Log in

Search

Latest topics

» TEE DEE Having issuesby TD ABUSER Today at 9:43 pm

» Landing-gear tips

by roddie Today at 6:17 pm

» Roger Harris revisited

by TD ABUSER Today at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Today at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 1:37 pm

» Happy 77th birthday Andrew!

by getback Today at 11:52 am

» My latest doodle...

by roddie Today at 10:43 am

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Racing Wheels!

Page 1 of 1

Racing Wheels!

Racing Wheels!

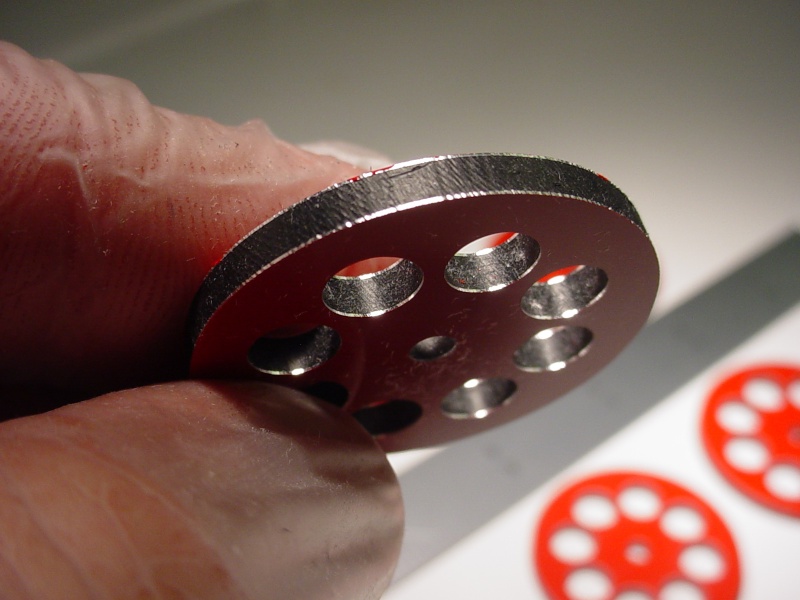

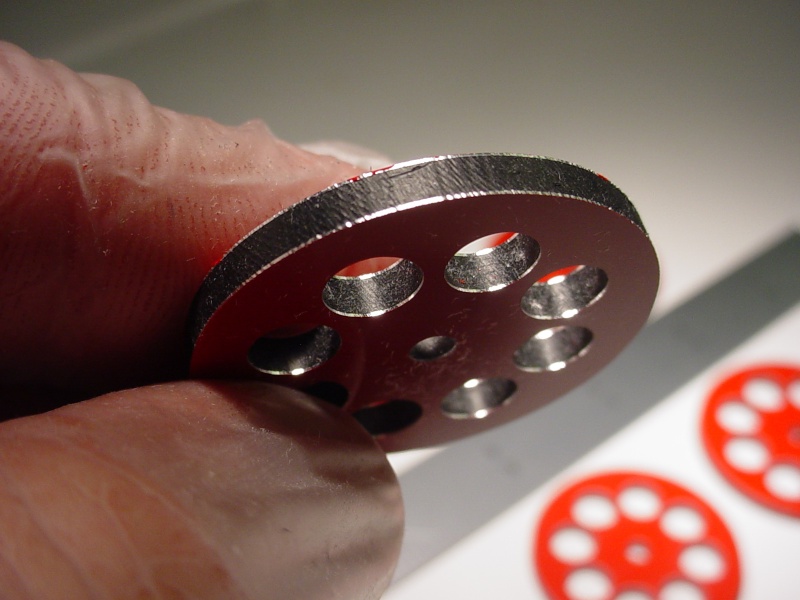

I made these today during lunch on the CNC router.

The material is a 3mm thickness exterior-grade "sign-panel" sheet-product that we have where I work. The core is PVC with thin aluminum "faces" bonded to each side. We also have it in "white".. but the white has a white "core". The red has a black core.. and I plan on milling the aluminum "off one side" around the outer edge; to give the "faux" appearance of a black tire.

The hubs are drilled 1/8" diameter and can be "bushed" smaller, as I did with the tail-wheels that I recently made from black 6mil PVC.

I'm not sure what would be better.. the "spoked" or the "solid" design? The solid wheel(s) would have less drag.. but the spoked version would be lighter. (I'm splitting-hairs here.. because these wheels are VERY lightweight) They also could be scuff-sanded and re-painted a different color.

These wheels are most suited to 1/4A-1/2A size models. Any bigger; you'd want to go with a conventional wheel with a sponge-tire, for it's shock-absorbing properties.

If any of you; 2nd-round "CEF Reed-Speed" contestants are building models with "gear".. these wheels would be a super-lightweight option. The ones shown are 1.25", 1.375" and 1.5" in diameter.. but I can "custom" make any diameter.. and "bush" them for your planned axle... tail-wheel as well. Let me know soon if you're interested. I'm not looking to make a lot of money off these wheels.. but what would "you" pay for a set? I'd like some feedback on this.

The material is a 3mm thickness exterior-grade "sign-panel" sheet-product that we have where I work. The core is PVC with thin aluminum "faces" bonded to each side. We also have it in "white".. but the white has a white "core". The red has a black core.. and I plan on milling the aluminum "off one side" around the outer edge; to give the "faux" appearance of a black tire.

The hubs are drilled 1/8" diameter and can be "bushed" smaller, as I did with the tail-wheels that I recently made from black 6mil PVC.

I'm not sure what would be better.. the "spoked" or the "solid" design? The solid wheel(s) would have less drag.. but the spoked version would be lighter. (I'm splitting-hairs here.. because these wheels are VERY lightweight) They also could be scuff-sanded and re-painted a different color.

These wheels are most suited to 1/4A-1/2A size models. Any bigger; you'd want to go with a conventional wheel with a sponge-tire, for it's shock-absorbing properties.

If any of you; 2nd-round "CEF Reed-Speed" contestants are building models with "gear".. these wheels would be a super-lightweight option. The ones shown are 1.25", 1.375" and 1.5" in diameter.. but I can "custom" make any diameter.. and "bush" them for your planned axle... tail-wheel as well. Let me know soon if you're interested. I'm not looking to make a lot of money off these wheels.. but what would "you" pay for a set? I'd like some feedback on this.

Re: Racing Wheels!

Re: Racing Wheels!

I am building a small RC bird using dollar tree foam wheels with hot glue tires. Coffee stirrers for the axle to pass.

Yea, you have me beat by miles and miles. Nicely done.

Phil

Yea, you have me beat by miles and miles. Nicely done.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Racing Wheels!

Re: Racing Wheels!

Seems like I paid 5 or 6 bucks a set for the 1/2a proto wheels I used on my last reed speed models. I would make them solid. Unless you're saving a significant amount of weight aerodynamics trumps weight savings.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Racing Wheels!

Re: Racing Wheels!

Thanks both to Phil and Jim.

Phil.. if I didn't have access to the CNC router.. and the vast array of interesting materials that I do at work.. I'd most definitely be experimenting with easily accessible materials available at the store.. using the tools I have at home.. the same as you are. That's truly "hand-made".. and really what modeling is all about.

Jim, The "solids" were what I was thinking would be better aerodynamically as well. The "spoked" versions look cool.. but I imagine the holes would cause unwanted turbulence/drag. We're talking "micro-grams" of weight difference between the two.

So.. Is a set of my "main" wheels worth 5 bucks.. or 7 bucks with a tailwheel plus shipping? (that's "rigid-bushed" for your axle diameters).. That's kinda' what I was thinking... but I wanted some feedback before offering them at that price.

EDIT: tail-wheels can be made of the same 3mm (approx. .118" thickness) material.. rather than the 6mil one shown.. which is for a considerably larger model.

Phil.. if I didn't have access to the CNC router.. and the vast array of interesting materials that I do at work.. I'd most definitely be experimenting with easily accessible materials available at the store.. using the tools I have at home.. the same as you are. That's truly "hand-made".. and really what modeling is all about.

Jim, The "solids" were what I was thinking would be better aerodynamically as well. The "spoked" versions look cool.. but I imagine the holes would cause unwanted turbulence/drag. We're talking "micro-grams" of weight difference between the two.

So.. Is a set of my "main" wheels worth 5 bucks.. or 7 bucks with a tailwheel plus shipping? (that's "rigid-bushed" for your axle diameters).. That's kinda' what I was thinking... but I wanted some feedback before offering them at that price.

EDIT: tail-wheels can be made of the same 3mm (approx. .118" thickness) material.. rather than the 6mil one shown.. which is for a considerably larger model.

Re: Racing Wheels!

Re: Racing Wheels!

$5-7? wow, that's expensive, $2.50 should be enough; Tower Hobbies

Just kidding, homemade is always better, then you are sure to have something unique too.

Just kidding, homemade is always better, then you are sure to have something unique too.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Racing Wheels!

Re: Racing Wheels!

Machine a groove around the outside and slip on a correct sized O ring

at that size diaameter and the width of the frontal section (relative to the wind being flown through) there should be zero drag coefficient difference between the two designes

at that size diaameter and the width of the frontal section (relative to the wind being flown through) there should be zero drag coefficient difference between the two designes

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Racing Wheels!

Re: Racing Wheels!

fredvon4 wrote:Machine a groove around the outside and slip on a correct sized O ring

at that size diaameter and the width of the frontal section (relative to the wind being flown through) there should be zero drag coefficient difference between the two designes

I don't have access to a lathe Fred.. but there is the possibility that a tight enough fitting O-ring might "seat" itself if the wheel was heated a little.. with the O-ring installed. The PVC core might soften.. and the O-ring might "shrink-set" between the aluminum skins. I just might try that.. to see if it works. It might be as simple as laying the wheel with the O-ring around it.. in a frying-pan and heating on the stove-top.

(that's a lot of "mights"..)

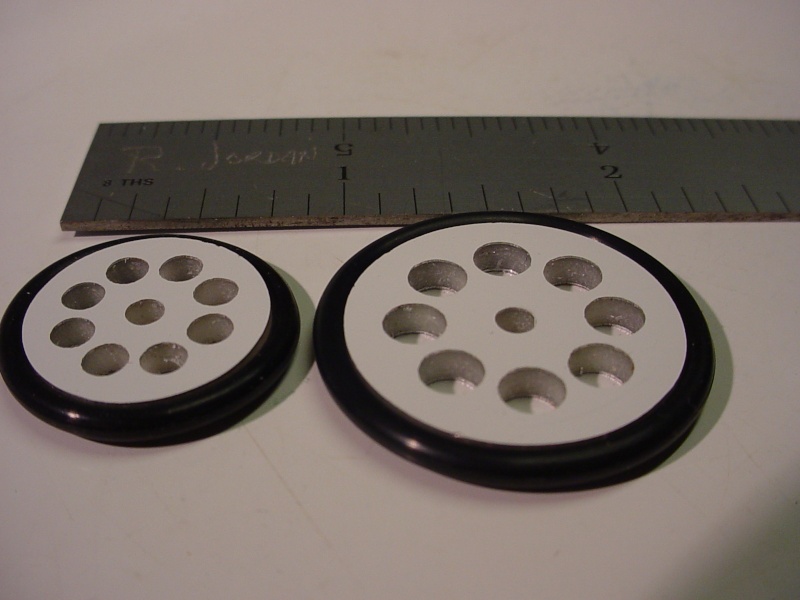

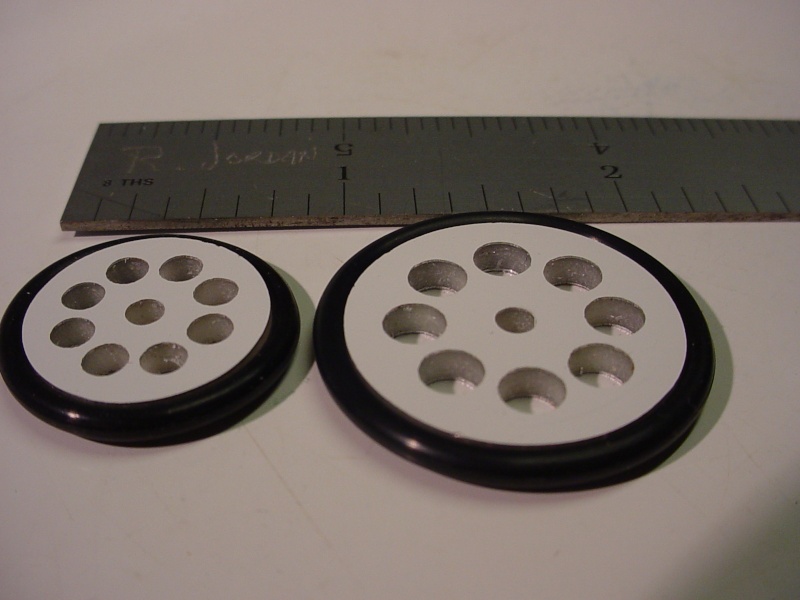

(that's a lot of "mights"..)Here's a look with an O-ring tire.. and some weight (in grams) comparisons of "spoked" vs. "solids".

My digital scale isn't super accurate.. but the "spoked" wheel/tire surely must weigh close to one gram. I really like the look of the O-ring tire. I thought it would add a lot of weight.. but it doesn't. If I can achieve a reliable "bond" between the two.. it would be a much better option. I may have to charge more $$ though... It all depends on how many wheels I can fit in the frying pan at a time!

Re: Racing Wheels!

Re: Racing Wheels!

A regular drill on slow speed and a hand file would do the job...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Racing Wheels!

Re: Racing Wheels!

Surfer_kris wrote:A regular drill on slow speed and a hand file would do the job...

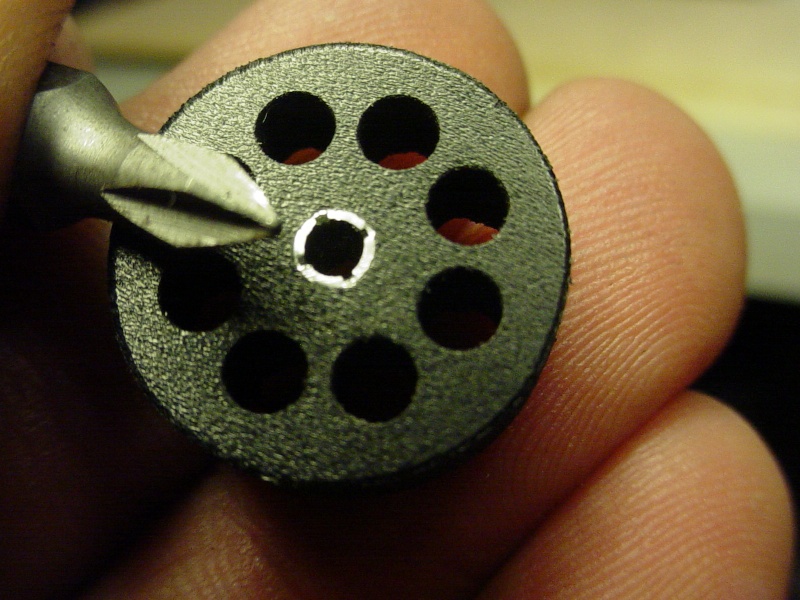

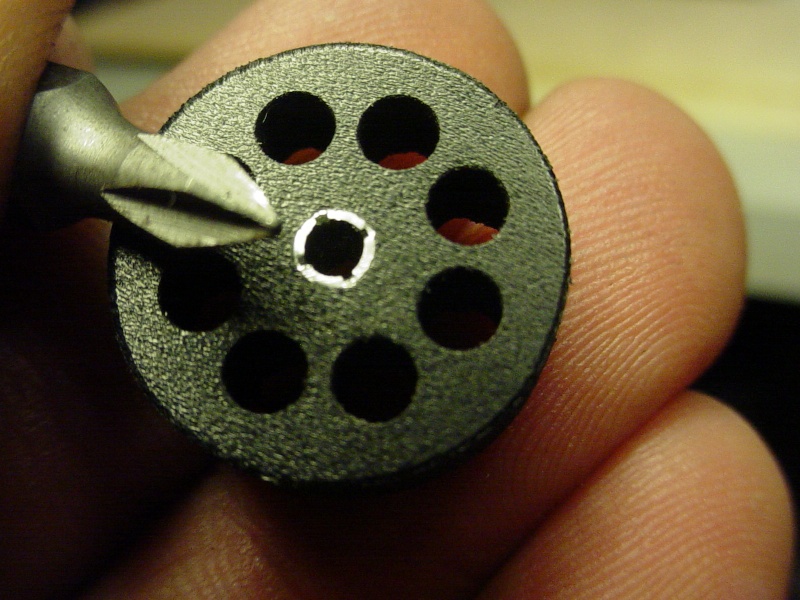

Yes indeed it would. I have a bagful of long 5-40 screws that I could make a mandrel from, for turning in a drill before I install any hub bushings. I'll try cutting the head off one, and use two nuts and rubber washers to sandwich the wheel-hub.. to help keep it secure. I have small Riffler and rat-tail files that should do the job. Thanks for mentioning that Kris!

Re: Racing Wheels!

Re: Racing Wheels!

Here's my latest wheels consisting of a different "white" 3mm composite sheet.. with a PVC core and .010" aluminum d/s facers. These wheels measure 1" and 3/4" in diameter. The O-rings are very tight as shown without a "rim" being formed. They should fit nicely once that's done. 3mm is less than 1/8" thickness.. so these wheels will have very little drag.

cutting the sheet..

and with the O-ring "tire" look.

These will have their 1/8" dia. hubs bushed for .062" music-wire axles, using aluminum tubing.

cutting the sheet..

and with the O-ring "tire" look.

These will have their 1/8" dia. hubs bushed for .062" music-wire axles, using aluminum tubing.

Re: Racing Wheels!

Re: Racing Wheels!

They look great Roddie. Do you plan on selling them?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Racing Wheels!

Re: Racing Wheels!

Cribbs74 wrote:They look great Roddie. Do you plan on selling them?

Ron, I wanted to see how they "fabbed-up".. and tonight I made a "turning-mandrel" from a 1"L. 5-40 machine-screw, two nuts and fiber washers.. to fit my moto-tool and hold the wheel tight, and used a small tapered round-file to cut the seat for the rubber O-ring/tire.. in between the aluminum facers.

The O-ring tire was a nice TIGHT fit.. so I proceeded to cut the two aluminum-tubing hub-reduction bushings to fit a 1/16" music-wire axle.. (1/8" and 3/32" o.d. tubing diameters) to the wheels 3mm thickness.. and staked them both into the hub, using size PH-0 and PH-00 Phillips insert bit/drivers.

This is a 3/4" wheel with it's tire. It would make a sweet "pair" of mains for a little 1/4A tail-dragger model.. or serve as a tail-wheel for a larger airplane.

These wheels are very thin.. about .118" (3mm) and may not work too well in the grass.. because there's not enough tire/wheel width for plowing a path for the axle/strut.. and they will snag the grass while R.O.G. or landing.

I'll more than likely mail you a set or two; for prizes/awards for CEF's Reed Speed II, as discussed previously. When you receive them, let me know what you think. I wouldn't know what to ask for a custom set. Domestically.. (U.S.) shipping is about $2.. (that's what it cost me to mail the postage-stamp mounts) I've made the "raw" wheels of this type; in sizes of 3/4", 1.0" and 1.25" diameters.. about 40 sets/ea. on the last run. I need to spec-out "O-ring sizes" for the larger two wheels.. and then I'll have the components for a production-run of those 3 sizes. I think they're a good spread for the small model airplanes that are generally discussed here.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules