. I have options there too.

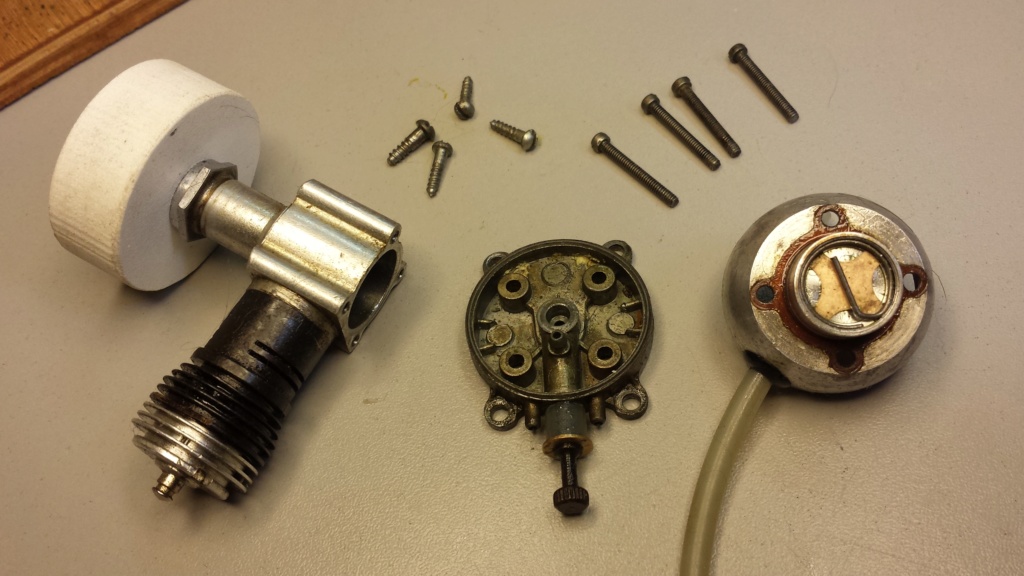

The Cox #1970 heat-sink, which is a clamp-on accessory. The Cox "Sandblaster" P/N is 8477...

Then there's "water-cooling". Shown below is a Dumas model-boat part #3601 designed to clamp-around the glow-head of the Cox .049 engine.)

So............... there's some options for throttling/cooling a Cox .049 engine that's being bench-run without an air-screw (propeller)

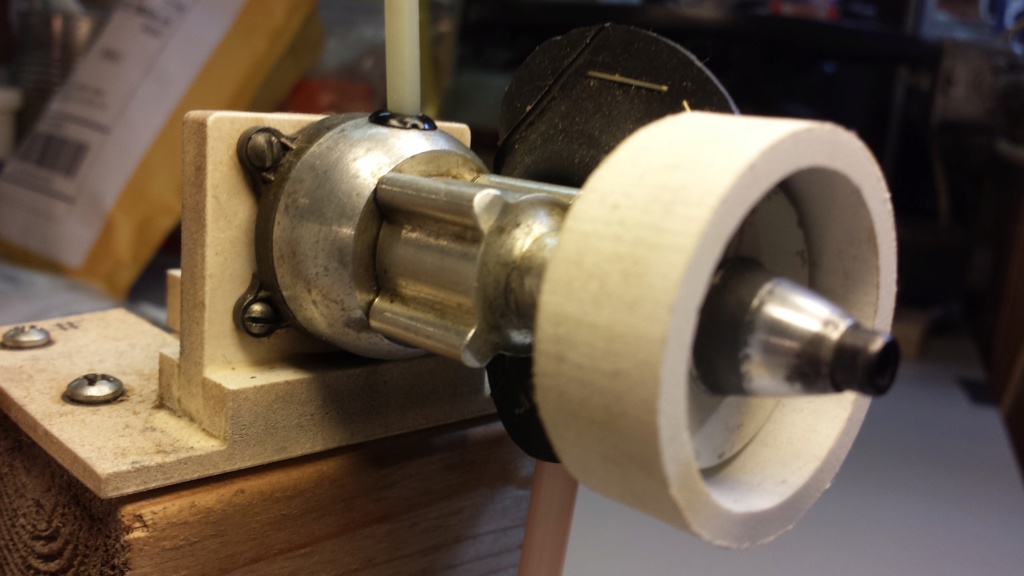

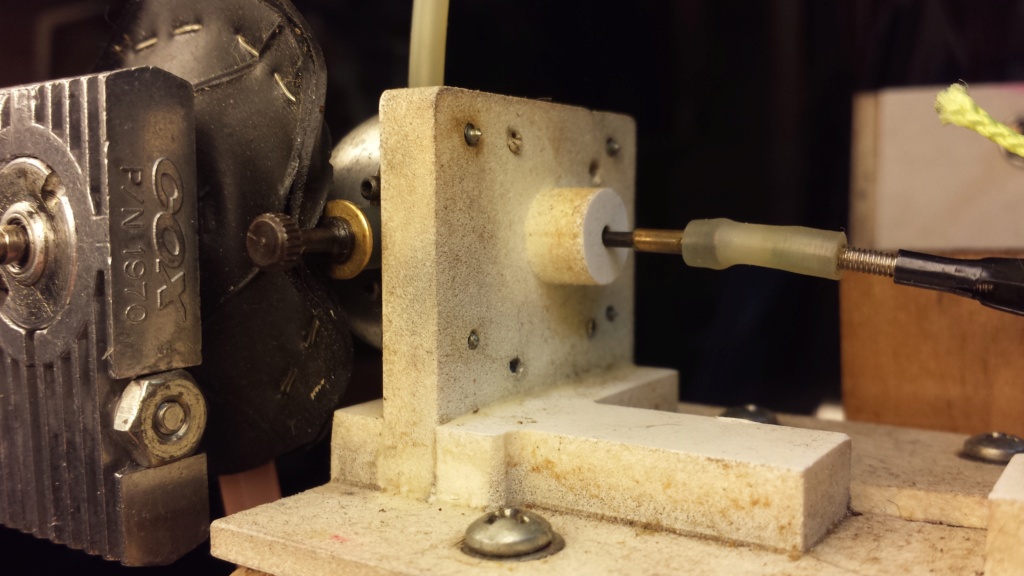

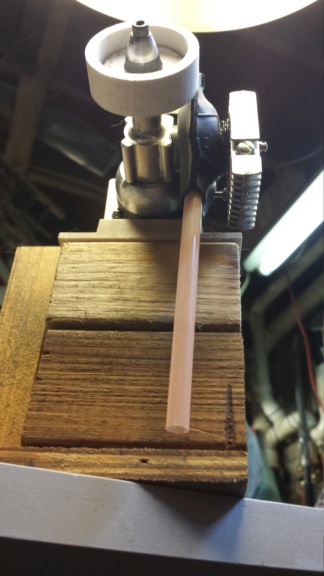

prep for bench-run

prep for bench-run

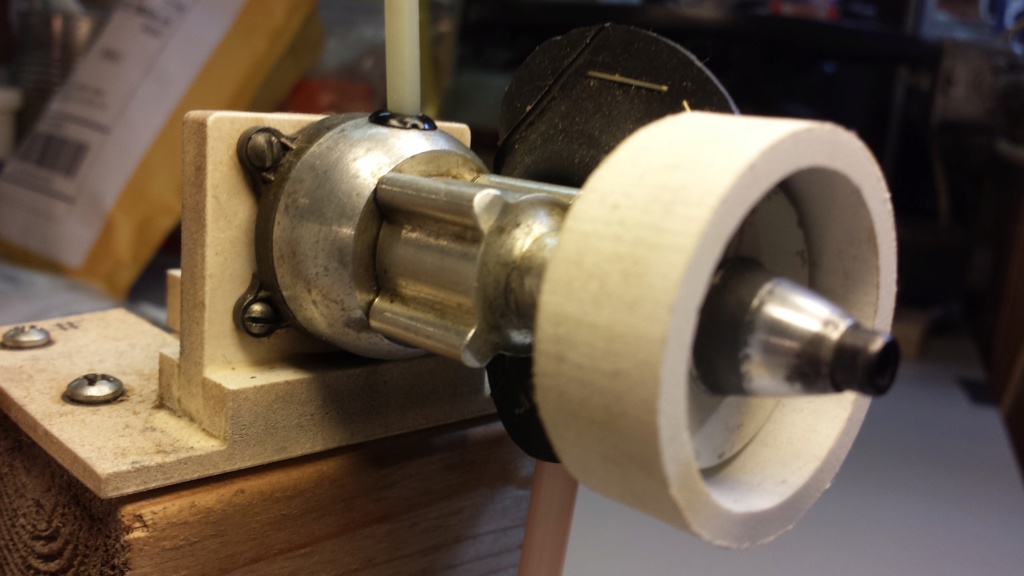

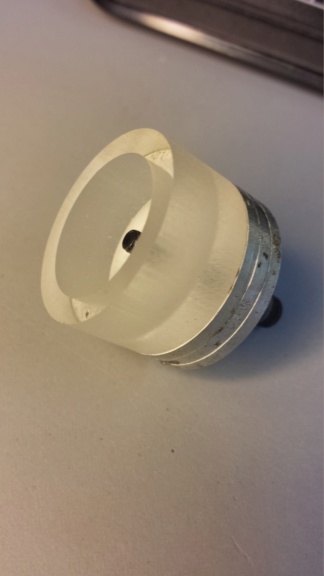

I'm so freakin' glad it's Friday..  (does a happy-dance..) so I decided to prep an engine for bench-running a flywheel. I prepared a lighter-weight flywheel from some various parts that I made on a CNC router-machine a few years ago. These pieces are made from PVC, Acrylic and Aluminum in various sizes.. but are mostly "small discs" having a .125" (1/8") diameter center-hole. This is the correct-size "bore/hole" for the Cox .049's 5-40 size propeller-screw.

(does a happy-dance..) so I decided to prep an engine for bench-running a flywheel. I prepared a lighter-weight flywheel from some various parts that I made on a CNC router-machine a few years ago. These pieces are made from PVC, Acrylic and Aluminum in various sizes.. but are mostly "small discs" having a .125" (1/8") diameter center-hole. This is the correct-size "bore/hole" for the Cox .049's 5-40 size propeller-screw.

I can vary flywheel-weight by a considerable amount.. which might prove to be interesting.

The weather here in Rhode Island has been consistently cold.. (this is our Winter-season) and "I" haven't been feeling well (physically) either.. but I'm dealing..

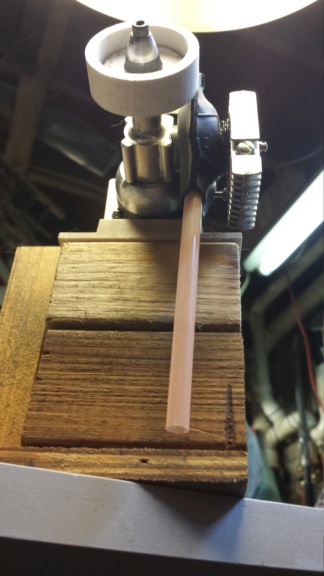

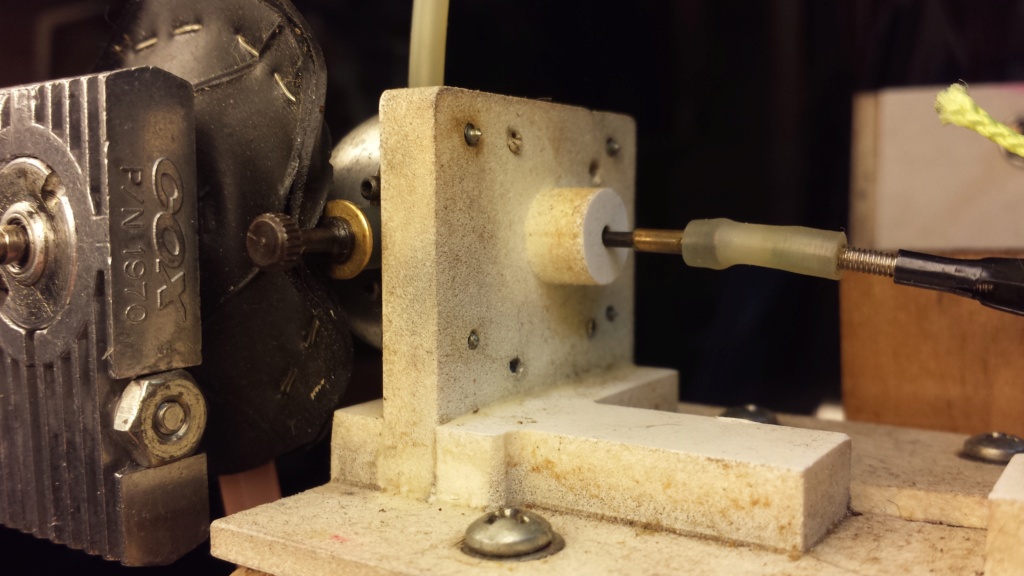

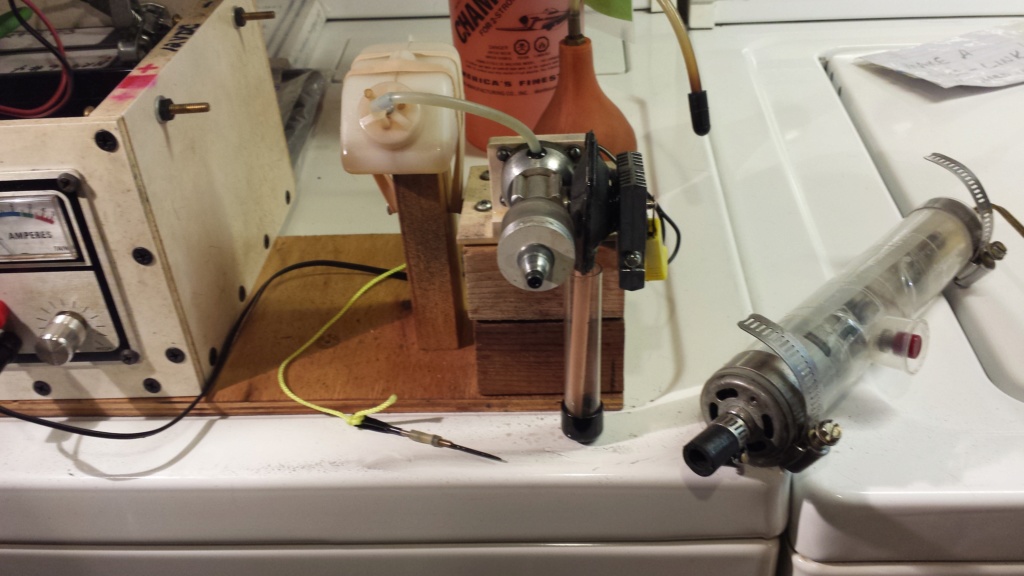

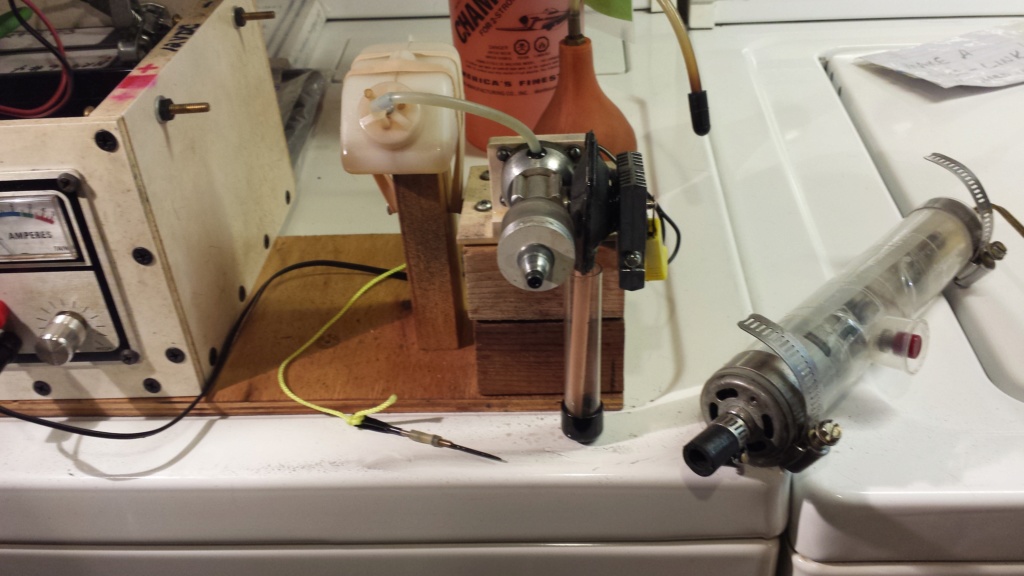

I built a rig tonight for indoor bench-running. I had most of what I needed. It was just a matter of configuring some components to work in harmony.

I wanted to "muffle" the exhaust.. as well as routing exhaust-wastes (oil) into a sump.. if possible. My homemade muffler-design might take care of both concerns.

I'll be running a Cox-(brand) heat-sink.. but I also have a Dumas "water-jacket".. in case the engine shows signs of excessive heat.

Then there's the throttle..

I can vary flywheel-weight by a considerable amount.. which might prove to be interesting.

The weather here in Rhode Island has been consistently cold.. (this is our Winter-season) and "I" haven't been feeling well (physically) either.. but I'm dealing..

I built a rig tonight for indoor bench-running. I had most of what I needed. It was just a matter of configuring some components to work in harmony.

I wanted to "muffle" the exhaust.. as well as routing exhaust-wastes (oil) into a sump.. if possible. My homemade muffler-design might take care of both concerns.

I'll be running a Cox-(brand) heat-sink.. but I also have a Dumas "water-jacket".. in case the engine shows signs of excessive heat.

Then there's the throttle..

Re: messing around with flywheels

Re: messing around with flywheels

Hey Roddie, I’ve been a fan of your inventions and experiments for a long time  This will be interesting.

This will be interesting.

One thing to keep in mind though is that the flywheel causes only ”inertia” load, that is, the load is steady and it is applied only during acceleration. With a propeller the load increases as the rpms increase, and that causes the engine speed to stabilize at a certain level where the engine power curve meets the propeller load curve. With a flywheel only, the limit of the revs is met when the internal friction of the engine meets engine power. Sometimes they don’t meet at all and the engine destructs.

Hard for me to explain, I hope it makes at least some sense Kind of like accelerating a car on top gear going up a grade vs having it on neutral and just keeping the gas pedal to the floor. And doing that with a race engine with no rev limiter

Kind of like accelerating a car on top gear going up a grade vs having it on neutral and just keeping the gas pedal to the floor. And doing that with a race engine with no rev limiter

The bottom line is, as a backup, keep a leather glove or something ready so that you can apply ”brake” on the flywheel if it seems your rpm gets too high, to avoid engine destruction.

EDIT: Or you can just pinch the fuel line I was so concentrated looking at the flywheel, muffler, heatsink etc that did not notice you had the Babe equipped with an external tank. So you should be fine

I was so concentrated looking at the flywheel, muffler, heatsink etc that did not notice you had the Babe equipped with an external tank. So you should be fine

EDIT2: And looks like you have a throttle too... You have it all figured out so I’ll just shut up now and watch

This will be interesting.

This will be interesting.One thing to keep in mind though is that the flywheel causes only ”inertia” load, that is, the load is steady and it is applied only during acceleration. With a propeller the load increases as the rpms increase, and that causes the engine speed to stabilize at a certain level where the engine power curve meets the propeller load curve. With a flywheel only, the limit of the revs is met when the internal friction of the engine meets engine power. Sometimes they don’t meet at all and the engine destructs.

Hard for me to explain, I hope it makes at least some sense

Kind of like accelerating a car on top gear going up a grade vs having it on neutral and just keeping the gas pedal to the floor. And doing that with a race engine with no rev limiter

Kind of like accelerating a car on top gear going up a grade vs having it on neutral and just keeping the gas pedal to the floor. And doing that with a race engine with no rev limiter The bottom line is, as a backup, keep a leather glove or something ready so that you can apply ”brake” on the flywheel if it seems your rpm gets too high, to avoid engine destruction.

EDIT: Or you can just pinch the fuel line

I was so concentrated looking at the flywheel, muffler, heatsink etc that did not notice you had the Babe equipped with an external tank. So you should be fine

I was so concentrated looking at the flywheel, muffler, heatsink etc that did not notice you had the Babe equipped with an external tank. So you should be fine

EDIT2: And looks like you have a throttle too... You have it all figured out so I’ll just shut up now and watch

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: messing around with flywheels

Re: messing around with flywheels

Looks like its coming together bro , glad you went with the heat sink will make life easier , this will bee interesting to see what the Rs will do !

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: messing around with flywheels

Re: messing around with flywheels

KariFS wrote:Hey Roddie, I’ve been a fan of your inventions and experiments for a long timeThis will be interesting.

One thing to keep in mind though is that the flywheel causes only ”inertia” load, that is, the load is steady and it is applied only during acceleration. With a propeller the load increases as the rpms increase, and that causes the engine speed to stabilize at a certain level where the engine power curve meets the propeller load curve. With a flywheel only, the limit of the revs is met when the internal friction of the engine meets engine power. Sometimes they don’t meet at all and the engine destructs.

Hard for me to explain, I hope it makes at least some senseKind of like accelerating a car on top gear going up a grade vs having it on neutral and just keeping the gas pedal to the floor. And doing that with a race engine with no rev limiter.

Hi Kari, Thanks for your support. I appreciate it very much. I don't always deliver with some of my claims.. and my test-methods often fall short of being scientific.

That said; I do manage to have fun.

That said; I do manage to have fun.I paid some mind to your explanation of inertial-load and its' effect on acceleration.. as compared to the continuous-load of an airscrew. I never really thought about it.. but it makes perfect sense.

The 1 oz. weight of the Cox buggy-style flywheel and also the Dumas marine-type for the .049 seems to be a magic-number for providing the inertia to keep the engine running.. but also keeps rpm's within a safe-range under a no-load condition.

The flywheel assembly that I show in the above photos has over 60% less mass. That might be a poor choice.. (at least to start with...) but as I mentioned; I have components for custom-tailoring the flywheel-weight/mass.

Here's an interesting combination..

It's a cast-acrylic "hub" having a .750" diameter bore which will fit over an engines' prop-drive plate.. (including the "hex" type).

This combo weighs-in at .5 oz. with the screw and Tee Dee-style aluminum spinner.

I don't really need the spinner.. (which requires .413" of useable screw-length..

Here's what I came up with for a sump to catch exhaust-oil..

I'm not sure if the plastic "straw" tube will hold-up to the heat.. but it's a nice tight-fit around the .22cal. shell-casing which serves as a header-pipe.

Re: messing around with flywheels

Re: messing around with flywheels

You might want to see my latest test. Just to prepare yourself.

You shouldn’t have the same problem with your setup.

You shouldn’t have the same problem with your setup.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: messing around with flywheels

Re: messing around with flywheels

getback wrote:Looks like its coming together bro , glad you went with the heat sink will make life easier , this will bee interesting to see what the Rs will do !

Yea.. I've never tried using the water-jacket. I bought that back in the early 1990's at a LHS that we had in my hometown of Franklin, MA. That's also where I got the Dumas running-hardware kit (H5 #2306) for their AVL hydro which included a flywheel which was designed for the Cox .049 engine.

Somewhere packed-away.. I have a pair of replacement WS washer-system pumps.. (I think they were made by Roberk) and one could be used to pump cooling-water from a reservoir-bottle through a head-jacket/coil and back into the bottle. A bit more fuss/work than popping-on a Cox heat-sink.. but it would provide optimal cooling.

I'm not sure how much actual cooling that the Cox heat-sink "alone" provides..

The Cox flywheel(s) all seem to have vane-like features which would provide some additional air-circulation with or without a heat-sink.

The Cox flywheel(s) all seem to have vane-like features which would provide some additional air-circulation with or without a heat-sink.

Re: messing around with flywheels

Re: messing around with flywheels

My GT-40 has had all of it's fins broken off the cooling fan for the past 40 years. It's never over heated. I really don't think that heat sink is doing all that much for the engine aside from offering a additional part to get burned on. In addition, flying combat with TD's, I have had dozens of mid airs which the prop entirely shatters, the drive plate snaps off, or the prop screw breaks off taking prop with it. The engine is now on a shaft run and it's screaming. I have never seized a engine as a result of this, nor has one threw a rod or broken crankpin. Whenever, I had a catastrophic failure the engine always had a load on it. This was with TD's so I can't comment on product engines as the crankshafts are entirely different.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: messing around with flywheels

Re: messing around with flywheels

Thanks for checking-in.. and your comments Ken. That's some valuable info. which puts my mind a bit at ease. I'm hoping to learn a few different lessons with my experiment here.

My bad for not ID'ing the cylinder/porting prior to configuring this engine.. so I can't report on that... as of yet. If the cylinder has sub-port induction.. it will be interesting to see how it runs with a muffler.

so I can't report on that... as of yet. If the cylinder has sub-port induction.. it will be interesting to see how it runs with a muffler.

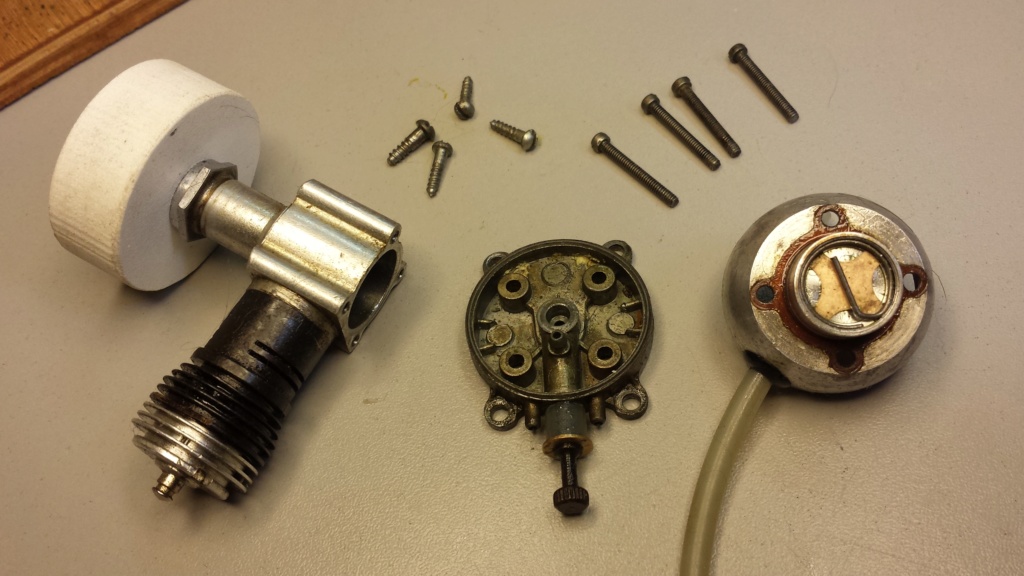

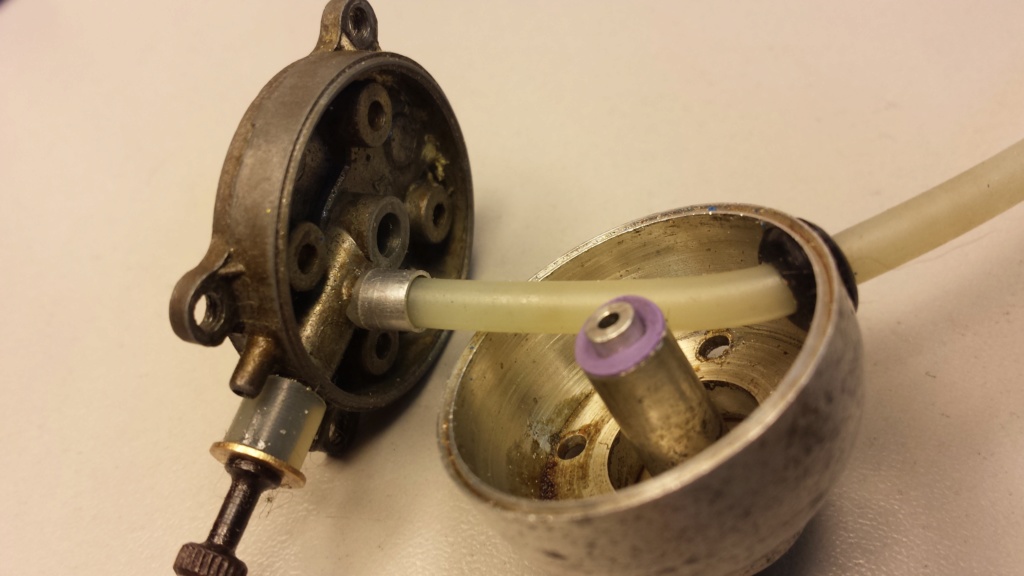

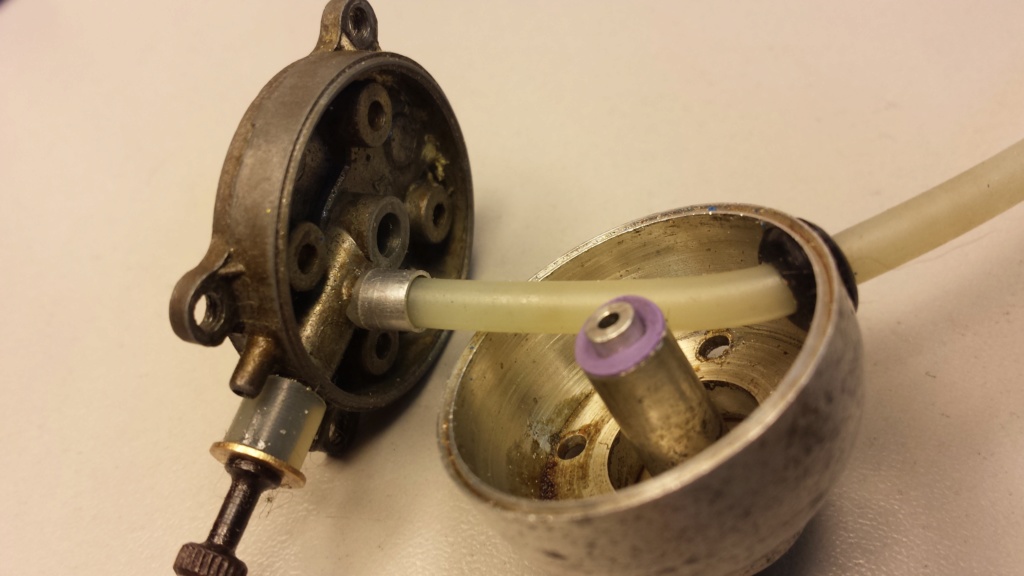

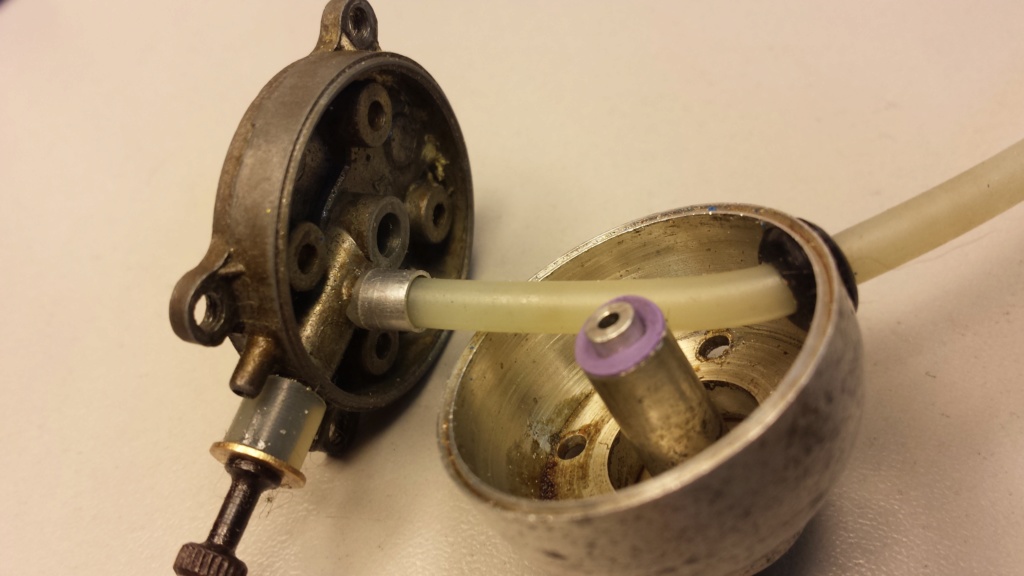

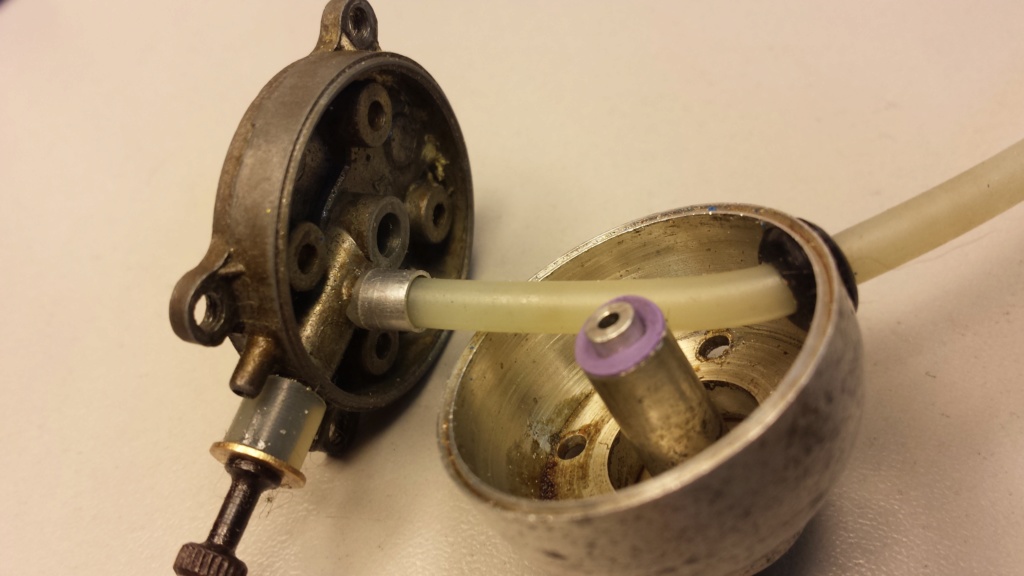

The reed is the old copper-star type. I did verify its' functionality when I had the tank off. I removed the tank to renew the fuel-line connection on the backplate-nipple.

(repeat-photo) note the venturi (purple) gasket. It was made from a rubber kitchen-glove.

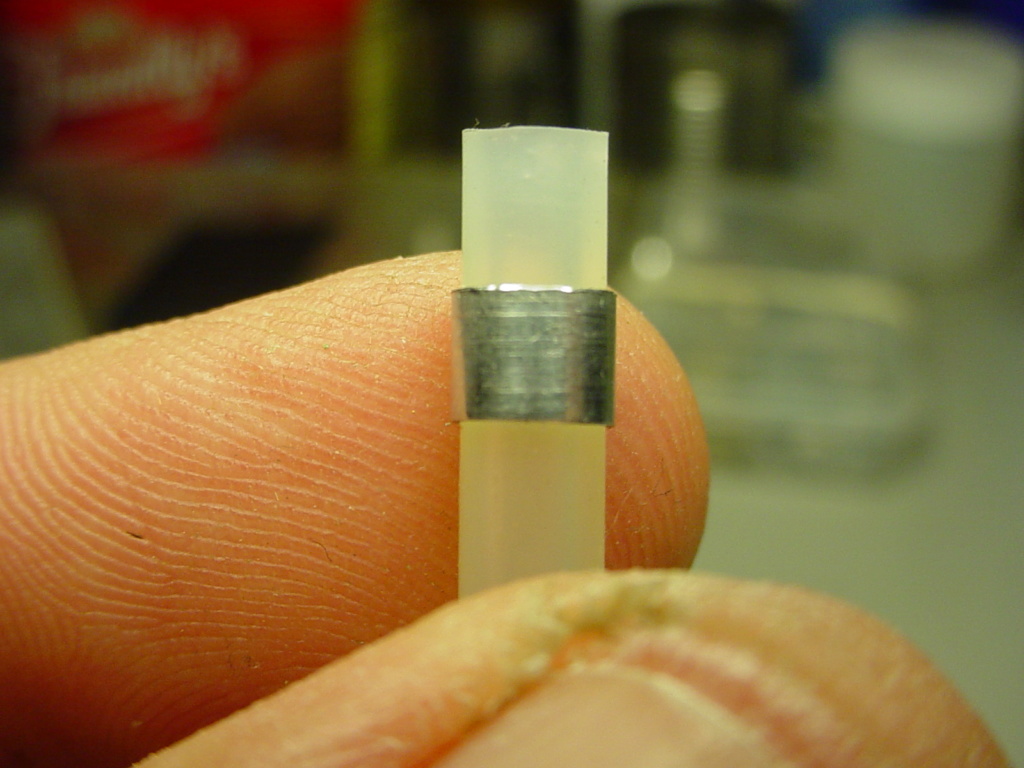

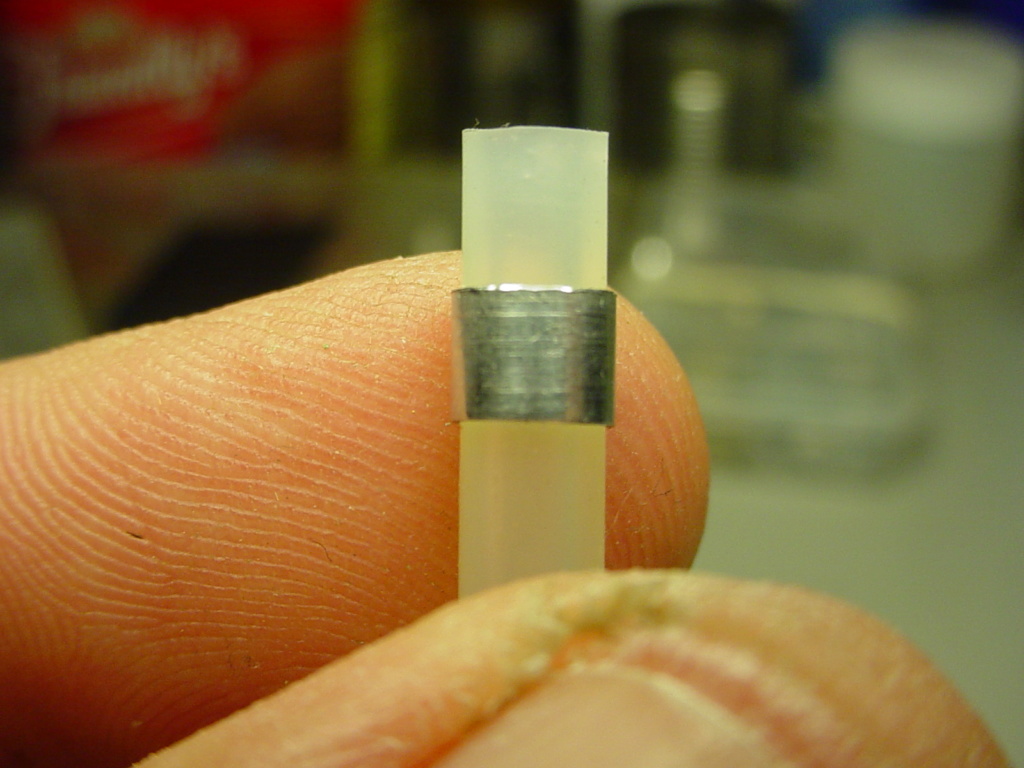

I make a "collar" from alloy-tubing which serves as a compression-fitting for the silicone fuel-line that I use. The silicone fuel-line "alone" won't stay tightly-connected to the short nipple. The "collar" is installed over the fuel-line prior to attachment to the nipple.. then it's forced-over the connection, which "locks" the line in-place. It's a PIA.. but worth-it from a reliability standpoint.

some photos below for clarification..

You may ask "why"? I'll explain.. Several years ago I discovered the "Ace" (Ralph Cooney designed) venturi-throttle, designed for the Cox .049 Babe Bee engine. It works quite well and is so simple; it's amazing. You can make one from a short piece of 1/16" diameter music-wire.. by slightly tapering one end. It's simply a "plunger" which moves in and out of the engine's air-intake, after the mesh/debris-screen is removed. It's a super-lightweight mod, that turns your little .049 Bee into an RC (throttled) engine. Add to that; an increased fuel-capacity.. combined with 21st century featherweight radio gear.. and you have a petrol-burning power-plant with plenty of power for micro-RC aircraft.

I'll be using that Ace/Cooney throttle for these flywheel tests..

My bad for not ID'ing the cylinder/porting prior to configuring this engine..

so I can't report on that... as of yet. If the cylinder has sub-port induction.. it will be interesting to see how it runs with a muffler.

so I can't report on that... as of yet. If the cylinder has sub-port induction.. it will be interesting to see how it runs with a muffler. The reed is the old copper-star type. I did verify its' functionality when I had the tank off. I removed the tank to renew the fuel-line connection on the backplate-nipple.

(repeat-photo) note the venturi (purple) gasket. It was made from a rubber kitchen-glove.

I make a "collar" from alloy-tubing which serves as a compression-fitting for the silicone fuel-line that I use. The silicone fuel-line "alone" won't stay tightly-connected to the short nipple. The "collar" is installed over the fuel-line prior to attachment to the nipple.. then it's forced-over the connection, which "locks" the line in-place. It's a PIA.. but worth-it from a reliability standpoint.

some photos below for clarification..

You may ask "why"? I'll explain.. Several years ago I discovered the "Ace" (Ralph Cooney designed) venturi-throttle, designed for the Cox .049 Babe Bee engine. It works quite well and is so simple; it's amazing. You can make one from a short piece of 1/16" diameter music-wire.. by slightly tapering one end. It's simply a "plunger" which moves in and out of the engine's air-intake, after the mesh/debris-screen is removed. It's a super-lightweight mod, that turns your little .049 Bee into an RC (throttled) engine. Add to that; an increased fuel-capacity.. combined with 21st century featherweight radio gear.. and you have a petrol-burning power-plant with plenty of power for micro-RC aircraft.

I'll be using that Ace/Cooney throttle for these flywheel tests..

Re: messing around with flywheels

Re: messing around with flywheels

Incidentally.. (I forgot to mention..) I am curious to see how the copper-reed (which is installed in this test-engine) performs when the rpm's get into the upper-range. Some modeler's claim that the vintage thin copper-reed tends to "float" at the upper-end.. (whatever that # is..)

Re: messing around with flywheels

Re: messing around with flywheels

I hope to have a video within a few hours..  The camera (of choice..) is charging.. and I've already "lit the fire" to get a ball-park needle-setting and check fuel-draw from the Sullivan #435 (1 oz.) slant-type clunk-tank.

The camera (of choice..) is charging.. and I've already "lit the fire" to get a ball-park needle-setting and check fuel-draw from the Sullivan #435 (1 oz.) slant-type clunk-tank.

This setup has always drawn fuel really well.. I must say. Because of the muffler-installation; I couldn't perform an exhaust-prime. When the Ace throttle/plunger is advanced "into" the air-intake, it effectively "chokes" the venturi when cranking. Fuel is quickly drawn through the line.. especially when using an electric-starter.

This setup has always drawn fuel really well.. I must say. Because of the muffler-installation; I couldn't perform an exhaust-prime. When the Ace throttle/plunger is advanced "into" the air-intake, it effectively "chokes" the venturi when cranking. Fuel is quickly drawn through the line.. especially when using an electric-starter.

FUN WITH FLYWHEELS

FUN WITH FLYWHEELS

Ready, Set, Go...you got it all set up. Video camera fully charged? Sounds like a great Saturday nights fun! Like others, I’ll shut up and wait!!

Shout out to Ken! Hey thanks for the info on running your GT40 with out cooling fins without catastrophic results. My corvette engine has a fin missing and I was concerned about running it unbalanced. Kinda thought that “turbo” fan did nothing but sling castor oil all over the interior of the car anyways!

Ok, Roddie.....we are ready.

Shout out to Ken! Hey thanks for the info on running your GT40 with out cooling fins without catastrophic results. My corvette engine has a fin missing and I was concerned about running it unbalanced. Kinda thought that “turbo” fan did nothing but sling castor oil all over the interior of the car anyways!

Ok, Roddie.....we are ready.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: messing around with flywheels

Re: messing around with flywheels

Let me preface.. by letting ya'll know that the "fuel" being burned in this engine is almost 30 years old.. and is a mixture of Sig-Champion 25/35 blends that I combined in one qt. size bottle last Summer.

https://www.youtube.com/watch?v=TETrZlI5L7o&feature=youtu.be

https://www.youtube.com/watch?v=TETrZlI5L7o&feature=youtu.be

Re: messing around with flywheels

Re: messing around with flywheels

Here's a 2nd test running a .3 oz. flywheel..

Last edited by roddie on Sun Jan 20, 2019 11:50 am; edited 3 times in total (Reason for editing : trying to fix vid-link)

Page 2 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» Messing with Sasquach

» Cox needle-valve seals

» Testors/McCoy .049 smoked...

» flywheels.. weighting your crankshaft

» Cox needle-valve seals

» Testors/McCoy .049 smoked...

» flywheels.. weighting your crankshaft

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules