Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Contest Balsa

Page 1 of 2

Page 1 of 2 • 1, 2

Contest Balsa

Contest Balsa

What constitutes "Contest" balsa? I see references to it but what exactly makes a piece of balsa contest balsa?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Contest Balsa

Re: Contest Balsa

Weight, it is not durable at all and tends to explode on impact.

At contest level, you want light and maneuverable. Durability is not a consideration.

At contest level, you want light and maneuverable. Durability is not a consideration.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Contest Balsa

Re: Contest Balsa

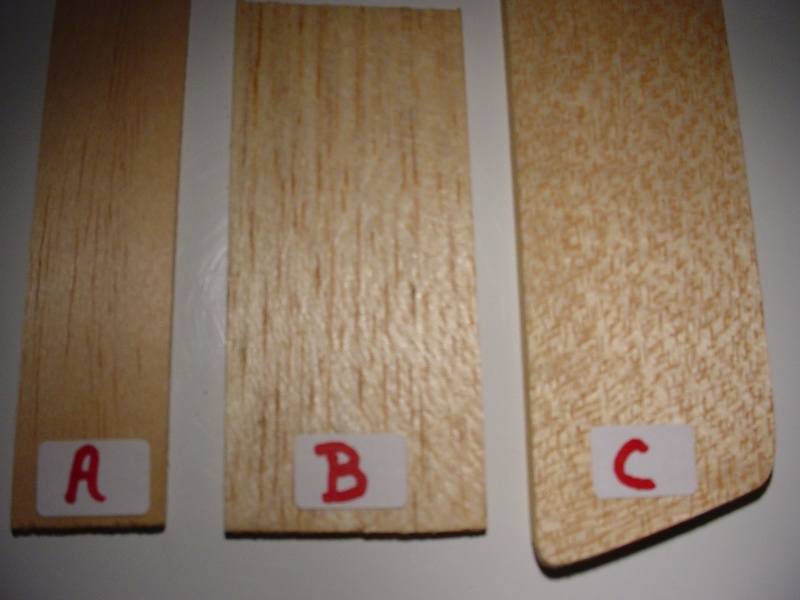

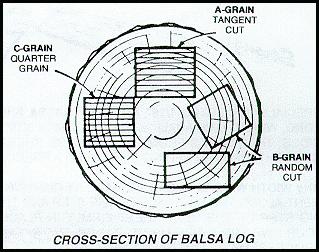

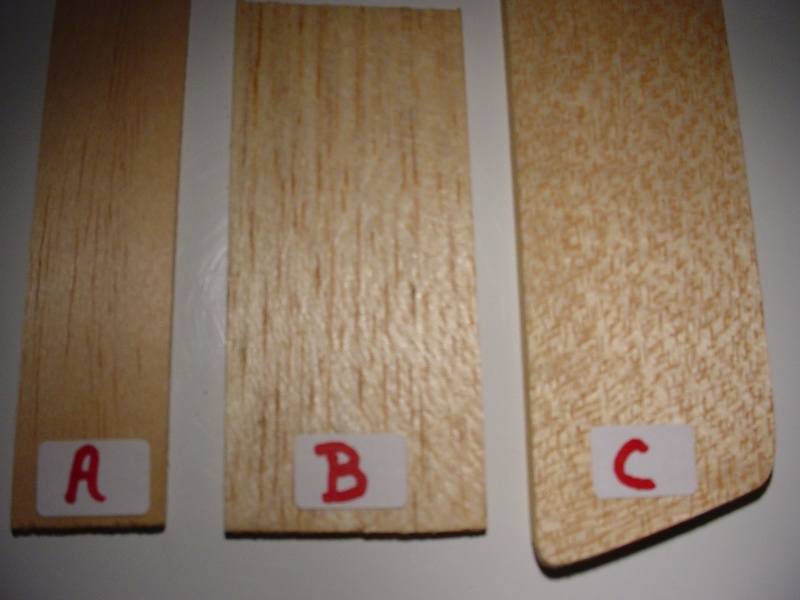

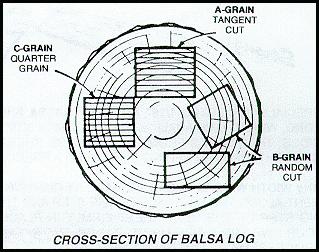

I always considered "contest-balsa" to also be "A"-grain (whatever the thickness) Take a look at your balsa scrap.. and take notice of the grain patterns of different sheets. Balsa can be cut at varying degrees in cross-section regarding the grain.. like any wood. Cutting 90 degrees cross-grain will be "heavier" and stronger wood ("C"-grain). Cutting parallel with the grain produces the lightest wood.. ("A"-grain) Cutting 45 degrees to the grain, yields a "general-purpose" (and most common) "B"-grain.

This is "my" take on the subject.. .. If you have a digital scale; weigh some "same-size" samples of the three grain types.. and you'll see for yourself.

.. If you have a digital scale; weigh some "same-size" samples of the three grain types.. and you'll see for yourself.

This is "my" take on the subject..

.. If you have a digital scale; weigh some "same-size" samples of the three grain types.. and you'll see for yourself.

.. If you have a digital scale; weigh some "same-size" samples of the three grain types.. and you'll see for yourself.Last edited by roddie on Tue Aug 12, 2014 9:28 pm; edited 1 time in total

Re: Contest Balsa

Re: Contest Balsa

From my experience that A grain doesn't even look like contest balsa, the stuff has less grain than that and what I've seen has been very white colored. You can barely touch it. You risk breaking a sheet of 1/8 by picking it up from one end. The ribs in some Brodak kits are like that.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Contest Balsa

Re: Contest Balsa

Thanks for the replies and thanks Rusty for the cutting diagram. I had wondered what Windy was talking about as he often refers to "C" grain.

Now I know - "C" grain is what I know as "quarter cu"t, "A" grain is "tangential cut" and "b" grain is "random cut".

However each cut is performed on balsa of varying weights (densities) and balsa can range from 4lb/cu ft to over 14lb/cu ft.

As a child I knew of balsa as being soft, medium and hard. Now it is referred to by grade

Grade lb/ft

Ultra Light 4 - 5.4

Light 5.5 - 6.0

Light Medium 6.1 - 7.5

Medium 7.6 - 9.5

Medium Hard 9.6 - 12

Hard 14 +

I am now assuming from the replies that "Contest Balsa" is in the "Ultra Light" category. I had thought that a kit prophesying to use "Contest" balsa would use an appropriate selection of balsa rather than the lightest.

For example, hard for major spars - with a spars hardness depending on cross section to give strength and support and the number of them.

Medium for leading a trailing edges with a light medium for ribs.

Light for things like tip blocks, maybe ribs and wing sheeting.

Ultra light only as a substrate for sheeting with fiberglass.

Light and ultra light balsa is not very strong at all. A complete aeroplane of contest balsa would be a little flimsy if all the wood is in the light/ultra light category and not used selectively.

Still, you live and learn.

Now I know - "C" grain is what I know as "quarter cu"t, "A" grain is "tangential cut" and "b" grain is "random cut".

However each cut is performed on balsa of varying weights (densities) and balsa can range from 4lb/cu ft to over 14lb/cu ft.

As a child I knew of balsa as being soft, medium and hard. Now it is referred to by grade

Grade lb/ft

Ultra Light 4 - 5.4

Light 5.5 - 6.0

Light Medium 6.1 - 7.5

Medium 7.6 - 9.5

Medium Hard 9.6 - 12

Hard 14 +

I am now assuming from the replies that "Contest Balsa" is in the "Ultra Light" category. I had thought that a kit prophesying to use "Contest" balsa would use an appropriate selection of balsa rather than the lightest.

For example, hard for major spars - with a spars hardness depending on cross section to give strength and support and the number of them.

Medium for leading a trailing edges with a light medium for ribs.

Light for things like tip blocks, maybe ribs and wing sheeting.

Ultra light only as a substrate for sheeting with fiberglass.

Light and ultra light balsa is not very strong at all. A complete aeroplane of contest balsa would be a little flimsy if all the wood is in the light/ultra light category and not used selectively.

Still, you live and learn.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Contest Balsa

Re: Contest Balsa

In a wing, harder balsa will splinter in an impact where lighter balsa may spring back.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Contest Balsa

Re: Contest Balsa

RknRusty wrote:In a wing, harder balsa will splinter in an impact where lighter balsa may spring back.

Not sure about this one Rusty. Some of the resilience is attributable to the grain.

Quarter grain ("C") wood splits easily - hard or soft but resists warping. Ideal for solid tail planes, ailerons ......... I think it is easy to be general but there is a balance between balsa density and the cut (grain) for a particular application or part.

I didn't understand the term "contest" balsa but now I understand it to be sub 6lb/cu ft. This is delicate and with my clumsiness and lack of feel when building the model would probably end up being mostly glue!

I do know that with combat models (40 +) years ago the leading edge was constructed using a "hard" balsa leading edge (sometimes spruce reinforced) and the wings survived much abuse.

Some of the RC models I have built - although lightweight - have not survived a rough landing (not what I would call a crash).

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Contest Balsa

Re: Contest Balsa

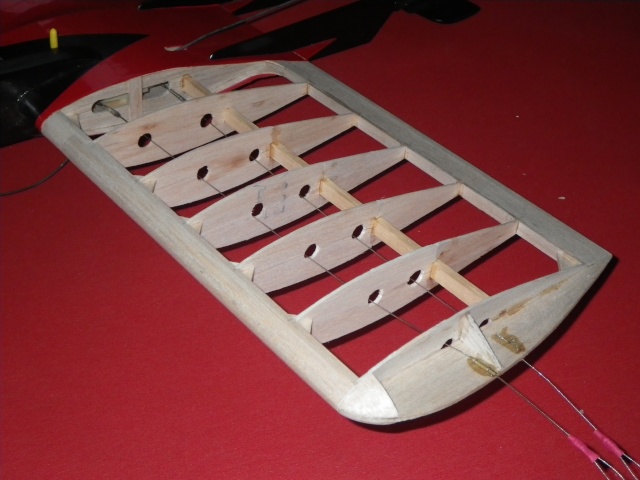

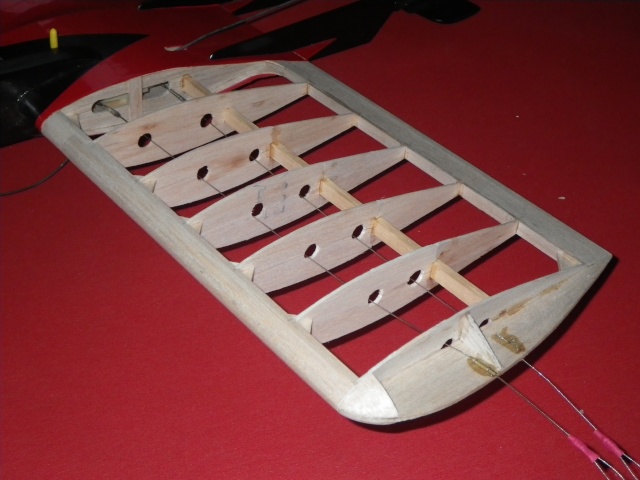

Contest grade.

Every single Rib inside that wing has been blown to bits. I think hard balsa would have stood up better.

Every single Rib inside that wing has been blown to bits. I think hard balsa would have stood up better.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Contest Balsa

Re: Contest Balsa

It does seem that way. I was repeating what I read that Brett Buck wrote on the Aeromaniacs page comparing the durability of the balsa cloned Skyrays versus the Lite ply regarding crash survival. [insert parrot smiley here]

I also recommend that you use the plans to clone a second and third airplane. Make the wings out of balsa - 3/32" ribs, full at every station, with 1/2"x1/8 medium balsa spars set vertically at the high point. Everything else is fine as it is. What this does is save about 5-6 oz. Surprisingly, without other mods, it doesn't fly significantly better (plenty of power even at 36 oz), but it's much more durable. The stock wings tend to self-destruct due to excess weight. When the nose hits, the tips just keep going, and the structure just disintegrates, even on grass. The lighter wings will just flex and then return to shape with no damage. On pavement, it's broken in any case.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Contest Balsa

Re: Contest Balsa

Here is my take:

Pound for pound, lighter balsa is stronger for its weight than heavier balsa. Heavier balsa is stronger for a given set of dimensions than lighter balsa. There is a "best" for various purposes. The assumption is clear sound wood, no splits and defects.

Balsa is sometimes not the best choice. Maple engine bearers, spruce spars, birch plywood, carbon fiber, kevlar, fiberglass, foam... Lots of choices, some are easier to select than others, some cost much more. Some require some stationary tools.

Make design choices and use them. Don't blindly follow a kit, evaluate the contents and act accordingly.

Phil

Pound for pound, lighter balsa is stronger for its weight than heavier balsa. Heavier balsa is stronger for a given set of dimensions than lighter balsa. There is a "best" for various purposes. The assumption is clear sound wood, no splits and defects.

Balsa is sometimes not the best choice. Maple engine bearers, spruce spars, birch plywood, carbon fiber, kevlar, fiberglass, foam... Lots of choices, some are easier to select than others, some cost much more. Some require some stationary tools.

Make design choices and use them. Don't blindly follow a kit, evaluate the contents and act accordingly.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Contest Balsa

Re: Contest Balsa

Ron, I saw this in your other posting and didn't really know what to say. Seeing a wrecked model leaves me (rare event!) at a loss for words but not emotional.

When it happens to me (I am used to it!), I try and look at the model and see if a change in the build would make it better but then I get a little perplexed as to the obsession I see with extreme lightness in material selection and why this would make a model better for a competition.

I thought that the combination of weight vs engine/propeller power was key.

With control line, it appears to me that the engine is adjusted to match the propeller in order for it to drag the model around at a comfortable 5+ seconds per lap

I know there are more complicated adjustments - line length, tip weight, lead out position, rabe rudders, c of g, thrust line .... it goes on.

To build one that ends up being delicate doesn't seem the best thing to do. Obviously, weight is an issue as too heavy (my normal build!) means it has to fly too fast (RC) but too light and the slightest breeze can take over.

I have also noticed that some coverings impart little strength to a models wings. The iron on stuff that I have been using doesn't seem to bind (or stay bound) with the ribs. However, dope and tissue/silk does but I am not very good at controlling the weight with "liquid" finishes.

Again there is another balance to be found with finishings.

I have more questions than answers but a word that keeps cropping up is longevity. In the Windy videos (I am addicted) he builds with 4 lb balsa and most of his planes were airworthy after 8+ years. There are three videos on the repair to his Novanta and it looked like new when he had finished.

What I did notice though is that although he uses 4lb balsa - his wings are sheeted, doped and tissued after strengthening by soaking in CA glue and areas are glassed.

When it happens to me (I am used to it!), I try and look at the model and see if a change in the build would make it better but then I get a little perplexed as to the obsession I see with extreme lightness in material selection and why this would make a model better for a competition.

I thought that the combination of weight vs engine/propeller power was key.

With control line, it appears to me that the engine is adjusted to match the propeller in order for it to drag the model around at a comfortable 5+ seconds per lap

I know there are more complicated adjustments - line length, tip weight, lead out position, rabe rudders, c of g, thrust line .... it goes on.

To build one that ends up being delicate doesn't seem the best thing to do. Obviously, weight is an issue as too heavy (my normal build!) means it has to fly too fast (RC) but too light and the slightest breeze can take over.

I have also noticed that some coverings impart little strength to a models wings. The iron on stuff that I have been using doesn't seem to bind (or stay bound) with the ribs. However, dope and tissue/silk does but I am not very good at controlling the weight with "liquid" finishes.

Again there is another balance to be found with finishings.

I have more questions than answers but a word that keeps cropping up is longevity. In the Windy videos (I am addicted) he builds with 4 lb balsa and most of his planes were airworthy after 8+ years. There are three videos on the repair to his Novanta and it looked like new when he had finished.

What I did notice though is that although he uses 4lb balsa - his wings are sheeted, doped and tissued after strengthening by soaking in CA glue and areas are glassed.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Contest Balsa

Re: Contest Balsa

Phil,

I think you are quite correct and that choosing materials for a specific purpose is a must. That is why "contest" balsa for a kit confuses me - why not say the best selection of balsa.

Rusty,

I have never flown off tarmac but have busted many models on grass, sand and mud.

I don't see that a plane hitting the dirt causes less damage other than it will come to a more abrupt stop as it digs itself into the ground. Unless of course it skids for a much longer time on tarmac.

What I have noticed is that motors have a better chance of survival hitting the dirt than they do hitting tarmac or concrete!

I think you are quite correct and that choosing materials for a specific purpose is a must. That is why "contest" balsa for a kit confuses me - why not say the best selection of balsa.

Rusty,

I have never flown off tarmac but have busted many models on grass, sand and mud.

I don't see that a plane hitting the dirt causes less damage other than it will come to a more abrupt stop as it digs itself into the ground. Unless of course it skids for a much longer time on tarmac.

What I have noticed is that motors have a better chance of survival hitting the dirt than they do hitting tarmac or concrete!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Contest Balsa

Re: Contest Balsa

Ian, you have to search for Bob hunt's wing and fuse building. Windy and Bob are from the same crowd and age. A grain is used for molding leading edges and fuse parts which Bob is famous for. What is not being recognized here is how the wood becomes strong again. Bob's joinery is over the top and I don't think machines could replicate how he builds. In order to achieve the finishes that Windy and Bob do on their planes, one has to realize the amount of dope is used to do so. Were talking 3-4 coats of thinned dope brushed on, sanded in between followed by a spray coat and then an application coat for silkspan. After this your looking at 4-5 more spray coats of dope. This is prior to color. This is how the wood regains it's strength not to mention stability. Bob builds in a geodetic fashion eliminating half the ribs required in a standard wing. You need the light wood to keep the model light and also to stay within the target weight. After the clear coats have been established, both Bob and Windy use lacquer primer applied and completely sanded off, resprayed, sanded off again followed by a silver highlighter coat. White is used under certain colors and polar gray is then used under others. Once base coats have been established and trim coats, 4-5 more coats of clear are applied. This is an amazing amount of work and material. The silkspan on these models feel like Monokote if you touched it.

Dope and silkspan is extremely important and in many designs was the integrity of the model. Silkspan was used to prevent many wing designs from folding. Iron on coverings don't have the ability to do the same. Ken

Dope and silkspan is extremely important and in many designs was the integrity of the model. Silkspan was used to prevent many wing designs from folding. Iron on coverings don't have the ability to do the same. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Contest Balsa

Re: Contest Balsa

ian1954 wrote:Phil,

I think you are quite correct and that choosing materials for a specific purpose is a must. That is why "contest" balsa for a kit confuses me - why not say the best selection of balsa.

Rusty,

I have never flown off tarmac but have busted many models on grass, sand and mud.

I don't see that a plane hitting the dirt causes less damage other than it will come to a more abrupt stop as it digs itself into the ground. Unless of course it skids for a much longer time on tarmac.

What I have noticed is that motors have a better chance of survival hitting the dirt than they do hitting tarmac or concrete!

I assure you they break much worse on tarmac, (asphalt, concrete) than grass and dirt. A landing on grass and dirt that is poor will likely result in a flipped model, no damage but maybe a prop, the same landing on tarmac will probably break things.

A bad take off on grass snags the prop and stops things, or digs a trench and keeps going. A bad takeoff on tarmac with a prop strike will shatter the prop, and may take the nose off the airplane.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Contest Balsa

Re: Contest Balsa

When flying over asphalt, I like to use soft steel screws which usually results in the engine just breaking the heads off and the engine coming out. Usually if you use socket head screws they don't break at least not without taking something else out. I've had many engines appearance wise like fine on the outside, but the bushing was shattered in the case. It really doesn't matter what grade of balsa is used for asphalt flying, the plane is going to break. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Contest Balsa

Re: Contest Balsa

In my opinion.. aircraft should be built to fly to the best of their potential.. "primarily"; using the lightest materials possible; along with sensible airframe joinery. If it has landing-gear.. it should provide ample shock-absorbing.. as well as shock "distribution" in it's mounting. Heavy-rigid wheels or more so; "tires".. can transmit a lot of shock up through the gear during a hard landing. I think that using lightweight "spoke" wheels with "spongy" tires is a good idea. They may not last a season.. but they're easy to replace. If you shatter a lightweight spoke-wheel on a hard landing.. chances are; it may have absorbed enough of the impact to prevent any airframe damage.. kind of like a "crumple-zone".

Please pardon this post for it's content.. but the thread seemed to be heading in the direction of "crash-worthiness". A bad crash will "take-out" any airplane.. but there are sensible and lightweight precautions that can be designed-in, to possibly "lessen" the damage. A ground-strike often involves the "gear" as the first point of impact.

Please pardon this post for it's content.. but the thread seemed to be heading in the direction of "crash-worthiness". A bad crash will "take-out" any airplane.. but there are sensible and lightweight precautions that can be designed-in, to possibly "lessen" the damage. A ground-strike often involves the "gear" as the first point of impact.

Re: Contest Balsa

Re: Contest Balsa

Roddie,

A few threads change tack and this is no exception. I do not mind one little bit it is all useful information for budding builders.

It may have started as "What is contest balsa" but contributions quite rightly take it to another level and there are hidden snippets, hints and tips for the aforementioned budding builders (and the "experienced" amongst us).

There is some consensus though - I have not used "Monokote" - it is not available here - but I have used what I think are equivalents - Solarfilm, Ligh Tex, Tough Lon and a few others. While I find them to be a quick covering method and produce a better overall finish than I can with liquids they do not impart strength to the structure.

As Ron pointed out, contest balsa needs supplementing with a doped silkspan type finish that just doesn't merely cover but becomes part of the structure. This highlights one of my building issues - once covered and sealed, I am not sure that I could match the finish, or even achieve an acceptable finish, with the subsequent coloured and clear coats.

However, I am thinking of reaching the covering with silkspan and sealing stage and then applying Solarfilm. I am sure that would be lighter and quicker than me applying further liquids.

Ron also mentioned using soft steel headed screws for mounting the motor. Another good suggestion which sparked a memory - I always used to use brass screws. These were applied with the slotted head on the opposite side of the bearer to the engine. The slots were lined up on each bearer, a piece of piano wire soldered across the two slots and the engine mounted using a washer and two nuts (for locking) on each screw. Lock nuts and pronged t nuts didn't exist then. I remember snapping a few of those and bending even more.

Roddie's introduction of a "crumple zone" concept is another nice suggestion. I tend to use over engineered undercarriages wherever possible but make sure that the load is spread on the model. A springy undercart with soft wheels seems to be an excellent alternative but with some of my landings (RC) I can just imagine it bouncing back into the air like a gorilla on a pogo stick!

Last night, I had another look at the Sig Skyray kit that I cast to one side. Not impressed with the materials at all but I have been watching Rusty's thread to steal ideas and I have programmed rib cutting details ready to start.

I can see what Rusty means about the weight of that wing making it prone to snapping when the model comes to a sudden halt but the wing still carries momentum. This lead me to realise that this effect would also be compounded by heavy wing tips, tip weights and line adjusters. The plot thickens - but at this stage, after looking out at the stars through the window - pondering about the meaning of life and the wonder of the far reaches of the galaxy - I drew the curtains and thought "What has all this got to do with me?"

Anyway, I also realised that the profile fuselages also compound the issue. The contact area between wing and fuselage is very small and akin to a blunt chisel. From the pictures I have seen, there is a tendency to break at the end of the plywood reinforcement just aft of the leading edge leaving the blunt chisel freedom to travel assisted by the wing momentum. Result firewood! (Well it would be for me, don't like dwelling on my disasters!).

I do not see why there isn't a prevalence of the reinforcement wrapping around the wing and moving the break point behind the wing. In built up fuselages there is usually a former the width of the fuselage spreading the load and the fuselage sides are reinforced.

At this stage - again - more questions and thoughts.

A few threads change tack and this is no exception. I do not mind one little bit it is all useful information for budding builders.

It may have started as "What is contest balsa" but contributions quite rightly take it to another level and there are hidden snippets, hints and tips for the aforementioned budding builders (and the "experienced" amongst us).

There is some consensus though - I have not used "Monokote" - it is not available here - but I have used what I think are equivalents - Solarfilm, Ligh Tex, Tough Lon and a few others. While I find them to be a quick covering method and produce a better overall finish than I can with liquids they do not impart strength to the structure.

As Ron pointed out, contest balsa needs supplementing with a doped silkspan type finish that just doesn't merely cover but becomes part of the structure. This highlights one of my building issues - once covered and sealed, I am not sure that I could match the finish, or even achieve an acceptable finish, with the subsequent coloured and clear coats.

However, I am thinking of reaching the covering with silkspan and sealing stage and then applying Solarfilm. I am sure that would be lighter and quicker than me applying further liquids.

Ron also mentioned using soft steel headed screws for mounting the motor. Another good suggestion which sparked a memory - I always used to use brass screws. These were applied with the slotted head on the opposite side of the bearer to the engine. The slots were lined up on each bearer, a piece of piano wire soldered across the two slots and the engine mounted using a washer and two nuts (for locking) on each screw. Lock nuts and pronged t nuts didn't exist then. I remember snapping a few of those and bending even more.

Roddie's introduction of a "crumple zone" concept is another nice suggestion. I tend to use over engineered undercarriages wherever possible but make sure that the load is spread on the model. A springy undercart with soft wheels seems to be an excellent alternative but with some of my landings (RC) I can just imagine it bouncing back into the air like a gorilla on a pogo stick!

Last night, I had another look at the Sig Skyray kit that I cast to one side. Not impressed with the materials at all but I have been watching Rusty's thread to steal ideas and I have programmed rib cutting details ready to start.

I can see what Rusty means about the weight of that wing making it prone to snapping when the model comes to a sudden halt but the wing still carries momentum. This lead me to realise that this effect would also be compounded by heavy wing tips, tip weights and line adjusters. The plot thickens - but at this stage, after looking out at the stars through the window - pondering about the meaning of life and the wonder of the far reaches of the galaxy - I drew the curtains and thought "What has all this got to do with me?"

Anyway, I also realised that the profile fuselages also compound the issue. The contact area between wing and fuselage is very small and akin to a blunt chisel. From the pictures I have seen, there is a tendency to break at the end of the plywood reinforcement just aft of the leading edge leaving the blunt chisel freedom to travel assisted by the wing momentum. Result firewood! (Well it would be for me, don't like dwelling on my disasters!).

I do not see why there isn't a prevalence of the reinforcement wrapping around the wing and moving the break point behind the wing. In built up fuselages there is usually a former the width of the fuselage spreading the load and the fuselage sides are reinforced.

At this stage - again - more questions and thoughts.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Contest Balsa

Re: Contest Balsa

Hey Ian, I enjoyed that "philosophical" moment in your last post..

Interesting thoughts on a profile model's "blunt-chisel" forces snapping the wing at it's root.. Yes; there's less fuse-area to absorb a hard "belly-landing" (which would exert the most stress on the wing). The wing's leading edge plywood "joiner/brace".. is an area that can be beefed-up by glassing. Ron Cribbs recommended this to me, for my Ringmaster's wing.

When Lieven rebuilt his Jr. Satan.. it required repairing his wing's leading-edge. He took the painstaking time and patience to incorporate a "lap-joint" into the structure using square-stock.. and "sanded-in" the L/E profile... rather than just "butt-joining" new L/E stock with a brace behind it, to bridge what would have been a "weak" butt-joint.

I have to wonder if it's worth the extra effort to join your leading-edge halves in this way, when building a new wing? It would certainly be stronger.. and along with a glassed plywood brace behind.. would be the ultimate in guarding against shear-forces that the wing could encounter.

Interesting thoughts on a profile model's "blunt-chisel" forces snapping the wing at it's root.. Yes; there's less fuse-area to absorb a hard "belly-landing" (which would exert the most stress on the wing). The wing's leading edge plywood "joiner/brace".. is an area that can be beefed-up by glassing. Ron Cribbs recommended this to me, for my Ringmaster's wing.

When Lieven rebuilt his Jr. Satan.. it required repairing his wing's leading-edge. He took the painstaking time and patience to incorporate a "lap-joint" into the structure using square-stock.. and "sanded-in" the L/E profile... rather than just "butt-joining" new L/E stock with a brace behind it, to bridge what would have been a "weak" butt-joint.

I have to wonder if it's worth the extra effort to join your leading-edge halves in this way, when building a new wing? It would certainly be stronger.. and along with a glassed plywood brace behind.. would be the ultimate in guarding against shear-forces that the wing could encounter.

Re: Contest Balsa

Re: Contest Balsa

In regards to the lap joint, while I feel Lieven did a very nice repair. the repair is still going to break where the lap joint stops. A stress riser has now been created there and fiberglass won't stop it from occurring.Even glassed, the leading edge will break where the glass stops. Leading edges with the rabbets in them to accept the ribs are a poor design to begin with due to the same reasoning. The leading edge rarely breaks in between ribs but rather on them. The picture that's shown in your post Roddie appears to be a S-1 Ringmaster wing. Glassing that leading edge in my opinion should be discouraged. Glassing the trailing edge is much more relevant and important. The S-1 uses a ply biscuit.You want the glue joint to fail at the butt as this will make repairing easier. Due to the wing moving forward from momentum, the trailing edge is what breaks thus allowing the glue joint to fail at the butt of the leading edge which takes out the center sheeting as well. When the wing of a Ring goes forward, so does the bellcrank which now tears out your hinges or totally breaks off the elevator. Essentially the leading edge goes unharmed just pivoting around the biscuit. The problem however is that while in motion, the "RIB RIPPER" is now functioning which breaks every rib in the wing as the wing starts to swing forward. This is why I suggest never to use that piece. For one, it's unnecessary and two it just creates a fracture point directly at every rib it penetrates and using harder balsa doesn't solve this problem. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Contest Balsa

Re: Contest Balsa

Regarding the fragility of profiles in general, I did my complete beginner stunt training on my Goldberg Shoestring and I flat out walloped it a bunch of times, bottoming out and splaying the Dural LG. I never broke anything except maybe one or two ribs and some Monokote. I think if built with strong joints, they're pretty rugged. It was built with fairly firm wood, as it was built decades before laser cutting existed. Even my bamboo skewered rear fuselage stayed intact. My Baby Steaks have taken some nose-in impacts at the hands of beginners, leaving the epoxy strip around the wing saddle when the nose separated. That fix was as easy as slathering the bare wood of the broken off nose with 6 minute epoxy and jamming them back together hand clamping for a couple of minutes. No broken ribs in either. The LE butt joints on all of my planes are glassed with epoxy, but after reading Ken's post I might not do it any more. In fact I did not glass the Skyray LE joint.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Contest Balsa

Re: Contest Balsa

Ken, I stand corrected on what I said about Ron C's advice. (and yes; it's an S1) I believe he recommended the same advice about the "trailing-edge" as you have.

I guess it all depends on the impact angle, as to the damage that occurs. A direct "nose-in" would indeed cause the reaction/damage that Ken mentioned. I think that the wing has most of it's integral strength in that kind of impact. With a hard "belly-flop".. the only thing supporting the wing, is its leading-edge and spar (especially on a profile fuse) and depending on the design.. the spar is only glued to the wing ribs.. leaving the leading-edge and the integrity of the root-fillet/joint to absorb the impact. It's been discussed; to use the lightest weight materials possible, when building out toward the wingtips. This makes extremely good sense to me. Crashes will obviously happen.. but many more "ground-strikes" (I would think..) happen at less of an angle than a "straight-in" 90 degrees to the airframe "face-plant".

I guess I'm trying to interpret Ian's take on "profile" fuses.. having less area to support the wing. This "is" true.. but there's both; vertical and horizontal forces that come into effect. A 1/2" wide "profile-fuse"; compared to a 3+ inch wide "built-up" fuse is a whole lot of difference in support area.. at any impact angle.

I guess it all depends on the impact angle, as to the damage that occurs. A direct "nose-in" would indeed cause the reaction/damage that Ken mentioned. I think that the wing has most of it's integral strength in that kind of impact. With a hard "belly-flop".. the only thing supporting the wing, is its leading-edge and spar (especially on a profile fuse) and depending on the design.. the spar is only glued to the wing ribs.. leaving the leading-edge and the integrity of the root-fillet/joint to absorb the impact. It's been discussed; to use the lightest weight materials possible, when building out toward the wingtips. This makes extremely good sense to me. Crashes will obviously happen.. but many more "ground-strikes" (I would think..) happen at less of an angle than a "straight-in" 90 degrees to the airframe "face-plant".

I guess I'm trying to interpret Ian's take on "profile" fuses.. having less area to support the wing. This "is" true.. but there's both; vertical and horizontal forces that come into effect. A 1/2" wide "profile-fuse"; compared to a 3+ inch wide "built-up" fuse is a whole lot of difference in support area.. at any impact angle.

Re: Contest Balsa

Re: Contest Balsa

roddie wrote:Hey Ian, I enjoyed that "philosophical" moment in your last post..

When Lieven rebuilt his Jr. Satan.. it required repairing his wing's leading-edge. He took the painstaking time and patience to incorporate a "lap-joint" into the structure using square-stock.. and "sanded-in" the L/E profile... rather than just "butt-joining" new L/E stock with a brace behind it, to bridge what would have been a "weak" butt-joint.

I have to wonder if it's worth the extra effort to join your leading-edge halves in this way, when building a new wing? It would certainly be stronger.. and along with a glassed plywood brace behind.. would be the ultimate in guarding against shear-forces that the wing could encounter.

Roddie,

The leading edge on the Jr Satan was originally not made from LE stock but from square stock as well

It is very light balsa that you can dent with your finger. I used this because at that moment I didn't know any better. For me, it just had to be light and I ignored that LE stock existed. Making the lap joint during the repair was just a natural choise. When I was in Colchester, England for the Ancient Vehicle Restoration Course, I had woodwork class where I learned to make this and more joints. I used the flat forward edge of the first rib as a guide which was a more easy start.

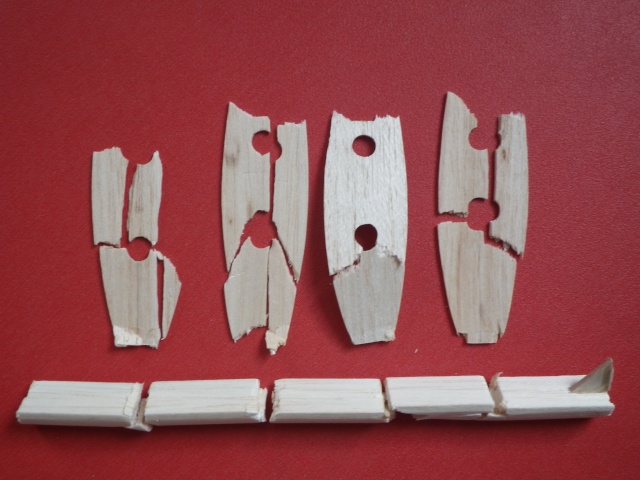

Making these notches in the leading-edge-to-be as per plan was a hell of a job. Since then, I saw plans where the back of the LE was just flat and gussets were used to srtengthen the LE to rib joint. This is the method I used for the repair. Also, as said above, these notches are a week point where the LE will break first. Below are the Leading edge bits of the Jr Satan puzzled together. It can be clearly seen that the LE broke in way of the rib joints.

Also, these joints were glued by letting it impregnate with CA glue after the ribs were all put into the notches. I found out when inspecting the broken wing that the ribs were not properly fixed using this way of glueing.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Contest Balsa

Re: Contest Balsa

All that CA soaked into the balsa but didn't necessarily go where you or I imagined it did. I've had my doubts about that method, and your wreckage gives us a look into it. Definitely a job for wood glues like Titebond.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Contest Balsa

Re: Contest Balsa

I am with Rusty on that , I would not use ca for anything other than tacking if you must then a slower set glue I have been using the Titebond but have not put it to the test under crash conditions YET !  I am looking forward to it soon ! Getback

I am looking forward to it soon ! Getback

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Contest Balsa

Re: Contest Balsa

I don't want to start another tangent but have to say I do love CA for things like the little right angle gussets I had to glue on my wingtip. Position it, tack it then run a bead.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Sig Deweybird 1/2A

» Contest - Contest - Contest Version 2.0 Big Brother

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Balsa Sources

» Chopping up balsa again

» Contest - Contest - Contest Version 2.0 Big Brother

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Balsa Sources

» Chopping up balsa again

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules