Log in

Search

Latest topics

» Landing-gear tipsby roddie Today at 4:17 pm

» Roger Harris revisited

by TD ABUSER Today at 12:13 pm

» Tee Dee .020 combat model

by Ken Cook Today at 11:41 am

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 11:37 am

» Happy 77th birthday Andrew!

by getback Today at 9:52 am

» My latest doodle...

by roddie Today at 8:43 am

» My N-1R build log

by GallopingGhostler Yesterday at 1:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 11:13 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 9:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 7:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 1:21 pm

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 4:35 pm

Cox Engine of The Month

custom wheels

Page 1 of 1

custom wheels

custom wheels

I will be making some custom wheels for model airplanes. They will be in many different sizes and configurations. They will be extremely lightweight.. but durability will depend on the materials I use... and how well a landing is "greased". I intend on "bushing" (staking) the hubs with alloy tubing in various sizes.. to fit various axles. For starters; they will fit 1/16" (.062), 3/32" (.093) and 1/8" (.125) which should cover up to a .35 engine sized model.

The old "Perfect" and "Veco" wheels were a testament of scale-realism, quality and longevity... but they were also very heavy. What I'm going to make; are aerodynamic, lightweight and thin (flat) discs.. that serve the purpose of R.O.G and a "roll-out" landing.

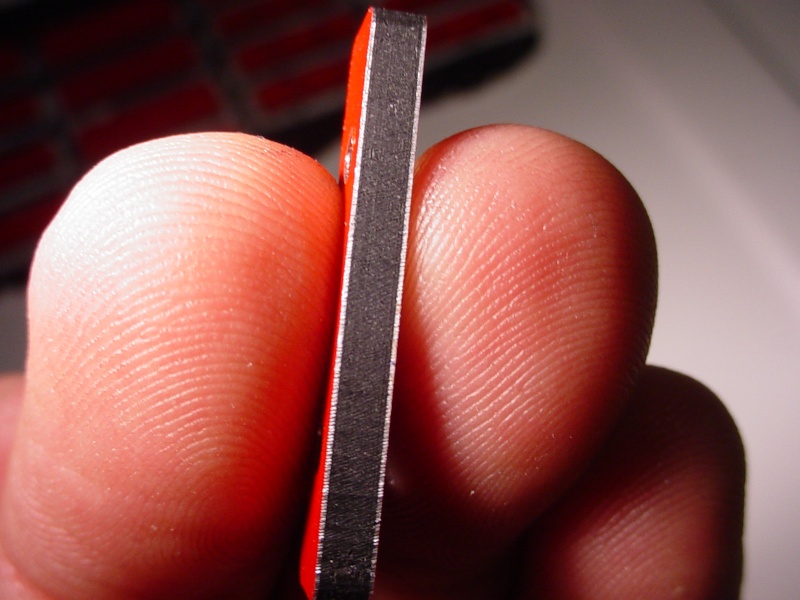

They will be CNC cut from "sheet-goods" on a table-router that I have access to at work. There are a variety of materials to choose from. One that looks most promising for smaller (up to .15 size) models.. is a composite sheet approximately 3mm in thickness (.117") and has a core of dense "black" plastic and faced both sides with thin bright-red enameled aluminum. "Tires" (or the "look" of tires) could be accomplished by milling through the thin aluminum skin.. down to the black plastic core on the "outer"-side of the wheel (I can only do this on one side).

The styling will be the same as the wheels I made for my Rare-Bear CEF Speed Contest model... which has a radial pattern of holes around the hub. It was just a matter of re-sizing the CAD file for different diameters... which I have already done. The sizes are 1/2" through 2".. "proportionately" in 1/8" increments.

Here's a pic of the Rare-Bear wheels, that I made several years ago.. They are 7/8" o.d. with a rubber O-ring for a tire.. making them 1" in diameter overall. Their "strength" has yet to be tested though. The wheel material is extremely lightweight styrene-faced foam-board.. which I reinforced by filling the radial holes around the hub with hot-melt glue.. The #15 O-ring tire is a "compression-fit" which squishes the foam-core.. and the styrene facers act as a "rim".

Here's some other wheels I made; back years ago. Some have tires made of black foam mounting tape... but they're too wide to be aerodynamically practical.

I will post some pics of the new prototype wheel soon.. but it's the same sheet-material shown here, in these experimental engine mount-plates that I'm working on.

The old "Perfect" and "Veco" wheels were a testament of scale-realism, quality and longevity... but they were also very heavy. What I'm going to make; are aerodynamic, lightweight and thin (flat) discs.. that serve the purpose of R.O.G and a "roll-out" landing.

They will be CNC cut from "sheet-goods" on a table-router that I have access to at work. There are a variety of materials to choose from. One that looks most promising for smaller (up to .15 size) models.. is a composite sheet approximately 3mm in thickness (.117") and has a core of dense "black" plastic and faced both sides with thin bright-red enameled aluminum. "Tires" (or the "look" of tires) could be accomplished by milling through the thin aluminum skin.. down to the black plastic core on the "outer"-side of the wheel (I can only do this on one side).

The styling will be the same as the wheels I made for my Rare-Bear CEF Speed Contest model... which has a radial pattern of holes around the hub. It was just a matter of re-sizing the CAD file for different diameters... which I have already done. The sizes are 1/2" through 2".. "proportionately" in 1/8" increments.

Here's a pic of the Rare-Bear wheels, that I made several years ago.. They are 7/8" o.d. with a rubber O-ring for a tire.. making them 1" in diameter overall. Their "strength" has yet to be tested though. The wheel material is extremely lightweight styrene-faced foam-board.. which I reinforced by filling the radial holes around the hub with hot-melt glue.. The #15 O-ring tire is a "compression-fit" which squishes the foam-core.. and the styrene facers act as a "rim".

Here's some other wheels I made; back years ago. Some have tires made of black foam mounting tape... but they're too wide to be aerodynamically practical.

I will post some pics of the new prototype wheel soon.. but it's the same sheet-material shown here, in these experimental engine mount-plates that I'm working on.

Re: custom wheels

Re: custom wheels

Those are some neat wheels Roddy.

Shawn

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: custom wheels

Re: custom wheels

Yep,

I like those!

I like those!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: custom wheels

Re: custom wheels

Nice Roddie , I am grad you got your old job back ! any other may have not been as friendly for the hobby

Eric

Eric

Eric

Eric

getback- Top Poster

Posts : 10442

Join date : 2013-01-17

Age : 67

Location : julian , NC

Re: custom wheels

Re: custom wheels

I posted photos recently (my P-51 thread..) of some wheels I made from foam pipe insulation for tires.. with hardwood dowel cut-offs for wheels.

Bob (rsv1cox) commented on them.. which gave me another similar idea. You've probably seen these foam "noodles" in the swimming-pool accessories at the store. They have an (avg.) 2.5" diameter with a 1.0" core.. and are "seamless", unlike pipe-insulation. They are available in "black" too.

https://www.amazon.com/Sports-Team-Cheering-Noodle-Noise/dp/B01M9AVEV0/ref=sr_1_7?ie=UTF8&qid=1487447749&sr=8-7&keywords=pool+noodles+black

A wheel would consist of a 1.0" hardwood dowel cut-off, epoxied into the core, with a center-hole drilled as a hub for the axle. Imagine how many pairs of wheels that could be made from just one length of noodle/dowel! You could even color-match the wheel to your model if desired. They'd be extremely lightweight and shock-absorbing. What does a pair of 2.5" model wheels cost today? You could probably turn-them using a screw-mandrel (dremel-style) chucked in a hand-drill, to shape (streamline) the foam-tire with sandpaper once the wheel is glued-in and it's hub-hole drilled.

Smaller diameters could be made by using these.. (1.3" diameter x .75" core) You're only limited by the boundaries of your imagination..

https://www.amazon.com/TOOGOO-Bicycle-Sponge-Rubber-Handlebar/dp/B0177DJMEW/ref=sr_1_2?ie=UTF8&qid=1487449622&sr=8-2&keywords=foam+grips

I have one of those noodles somewhere around here.. and think I'll try making a pair!

Bob (rsv1cox) commented on them.. which gave me another similar idea. You've probably seen these foam "noodles" in the swimming-pool accessories at the store. They have an (avg.) 2.5" diameter with a 1.0" core.. and are "seamless", unlike pipe-insulation. They are available in "black" too.

https://www.amazon.com/Sports-Team-Cheering-Noodle-Noise/dp/B01M9AVEV0/ref=sr_1_7?ie=UTF8&qid=1487447749&sr=8-7&keywords=pool+noodles+black

A wheel would consist of a 1.0" hardwood dowel cut-off, epoxied into the core, with a center-hole drilled as a hub for the axle. Imagine how many pairs of wheels that could be made from just one length of noodle/dowel! You could even color-match the wheel to your model if desired. They'd be extremely lightweight and shock-absorbing. What does a pair of 2.5" model wheels cost today? You could probably turn-them using a screw-mandrel (dremel-style) chucked in a hand-drill, to shape (streamline) the foam-tire with sandpaper once the wheel is glued-in and it's hub-hole drilled.

Smaller diameters could be made by using these.. (1.3" diameter x .75" core) You're only limited by the boundaries of your imagination..

https://www.amazon.com/TOOGOO-Bicycle-Sponge-Rubber-Handlebar/dp/B0177DJMEW/ref=sr_1_2?ie=UTF8&qid=1487449622&sr=8-2&keywords=foam+grips

I have one of those noodles somewhere around here.. and think I'll try making a pair!

Last edited by roddie on Sat Feb 18, 2017 12:33 pm; edited 1 time in total (Reason for editing : added source-links)

Re: custom wheels

Re: custom wheels

"Filling the holes with hot melt glue." How do you come up with this stuff........... Put me down for a couple.

Bob

Bob

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: custom wheels

Re: custom wheels

rsv1cox wrote:"Filling the holes with hot melt glue." How do you come up with this stuff........... Put me down for a couple.

Bob

Hi Bob, I'd be glad to send you some custom wheels. Have you seen this other thread of mine?

https://www.coxengineforum.com/t7113-racing-wheels?highlight=wheels

I can make more wheels.. but don't have access to the router-machine, due to changing jobs a few years ago. Geez.. how time flies

The good news is; I cut a lot of wheel-blanks when I "was" making them.. so I have some stock in different diameters/materials/styles to choose from. Widths vary between 1/8" to 1/2".. and hubs are all pre-drilled to 1/8". Most are suited (width-wise..) for 1/2A models.. but the larger diameters could be used on "A" size models.

The hubs I can bush smaller for .094"/.062" music-wire axles, by using 1/8" or 3/32" alloy-tube respectively.

Do you have a particular wheel-size in mind?

Pure redneck

Pure redneck

Need a pair of wheels for your 1/2A airplane.. and can't find any? Well... you "can" make them. I wanted a pair of 1.5" diameter wheels that were lightweight.. and had soft-foam tires. I could have probably bought a pair of park-flyer (electric) wheels if I could find them.. but being "me".. I got inventive.

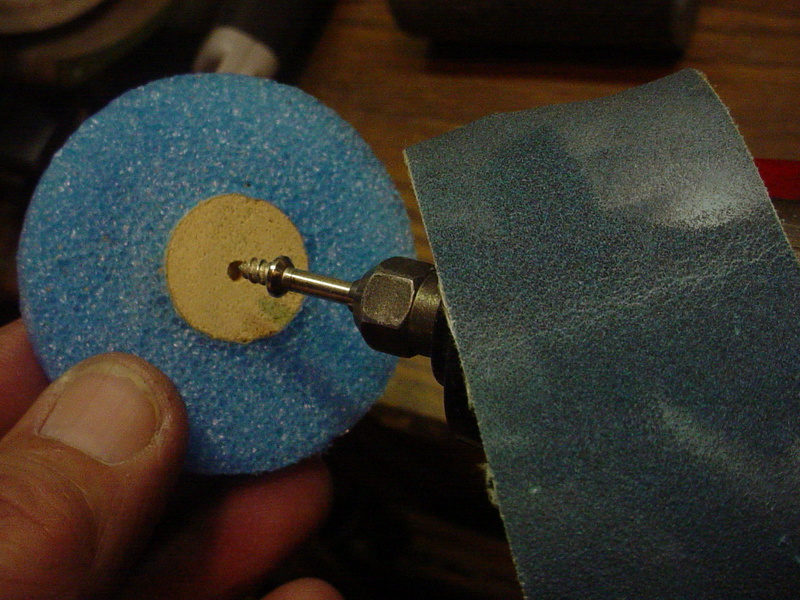

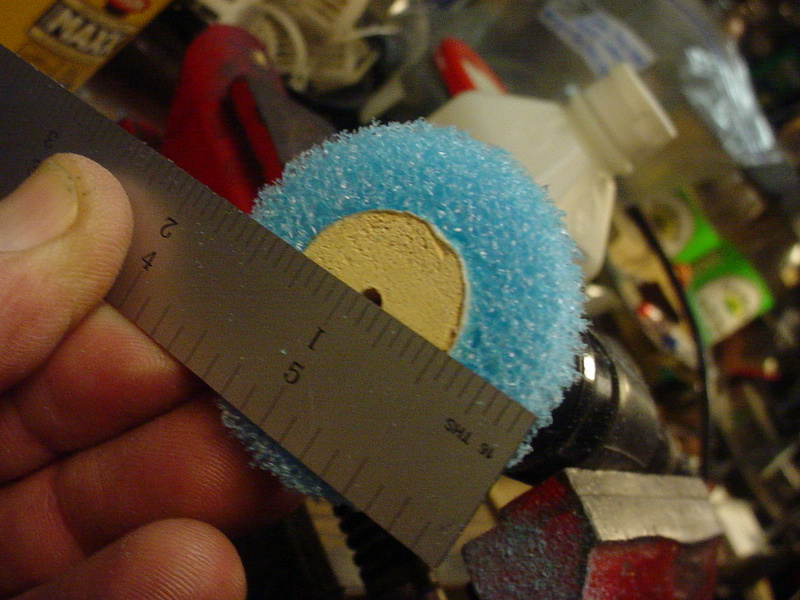

I thought about foam-tire material.. and bought a "noodle" (swimming-pool accessory).. wait.. stay with me. It cost $2.. is "seamless" and has an OD of 2.25" and an ID of approx. .750". I already had some assorted-size hardwood-dowels in a box.. and found one that fit snugly in the core of the noodle.. (humor me please..)

wait.. stay with me. It cost $2.. is "seamless" and has an OD of 2.25" and an ID of approx. .750". I already had some assorted-size hardwood-dowels in a box.. and found one that fit snugly in the core of the noodle.. (humor me please..)

So.. I set-up a "stop" on my miter-saw to separately slice thin "discs" of the dowel and then the foam noodle. This produces wheels and tire-blanks. I made them about 5/16" thick.. but probably could have gone thinner.

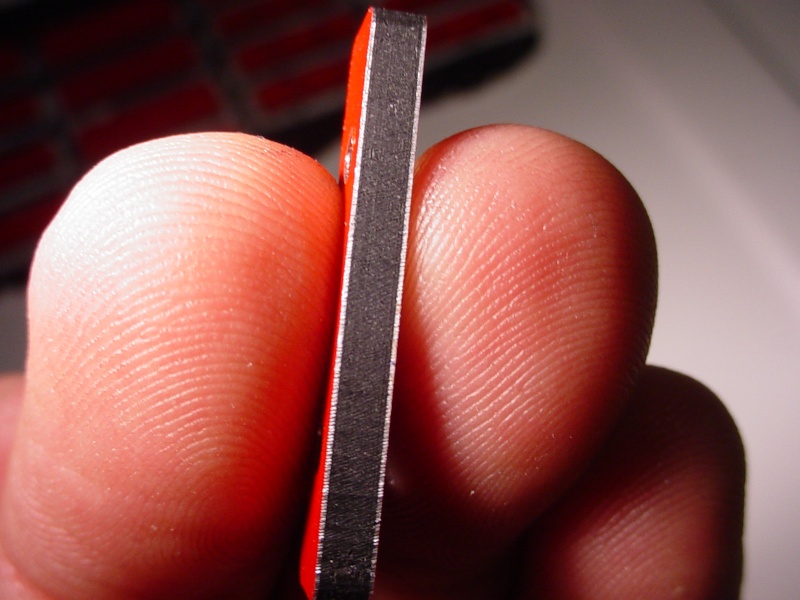

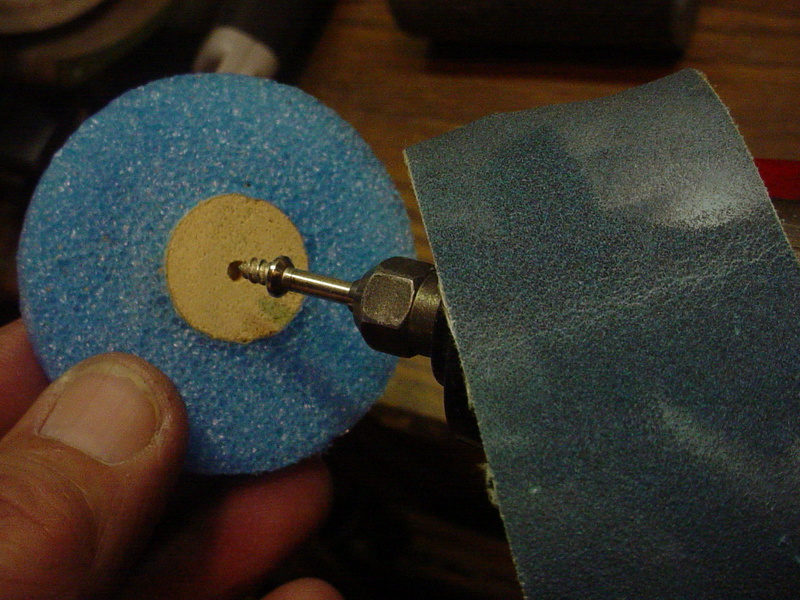

Now... "most of us" have a rotary-tool (dremel or similar..) that has a screw-mandrel for using a buffing-accessory. It looks like a stubby wood-screw on the end and has a shoulder/stop. This is required to proceed.

The hardwood-dowels (wheels) need to be drilled on-center. I used a 1/8" drill-bit. This allows the "wheel" to be screwed-onto the mandrel.

Before I get ahead of myself here.. the "tire" needs to be adhered to the wheel. I used two-sided tape.. but whatever you can find that works.. use it.

the "tire" needs to be adhered to the wheel. I used two-sided tape.. but whatever you can find that works.. use it.

With the mandrel chucked into my rotary-tool; I snugged-it (lightly) in my bench-vise. Lock the shaft of the rotary-tool and screw the wheel/tire assembly all the way onto the mandrel until it's snug against the shoulder. Get a piece of sandpaper (I used a small piece of "crocus-cloth"..) put on your safety-glasses, choose a low-speed on your rotary-tool.. and start it up. You can increase the speed if the tool labors while shaping the tire.

This is a fun way to spend a Monday night.. I experimented a bit with shaping.. to see how the foam would behave.

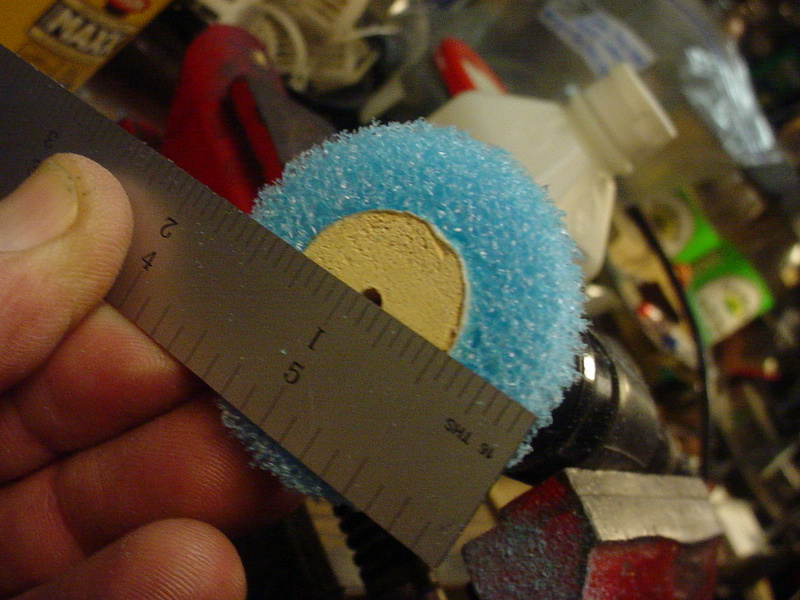

At the 5/16" thickness (width) a 1.5" diameter tire has a fairly rigid sidewall; enough (in pairs) to support a 1/2A model-airplane. Any larger; I would recommend increasing the wheel/tire width.

Here are two pair of 1.5" diameter examples..

Weight (less hubs)

I drilled the hub-holes 1/8". Hubs can be easily made by using pieces of K & S 1/8" and 3/32" OD aluminum tubing.. which reduces the diameter down to fit a 1/16" diameter (music-wire) axle.

My tires are blue...... but the "noodles" can be found on the inter-web in black. The wood-dowel/wheels can be painted to match your models color-scheme before or after mounting the tires.

but the "noodles" can be found on the inter-web in black. The wood-dowel/wheels can be painted to match your models color-scheme before or after mounting the tires.

They may not last too long... but they "will" absorb more shock when landing, than most wheels that you'll find. That equates to less stress on the airframe. Once you're set-up to make them.. why not make several pair for spares? When they wear-out.. just replace them. You can literally make dozens of pairs from one "foam-noodle" and a 36" length of dowel for the what it would cost for one pair of name-brand wheels.

I thought about foam-tire material.. and bought a "noodle" (swimming-pool accessory)..

So.. I set-up a "stop" on my miter-saw to separately slice thin "discs" of the dowel and then the foam noodle. This produces wheels and tire-blanks. I made them about 5/16" thick.. but probably could have gone thinner.

Now... "most of us" have a rotary-tool (dremel or similar..) that has a screw-mandrel for using a buffing-accessory. It looks like a stubby wood-screw on the end and has a shoulder/stop. This is required to proceed.

The hardwood-dowels (wheels) need to be drilled on-center. I used a 1/8" drill-bit. This allows the "wheel" to be screwed-onto the mandrel.

Before I get ahead of myself here..

With the mandrel chucked into my rotary-tool; I snugged-it (lightly) in my bench-vise. Lock the shaft of the rotary-tool and screw the wheel/tire assembly all the way onto the mandrel until it's snug against the shoulder. Get a piece of sandpaper (I used a small piece of "crocus-cloth"..) put on your safety-glasses, choose a low-speed on your rotary-tool.. and start it up. You can increase the speed if the tool labors while shaping the tire.

This is a fun way to spend a Monday night.. I experimented a bit with shaping.. to see how the foam would behave.

At the 5/16" thickness (width) a 1.5" diameter tire has a fairly rigid sidewall; enough (in pairs) to support a 1/2A model-airplane. Any larger; I would recommend increasing the wheel/tire width.

Here are two pair of 1.5" diameter examples..

Weight (less hubs)

I drilled the hub-holes 1/8". Hubs can be easily made by using pieces of K & S 1/8" and 3/32" OD aluminum tubing.. which reduces the diameter down to fit a 1/16" diameter (music-wire) axle.

My tires are blue......

They may not last too long... but they "will" absorb more shock when landing, than most wheels that you'll find. That equates to less stress on the airframe. Once you're set-up to make them.. why not make several pair for spares? When they wear-out.. just replace them. You can literally make dozens of pairs from one "foam-noodle" and a 36" length of dowel for the what it would cost for one pair of name-brand wheels.

Re: custom wheels

Re: custom wheels

Roddie, As always, you have come up with a Very Fine Idea and photo examples of a Great "How to" for those of us in the Hobby. I have a much greater chance of following your example and making some light weight wheels for my 1/2A models, than I would of making the homemade propeller that Mark B linked to on the Shed Saga Topic, even though I think it too, is on my bucket list. Thanks for sharing your time and ingenuity, I enjoy it very much.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: custom wheels

Re: custom wheels

Marleysky wrote:Roddie, As always, you have come up with a Very Fine Idea and photo examples of a Great "How to" for those of us in the Hobby. I have a much greater chance of following your example and making some light weight wheels for my 1/2A models, than I would of making the homemade propeller that Mark B linked to on the Shed Saga Topic, even though I think it too, is on my bucket list. Thanks for sharing your time and ingenuity, I enjoy it very much.

It's my pleasure Rene. Many of my ideas are "hair-brained".. but they don't usually involve much expense.. and can even be a cure for boredom.

Re: custom wheels

Re: custom wheels

Has it really been 7 years?  ........ A few days ago, I made more wheels similar to the blue ones from 7 years ago..

........ A few days ago, I made more wheels similar to the blue ones from 7 years ago..  .......

.......  oh well..

oh well..

yea.. I had sourced some black foam pool-noodles from the local dollar store this past Summer.

Same size inside diameter (3/4")

good for the 3/4" hardwood dowel (whl./hub stk.) that I had leftover from the blue foam wheels.

Same outside diameter too.. I think..

The dowel fit FIRMLY into the foam-noodle.. so I decided to try cutting-off "slices" (sans glue..) using my compound miter-saw.

worked like a charm..

then came bonding the foam to the wood.. and marking the center for drilling a hole for the screw-mandrel..

I sprinkled bicarbonate of soda (baking soda) over the CyA glued areas of the wheels (both sides) which accelerates the glue-bond.

This is necessary to keep the "hub" from spinning-out when shaping the "foam-tire" with abrasive-paper.

I chucked the screw-mandrel in my drill-press this time. I don't think that its slower-speed was conducive to smooth finish.

That's ok.. What I did notice though; is a difference in the density of the foam. This black foam seems less dense.. and prone to deformation if the tire's "track" isn't wide enough. An ideal width would be approx 3/8" or at least .300" wide. That's a bit wide for a 1/2A single-engine model airplane.. and also requires a long-enough axle; to fit a retainer and flat-washer. I want to make some homemade wheels for my current twin-engine N-1R build.. and these may work if I use the wider ones.

yea.. I had sourced some black foam pool-noodles from the local dollar store this past Summer.

Same size inside diameter (3/4")

good for the 3/4" hardwood dowel (whl./hub stk.) that I had leftover from the blue foam wheels.

Same outside diameter too.. I think..

The dowel fit FIRMLY into the foam-noodle.. so I decided to try cutting-off "slices" (sans glue..) using my compound miter-saw.

worked like a charm..

then came bonding the foam to the wood.. and marking the center for drilling a hole for the screw-mandrel..

I sprinkled bicarbonate of soda (baking soda) over the CyA glued areas of the wheels (both sides) which accelerates the glue-bond.

This is necessary to keep the "hub" from spinning-out when shaping the "foam-tire" with abrasive-paper.

I chucked the screw-mandrel in my drill-press this time. I don't think that its slower-speed was conducive to smooth finish.

That's ok.. What I did notice though; is a difference in the density of the foam. This black foam seems less dense.. and prone to deformation if the tire's "track" isn't wide enough. An ideal width would be approx 3/8" or at least .300" wide. That's a bit wide for a 1/2A single-engine model airplane.. and also requires a long-enough axle; to fit a retainer and flat-washer. I want to make some homemade wheels for my current twin-engine N-1R build.. and these may work if I use the wider ones.

Last edited by roddie on Wed Nov 06, 2024 3:27 pm; edited 1 time in total (Reason for editing : roddie blah blah..)

Similar topics

Similar topics» Cox Engine Forum Speed Contest 2018!!!

» big kid big wheels

» Wheel replacements for T-28 Trojan

» Wheels , Wheels , Wheels

» (Wanted) Carl Goldberg 1/2A wheels

» big kid big wheels

» Wheel replacements for T-28 Trojan

» Wheels , Wheels , Wheels

» (Wanted) Carl Goldberg 1/2A wheels

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules